EN 10283:2019

(Main)Corrosion resistant steel castings

Corrosion resistant steel castings

This document applies to corrosion resistant steel castings for general purposes.

This document relates to castings manufactured from martensitic, austenitic, fully austenitic and

austenitic-ferritic steel grades characterized by their chemical composition (see Table 1) and mechanical properties (see Table 2).

ln cases where castings are joined by welding by the founder, this document applies.

ln cases where castings are welded:

- to wrought products (plates, tubes, forgings);

- or by non-founders,

this document does not apply.

Korrosionsbeständiger Stahlguss

Diese Europäische Norm gilt für korrosionsbeständigen Stahlguss für allgemeine Verwendung.

Diese Norm gilt für aus martensitischen, austenitischen, voll austenitischen und ferritisch-austenitischen Stahlsorten hergestellte Gussstücke, die durch ihre chemische Zusammensetzung (siehe Tabelle 1) und ihre mechanischen Eigenschaften (siehe Tabelle 2) gekennzeichnet sind.

In Fällen, in denen Gussstücke vom Gießer zusammengeschweißt werden, gilt diese Europäische Norm.

In Fällen, in denen Gussstücke geschweißt werden:

- zusammen mit umformbaren Erzeugnissen (Bleche, Rohre, Schmiedestücke);

- von anderen als Gießern;

gilt diese Europäische Norm nicht.

Aciers moulés résistant à la corrosion

Le présent document s'applique aux pièces moulées en acier résistant à la corrosion, pour usage général.

Le présent document concerne les pièces moulées en acier de nuances martensitiques, austénitiques, entièrement austénitiques et austéno-ferritiques, caractérisées par leur composition chimique (voir Tableau 1) et leurs propriétés mécaniques (voir Tableau 2).

Le présent document s'applique lorsque les pièces moulées sont soudées par le fondeur.

Lorsque des pièces moulées sont soudées :

- à des produits corroyés (tôles, tubes, pièces forgées) ;

- ou par des non-fondeurs,

le présent document ne s'applique pas.

Korozijsko obstojni jekleni ulitki

Ta dokument se uporablja za korozijsko obstojne jeklene ulitke za splošne namene.

Ta dokument se navezuje na ulitke, proizvedene iz martenzitnih, avstenitnih, v celoti avstenitnih in avstenitno-feritnih razredov jekel, katerih značilnosti določajo njihova kemijska sestava (glej preglednico 1) in mehanske lastnosti (glej preglednico 2).

Ta dokument se uporablja v primerih, ko spajanje ulitkov z varjenjem izvaja livar.

Kadar se ulitke vari

– na gnetene zlitine (plošče, cevi, kovane predmete)

– ali ko varjenje izvajajo osebe, ki niso livarji,

se ta dokument ne uporablja.

General Information

- Status

- Published

- Publication Date

- 26-Mar-2019

- Withdrawal Date

- 29-Sep-2019

- Technical Committee

- ECISS/TC 111 - Steel castings and forgings

- Drafting Committee

- ECISS/TC 111 - Steel castings and forgings

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 30-Jan-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 18-Oct-2017

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 10283:2019 - Corrosion resistant steel castings (CEN) defines technical delivery conditions for corrosion‑resistant steel castings for general purposes. It covers castings manufactured from martensitic, austenitic, fully austenitic and austenitic‑ferritic (duplex) steel grades and specifies requirements referenced by chemical composition (Table 1) and mechanical properties and heat treatment (Table 2). The standard applies when castings are welded by the founder (the foundry). It does not apply where castings are welded to wrought products (plates, tubes, forgings) or welded by non‑foundry organizations.

Key topics and requirements

- Material grades and composition: Groups and grade designations (martensitic, austenitic, fully austenitic, ferritic‑austenitic) are defined by cast analysis limits in Table 1.

- Mechanical properties & heat treatment: Tensile and impact requirements and heat‑treatment symbols (+Q, +T, +AT) are given in Table 2 for each grade and thickness range.

- Manufacture and melting: Melting and alternative processes left to manufacturer discretion but subject to agreed requirements.

- Welding: The standard applies when production welding is performed by the founder and gives guidance on preheat, interpass and post‑weld heat treatment; Annex A contains welding group information. Note: certain austenitic grades with C > 0.030 % may risk intergranular corrosion if solution annealing is not performed after welding.

- Inspection and testing: Clause structure follows EN 1559‑1/2 and specifies inspection levels, test units, sampling, test procedures, retest and sorting/reprocessing rules.

- Marking, packaging and complaints: Requirements for marking, packaging, surface protection and complaint handling are included.

- Informative guidance: Annex A - welding guidance; Annex B - physical properties.

Applications and users

EN 10283:2019 is intended for any specification, procurement or manufacturing activity involving corrosion‑resistant steel castings for general engineering use. Typical users include:

- Foundries and casting manufacturers specifying corrosion resistant steel castings

- Design and engineering teams selecting materials for components exposed to corrosive service

- Welding engineers and fabrication planners who need guidance on production welding and post‑weld heat treatment

- Quality, inspection and procurement teams creating or verifying technical contracts and delivery conditions

Practical applications include cast components in corrosive environments where standardised material composition, mechanical performance and welding rules are required.

Related standards

- EN 1559‑1:2011 (Founding - Technical conditions of delivery - Part 1: General)

- EN 1559‑2:2014 (Part 2: Additional requirements for steel castings) - EN 10283:2019 is intended to be used in conjunction with these documents.

- EN 10027‑1 (Designation systems for steels)

- EN ISO 3651‑2 (Resistance to intergranular corrosion testing)

Keywords: EN 10283:2019, corrosion resistant steel castings, martensitic, austenitic, duplex, foundry welding, casting inspection, heat treatment, mechanical properties.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 10283:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Corrosion resistant steel castings". This standard covers: This document applies to corrosion resistant steel castings for general purposes. This document relates to castings manufactured from martensitic, austenitic, fully austenitic and austenitic-ferritic steel grades characterized by their chemical composition (see Table 1) and mechanical properties (see Table 2). ln cases where castings are joined by welding by the founder, this document applies. ln cases where castings are welded: - to wrought products (plates, tubes, forgings); - or by non-founders, this document does not apply.

This document applies to corrosion resistant steel castings for general purposes. This document relates to castings manufactured from martensitic, austenitic, fully austenitic and austenitic-ferritic steel grades characterized by their chemical composition (see Table 1) and mechanical properties (see Table 2). ln cases where castings are joined by welding by the founder, this document applies. ln cases where castings are welded: - to wrought products (plates, tubes, forgings); - or by non-founders, this document does not apply.

EN 10283:2019 is classified under the following ICS (International Classification for Standards) categories: 77.140.20 - Stainless steels; 77.140.80 - Iron and steel castings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10283:2019 has the following relationships with other standards: It is inter standard links to EN 10283:2010, EN 1559-1:2011, EN ISO 3651-2:1998, EN 10027-1:2016, EN 1559-2:2014, EN 14420-5:2013, EN 14422:2004, EN 14420-5:2004, EN 14420-2:2004, EN 14423:2013, EN 14420-4:2004+A1:2007, EN 14420-2:2013, EN 14423:2013+A2:2019, EN 14420-4:2013, EN 14423:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10283:2019 is associated with the following European legislation: Standardization Mandates: M/005, M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10283:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Korozijsko obstojni jekleni ulitkiKorrosionsbeständiger StahlgussAciers moulés résistant à la corrosionCorrosion resistant steel castings77.140.80Železni in jekleni ulitkiIron and steel castings77.140.20Visokokakovostna jeklaStainless steelsICS:Ta slovenski standard je istoveten z:EN 10283:2019SIST EN 10283:2019en,fr,de01-junij-2019SIST EN 10283:2019SLOVENSKI

STANDARDSIST EN 10283:20101DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 10283

March

t r s { ICS

y yä s v rä t râ

y yä s v rä z r Supersedes EN

s r t z uã t r s rEnglish Version

Corrosion resistant steel castings Aciers moulés résistant à la corrosion

Korrosionsbeständiger Stahlguss This European Standard was approved by CEN on

s v December

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s { CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s r t z uã t r s { ESIST EN 10283:2019

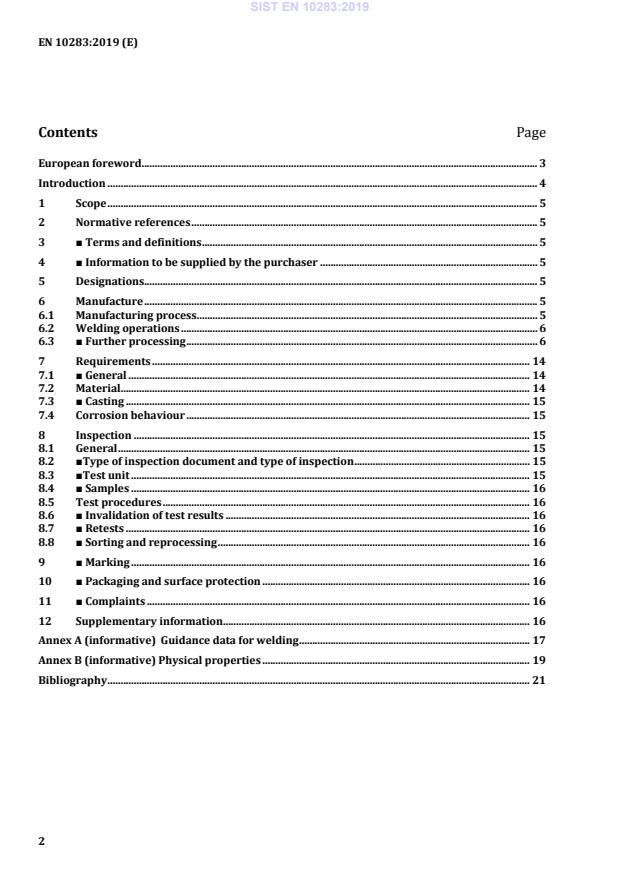

Guidance data for welding . 17 Annex B (informative) Physical properties . 19 Bibliography . 21

EN 1559-2:2014 Note When additional information is given in a clause or subclause of this document (versus the same clause or subclause of EN 1559-1:2011 or EN 1559-2:2014) it is preceded by: "ln addition to EN 1559:". — subclauses and paragraphs marked with a single dot at the time of enquiry and order; — and order (optional); — subclauses without dot marking are mandatory. SIST EN 10283:2019

austenitic-ferritic steel grades characterized by their chemical composition (see Table 1) and mechanical properties (see Table 2). ln cases where castings are joined by welding by the founder, this document applies. ln cases where castings are welded: — to wrought products (plates, tubes, forgings); — or by non-founders, this document does not apply. 2 Normative references The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 1559-1:2011, Founding — Technical conditions of delivery — Part 1: General EN 1559-2:2014, Founding — Technical conditions of delivery — Part 2: Additional requirements for steel castings EN 10027-1, Designation systems for steels — Part 1: Steel names EN ISO 3651-2, Determination of resistance to intergranular corrosion of stainless steels — Part 2: Ferritic, austenitic and ferritic-austenitic (duplex) stainless steels — Corrosion test in media containing sulfuric acid (ISO 3651-2:1998) 3 v Terms and definitions No terms and definitions are listed in this document. ISO and IEC maintain terminological databases for use in standardization at the following addresses:

IEC Electropedia: available at http://www.electropedia.org/

ISO Online browsing platform: available at http://www.iso.org/obp 4 v Information to be supplied by the purchaser 5 Designations In addition to EN 1559-2:2014: For a steel grade manufactured to different strength levels, according to the heat treatment, a suffix shall be added in accordance with EN 10027-1. 6 Manufacture 6.1 Manufacturing process 6.1.1 Melting In addition to EN 1559-2:2014: Alternative processes are left to the discretion of the manufacturer. SIST EN 10283:2019

Name Number

max. max. max. max.

max. Martensitic grades GX12Cr12 1.4011 0,15

11,50 max. max.

max. 1,00 1,00 0,035 0,025 to 13,50 0,50 1,00 - - - - GX20Cr14 1.4027 0,16

12,50

to 0,23 1,00 1,00 0.045 0,03 b to 14,50 - 1,00 - - - - GX7CrNiMo12–1 1.4008 0,10

12,00 0,20 1,00

max. 1,00 1,00 0,035 0,025 to 13,50 to 0,50 to 2,00 - - - - GX4CrNi13–4 1.4317 0,06

12,00 max. 3,50

max. 1,00 1,00 0,035 0,025 to 13,50 0,70 to 5,00 - - - - GX4CrNiMo16–5-1 1.4405 0,06

15,00 0,70 4,00

max. 0,80 1,00 0,035 0,025 to 17,00 to 1,50 to 6,00 - - - - GX4CrNiMo16–5-2 1.4411 0,06

15,00 1,50 4,00

max. 0,80 1,00 0,035 0,025 to 17,00 to 2,00 to 6,00 - - - - GX5CrNiCu16–4 1.4525 0,07

15,00 max. 3,50 max. 2,50 max.

max. 0,80 1,00 0,035 0,025 to 17,00 0,80 to 5,50 0,05 to 4,00 0,35 - SIST EN 10283:2019

Name Number

max. max. max. max.

max. Austenitic grades GX2CrNi19–11 1.4309 0,030

18,00

9,00 max.

max. 1,50 2,00 0,035 0,025 to 20,00

- to 12,00 0,20 - - - GX5CrNi19–10 1.4308 0,07

18,00

8,00

max. 1,50 1,50 0,040 0,030 to 20,00

- to 11,00 - - - - GX5CrNiNb19–11 1.4552 0,07

18,00

9,00

8 x % C

max. 1,50 1,50 0,040 0,030 to 20,00 -

to 12,00 - -

¶ 1,00 -

GX2CrNiMo19–11–2 1.4409 0,030

18,00 2,00 9,00 max.

max. 1,50 2,00 0,035 0,025 to 20,00 to 2,50 to 12,00 0,20 - - - GX5CrNiMo19–11–2 1.4408 0,07

18,00 2,00 9,00

max. 1,50 1,50 0,040 0,030 to 20,00 to 2,50 to 12,00 - - - - GX5CrNiMoNb19–11–2 1.4581 0,07

18,00 2,00 9,00

8 x % C

max. 1,50 1,50 0,040 0,030 to 20,00 to 2,50 to 12,00 - -

¶ 1,00 -

Name Number

max. max. max. max.

max.

GX4CrNiMo19–11–3 1.4443 0,05

18,00 2,50 10,00

max. 1,50 2,00 0,040 0,030 to 20,00 to 3,00 to 13,00

- - - - GX5CrNiMo19–11–3 1.4412 0,07

18,00 3,00 10,00

max. 1,50 1,50 0,040 0,030 to 20,00 to 3,50 to 13,00 - - - - GX2CrNiMoN17–13–4 1.4446 0,030

16,50 4,00 12,50 0,12

max. 1,00 1,50 0,040 0,030 to 18,50 to 4,50 to 14,50 to 0,22 - - - Fully austenitic grades GX2NiCrMo28–20–2 1.4458 0,030

19,00 2,00 26,00 max. max.

max. 1,00 2,00 0,035 0,025 to 22,00 to 2,50 to 30,00 0,20 2,00 - - GX4NiCrCuM

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...