EN 17963:2024

(Main)Natural gas vehicles - LNG vehicle fuelling procedures

Natural gas vehicles - LNG vehicle fuelling procedures

This document gives guidelines for safe fuelling operations of vehicles that use liquefied natural gas (LNG) as a fuel for propulsion, covering the activities and procedures to be followed for safe operation. It provides procedures applicable to different fuelling systems and technologies.

NOTE Regarding the responsibility surrounding the training of drivers of LNG vehicles, see the framework of Directive 89/391 EEC.

Erdgasfahrzeuge - Betankungsabläufe für LNG Fahrzeuge

Dieses Dokument gibt Leitlinien für sichere Betankungsabläufe für Fahrzeuge, deren Antrieb auf Flüssigerdgas (LNG, en: liquefied natural gas) als Kraftstoff beruht, und behandelt die Aktivitäten und Abläufe, die für einen sicheren Betrieb zu befolgen sind. Es enthält Verfahren, die auf unterschiedliche Betankungssysteme und technologien anwendbar sind.

ANMERKUNG In Bezug auf die Verantwortung für die Ausbildung der LNG Fahrzeugführer siehe die Richtlinie 89/391/EWG.

Véhicules au gaz naturel - Procédures de ravitaillement des véhicules GNL

Le présent document donne les lignes directrices pour les opérations de ravitaillement des véhicules qui utilisent du gaz naturel liquéfié (GNL) comme carburant de propulsion, couvrant les activités et les procédures à suivre pour un fonctionnement en toute sécurité. Il fournit les procédures applicables aux différents systèmes et technologies de ravitaillement.

NOTE Concernant la responsabilité entourant la formation des conducteurs de véhicules GNL, voir le cadre de la directive 89/391 CEE

Vozila na zemeljski plin - Postopki polnjenja vozil na utekočinjeni zemeljski plin

Ta dokument podaja smernice za varno polnjenje vozil, ki kot pogonsko gorivo uporabljajo utekočinjeni zemeljski plin (LNG), ter zajema dejavnosti in postopke, ki jih je treba upoštevati za varno delovanje.

Zagotavlja postopke, ki se uporabljajo za različne sisteme in tehnologije za polnjenje.

OPOMBA: V zvezi z odgovornostjo za usposabljanje voznikov vozil na utekočinjeni zemeljski plin glej okvirno direktivo 89/391/EGS.

General Information

- Status

- Published

- Publication Date

- 20-Aug-2024

- Technical Committee

- CEN/TC 326 - Gas supply for Natural Gas Vehicles (NGV)

- Drafting Committee

- CEN/TC 326/WG 5 - LNG Vehicle Use and Operation

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 21-Aug-2024

- Due Date

- 02-Sep-2024

- Completion Date

- 21-Aug-2024

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - EN 17963:2024 (LNG vehicle fuelling procedures)

EN 17963:2024 is a CEN European standard that provides operational guidelines and safety procedures for fuelling vehicles with liquefied natural gas (LNG). The document covers the sequence of activities for safe LNG fuelling at public or fleet stations, including pre‑fuelling checks, vapour pressure reduction, connection and disconnection of nozzles, and final operations. It applies to different fuelling systems and technologies and includes informative and normative annexes (e.g., emergency troubleshooting and warm‑tank refuelling).

Key topics and technical requirements

- Safety precautions and hazard control

- Elimination of ignition sources, no‑smoking rules, and thunderstorm restrictions.

- Station‑specific emergency procedures and evacuation actions.

- Personal protective equipment (PPE)

- Minimum PPE includes a face shield (EN ISO 16321‑1), long cryogenic gloves (EN 511), long‑sleeved clothing and closed shoes to prevent cryogenic burns.

- Pre‑fuelling requirements

- Vehicle parking, engine off, parking brake engaged, windows closed, and auxiliary heating/cooling turned off.

- Identification procedures at dispenser (fuel type selection, vehicle info) where required.

- Vapour pressure reduction procedures

- Two main methods: separate vapour return (use dedicated vapour return hose and vent‑to‑station valve) and integrated vapour return (vapour returns via the fill line/nozzle).

- Monitoring of vehicle tank pressure gauge and following station‑specific instructions.

- Nozzle connection and fuelling operations

- Visual inspection, cleaning with air blow gun, correct grounding if required, possible pre‑cooling, and adherence to dispenser “dead‑man” controls.

- Two‑stage disconnection procedure - unlock then remove only if no leakage is detected.

- Annexes

- Annex A: troubleshooting, emergency response, first aid for cryogenic burns, leak and fire guidance.

- Annex B (normative): warm tank refuelling procedure for vehicles with tanks near ambient temperature.

Practical applications and who uses this standard

- Fleet operators and logistics companies operating LNG trucks and buses.

- Station designers, forecourt operators and dispenser manufacturers specifying safe LNG dispensing equipment and user interfaces.

- Safety managers, site operatives and maintenance personnel responsible for LNG fuelling station procedures and emergency response.

- Regulators and national standards bodies harmonising fuelling practices across CEN member states.

Related standards and notes

- Normative references include EN 511 (protective gloves against cold) and EN ISO 16321‑1 (eye and face protection).

- Training responsibility for LNG drivers is outside this standard; see the framework of Directive 89/391 EEC for employer obligations.

- Keywords: EN 17963:2024, LNG fuelling procedures, natural gas vehicles, cryogenic safety, vapour pressure reduction, LNG nozzle, grounding, CEN standard.

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Sponsored listings

Frequently Asked Questions

EN 17963:2024 is a standard published by the European Committee for Standardization (CEN). Its full title is "Natural gas vehicles - LNG vehicle fuelling procedures". This standard covers: This document gives guidelines for safe fuelling operations of vehicles that use liquefied natural gas (LNG) as a fuel for propulsion, covering the activities and procedures to be followed for safe operation. It provides procedures applicable to different fuelling systems and technologies. NOTE Regarding the responsibility surrounding the training of drivers of LNG vehicles, see the framework of Directive 89/391 EEC.

This document gives guidelines for safe fuelling operations of vehicles that use liquefied natural gas (LNG) as a fuel for propulsion, covering the activities and procedures to be followed for safe operation. It provides procedures applicable to different fuelling systems and technologies. NOTE Regarding the responsibility surrounding the training of drivers of LNG vehicles, see the framework of Directive 89/391 EEC.

EN 17963:2024 is classified under the following ICS (International Classification for Standards) categories: 43.080.01 - Commercial vehicles in general; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17963:2024 has the following relationships with other standards: It is inter standard links to EN ISO 16321-1:2022, EN 511:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17963:2024 is associated with the following European legislation: EU Directives/Regulations: 89/391/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 17963:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2025

Vozila na zemeljski plin - Postopki polnjenja vozil na utekočinjeni zemeljski plin

Natural gas vehicles - LNG vehicle fuelling procedures

Erdgasfahrzeuge - Betankungsabläufe für LNG Fahrzeuge

Véhicules au gaz naturel - Procédures de ravitaillement des véhicules GNL

Ta slovenski standard je istoveten z: EN 17963:2024

ICS:

43.020 Cestna vozila na splošno Road vehicles in general

75.060 Zemeljski plin Natural gas

75.200 Oprema za skladiščenje Petroleum products and

nafte, naftnih proizvodov in natural gas handling

zemeljskega plina equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17963

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2024

EUROPÄISCHE NORM

ICS 43.080.01; 75.200

English Version

Natural gas vehicles - LNG vehicle fuelling procedures

Véhicules au gaz naturel - Procédures de ravitaillement Erdgasfahrzeuge - Betankungsabläufe für LNG

des véhicules GNL Fahrzeuge

This European Standard was approved by CEN on 24 June 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17963:2024 E

worldwide for CEN national Members.

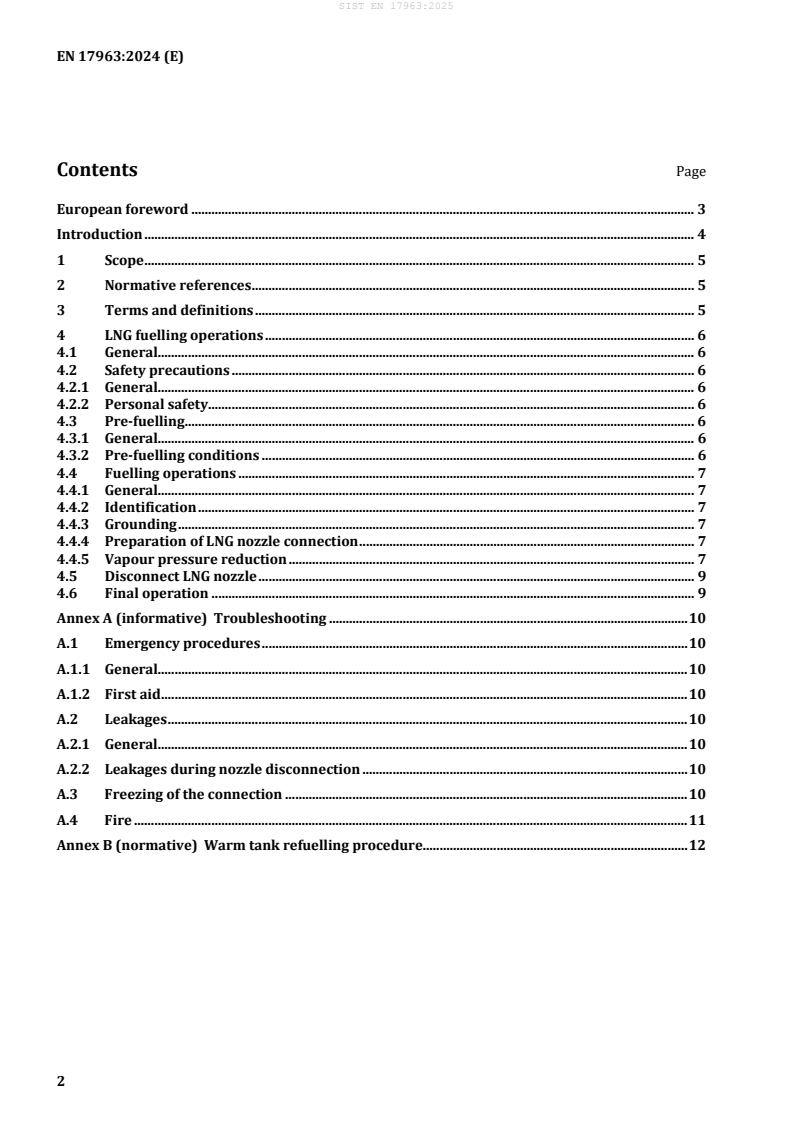

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 LNG fuelling operations . 6

4.1 General. 6

4.2 Safety precautions . 6

4.2.1 General. 6

4.2.2 Personal safety . 6

4.3 Pre-fuelling. 6

4.3.1 General. 6

4.3.2 Pre-fuelling conditions . 6

4.4 Fuelling operations . 7

4.4.1 General. 7

4.4.2 Identification . 7

4.4.3 Grounding . 7

4.4.4 Preparation of LNG nozzle connection . 7

4.4.5 Vapour pressure reduction . 7

4.5 Disconnect LNG nozzle . 9

4.6 Final operation . 9

Annex A (informative) Troubleshooting . 10

A.1 Emergency procedures . 10

A.1.1 General. 10

A.1.2 First aid . 10

A.2 Leakages . 10

A.2.1 General. 10

A.2.2 Leakages during nozzle disconnection . 10

A.3 Freezing of the connection . 10

A.4 Fire . 11

Annex B (normative) Warm tank refuelling procedure . 12

European foreword

This document (EN 17963:2024) has been prepared by Technical Committee CEN/TC 326 “Natural gas

Vehicles”, the secretariat of which is held by TSE.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2025, and conflicting national standards shall

be withdrawn at the latest by January 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

Introduction

This document addresses the general operational and safety instructions for fuelling of LNG vehicles.

Training of LNG vehicle drivers is not part of this procedure.

1 Scope

This document gives guidelines for safe fuelling operations of vehicles that use liquefied natural gas

(LNG) as a fuel for propulsion, covering the activities and procedures to be followed for safe operation.

It provides procedures applicable to different fuelling systems and technologies.

NOTE Regarding the responsibility surrounding the training of drivers of LNG vehicles, see the framework of

Directive 89/391 EEC.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 511, Protective gloves against cold

EN ISO 16321-1, Eye and face protection for occupational use — Part 1: General requirements

(ISO 16321 1)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

LNG vehicle fuel system

assembly of components (tank(s), valves, flexible fuel lines, etc.) and connecting parts (rigid fuel lines,

pipes fitting, etc.) fitted on motor vehicles using LNG in their propulsion system

3.2

liquefied natural gas

LNG

natural gas that has been liquefied, after processing, for storage or transportation purposes used as a

transport fuel, regardless of its production pathways (e.g. renewable, synthetic or fossil)

3.3

vehicle tank

cryogenic tank mounted on a vehicle for the storage of LNG as a fuel

3.4

ignition source

source of energy sufficient to ignite a flammable atmosphere

3.5

dispenser

equipment through which the liquefied natural gas is supplied to the vehicle

3.6

operator

person executing the fuelling

3.7

cryogenic burns

cold burns caused by cryogenic gas

4 LNG fuelling operations

4.1 General

How to operate the dispenser can vary from station to station. This pa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...