EN 14841:2023

(Main)LPG equipment and accessories - Filling and discharge procedures for LPG rail tankers

LPG equipment and accessories - Filling and discharge procedures for LPG rail tankers

This document specifies procedures for filling, discharge and handling operations as well as emergency procedures for rail tankers used for the transport of liquefied petroleum gas (LPG).

This document does not apply to “tank containers” and “batteries of receptacles”.

Flüssiggas-Geräte und Ausrüstungsteile - Füll- und Entleerungsverfahren für Eisenbahnkesselwagen für Flüssiggas (LPG)

Dieses Dokument legt Arbeitsvorgänge zum Befüllen und Entleeren sowie Abfertigungstätigkeiten und Notfallmaßnahmen für Eisenbahnkesselwagen fest, die zur Beförderung von Flüssiggas (LPG, en: liquefied petroleum gas) eingesetzt werden.

Dieses Dokument gilt nicht für „Tankcontainer“ und „Behälterbatterien“.

Équipements pour GPL et leurs accessoires - Procédures de chargement et déchargement des wagons-citernes pour GPL

Le présent document spécifie des procédures pour les opérations de chargement, de déchargement et de manutention, ainsi que des procédures d'urgence pour les wagons-citernes utilisés pour le transport de gaz de pétrole liquéfié (GPL).

Le présent document ne s'applique pas aux « conteneurs-citernes » ni aux « véhicules-batteries ».

Oprema in pribor za utekočinjeni naftni plin (UNP) - Postopek polnjenja in praznjenja železniških cistern za UNP

Ta dokument določa praznjenje, ravnanje in postopke v sili za železniške cisterne, ki se uporabljajo za prevoz utekočinjenega naftnega plina (LPG).

Ta dokument se uporablja za postopke, pri katerih se utekočinjeni naftni plin raztovarja iz železniških cistern v nepremična skladišča za utekočinjeni naftni plin in cestne cisterne.

Ta dokument zajema omejitve, da se omeji raztovarjanje železniških cistern v druge železniške cisterne.

Ta dokument se ne uporablja za »cisterne zabojnike« ali »baterije posod«.

General Information

- Status

- Published

- Publication Date

- 30-May-2023

- Technical Committee

- CEN/TC 286 - Liquefied petroleum gas equipment and accessories

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 31-May-2023

- Due Date

- 22-May-2023

- Completion Date

- 31-May-2023

- Mandate

- M/XXX - M/XXX

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

Overview

EN 14841:2023 (CEN) is the European standard that specifies filling, discharge and handling procedures for LPG rail tankers. It defines operational and emergency procedures to ensure safe transfer of liquefied petroleum gas (LPG) by rail. The standard applies to rail tankers only and explicitly excludes “tank containers” and “batteries of receptacles”. EN 14841:2023 supersedes the 2013 edition and includes updates for filling operations, integrated shut down systems and harmonisation with related LPG transfer standards.

Key topics and requirements

- Site procedures and supervision

- Written site procedures and emergency procedures must be available, understood and followed by trained personnel.

- A competent person (site operator) must supervise acceptance, filling, discharge and return operations.

- Pre-transfer checks

- Verification of tanker marking, integrity, tamper-evident seals and LPG grade.

- Isolation from other rail traffic, parking brakes, wheel chocks and anti-drive-away interlocks where fitted.

- Connection and electrostatic control

- Equalisation of electrostatic potential between tanker and loading equipment before connecting hoses/loading arms.

- Inspection of hoses, couplings and seals for damage and contamination before use.

- Filling and discharge operations

- Controlled sequence for opening and closing product and vapour valves per site procedures; leak checks before and during transfer.

- Monitoring of gauging devices and weighing systems to prevent overfilling; prompt controlled removal if overfill occurs.

- Specific notes for discharging by pumps or compressors and for use of tanker loading control systems.

- Completion and stowage

- Safe venting of residual LPG in transfer couplings, secure closure of all tanker valves, stowing of lines, and verification of filled quantity and hazard labelling.

- Emergency and Integrated Shut Down

- Procedures for emergency response and a new clause on integrated shut down systems to stop transfers safely.

- Personal protection & fire precautions

- Personnel must use appropriate PPE (recommendations in Annex A) and fire protection must be available per national regulations.

Applications and who uses it

- Operators and staff at LPG terminals, rail freight depots and bulk distribution sites

- Rail tanker owners, loaders/unloaders, safety managers and compliance officers

- Equipment manufacturers, system integrators and emergency planners Practical benefits include reduced transfer incidents, clearer responsibilities, improved environmental and safety performance, and compliance support for transport regulations.

Related standards and guidance

- CEN/TS 16769 (terminology)

- CEN/TS 16765 (environmental aspects for LPG equipment)

- EN 13776 (harmonisation of filling/discharge practices)

- RID / ADR (transport regulations) and EN ISO 14001 (environmental management)

Using EN 14841:2023 helps organizations manage LPG rail transfer risks, meet regulatory expectations and implement consistent, auditable filling and discharge procedures.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 14841:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "LPG equipment and accessories - Filling and discharge procedures for LPG rail tankers". This standard covers: This document specifies procedures for filling, discharge and handling operations as well as emergency procedures for rail tankers used for the transport of liquefied petroleum gas (LPG). This document does not apply to “tank containers” and “batteries of receptacles”.

This document specifies procedures for filling, discharge and handling operations as well as emergency procedures for rail tankers used for the transport of liquefied petroleum gas (LPG). This document does not apply to “tank containers” and “batteries of receptacles”.

EN 14841:2023 is classified under the following ICS (International Classification for Standards) categories: 23.020.20 - Vessels and containers mounted on vehicles; 45.060.20 - Trailing stock. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14841:2023 has the following relationships with other standards: It is inter standard links to EN 14841:2013, CEN/TS 16769:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14841:2023 is associated with the following European legislation: EU Directives/Regulations: 2008/68/EC; Standardization Mandates: M/TDG, M/XXX. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14841:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2023

Nadomešča:

SIST EN 14841:2014

Oprema in pribor za utekočinjeni naftni plin (UNP) - Postopek polnjenja in

praznjenja železniških cistern za UNP

LPG equipment and accessories - Filling and discharge procedures for LPG rail tankers

Flüssiggas-Geräte und Ausrüstungsteile - Füll- und Entleerungsverfahren für

Eisenbahnkesselwagen für Flüssiggas (LPG)

Équipements pour GPL et leurs accessoires - Procédures de chargement et

déchargement des wagons-citernes pour GPL

Ta slovenski standard je istoveten z: EN 14841:2023

ICS:

23.020.20 Posode in vsebniki, montirani Vessels and containers

na vozila mounted on vehicles

45.060.20 Železniški vagoni Trailing stock

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14841

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2023

EUROPÄISCHE NORM

ICS 23.020.20; 45.060.20 Supersedes EN 14841:2013

English Version

LPG equipment and accessories - Filling and discharge

procedures for LPG rail tankers

Équipements pour GPL et leurs accessoires - Flüssiggas-Geräte und Ausrüstungsteile - Füll- und

Procédures de chargement et déchargement des Entleerungsverfahren für Eisenbahnkesselwagen für

wagons-citernes pour GPL Flüssiggas (LPG)

This European Standard was approved by CEN on 24 April 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14841:2023 E

worldwide for CEN national Members.

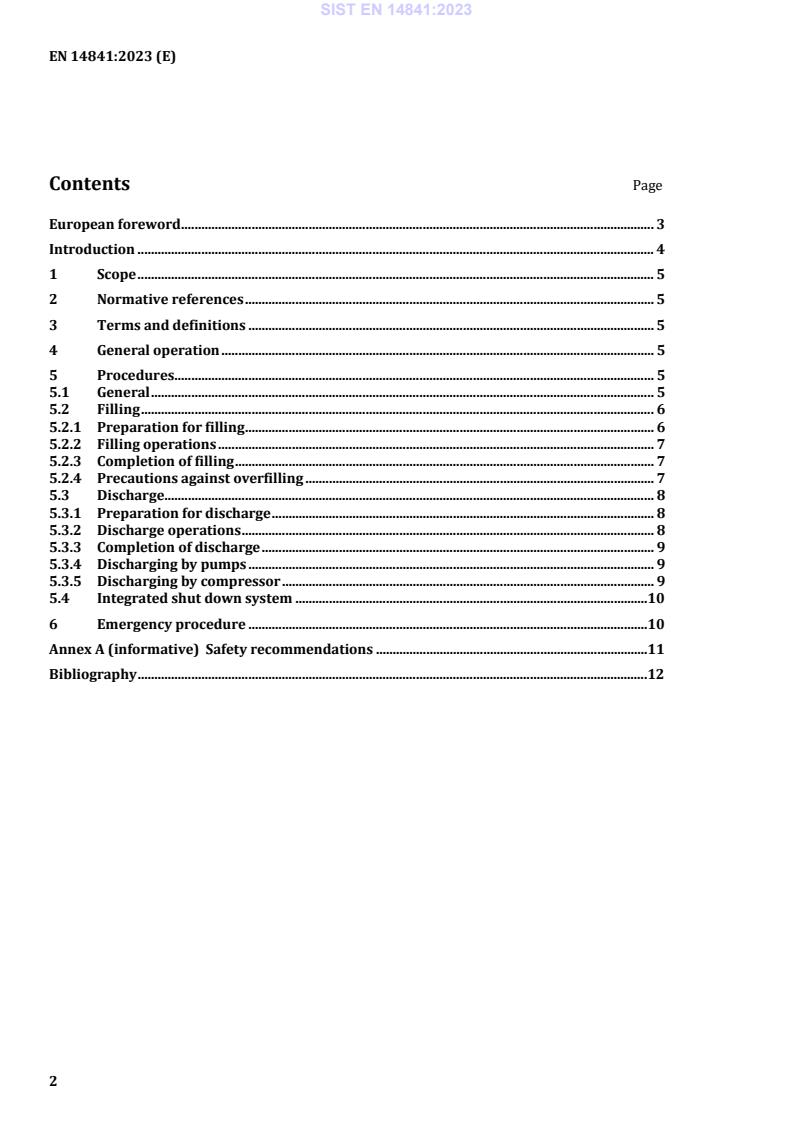

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 General operation . 5

5 Procedures. 5

5.1 General . 5

5.2 Filling . 6

5.2.1 Preparation for filling . 6

5.2.2 Filling operations . 7

5.2.3 Completion of filling . 7

5.2.4 Precautions against overfilling . 7

5.3 Discharge . 8

5.3.1 Preparation for discharge . 8

5.3.2 Discharge operations . 8

5.3.3 Completion of discharge . 9

5.3.4 Discharging by pumps . 9

5.3.5 Discharging by compressor . 9

5.4 Integrated shut down system .10

6 Emergency procedure .10

Annex A (informative) Safety recommendations .11

Bibliography .12

European foreword

This document (EN 14841:2023) has been prepared by Technical Committee CEN/TC 286 “Liquefied

petroleum gas equipment and accessories”, the secretariat of which is held by NSAI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2023, and conflicting national standards shall

be withdrawn at the latest by November 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14841:2013.

In comparison with the previous edition, the following technical modifications have been made:

— Removal of the Annex A on the Environmental checklist;

— Addition of a reference to CEN/TS 16765;

— A new Annex A was added giving recommendations on the personal protection equipment;

— Updating of the Introduction;

— In addition to the discharge of LPG, requirements for the filling of LPG were also added;

— The document was harmonized in both the filling and the discharge sections with EN 13776;

— A new clause on Integrate shut down systems was added.

This document will be submitted for reference in:

— the RID [4]; and/or

— the technical annexes of the ADR [5].

NOTE These regulations take precedence over any clause of this standard. It is emphasized that RID/ADR are

being revised regularly at intervals of two years which can lead to temporary non-compliances with the clauses of

this standard.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document calls for the use of substances and procedures that can be injurious to health if adequate

precautions are not taken. It refers only to technical suitability and does not absolve the user from legal

obligations relating to health and safety at any stage.

The frequencies of the different types of pressure vessel inspection are given by the relevant international

regulations concerning the transport of dangerous goods.

Protection of the environment is a key political issue in Europe and elsewhere. For CEN/TC 286 this is

covered in CEN/TS 16765 [1], and this Technical Specification should be read in conjunction with this

document. CEN/TS 16765 provides guidance on the environmental aspects to be considered regarding

equipment and accessories produced for the LPG industry and the following is addressed:

a) design;

b) manufacture;

c) packaging;

d) use and operation; and

e) disposal.

It is recommended that companies using this document develop an environmental management policy.

For guidance, see EN ISO 14001 [2].

It has been assumed in the drafting of this document that the execution of its provisions is entrusted to

appropriately qualified and experienced people.

All pressures are gauge pressures unless otherwise stated.

NOTE This document requires measurement of material properties, dimensions and pressures. All such

measurements are subject to a degree of uncertainty due to tolerances in measuring equipment, etc. It can be

beneficial to refer to the leaflet “Measurement uncertainty leaflet” SP INFO 2000 27 [3].

1 Scope

This document specifies procedures for filling, discharge and handling operations as well as emergency

procedures for rail tankers used for the transport of liquefied petroleum gas (LPG).

This document does not apply to “tank containers” and “batteries of receptacles”.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

CEN/TS 16769, LPG equipment and accessories - Terminology

3 Terms and definitions

For the purposes of this document, the terms and definitions given in CEN/TS 16769 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

4 General operation

Handling operations such as:

— accepting rail tankers upon arrival;

— filling and/or discharge of LPG; and

— preparation and returning rail tanker

shall be carried out under the supervision of a competent person (e.g. operator of the site) and shall be

in accordance with the site procedures.

5 Procedures

5.1 General

Site procedures in written form including emergency procedures shall be available, understood and

followed by all persons involved in each operation. This shall be achieved by training and supervision.

The responsibilities of the persons involved shall be clearly specified.

The procedures shall include a check of the rail tanker that is to be carried out before it is accepted. This

shall include:

— the marking;

— a check of the integrity of the rail tanker;

— a check of tamper evident seals; and

— an identification check of LPG quality and grade.

In case of transfer to/from another tanker, the procedures shall also include the check of that other

tanker.

Where deficiencies are found, they shall be recorded and reported to the appropriate body (e.g. rail

tanker loader) and the rail tanker operator. A rail tanker shall not be filled and/or discharged until any

necessary remedial work has been completed.

Copies of checklists and deficiency reports shall be retained.

Personnel carrying out LPG transfer operations shall wear personal protection equipment. The

operations of filling and discharging shall be done under constant supervision.

NOTE 1 Recommendations for personal protection equipment are given in Annex A.

The filling and discharge areas shall be inspected for fire hazards prior to beginning operations. Suitable

fire protection shall be readily available.

NOTE 2 Responsibilities for fire protection are subject to national regulations.

5.2 Filling

5.2.1 Preparation for filling

5.2.1.1 The rail tanker to be filled shall be moved to the filling area and positioned in accordance with

the site procedures.

5.2.1.2 Any device provided to check the loaded quantity (e.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...