EN 14163:2001

(Main)Petroleum and natural gas industries - Pipeline transportation systems - Welding of pipelines (ISO 13847:2000 modified)

Petroleum and natural gas industries - Pipeline transportation systems - Welding of pipelines (ISO 13847:2000 modified)

This European Standard specifies the requirements for producing and inspecting girth, branch and fillet welds in the pipeline part of pipeline transportation systems for the petroleum and natural gas industries meeting the requirements of ISO 13623.

On-land supply systems used by the gas supply industry are excluded from the scope of the International Standard.

This European Standard is applicable to the requirements for welding of carbon and low-alloy steel pipes. Application is restricted to pipes with a diameter of 20 mm and larger and wall thickness of 3 mm or more, and a specified minimum yield strength of 555 MPa or less. It is also applicable to welding into pipelines, items such as spools, risers, launchers/receivers, fittings, flanges and "pups" to pipeline valves.

The welding processes covered are shielded metal arc welding, gas tungsten arc welding, gas metal arc welding, flux-cored arc welding with and without shielding gas, and submerged arc welding.

This European Standard is not applicable to flash girth welding, resistance welding, solid-phase welding or other one-shot welding processes, nor to longitudinal welds in pipe or fittings, to "hot-tap" welding of pipelines in service or to the welding of process piping outside of the scope of ISO 13623.

NOTE Additional requirements may be necessary for welding of pipeline for particular pipeline operating conditions. These can include limitations on maximum hardness or strength, minimum impact toughness values, crack tip-opening dis

NOTE Additional requirements may be necessary for welding of pipeline for particular pipeline operating conditions. These can include limitations on maximum hardness or strength, minimum impact toughness values, crack tip-opening displacement, all weld metal tensile testing or bend testing, thermal stress relief or others. Where appropriate, these additional requirements should be added to the requirements of this International Standard in a project-specific supplement.

Erdöl- und Erdgasindustrien - Rohrleitungstransportsysteme - Schweißen von Rohrleitungen (ISO 13847:2000 modifiziert)

Diese Europäische Norm legt die Anforderungen für die Herstellung und Prüfung von Umfangsnähten (Rund-nähten), Anschlussnähten und Kehlnähten in der Rohrleitung von Rohrleitungstransportsystemen für die Erdöl- und Erd-gasindustrien nach den Anforderungen in ISO 13623 fest.

Rohrleitungstransportsysteme für die Gasversorgung an Land fallen nicht in den Anwendungsbereich dieser Norm.

Diese Europäische Norm enthält die Anforderungen für das Schweißen von Rohren aus unlegiertem und niedriglegiertem Stahl. Der Anwendungsbereich beschränkt sich auf Rohre mit einem Durchmesser ab 20 mm und einer Wanddicke ab 3 mm mit einer festgelegten Mindest-Streckgrenze bis 555 MPa. Sie gilt auch für das Einschweißen von Ausrüstungsteilen in Rohrleitungen, z. B. Zwischenstücke, Steigleitungen, Molchaufgabe- und Molchempfangs-stationen, Formstücke, Flansche und ¿kurze Verbindungsstücke" für Rohrleitungsarmaturen.

Die folgenden Schweißverfahren sind in dieser Norm festgelegt: Lichtbogenhandschweißen, Wolfram-Inertgas-schweißen, Metall-Schutzgasschweißen, Metall-Lichtbogenschweißen mit Fülldrahtelektrode mit und ohne Schutzgas sowie Unterpulverschweißen.

Diese Europäische Norm gilt nicht für das Abbrennstumpfschweißen, Widerstandsschweißen, Festphasen-schweißen oder weitere Einstufenschweißverfahren, Längsnähte in Rohren oder Formstücken (Fittings), für das Schweißen an unter Druck, Medium und Temperaturen stehenden Rohrleitungen (Hot Tapping) oder für das Schweißen von Prozess-Rohrleitungen, die nicht in den Anwendungsbereich von ISO 13623 fallen.

Industries du pétrole et du gaz naturel - Conduites pour systèmes de transport - Soudage des conduites (ISO 13847:2000 modifiée)

Industrija za predelavo nafte in zemeljskega plina - Transportni cevovodni sistemi - Varjenje cevovodov (ISO 13847:2000, spremenjen)

General Information

- Status

- Published

- Publication Date

- 11-Dec-2001

- Withdrawal Date

- 29-Jun-2002

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 14-Feb-2007

- Completion Date

- 14-Feb-2007

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - EN 14163:2001 (Welding of Pipelines)

EN 14163:2001 (adopted from ISO 13847:2000, modified) defines requirements for producing and inspecting girth, branch and fillet welds in pipeline transportation systems for the petroleum and natural gas industries. It applies to welding of carbon and low-alloy steel pipes with diameter ≥ 20 mm, wall thickness ≥ 3 mm and specified minimum yield strength (SMYS) ≤ 555 MPa. The standard supports compliance with ISO 13623 and covers common arc welding processes while noting project-specific additions may be needed for special operating conditions.

Key topics and technical requirements

- Scope and exclusions: Covers pipeline welds, spools, risers, fittings and valves; excludes on‑land gas supply systems (per CEN adoption), flash girth welding, resistance/solid‑phase/one‑shot processes, longitudinal welds in pipe/fittings and hot‑tap welding in service.

- Covered welding processes: SMAW (shielded metal arc), GTAW (gas tungsten), GMAW (gas metal), FCAW (flux‑cored, with/without shielding gas), SAW (submerged arc).

- Welding procedure specification (WPS): WPS approval/testing follows ISO 9956 series (ISO 9956-2/3) and requires welding of test pieces, inspection and documented approval before production.

- Qualification: Requirements for approval and testing of welders and welding operators (ISO 14732 referenced); inspector witness of WPS tests is required.

- Production controls and NDE: Production welding, non‑destructive examination (NDE) methods (radiography, UT, LP, MT) and acceptance criteria are specified; repair/removal procedures and documentation requirements are included.

- Supplementary/project requirements: Recognizes that additional limits (maximum hardness, minimum impact toughness, CTOD, all‑weld‑metal tensile testing, PWHT, etc.) may be required by specific pipeline operating conditions and should be added in project supplements.

- Informative annexes: Include hyperbaric welding, CRA‑clad/CRA pipeline requirements, brazing/aluminothermic notes and NDE report examples.

Practical applications

- Ensures consistent quality and safety for welded joints in onshore/offshore petroleum and natural gas pipelines.

- Used during procurement, fabrication, installation and inspection of pipeline sections, spools, risers, fittings and valve pups.

- Guides development and approval of WPS documents, welder/operator qualification programs, NDE plans and repair procedures.

Who uses EN 14163

- Pipeline welding engineers and welding supervisors

- Fabrication contractors and welding operators

- Quality assurance / quality control (QA/QC) inspectors and NDE technicians

- Project engineers, owners and regulatory compliance teams in oil & gas

Related standards

- ISO 13623 (pipeline systems)

- ISO 9956 series (WPS specification and testing)

- ISO 14732 (welding operator approval)

- ISO 9712 (NDT personnel qualification)

- EN and ISO standards referenced for destructive and NDE testing (e.g., EN 876, EN 1043‑1, ISO 148)

Use EN 14163 when you need an industry‑accepted framework for welding practices, welder qualification, NDE and documentation for pipeline welding aligned with ISO pipeline requirements.

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

Sponsored listings

Frequently Asked Questions

EN 14163:2001 is a standard published by the European Committee for Standardization (CEN). Its full title is "Petroleum and natural gas industries - Pipeline transportation systems - Welding of pipelines (ISO 13847:2000 modified)". This standard covers: This European Standard specifies the requirements for producing and inspecting girth, branch and fillet welds in the pipeline part of pipeline transportation systems for the petroleum and natural gas industries meeting the requirements of ISO 13623. On-land supply systems used by the gas supply industry are excluded from the scope of the International Standard. This European Standard is applicable to the requirements for welding of carbon and low-alloy steel pipes. Application is restricted to pipes with a diameter of 20 mm and larger and wall thickness of 3 mm or more, and a specified minimum yield strength of 555 MPa or less. It is also applicable to welding into pipelines, items such as spools, risers, launchers/receivers, fittings, flanges and "pups" to pipeline valves. The welding processes covered are shielded metal arc welding, gas tungsten arc welding, gas metal arc welding, flux-cored arc welding with and without shielding gas, and submerged arc welding. This European Standard is not applicable to flash girth welding, resistance welding, solid-phase welding or other one-shot welding processes, nor to longitudinal welds in pipe or fittings, to "hot-tap" welding of pipelines in service or to the welding of process piping outside of the scope of ISO 13623. NOTE Additional requirements may be necessary for welding of pipeline for particular pipeline operating conditions. These can include limitations on maximum hardness or strength, minimum impact toughness values, crack tip-opening dis NOTE Additional requirements may be necessary for welding of pipeline for particular pipeline operating conditions. These can include limitations on maximum hardness or strength, minimum impact toughness values, crack tip-opening displacement, all weld metal tensile testing or bend testing, thermal stress relief or others. Where appropriate, these additional requirements should be added to the requirements of this International Standard in a project-specific supplement.

This European Standard specifies the requirements for producing and inspecting girth, branch and fillet welds in the pipeline part of pipeline transportation systems for the petroleum and natural gas industries meeting the requirements of ISO 13623. On-land supply systems used by the gas supply industry are excluded from the scope of the International Standard. This European Standard is applicable to the requirements for welding of carbon and low-alloy steel pipes. Application is restricted to pipes with a diameter of 20 mm and larger and wall thickness of 3 mm or more, and a specified minimum yield strength of 555 MPa or less. It is also applicable to welding into pipelines, items such as spools, risers, launchers/receivers, fittings, flanges and "pups" to pipeline valves. The welding processes covered are shielded metal arc welding, gas tungsten arc welding, gas metal arc welding, flux-cored arc welding with and without shielding gas, and submerged arc welding. This European Standard is not applicable to flash girth welding, resistance welding, solid-phase welding or other one-shot welding processes, nor to longitudinal welds in pipe or fittings, to "hot-tap" welding of pipelines in service or to the welding of process piping outside of the scope of ISO 13623. NOTE Additional requirements may be necessary for welding of pipeline for particular pipeline operating conditions. These can include limitations on maximum hardness or strength, minimum impact toughness values, crack tip-opening dis NOTE Additional requirements may be necessary for welding of pipeline for particular pipeline operating conditions. These can include limitations on maximum hardness or strength, minimum impact toughness values, crack tip-opening displacement, all weld metal tensile testing or bend testing, thermal stress relief or others. Where appropriate, these additional requirements should be added to the requirements of this International Standard in a project-specific supplement.

EN 14163:2001 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14163:2001 has the following relationships with other standards: It is inter standard links to ISO 148:1983, ISO 10474:1991, ISO 6507-1:1997, ISO 9956-2:1995, ISO 9956-3:1995, EN 1321:1996, EN 886:2004, EN 3475-413:2002, ENV 13797:2000, EN 876:1995, EN 4214:2005, EN ISO 9902-3:2001, EN 9121:2005, EN 2591-6323:2002, EN 1043-1:1995. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14163:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Industrija za predelavo nafte in zemeljskega plina - Transportni cevovodni sistemi - Varjenje cevovodov (ISO 13847:2000, spremenjen)Erdöl- und Erdgasindustrien - Rohrleitungstransportsysteme - Schweißen von Rohrleitungen (ISO 13847:2000 modifiziert)Industries du pétrole et du gaz naturel - Conduites pour systemes de transport - Soudage des conduites (ISO 13847:2000 modifiée)Petroleum and natural gas industries - Pipeline transportation systems - Welding of pipelines (ISO 13847:2000 modified)75.200Petroleum products and natural gas handling equipment25.160.10Varilni postopki in varjenjeWelding processesICS:Ta slovenski standard je istoveten z:EN 14163:2001SIST EN 14163:2004en01-maj-2004SIST EN 14163:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14163December 2001ICS 25.160.10; 75.200English versionPetroleum and natural gas industries - Pipeline transportationsystems - Welding of pipelines (ISO 13847:2000 modified)Industries du pétrole et du gaz naturel - Conduites poursystèmes de transport - Soudage des conduites (ISO13847:2000 modifiée)This European Standard was approved by CEN on 21 October 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2001 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14163:2001 ESIST EN 14163:2004

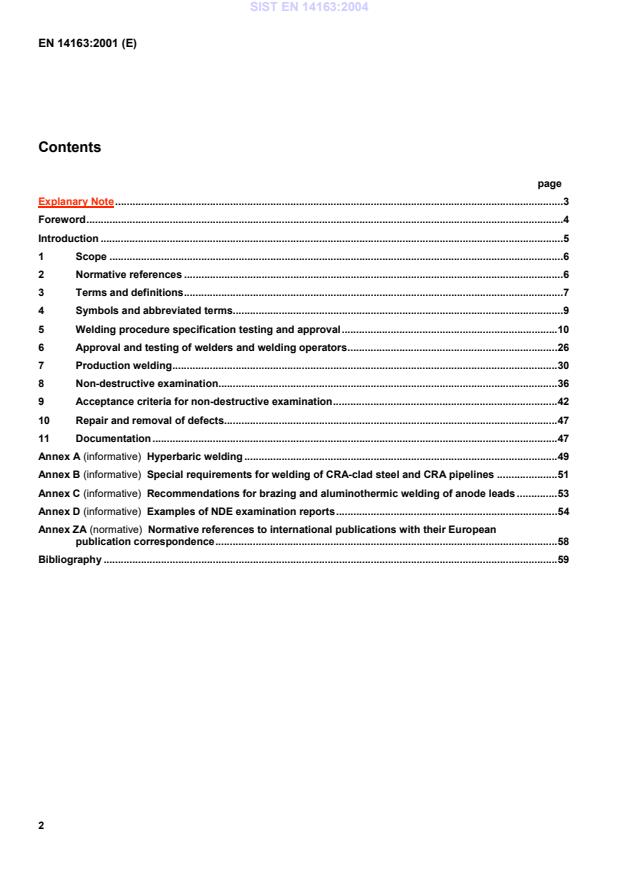

Hyperbaric welding.49Annex B (informative)

Special requirements for welding of CRA-clad steel and CRA pipelines.51Annex C (informative)

Recommendations for brazing and aluminothermic welding of anode leads.53Annex D (informative)

Examples of NDE examination reports.54Annex ZA (normative)

Normative references to international publications with their Europeanpublication correspondence.58Bibliography.59SIST EN 14163:2004

1)CEN, European Committee for Standardization, Management Centre, Rue de Stassart 36, B-1050, Brussels, Belgium.2)To be replaced by ISO 148-1:— (to be published), ISO 148-2:1998 and ISO 148-3:1998.SIST EN 14163:2004

3)American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, USA.4)The American Welding Society, 550 NW LeJeune Road, Miami, FL 33126, USA.SIST EN 14163:2004

20 mmMacro-examination and hardness test c1 specimenAll-weld-metal tensile test dby agreementaThis may be supplemented by UE by agreement.bTests may not be required for pipe with t u12 mm or with SMYS < 360 MPa.cThe company may decide that, for material with SMYS < 420 MPa, hardness testing is not necessary.dOptional requirement to confirm overmatching of the yield strength of the weld metal.The extent of inspection and testing of test pieces for the approval of a WPS for fillet and branch welds shall beestablished by agreement.5.4.2 Non-destructive examinationAll test pieces shall be examined visually and non-destructively in accordance with clause 8 following any requiredPWHT and prior to cutting of the test specimens.Test welds for the approval of a WPS for shop welding shall be subjected to NDE no sooner than 24 h aftercompletion of welding.SIST EN 14163:2004

20 mmNotch location: Weld metalNotch location : HAZNotch location : Weld metal rootSIST EN 14163:2004

9,5 mm250275250275t

9,5 mm250275250300Non-sour service and all thicknesses :Manual welding cellulosic electrodes275275275325Other welding processes275275350350aThe company shall specify when sour service requirements are to apply.5.4.3.8 All-weld-metal tensile testingWhen required by the company, test specimens for AWT shall be prepared and tested in accordance with EN 876.The measured yield strength shall be greater than or equal to the SMYS of the parent pipe metal, or another valueestablished by agreement.5.4.4 Destructive testing — Branch and fillet weldsTest pieces for the approval of a WPS for fillet welding shall be tested as specified in Table 1 of ISO 9956-3:1995and the additional fracture testing specified below.For pipe with a diameter of 168,3 mm or less, two fracture test specimens shall be taken from the test piece. Fourspecimens shall be taken for pipe with a diameter above 168,3 mm.The specimens shall be taken from diametrically opposed positions around the circumference.Fracture tests shall be performed by breaking specimens with the root of the weld in tension, using one of thefollowing methods : supporting both ends and striking the centre of the specimen ; or gripping one end and striking the other.The exposed surface of each broken specimen shall be free from cracks, lack of fusion and lack of penetration.The presence of other imperfections in the weld metal shall be within the following limits.a) Gas pores: the greatest dimension of any single pore shall not exceed 20 % of the wall thickness or 3 mm,whichever is smaller. The combined area of all pores shall not exceed 5 % of the affected area ;b) inclusions: individual inclusions shall not be greater than 1 mm in depth and 3 mm or 50 % of the wallthickness in length, whichever is less. There shall be at least 12 mm of sound metal between adjacentinclusions.5.5 Re-testing5.5.1 GeneralA new preliminary WPS may be prepared for approval testing in case a test piece fails to comply with therequirements of this European Standard for WPS approval.SIST EN 14163:2004

10 % ;b) the approved range for the voltage for any pass shall be the voltage recorded during the welding of the testpiece

10 % ;SIST EN 14163:2004

10 % ;d) the approved range for the distance between contact tip and work piece for any pass shall be the distancerecorded during the welding of the test piece

5 mm.5.6.5.3 Gas metal arc welding and gas-shielded flux-cored arc weldingThe approval given to the face and/or back-shielding gas shall be restricted to the type of gas and composition (see7.11) used during the welding of the test piece.The approval given to the wire diameter and system, such as single-wire or multiple-wire system, shall be restrictedto the diameter and system used during the welding of the test piece.The following welding parameter tolerances shall apply.a) The approved range for the travel speed for any pass shall be the travel speed recorded during the welding ofthe test piece

10 % ;b) the approved range for wire feed speed or current setting for any part of the weld shall be the speed or currentrecorded during the welding of the test piece

10 % ;c) the approved range for the distance between contact tip and work piece for any pass shall be the distancerecorded during the welding of the test piece

5 mm.5.6.5.4 Gas tungsten arc weldingThe approval given to the face- and/or back-shielding gas shall be restricted to the type of gas (nominalcomposition) used during the welding of the test piece.The approved range for current setting is the setting used during the welding of the test piece

10 %.5.6.5.5 Face-shielding gas flowrateFor processes GMAW, GSFCAW and GTAW, the approved range for the face-shielding gas flowrate is the flowraterecorded during the welding of the test piece

15 %.5.7 Welding procedure specification for repair weldingThe WPS used for the original weld may also be used for repair welding, provided the essential variables for therepair welding are within the ranges approved for the WPS except for the following repair types, which shall have aseparate approval test : repair weld consisting of a single pass ; internal repairs ; repair of a weld joining materials with a SMYS exceeding 360 MPa.The requirements for the approval of a WPS for repair welding shall be established by agreement.The groove for repair-welding tests shall be located typically as shown in Figure 5 and may include excavation ofweld deposit or HAZ and parent metal. The extent of testing and examination, including the number and locationsof test specimens, shall be established by agreement.SIST EN 14163:2004

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...