EN 1674:2000+A1:2009

(Main)Food processing machinery - Dough and pastry brakes - Safety and hygiene requirements

Food processing machinery - Dough and pastry brakes - Safety and hygiene requirements

This standard specifies safety and hygiene requirements for the design and manufacture of dough and pastry brakes used in the food industry and shops (bread-making, pastry-making, sweet industries, bakeries, confectioners, delicatessens, catering facilities, etc) for reducing the thickness of a solid mass of dough or pastry by rolling it out. The operation is generally carried out by passing the dough back and forth between the rollers whose distance apart is reduced progressively either by manual adjustment or automatically.

The standard covers the technical safety requirements for the installation, adjustment, operation, cleaning and maintenance of these machines, as defined in 3.12 of EN 292-1:1991 and in the manufacturer's instruction handbook.

The significant hazards covered by this standard are mechanical (drawing-in, crushing, shearing, cutting, entanglement and loss of stability), electrical, ergonomic and those resulting from inhalation of flour dust and lack of hygiene. The hazards are specifically listed in 5. Noise is not considered to be a significant hazard from dough and pastry brakes. This does not mean that the manufacturer of the machine is absolved from reducing noise and making a noise declaration. Therefore a noise test code is specified in Annex B.

It applies only to machines manufactured after the date of issue of the standard.

The following machines are excluded:

- experimental and testing machines under development by the manufacturer;

- domestic appliances

Nahrungsmittelmaschinen - Teigausrollmaschinen - Sicherheits-und Hygieneanforderungen

Machines pour les produits alimentaires - Laminoirs à pâte - Prescriptions relatives à la sécurité et l'hygiène

La présente norme spécifie les prescriptions d'hygiène et de sécurité relatives à la conception et à la construction des

laminoirs à pâte utilisés dans l'industrie alimentaire et les commerces de l'alimentation (boulangerie, pâtisserie,

biscuiterie, confiseries, traiteurs, restauration collective etc.) pour réduire l'épaisseur d'une masse solide de pâte à pain

ou de pâtisserie par laminage. L'opération est généralement réalisée par laminage en un mouvement de va et vient

entre des cylindres dont on réduit progressivement l'écartement, par réglage manuel ou automatique.

!La présente norme couvre les prescriptions techniques de sécurité relatives au transport, à l’installation,

au réglage, au fonctionnement, au nettoyage et à la maintenance de ces machines."

!La présente norme traite de tous les phénomènes, situations et événements dangereux significatifs spécifiques

des laminoirs à pâte, lorsqu'ils sont utilisés normalement et dans des conditions de mauvaises utilisation

raisonnablement prévisibles par le fabricant (voir Article 5).

Le bruit n’est pas considéré comme un phénomène dangereux significatif. Ceci ne signifie pas que le fabricant de la

machine est dispensé de réduire le bruit et d'établir une déclaration de bruit. Par conséquent, un code d'essai

acoustique est donné en Annexe B."

Les machines suivantes sont exclues :

- les machines expérimentales ou d'essais en cours de mise au point par le fabricant ;

- les appareils à usage domestique 1).

!La présente norme n’est pas applicable aux laminoirs à pâte fabriqués avant sa date de publication en tant que

Norme européenne."

Stroji za predelavo hrane - Stroji za valjanje testa - Varnostne in higienske zahteve

Ta standard določa varnostne in higienske zahteve za načrtovanje in izdelavo strojev za valjanje testa, ki se uporabljajo v prehrambeni industriji in trgovinah (izdelava kruha, izdelava peciv, izdelava slaščic, v pekarnah, slaščičarnah, delikatesah, gostinskih obratih itd.) za zmanjševanje gostote trdne mase testa ali peciva z valjanjem. Postopek se navadno izvede s podajanjem testa naprej in nazaj med valji, med katerimi se razdalja postopno zmanjšuje ročno ali samodejno. Standard zajema varnostne tehnične zahteve za prevoz, namestitev, nastavitev, delovanje, čiščenje in vzdrževanje teh strojev. Ta evropski standard obravnava vse velike nevarnosti, nevarne situacije in primere, ki se tičejo strojev za valjanje testa, kadar se uporabljajo, kot predvideno, in pod pogoji napačne uporabe, ki jih razumno predvidi proizvajalec (glej Klavzulo 5). Hrup ne šteje kot velika nevarnost. To ne pomeni, da je proizvajalec oproščen zmanjševanja hrupa in priprave deklaracije o hrupu. Zato je preskusna koda hrupa podana v Dodatku A. Izvzeti so naslednji stroji: - eksperimentalni in preskusni stroji, ki jih razvija proizvajalec; - gospodinjski aparati1) Ta standard ne velja za stroje za valjanje testa, ki so bili izdelani pred datumom objave v obliki EN.

General Information

- Status

- Withdrawn

- Publication Date

- 01-Dec-2009

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 1 - Bakery equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Sep-2015

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 136, C 136, C 136, C 136, C 136, C 136, C 136, C OJ Date: 26-May-2010

Not Harmonized98/37/EC - Machinery

Relations

- Merged From

EN 1674:2000 - Food processing machinery - Dough and pastry brakes - Safety and hygiene requirements - Effective Date

- 18-Jan-2023

- Replaced By

EN 1674:2015 - Food processing machinery - Dough sheeters - Safety and hygiene requirements - Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 1674:2000+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Dough and pastry brakes - Safety and hygiene requirements". This standard covers: This standard specifies safety and hygiene requirements for the design and manufacture of dough and pastry brakes used in the food industry and shops (bread-making, pastry-making, sweet industries, bakeries, confectioners, delicatessens, catering facilities, etc) for reducing the thickness of a solid mass of dough or pastry by rolling it out. The operation is generally carried out by passing the dough back and forth between the rollers whose distance apart is reduced progressively either by manual adjustment or automatically. The standard covers the technical safety requirements for the installation, adjustment, operation, cleaning and maintenance of these machines, as defined in 3.12 of EN 292-1:1991 and in the manufacturer's instruction handbook. The significant hazards covered by this standard are mechanical (drawing-in, crushing, shearing, cutting, entanglement and loss of stability), electrical, ergonomic and those resulting from inhalation of flour dust and lack of hygiene. The hazards are specifically listed in 5. Noise is not considered to be a significant hazard from dough and pastry brakes. This does not mean that the manufacturer of the machine is absolved from reducing noise and making a noise declaration. Therefore a noise test code is specified in Annex B. It applies only to machines manufactured after the date of issue of the standard. The following machines are excluded: - experimental and testing machines under development by the manufacturer; - domestic appliances

This standard specifies safety and hygiene requirements for the design and manufacture of dough and pastry brakes used in the food industry and shops (bread-making, pastry-making, sweet industries, bakeries, confectioners, delicatessens, catering facilities, etc) for reducing the thickness of a solid mass of dough or pastry by rolling it out. The operation is generally carried out by passing the dough back and forth between the rollers whose distance apart is reduced progressively either by manual adjustment or automatically. The standard covers the technical safety requirements for the installation, adjustment, operation, cleaning and maintenance of these machines, as defined in 3.12 of EN 292-1:1991 and in the manufacturer's instruction handbook. The significant hazards covered by this standard are mechanical (drawing-in, crushing, shearing, cutting, entanglement and loss of stability), electrical, ergonomic and those resulting from inhalation of flour dust and lack of hygiene. The hazards are specifically listed in 5. Noise is not considered to be a significant hazard from dough and pastry brakes. This does not mean that the manufacturer of the machine is absolved from reducing noise and making a noise declaration. Therefore a noise test code is specified in Annex B. It applies only to machines manufactured after the date of issue of the standard. The following machines are excluded: - experimental and testing machines under development by the manufacturer; - domestic appliances

EN 1674:2000+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1674:2000+A1:2009 has the following relationships with other standards: It is inter standard links to EN 1674:2000, EN 1674:2015, EN 60529:1991, EN ISO 11201:2009, EN 1672-2:2005, EN ISO 3743-1:2009, EN ISO 3744:2009, EN ISO 13849-1:2008, EN 1088:1995, EN ISO 12100-2:2003, EN 614-1:2006, EN ISO 12001:2009, EN 954-1:1996, EN ISO 11688-1:2009, EN ISO 4871:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1674:2000+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1674:2000+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo hrane - Stroji za valjanje testa - Varnostne in higienske zahteveNahrungsmittelmaschinen - Teigausrollmaschinen - Sicherheits-und HygieneanforderungenMachines pour les produits alimentaires - Laminoirs à pâte - Prescriptions relatives à la sécurité et l'hygièneFood processing machinery - Dough and pastry brakes - Safety and hygiene requirements67.260Tovarne in oprema za živilsko industrijoPlants and equipment for the food industryICS:Ta slovenski standard je istoveten z:EN 1674:2000+A1:2009SIST EN 1674:2002+A1:2010en,fr01-marec-2010SIST EN 1674:2002+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1674:2000+A1

December 2009 ICS 67.260 Supersedes EN 1674:2000English Version

Food processing machinery - Dough and pastry brakes - Safety and hygiene requirements

Machines pour les produits alimentaires - Laminoirs à pâte - Prescriptions relatives à la sécurité et l'hygiène

Nahrungsmittelmaschinen - Teigausrollmaschinen - Sicherheits-und Hygieneanforderungen This European Standard was approved by CEN on 11 June 2000 and includes Amendment 1 approved by CEN on 24 October 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1674:2000+A1:2009: ESIST EN 1674:2002+A1:2010

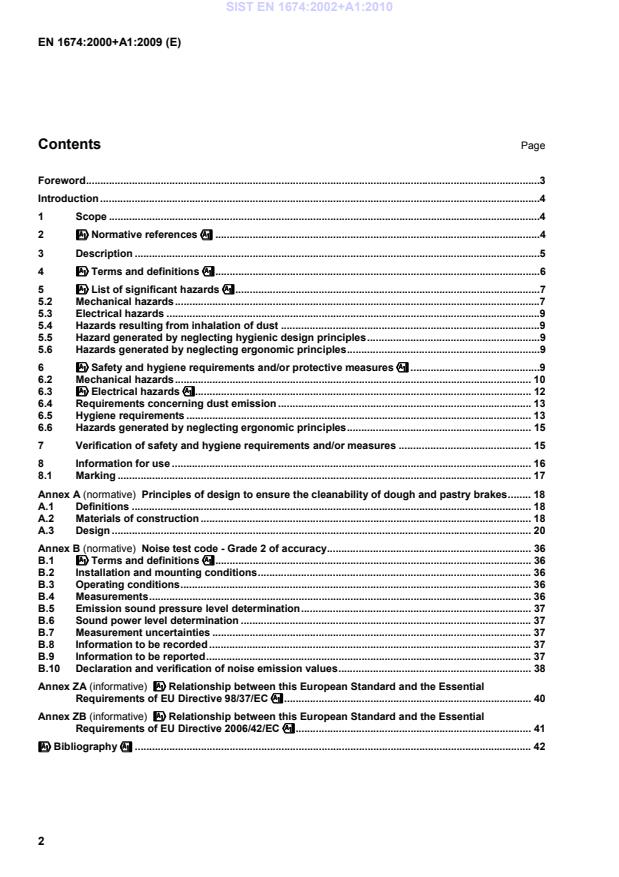

Principles of design to ensure the cleanability of dough and pastry brakes . 18A.1Definitions . 18A.2Materials of construction . 18A.3Design . 20Annex B (normative)

Noise test code - Grade 2 of accuracy. 36B.1!!!!Terms and definitions"""" . 36B.2Installation and mounting conditions . 36B.3Operating conditions . 36B.4Measurements . 36B.5Emission sound pressure level determination . 37B.6Sound power level determination . 37B.7Measurement uncertainties . 37B.8Information to be recorded . 37B.9Information to be reported . 37B.10Declaration and verification of noise emission values . 38Annex ZA (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC"""" . 40Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 41!!!!Bibliography"""" . 42 SIST EN 1674:2002+A1:2010

!This standard is not applicable to dough and pastry brakes which are manufactured before the date of its publication as EN." 2 !!!!Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 294:1992, Safety of machinery — Safety distances to prevent danger zones being reached by the upper limbs EN 349:1993, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body

1) EN 60335-1 and EN 60335-2-64 are applicable. SIST EN 1674:2002+A1:2010

Figure 1 — Main parts of a dough and pastry brake ! 4 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 12100-1:2003 and the following apply. 4.1 manual operation the rollers and conveyor belts are driven by electric motor and the roller gap is adjusted by hand control 4.2 automatic operation adjustment of the roller gap is by electric motor and it is normally automatically controlled, e.g. by microprocessor" SIST EN 1674:2002+A1:2010

Figure 2 — Danger zones of a dough and pastry brake

Use of dough and pastry brakes exposes operators to dust including flour and ingredients which may be harmful to their health, causing rhinitis (running noses), watering eyes and possibly occupational asthma. The major sources of airborne dust on these machines are as follows: flour used directly to prevent dough sticking to the belt, table or rollers; flour generated during filling of the dusting reservoir and during cleaning of the machine. 5.5 Hazard generated by neglecting hygienic design principles The neglecting of hygienic principles can create unacceptable modification of foodstuff and therefore a risk to human health, i.e. through physical, chemical or microbial pollution. 5.6 Hazards generated by neglecting ergonomic principles During operation, cleaning and maintenance, there is a risk of injury or chronic damage to the body resulting from awkward body postures. ! 6 Safety and hygiene requirements and/or protective measures"""" !!!! 6.1 General Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100-2 for relevant but not significant hazards, which are not dealt with by this document. SIST EN 1674:2002+A1:2010

Dimensions in millimetres A max. 35 40 45 50 55 60 65 70 105

B min. 200 225 250 300 350 400 450 500 550

C min.

300 300 300 D min. EN 294 Table 4

The interlocking mechanism, shall be housed within the machine body or otherwise protected, to ensure that its operation is not adversely affected by for example dough or flour. Movable interlocking guards shall be free to move at their ends furthest from the rollers in order to act like a trip device if an operator attempts to reach under any guard. If the guard is not solid, the distance between bars or mesh shall comply with table 4 of EN 294:1992.

Figure 3 — Guard dimensions

A:distance between the table and the front opening of the guard when the interlocking device is actuated; B:distance between the edge of the guard and the vertical plane through the axes of the rollers; C:distance between the end of guard and end of belt; D:distance between the lower edge of the guard and the table or conveyor belt. Lifting of the guard shall within one second: either cause the machine to stop. In this case restarting shall only be possible by intentionally actuating the starting control; or it shall result in the reversal of the rotation of the rollers so that the operator cannot be drawn in, i.e. that the nip between the rollers is outrunning. 6.2.2 Zone 4 The drive mechanism shall be located either within the machine frame or safeguarded by means of a fixed guard !(see EN 953)". 6.2.3 Zone 5 Access to the inrunning nip of the conveyors shall be prevented, e.g. by a guard such as the one marked (c) in figure 4.

a) Input or output conveyor b) Roller c) Inrunning nip guard Figure 4 — Inrunning nip guard

Food area

Splash area

Non food area Figure 5 — Hygiene areas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...