prEN 14163

(Main)Petroleum and natural gas industries - Pipeline transportation systems - Welding of pipelines (ISO 13847:2013, modified)

Petroleum and natural gas industries - Pipeline transportation systems - Welding of pipelines (ISO 13847:2013, modified)

This document specifies requirements for the petroleum, petrochemical and natural gas industries, for producing and inspecting girth, branch and fillet welds in the pipeline part of pipeline transportation systems which meet the requirements of ISO 13623:2017 or equivalent.

NOTE 1 ISO 13847:2013 refers to the requirements of ISO 13623:2009 or equivalent. At the time of publication of this document, ISO 13623:2009 is superseded by ISO 13623:2017 and reference is made to this edition of ISO 13623 throughout this document. ISO 13623 is modified adopted as EN 14161 to exclude on-land supply systems used by the European gas supply industry from the input of gas into the on-land transmission network up to the inlet connection of gas appliances.

This document is applicable to the requirements for welding of carbon and low-alloy steel pipes, and includes guidance for the welding of corrosion-resistant alloy (CRA) and CRA-clad pipelines in Annex A. Application is restricted to pipes with a diameter of 20 mm or more and a wall thickness of 3 mm or more, a specified minimum yield strength of 555 MPa or less, and which are designed not to exceed permissible equivalent stresses as defined in ISO 13623:2017 or equivalent. It is also applicable to welding into pipelines of items such as spools, risers, launchers/receivers, fittings, flanges and pup pieces to pipeline valves. On-land supply systems used by the European gas supply industry from the input of gas into the on-land transmission network up to the inlet connection of gas appliances are excluded from the scope of this document.

Guidance for special welding applications is provided in:

- Annex B for hyperbaric welding;

- Annex C for brazing and aluminothermic welding of anode leads;

- Annex D for branch and fillet welding on in-service pipelines.

The welding processes covered are shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), gas-shielded flux-cored arc welding (GSFCAW), self-shielded flux-cored arc welding (SSFCAW) and submerged arc welding (SAW).

This document is not applicable to flash girth welding, resistance welding, solid-phase welding or other one-shot welding processes, nor to longitudinal welds in pipe or fittings or to the welding of process piping outside the scope of ISO 13623:2017.

NOTE 2 Additional requirements might be necessary for the welding of pipeline for particular pipeline operating conditions, for pipelines with a specified yield strength exceeding 555 MPa and for pipelines designed to permissible strain criteria. These can include limitations on maximum hardness or strength, minimum impact toughness values, crack tip-opening displacement, all weld metal tensile testing or bend testing, thermal stress relief, or others. Where appropriate, it is advisable that these additional requirements be added to the requirements of this document in a project-specific supplement.

NOTE 3 Annex E specifies additional requirements for the welding of onshore gas supply systems applicable only when located in European member states. Annex F specifies additional requirements for the welding of gas distribution systems applicable only when located in European member states. It is the responsibility of the company to specify the normative applicability of these annexes.

Erdöl- und Erdgasindustrie - Pipeline-Transportsysteme - Schweißen von Pipelines (ISO 13847:2013, modifiziert)

Dieses Dokument legt Anforderungen für die Herstellung und Prüfung von Umfangsnähten (Rundnähten), Anschlussnähten und Kehlnähten in der Rohrleitung von Rohrleitungstransportsystemen für die Erdöl- und Erdgasindustrien nach den Anforderungen in ISO 13623:2017 oder gleichwertig fest.

ANMERKUNG 1 ISO 13847:2013 bezieht sich auf die Anforderungen von ISO 13623:2009 oder gleichwertig. Zum Zeitpunkt der Veröffentlichung dieses Dokuments wird ISO 13623:2009 durch ISO 13623:2017 ersetzt; in diesem Dokument wird durchgehend auf diese Ausgabe von ISO 13623 verwiesen. ISO 13623 wird modifiziert als EN 14161 übernommen, um die von der europäischen Gasversorgungsindustrie benutzten Überland-Versorgungssysteme von der Einspeisung des Erdgases in die Rohrleitungstransportsysteme für die Gasversorgung an Land bis zum Eingangsanschluss gasbetriebener Endgeräte auszuschließen.

Dieses Dokument gilt für die Anforderungen für das Schweißen von Rohren aus Kohlenstoffstahl und niedriglegiertem Stahl und enthält in Anhang A Anleitungen für das Schweißen von Rohrleitungen aus korrosionsbeständiger Legierung (CRA) und CRA-plattierten Rohren. Der Anwendungsbereich beschränkt sich auf Rohre mit einem Durchmesser ab 20 mm und einer Wanddicke ab 3 mm mit einer festgelegten Mindest-Streckgrenze bis 555 MPa, und die so ausgelegt sind, dass die zulässigen Vergleichsspannungen nach ISO 13623:2017 oder gleichwertig nicht überschritten werden. Das Dokument gilt auch für das Einschweißen von Ausrüstungsteilen in Rohrleitungen, z. B. Zwischenstücke, Steigleitungen, Molchaufgabe- und Molchempfangsstationen, Formstücke, Flansche und kurze Verbindungsstücke für Rohrleitungsarmaturen. Von der europäischen Gasversorgungsindustrie benutzte Überland-Versorgungssysteme von der Einspeisung des Erdgases in die Rohr¬leitungstransportsysteme für die Gasversorgung an Land bis zum Eingangsanschluss gasbetriebener Endgeräte fallen nicht in den Anwendungsbereich dieses Dokuments.

Eine Anleitung für spezielle Schweißanwendungen ist enthalten in:

- Anhang B für hyperbares Schweißen;

- Anhang C für das Löten und aluminothermische Schweißen von Anodenblei;

- Anhang D für Schweißen von Anschlussnähten und Kehlnähten an in Betrieb befindlichen Rohrleitungen.

Die behandelten Schweißprozesse sind das Lichtbogenhandschweißen (SMAW), Gas-Wolfram-Lichtbogen-schweißen (GTAW), Metall-Schutzgasschweißen (GMAW), gasgeschützte Flussmittel-Lichtbogenschweißen (GSFCAW), Metall-Lichtbogenschweißen mit Fülldrahtelektrode ohne Schutzgas (SSFCAW) und Unterpulverschweißen (SAW).

Dieses Dokument gilt nicht für das Abbrennstumpfschweißen, Widerstandsschweißen, Festphasenschweißen oder weitere Einstufenschweißverfahren, Längsnähte in Rohren oder Formstücken (Fittings) oder für das Schweißen von Prozess-Rohrleitungen, die nicht in den Zuständigkeitsbereich von ISO 13623:2017 fallen.

ANMERKUNG 2 Zusätzliche Anforderungen können für das Schweißen von Rohrleitungen für spezielle Betriebs-bedingungen der Rohrleitungen, für Rohrleitungen mit einer festgelegten Streckgrenze von mehr als 555 MPa und für Rohrleitungen, die entsprechend zulässigen Kriterien hinsichtlich der Dehnung ausgelegt sind erforderlich sein. Diese Anforderungen können u. a. Grenzwerte für die maximale Härte oder Festigkeit, die Mindestwerte für die Kerbschlag-zähigkeit, die Rissspitzenöffnungsverschiebung, die Prüfung der Zugfestigkeit des reinen Schweißguts oder den Biege-versuch und den Abbau von Wärmespannungen umfassen. Es ist gegebenenfalls ratsam, diese zusätzlichen Anforderungen in einem projektspezifischen Beiblatt zu den Anforderungen in diesem Dokument aufzunehmen.

ANMERKUNG 3 In Anhang E sind zusätzliche Anforderungen für das Schweißen von Gasversorgungssystemen an Land festgelegt, die nur anwendbar sind, wenn diese sich in europäischen Mitgliedstaaten befinden. In Anhang F sind zusätzliche Anforderungen für das Schweißen...

Industries du pétrole et du gaz naturel - Systèmes de transport par conduites - Soudage des conduites (ISO 13847:2013 modifiée)

Industrija za predelavo nafte in zemeljskega plina - Transportni cevovodni sistemi - Varjenje cevovodov (ISO 13847:2013, spremenjen)

General Information

- Status

- Not Published

- Publication Date

- 06-Feb-2023

- Current Stage

- 4060 - Closure of enquiry - Enquiry

- Start Date

- 07-Oct-2021

- Due Date

- 03-May-2021

- Completion Date

- 07-Oct-2021

Relations

- Effective Date

- 18-Jan-2023

Overview

prEN 14163:2021 is a modified adoption of ISO 13847:2013 developed by the European Committee for Standardization (CEN) focusing on the welding of pipelines in the petroleum, petrochemical, and natural gas industries. This standard applies to pipeline transportation systems that comply with ISO 13623:2017 or equivalent. It sets out the specifications for producing and inspecting girth, branch, and fillet welds on pipelines made primarily from carbon and low-alloy steels, with additional guidance for corrosion-resistant alloy (CRA) welds.

The scope includes pipelines with diameters of 20 mm or more and wall thicknesses of at least 3 mm, designed with a specified minimum yield strength up to 555 MPa. The standard also covers associated pipeline components such as spools, risers, launchers, receivers, fittings, flanges, and pipeline valves. Notably, it excludes on-land supply systems in European gas distribution networks from the input up to the inlet connection of gas appliances.

Key Topics

Welding Processes Covered

- Shielded Metal Arc Welding (SMAW)

- Gas Tungsten Arc Welding (GTAW)

- Gas Metal Arc Welding (GMAW)

- Gas-Shielded Flux-Cored Arc Welding (GSFCAW)

- Self-Shielded Flux-Cored Arc Welding (SSFCAW)

- Submerged Arc Welding (SAW)

Excluded Welding Methods

- Flash Girth Welding

- Resistance Welding

- Solid-Phase Welding

- Longitudinal Welds in Pipes and Fittings

Annex Guidance for Special Welding Applications

- Annex A: Welding of Corrosion-Resistant Alloy (CRA) and CRA-clad Pipelines

- Annex B: Hyperbaric Welding

- Annex C: Brazing and Aluminothermic Welding of Anode Leads

- Annex D: Branch and Fillet Welding on In-Service Pipelines

- Annex E & F: Additional Requirements for European Onshore Gas Supply and Distribution Systems

Inspection and Testing Requirements

- Non-destructive Testing (NDT) including radiographic, ultrasonic, magnetic particle, and liquid penetrant testing

- Destructive Testing for weld qualification such as tensile and bend testing

- Welding Procedure Specification (WPS) qualification and welder approvals

Weld Production and Documentation

- Guidelines on equipment, preheating, arc strikes, welding positions, and shielding gases

- Requirements for post-weld heat treatment and weld records

Material and Design Limitations

- Applicable to carbon and low-alloy steels within specified strength limits

- Emphasis on compliance with permissible equivalent stresses as defined in ISO 13623:2017

Applications

prEN 14163 serves as a comprehensive framework for welding activities in pipeline transportation systems within the petroleum and natural gas sectors. Key applications include:

Pipeline Construction and Maintenance

Ensuring the structural integrity and reliability of pipeline girth welds, branch connections, and associated fittings.Welding Quality Assurance

Standardizing welding procedures and welder qualifications to achieve consistent and defect-free welds in pipelines operating under various conditions.Inspection and Testing

Implementing rigorous inspection protocols including NDT and destructive testing to detect and address weld defects early in the fabrication process.Corrosion-Resistant Alloy Pipelines

Specialized guidelines for welding pipelines that require corrosion resistance, critical in harsh or chemically aggressive environments.European Gas Supply Infrastructure

Supporting compliance with specific regional requirements in gas transmission and distribution networks, particularly within European member states.

Related Standards

ISO 13623:2017 - Petroleum and natural gas industries - Pipeline transportation systems - This forms the primary design framework referenced and modified within prEN 14163 for pipeline transport systems.

ISO 13847:2013 - The base standard adapted in prEN 14163 for pipeline welding practices and procedures, originally referencing ISO 13623:2009 but updated to align with the 2017 edition.

EN 14161 - Modifies ISO 13623 to exclude on-land supply systems; complements welding standards for pipelines used in the European gas supply industry.

Standards on Welding Processes and NDT Methods - Various standards govern welding equipment, NDT procedures, and material testing contributing to the overall compliance environment for pipeline welding in the industry.

By adhering to prEN 14163, companies in the petroleum and natural gas sectors can achieve high-quality, safe, and reliable pipeline transportation welding outcomes tailored to meet rigorous international and European criteria. This standard offers detailed guidance from welding procedure development to production and testing, ensuring pipelines meet the demanding operational and safety requirements of modern energy infrastructure.

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

Sponsored listings

Frequently Asked Questions

prEN 14163 is a draft published by the European Committee for Standardization (CEN). Its full title is "Petroleum and natural gas industries - Pipeline transportation systems - Welding of pipelines (ISO 13847:2013, modified)". This standard covers: This document specifies requirements for the petroleum, petrochemical and natural gas industries, for producing and inspecting girth, branch and fillet welds in the pipeline part of pipeline transportation systems which meet the requirements of ISO 13623:2017 or equivalent. NOTE 1 ISO 13847:2013 refers to the requirements of ISO 13623:2009 or equivalent. At the time of publication of this document, ISO 13623:2009 is superseded by ISO 13623:2017 and reference is made to this edition of ISO 13623 throughout this document. ISO 13623 is modified adopted as EN 14161 to exclude on-land supply systems used by the European gas supply industry from the input of gas into the on-land transmission network up to the inlet connection of gas appliances. This document is applicable to the requirements for welding of carbon and low-alloy steel pipes, and includes guidance for the welding of corrosion-resistant alloy (CRA) and CRA-clad pipelines in Annex A. Application is restricted to pipes with a diameter of 20 mm or more and a wall thickness of 3 mm or more, a specified minimum yield strength of 555 MPa or less, and which are designed not to exceed permissible equivalent stresses as defined in ISO 13623:2017 or equivalent. It is also applicable to welding into pipelines of items such as spools, risers, launchers/receivers, fittings, flanges and pup pieces to pipeline valves. On-land supply systems used by the European gas supply industry from the input of gas into the on-land transmission network up to the inlet connection of gas appliances are excluded from the scope of this document. Guidance for special welding applications is provided in: - Annex B for hyperbaric welding; - Annex C for brazing and aluminothermic welding of anode leads; - Annex D for branch and fillet welding on in-service pipelines. The welding processes covered are shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), gas-shielded flux-cored arc welding (GSFCAW), self-shielded flux-cored arc welding (SSFCAW) and submerged arc welding (SAW). This document is not applicable to flash girth welding, resistance welding, solid-phase welding or other one-shot welding processes, nor to longitudinal welds in pipe or fittings or to the welding of process piping outside the scope of ISO 13623:2017. NOTE 2 Additional requirements might be necessary for the welding of pipeline for particular pipeline operating conditions, for pipelines with a specified yield strength exceeding 555 MPa and for pipelines designed to permissible strain criteria. These can include limitations on maximum hardness or strength, minimum impact toughness values, crack tip-opening displacement, all weld metal tensile testing or bend testing, thermal stress relief, or others. Where appropriate, it is advisable that these additional requirements be added to the requirements of this document in a project-specific supplement. NOTE 3 Annex E specifies additional requirements for the welding of onshore gas supply systems applicable only when located in European member states. Annex F specifies additional requirements for the welding of gas distribution systems applicable only when located in European member states. It is the responsibility of the company to specify the normative applicability of these annexes.

This document specifies requirements for the petroleum, petrochemical and natural gas industries, for producing and inspecting girth, branch and fillet welds in the pipeline part of pipeline transportation systems which meet the requirements of ISO 13623:2017 or equivalent. NOTE 1 ISO 13847:2013 refers to the requirements of ISO 13623:2009 or equivalent. At the time of publication of this document, ISO 13623:2009 is superseded by ISO 13623:2017 and reference is made to this edition of ISO 13623 throughout this document. ISO 13623 is modified adopted as EN 14161 to exclude on-land supply systems used by the European gas supply industry from the input of gas into the on-land transmission network up to the inlet connection of gas appliances. This document is applicable to the requirements for welding of carbon and low-alloy steel pipes, and includes guidance for the welding of corrosion-resistant alloy (CRA) and CRA-clad pipelines in Annex A. Application is restricted to pipes with a diameter of 20 mm or more and a wall thickness of 3 mm or more, a specified minimum yield strength of 555 MPa or less, and which are designed not to exceed permissible equivalent stresses as defined in ISO 13623:2017 or equivalent. It is also applicable to welding into pipelines of items such as spools, risers, launchers/receivers, fittings, flanges and pup pieces to pipeline valves. On-land supply systems used by the European gas supply industry from the input of gas into the on-land transmission network up to the inlet connection of gas appliances are excluded from the scope of this document. Guidance for special welding applications is provided in: - Annex B for hyperbaric welding; - Annex C for brazing and aluminothermic welding of anode leads; - Annex D for branch and fillet welding on in-service pipelines. The welding processes covered are shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), gas-shielded flux-cored arc welding (GSFCAW), self-shielded flux-cored arc welding (SSFCAW) and submerged arc welding (SAW). This document is not applicable to flash girth welding, resistance welding, solid-phase welding or other one-shot welding processes, nor to longitudinal welds in pipe or fittings or to the welding of process piping outside the scope of ISO 13623:2017. NOTE 2 Additional requirements might be necessary for the welding of pipeline for particular pipeline operating conditions, for pipelines with a specified yield strength exceeding 555 MPa and for pipelines designed to permissible strain criteria. These can include limitations on maximum hardness or strength, minimum impact toughness values, crack tip-opening displacement, all weld metal tensile testing or bend testing, thermal stress relief, or others. Where appropriate, it is advisable that these additional requirements be added to the requirements of this document in a project-specific supplement. NOTE 3 Annex E specifies additional requirements for the welding of onshore gas supply systems applicable only when located in European member states. Annex F specifies additional requirements for the welding of gas distribution systems applicable only when located in European member states. It is the responsibility of the company to specify the normative applicability of these annexes.

prEN 14163 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 14163 has the following relationships with other standards: It is inter standard links to EN 14163:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 14163 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2021

Industrija za predelavo nafte in zemeljskega plina - Transportni cevovodni sistemi

- Varjenje cevovodov (ISO 13847:2013, spremenjen)

Petroleum and natural gas industries - Pipeline transportation systems - Welding of

pipelines (ISO 13847:2013, modified)

Erdöl- und Erdgasindustrie - Pipeline-Transportsysteme - Schweißen von Pipelines (ISO

13847:2013, modifiziert)

Industries du pétrole et du gaz naturel - Systèmes de transport par conduites - Soudage

des conduites (ISO 13847:2013 modifiée)

Ta slovenski standard je istoveten z: prEN 14163

ICS:

25.160.10 Varilni postopki in varjenje Welding processes

75.200 Oprema za skladiščenje Petroleum products and

nafte, naftnih proizvodov in natural gas handling

zemeljskega plina equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

July 2021

ICS 25.160.10; 75.200 Will supersede EN 14163:2001

English Version

Petroleum and natural gas industries - Pipeline

transportation systems - Welding of pipelines (ISO

13847:2013, modified)

Industries du pétrole et du gaz naturel - Systèmes de Erdöl- und Erdgasindustrie - Pipeline-

transport par conduites - Soudage des conduites (ISO Transportsysteme - Schweißen von Pipelines (ISO

13847:2013 modifiée) 13847:2013, modifiziert)

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 12.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 14163:2021 E

worldwide for CEN national Members.

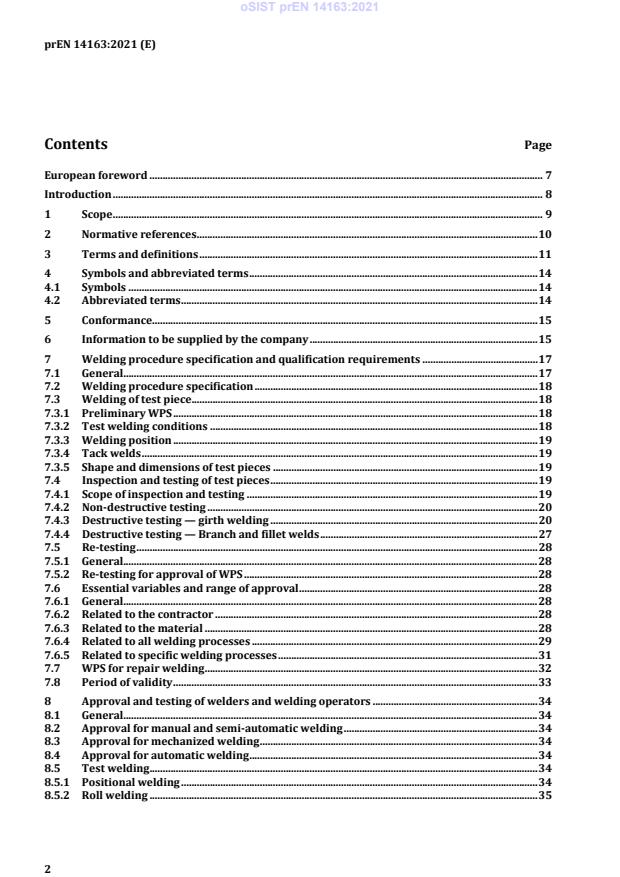

Contents Page

European foreword . 7

Introduction . 8

1 Scope . 9

2 Normative references . 10

3 Terms and definitions . 11

4 Symbols and abbreviated terms . 14

4.1 Symbols . 14

4.2 Abbreviated terms . 14

5 Conformance . 15

6 Information to be supplied by the company . 15

7 Welding procedure specification and qualification requirements . 17

7.1 General. 17

7.2 Welding procedure specification . 18

7.3 Welding of test piece . 18

7.3.1 Preliminary WPS . 18

7.3.2 Test welding conditions . 18

7.3.3 Welding position . 19

7.3.4 Tack welds . 19

7.3.5 Shape and dimensions of test pieces . 19

7.4 Inspection and testing of test pieces . 19

7.4.1 Scope of inspection and testing . 19

7.4.2 Non-destructive testing . 20

7.4.3 Destructive testing — girth welding . 20

7.4.4 Destructive testing — Branch and fillet welds . 27

7.5 Re-testing . 28

7.5.1 General. 28

7.5.2 Re-testing for approval of WPS . 28

7.6 Essential variables and range of approval . 28

7.6.1 General. 28

7.6.2 Related to the contractor . 28

7.6.3 Related to the material . 28

7.6.4 Related to all welding processes . 29

7.6.5 Related to specific welding processes . 31

7.7 WPS for repair welding . 32

7.8 Period of validity . 33

8 Approval and testing of welders and welding operators . 34

8.1 General. 34

8.2 Approval for manual and semi-automatic welding . 34

8.3 Approval for mechanized welding . 34

8.4 Approval for automatic welding . 34

8.5 Test welding . 34

8.5.1 Positional welding . 34

8.5.2 Roll welding . 35

8.6 Inspection and testing of test welds. 35

8.6.1 Non-destructive testing . 35

8.6.2 Destructive testing . 35

8.7 Re-testing . 36

8.8 Range of approval . 36

8.9 Records . 37

8.10 Period of validity. 37

9 Production welding . 37

9.1 General . 37

9.2 Equipment . 37

9.3 Working clearance . 38

9.4 Weather conditions. 38

9.5 Pipe end preparation . 38

9.6 Support . 38

9.7 Line-up . 38

9.8 Tack welding . 39

9.9 Earthing or grounding . 39

9.10 Electrodes and filler materials . 39

9.11 Shielding gases . 40

9.12 Preheating . 40

9.13 Arc strikes . 40

9.14 Backing . 41

9.15 Internal weld bead . 41

9.16 Weld metal deposition . 41

9.16.1 Girth welding . 41

9.16.2 Other welding. 41

9.17 Weld cleaning and peening . 41

9.18 Partially completed welds . 41

9.19 Post-weld heat treatment . 42

9.19.1 General . 42

9.19.2 Methods of heat treatment . 42

9.19.3 Post-weld heat-treatment procedure . 42

9.20 Pipe and weld record . 43

10 Non-destructive testing . 43

10.1 General . 43

10.2 NDT personnel . 43

10.3 NDT procedure approval . 43

10.4 Visual examination . 43

10.5 Radiographic testing . 44

10.5.1 Technique . 44

10.5.2 Procedure . 44

10.5.3 Procedure approval testing . 45

10.5.4 Information on radiograph . 45

10.5.5 Weld coverage . 45

10.5.6 Intensifying screens . 45

10.5.7 Radiographic density . 46

10.5.8 Film storage . 46

10.5.9 Radiographic images obscured by buckle-detector cable . 46

10.6 Ultrasonic testing . 46

10.6.1 Procedure . 46

10.6.2 Equipment . 46

10.6.3 Calibration and construction of reference curve . 46

10.6.4 Manual ultrasonic testing . 47

10.6.5 Mechanized testing . 47

10.6.6 Evaluation of indications . 47

10.7 Magnetic particle testing . 47

10.8 Liquid penetrant testing . 48

10.9 NDT report. 48

11 Acceptance criteria for non-destructive testing . 48

11.1 General. 48

11.2 Right of rejection . 49

11.3 Visual testing . 49

11.3.1 Weld profile . 49

11.3.2 Undercut . 49

11.4 Radiographic testing . 49

11.4.1 Lack of penetration . 49

11.4.2 Lack of fusion . 49

11.4.3 Root concavity . 50

11.4.4 Burn-through . 50

11.4.5 Inclusions . 50

11.4.6 Porosity . 51

11.4.7 Cracks . 51

11.4.8 Undercut . 51

11.4.9 Accumulation of discontinuities . 51

11.5 Ultrasonic testing . 52

11.5.1 General. 52

11.5.2 Spherical porosity . 52

11.5.3 Linear indications . 52

11.6 Surface testing . 52

11.6.1 Classification of indications . 52

11.6.2 Acceptance criteria. 52

11.7 Discontinuities in pipe or fittings . 53

11.8 Acceptance criteria — ECA . 53

12 Repair and removal of defects . 53

12.1 General. 53

12.2 Authorization for repair . 53

12.3 Multiple repairs . 53

12.4 Defect removal and preparation for repair . 53

13 Documentation . 54

Annex A (informative) Special requirements for welding of CRA pipelines and CRA-clad

steel pipelines . 55

A.1 General. 55

A.2 Specification and approval of welding procedure . 55

A.3 Production welding . 55

A.4 Procedure for non-destructive testing . 56

A.5 Acceptance criteria for non-destructive testing . 56

A.6 Repair and removal of defects . 56

Annex B (informative) Hyperbaric welding . 57

B.1 General. 57

B.2 WPS approval . 57

B.3 Welder approval. 57

B.4 Production welding . 58

B.5 Inspection and testing . 58

Annex C (informative) Recommendations for brazing and aluminothermic welding of

anode leads . 59

C.1 Joining technique . 59

C.2 Specification and approval of procedure . 59

C.2.1 General . 59

C.2.2 Copper penetration measurement . 59

C.2.3 Hardness survey . 59

Annex D (informative) Branch and fillet welding on in-service pipelines . 60

D.1 General . 60

D.2 General recommendations . 60

D.3 Specification, testing and approval of WPS . 61

D.3.1 Procedure specification . 61

D.3.2 Essential variables . 61

D.3.3 Welding of test pieces . 61

D.3.4 Inspection and testing of test pieces . 61

D.4 Testing and approval of welders . 65

D.5 Production welding . 65

D.5.1 Safety . 65

D.5.2 Inspection of in-service pipe . 65

D.5.3 Use of approved WPS and welders . 65

D.5.4 Supervision . 65

D.5.5 Weld testing . 66

Annex E (informative) Welding of European onshore natural gas transmission pipelines . 67

E.1 General . 67

E.2 Weld quality. 67

E.3 Non-destructive inspection of the weld joint . 68

E.3.1 General . 68

E.3.2 Non-destructive testing . 69

E.3.3 Time of inspection . 70

E.3.4 Destructive testing of production welds . 70

Annex F (informative) Welding of gas distribution systems in Europe . 72

F.1 General . 72

F.2 Approving of welders and welding operators . 72

F.3 Production welding . 72

F.4 Joint preparation . 72

F.5 Non-destructive inspection of the weld joint . 73

Annex G (normative) Automatic ultrasonic testing of girth welds . 74

G.1 General . 74

G.2 AUT system requirements . 74

G.3 Procedure . 74

G.4 Qualification of AUT system . 75

G.4.1 Calibration blocks. 75

G.4.2 Specific requirements for use with workmanship acceptance criteria . 75

G.4.3 Specific requirements for use with acceptance criteria determined by ECA . 75

G.5 Validity . 76

G.6 Operator qualification . 76

G.7 Acceptance criteria for AUT . 77

G.7.1 Workmanship criteria . 77

G.7.2 ECA criteria . 78

Annex H (informative) Examples of NDT reports . 79

Annex I (informative) Time of flight diffraction technique (ToFD) . 83

I.1 General. 83

I.2 Additional and substitutional requirements to ISO 10863:2020 . 83

I.2.1 Addition to ISO 10863:2020, Clause 1 (Scope) . 83

I.2.2 Addition to ISO 10863:2020, Clause 3 (Terms and definitions) . 83

I.2.3 Addition to ISO 10863:2020, Clause 5 (Testing levels) . 85

I.2.4 Addition to ISO 10863:2020, 7.2.2 (Ultrasonic probes). 85

rd

I.2.5 Substitution of ISO 10863:2020, Clause 11 (Weld testing), 3 paragraph . 85

I.2.6 Substitution of ISO 10863:2020, 12.6 (Definition and determination of length and

height) . 85

Bibliography . 90

European foreword

This document (prEN 14163:2021) has been prepared by Technical Committee CEN/TC 12 “Materials,

equipment and offshore structures for petroleum, petrochemical and natural gas industries”, the

secretariat of which is held by NEN and CYS.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 14163:2001.

The text of ISO 13847:2013 has been adopted by CEN/TC 12 with some modifications to exclude the

aspects that are covered by CEN/TC 234 “Gas infrastructure”. These modifications are indicated by a

vertical line in the left margin of the text [note: currently indicated with ‘track changes’].

Introduction

Users of this document are advised that further or differing requirements might be needed for

individual applications, using alternative engineering solutions, particularly where there is innovative

or developing technology. Where an alternative is offered, it is advisable that the manufacturer

identifies any variations from this document and provides details.

This second edition cancels and replaces the first edition (ISO 13847:2000), which has been technically

revised. The following annexes have been added compared with the first edition:

— branch and filet welding on in-service pipelines (Annex D);

— welding of European onshore natural gas transmission pipelines (Annex E);

— welding of gas distribution systems in Europe (Annex F);

— automatic ultrasonic testing of girth welds (Annex G);

— time of flight diffraction techniques (Annex I).

ISO 13847:2013, developed within ISO/TC 67/SC 2, has been adopted as EN 14163:202X (ISO

13847:2013, modified).

The scope of ISO/TC 67/SC 2 is pipeline transportation systems for the petroleum and natural gas

industries without exclusions. However, in CEN the scopes of CEN/TC 12 and CEN/TC 234 overlapped

until 1995. This scope overlap caused problems for the parallel procedure for the above-mentioned

item. The conflict in scope was resolved when both the CEN Technical Committees concerns and the

CEN Technical Board decided to amend the scope of CEN/TC 12 by explicitly excluding “on-land supply

systems used by the gas supply industry excluding gas infrastructure from the input of gas into the on-

shore transmission network up to the inlet connection of gas appliances”.

1 Scope

This document specifies requirements for the petroleum, petrochemical and natural gas industries, for

producing and inspecting girth, branch and fillet welds in the pipeline part of pipeline transportation

systems which meet the requirements of ISO 13623:2017 or equivalent.

NOTE 1 ISO 13847:2013 refers to the requirements of ISO 13623:2009 or equivalent. At the time of publication

of this document, ISO 13623:2009 is superseded by ISO 13623:2017 and reference is made to this edition of

ISO 13623 throughout this document. ISO 13623 is modified adopted as EN 14161 to exclude on-land supply

systems used by the European gas supply industry from the input of gas into the on-land transmission network up

to the inlet connection of gas appliances.

This document is applicable to the requirements for welding of carbon and low-alloy steel pipes, and

includes guidance for the welding of corrosion-resistant alloy (CRA) and CRA-clad pipelines in Annex A.

Application is restricted to pipes with a diameter of 20 mm or more and a wall thickness of 3 mm or

more, a specified minimum yield strength of 555 MPa or less, and which are designed not to exceed

permissible equivalent stresses as defined in ISO 13623:2017 or equivalent. It is also applicable to

welding into pipelines of items such as spools, risers, launchers/receivers, fittings, flanges and pup

pieces to pipeline valves. On-land supply systems used by the European gas supply industry from the

input of gas into the on-land transmission network up to the inlet connection of gas appliances are

excluded from the scope of this document.

Guidance for special welding applications is provided in:

— Annex B for hyperbaric welding;

— Annex C for brazing and aluminothermic welding of anode leads;

— Annex D for branch and fillet welding on in-service pipelines.

The welding processes covered are shielded metal arc welding (SMAW), gas tungsten arc welding

(GTAW), gas metal arc welding (GMAW), gas-shielded flux-cored arc welding (GSFCAW), self-shielded

flux-cored arc welding (SSFCAW) and submerged arc welding (SAW).

This document is not applicable to flash girth welding, resistance welding, solid-phase welding or other

one-shot welding processes, nor to longitudinal welds in pipe or fittings or to the welding of process

piping outside the scope of ISO 13623:2017.

NOTE 2 Additional requirements might be necessary for the welding of pipeline for particular pipeline

operating conditions, for pipelines with a specified yield strength exceeding 555 MPa and for pipelines designed to

permissible strain criteria. These can include limitations on maximum hardness or strength, minimum impact

toughness values, crack tip-opening displacement, all weld metal tensile testing or bend testing, thermal stress

relief, or others. Where appropriate, it is advisable that these additional requirements be added to the

requirements of this document in a project-specific supplement.

NOTE 3 Annex E specifies additional requirements for the welding of onshore gas supply systems applicable

only when located in European member states. Annex F specifies additional requirements for the welding of gas

distribution systems applicable only when located in European member states. It is the responsibility of the

company to specify the normative applicability of these annexes.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 148-1, Metallic materials — Charpy pendulum impact test — Part 1: Test method

ISO 857-1, Welding and allied processes — Vocabulary — Part 1: Metal welding processes

ISO 3183, Petroleum and natural gas industries — Steel pipe for pipeline transportation systems

ISO 3834 (all parts), Quality requirements for fusion welding of metallic materials

ISO 4136, Destructive tests on welds in metallic materials — Transverse tensile test

ISO 5173, Destructive tests on welds in metallic materials — Bend tests

ISO 5178, Destructive tests on welds in metallic materials — Longitudinal tensile test on weld metal in

fusion welded joints

ISO 6507-1, Metallic materials — Vickers hardness test — Part 1: Test method

ISO 6520-1, Welding and allied processes — Classification of geometric imperfections in metallic

materials — Part 1: Fusion welding

ISO 6947, Welding and allied processes — Welding positions

ISO 9015-1, Destructive tests on welds in metallic materials — Hardness testing — Part 1: Hardness test

on arc welded joints

ISO 9712, Non-destructive testing — Qualification and certification of NDT personnel

ISO 10474, Steel and steel products — Inspection documents

ISO 10863:2020, Non-destructive testing of welds — Ultrasonic testing — Use of time-of-flight diffraction

technique (TOFD)

ISO 13588, Non-destructive testing of welds — Ultrasonic testing — Use of automated phased array

technology

ISO 13623:2017, Petroleum and natural gas industries — Pipeline transportation systems

ISO 13916, Welding — Guidance on the measurement of preheating temperature, interpass temperature

and preheat maintenance temperature

ISO 14175, Welding consumables — Gases and gas mixtures for fusion welding and allied processes

ISO 14732, Welding personnel — Qualification testing of welding operators and weld setters for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...