EN 12151:2007

(Main)Machinery and plants for the preparation of concrete and mortar - Safety requirements

Machinery and plants for the preparation of concrete and mortar - Safety requirements

1.1 This document applies for machinery and plant for the preparation of concrete and mortar as defined in 3.1.

This document specifies the requirements for the design of:

a) batching and mixing installations for concrete and mortar;

b) powered mixers for concrete and mortar;

c) waste concrete reprocessing plant.

It does not include requirements relevant to truck mixers.

The machinery may be static or it may be capable of being moved to an alternative position.

1.2 This document deals with all significant hazards, hazardous situations and events relevant to machinery and plant for the preparation of concrete and mortar, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). The exceptions are explosion hazards when using flammable or explosive materials that are significant but not dealt with. This document specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. Maintenance is dealt with but not noise during maintenance.

1.3 This document is not applicable to machinery and plant which are manufactured before the date of publication of this document by CEN.

Maschinen und Anlagen zur Bereitung von Beton und Mörtel - Sicherheitsanforderungen

1.1 Dieses Dokument gilt für Maschinen und Anlagen zur Bereitung von Beton und Mörtel, wie in 3.1 definiert.

Dieses Dokument legt die Anforderungen für die Konstruktion von

a) Dosier- und Mischanlagen für Beton und Mörtel;

b) kraftbetriebenen Mischern für Beton und Mörtel einschließlich Lagerung und Handhabung;

c) Restfrischbetonaufbereitungsanlagen

fest.

Es enthält keine Anforderungen für Fahrmischer.

Die Maschinen dürfen ortsfest oder ortsveränderlich sein.

1.2 Dieses Dokument behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die auf Maschinen und Anlagen zur Bereitung von Beton und Mörtel zutreffen, wenn sie bestimmungsgemäß und entsprechend den vorhersehbaren Bedingungen des Herstellers verwendet werden (siehe Abschnitt 4). Ausgenommen sind Gefährdungen durch Explosionen bei der Verwendung von brennbaren oder explosiven Materialien, die signifikant sind, aber nicht behandelt werden. Dieses Dokument spezifiziert die angemessenen technischen Maßnahmen zur Beseitigung oder Verminderung der Risiken, die von den signifikanten Gefährdungen ausgehen. Instandhaltung wird behandelt, Lärm während der Instandhaltung jedoch nicht.

1.3 Dieses Dokument gilt nicht für Maschinen und Anlagen, die hergestellt wurden, bevor CEN dieses Dokument veröffentlichte.

Machines et centrales pour la préparation du béton et du mortier - Prescriptions de sécurité

La présente norme spécifie les prescriptions pour: 1.1.1 Les installations de dosage et de mélange pour le béton et le mortier; 1.1.2 Les malaxeurs à moteurs pour le béton et le mortier; 1.1.3 Les installations de retraitement des déchets de béton. Les machines peuvent être statiques ou elles peuvent pouvoir être déplacées vers une autre position. Par exploitation des machines, on doit comprendre l'installation, le fonctionnement, les essais, le travail de maintenance et le nettoyage.

Stroji in oprema za pripravo betona in malte - Varnostne zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 27-Nov-2007

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 151 - Construction equipment and building material machines - Safety

- Drafting Committee

- CEN/TC 151/WG 8 - Concrete preparation and handling equipment - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 05-Oct-2016

- Completion Date

- 11-Feb-2026

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 12151:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Machinery and plants for the preparation of concrete and mortar - Safety requirements". This standard covers: 1.1 This document applies for machinery and plant for the preparation of concrete and mortar as defined in 3.1. This document specifies the requirements for the design of: a) batching and mixing installations for concrete and mortar; b) powered mixers for concrete and mortar; c) waste concrete reprocessing plant. It does not include requirements relevant to truck mixers. The machinery may be static or it may be capable of being moved to an alternative position. 1.2 This document deals with all significant hazards, hazardous situations and events relevant to machinery and plant for the preparation of concrete and mortar, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). The exceptions are explosion hazards when using flammable or explosive materials that are significant but not dealt with. This document specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. Maintenance is dealt with but not noise during maintenance. 1.3 This document is not applicable to machinery and plant which are manufactured before the date of publication of this document by CEN.

1.1 This document applies for machinery and plant for the preparation of concrete and mortar as defined in 3.1. This document specifies the requirements for the design of: a) batching and mixing installations for concrete and mortar; b) powered mixers for concrete and mortar; c) waste concrete reprocessing plant. It does not include requirements relevant to truck mixers. The machinery may be static or it may be capable of being moved to an alternative position. 1.2 This document deals with all significant hazards, hazardous situations and events relevant to machinery and plant for the preparation of concrete and mortar, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). The exceptions are explosion hazards when using flammable or explosive materials that are significant but not dealt with. This document specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. Maintenance is dealt with but not noise during maintenance. 1.3 This document is not applicable to machinery and plant which are manufactured before the date of publication of this document by CEN.

EN 12151:2007 is classified under the following ICS (International Classification for Standards) categories: 91.220 - Construction equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12151:2007 has the following relationships with other standards: It is inter standard links to EN 60335-2-69:2003, EN 62262:2002, EN 60204-32:1998, EN 60529:1991, IEC 60364-4-41:2005, EN 60335-1:2002, EN 894-2:1997, EN 349:1993, EN 13309:2000, EN 12198-1:2000, EN ISO 11688-1:1998, EN 574:1996, EN ISO 4871:1996, EN 811:1996, EN 20594-1:1993. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12151:2007 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/BC/CEN/88/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12151:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji in oprema za pripravo betona in malte - Varnostne zahteveMaschinen und Anlagen zur Bereitung von Beton und Mörtel - SicherheitsanforderungenMachines et centrales pour la préparation du béton et du mortier - Prescriptions de sécuritéMachinery and plants for the preparation of concrete and mortar - Safety requirements91.220Gradbena opremaConstruction equipmentICS:Ta slovenski standard je istoveten z:EN 12151:2007SIST EN 12151:2009en01-februar-2009SIST EN 12151:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12151November 2007ICS 91.220 English VersionMachinery and plants for the preparation of concrete and mortar- Safety requirementsMachines et centrales pour la préparation du béton et dumortier - Prescriptions de sécuritéMaschinen und Anlagen zur Bereitung von Beton undMörtel - SicherheitsanforderungenThis European Standard was approved by CEN on 13 October 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12151:2007: ESIST EN 12151:2009

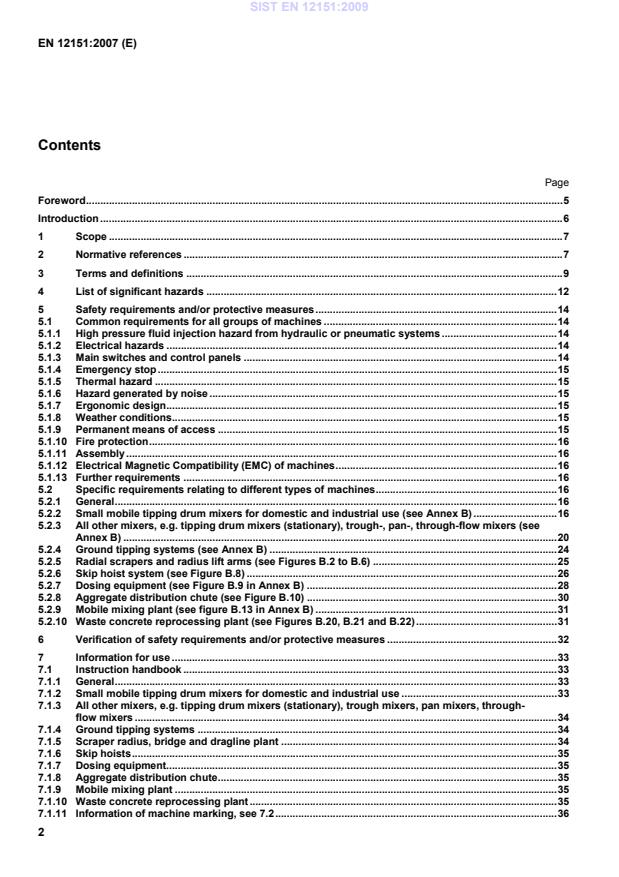

Stability, ground surface, headroom and access requirements.38 A.1 Ground surface and headroom of operation areas.38 A.2 General access.38 A.3 Stability test of small mobile tipping drum mixers.39 Annex B (informative)

Illustration of mixer and plants.40 Annex C (normative)

Noise test code.60 C.1 Scope.60 C.2 Sound power level determination.60 C.2.1 Mixers.60 C.2.2 Plants.61 C.3 Emission sound pressure level determination.62 C.3.1 Mixers.62 C.3.2 Plants.62 C.4 Installation conditions.62 C.5 Operating conditions.62 C.6 Information to be recorded.63 C.7 Information to be reported.63 C.8 Declaration of noise emission values.63 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.64 Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC.65 Bibliography.66

1 Scope 1.1 This document applies for machinery and plants for the preparation of concrete and mortar as defined in 3.1. This document specifies the requirements for the design of: a) batching and mixing installations for concrete and mortar; b) powered mixers for concrete and mortar, including for storage and handling; c) waste fresh concrete reprocessing plant. It does not include requirements relevant to truck mixers. The machinery may be static or it may be capable of being moved to an alternative position. 1.2 This document deals with all significant hazards, hazardous situations and events relevant to machinery and plant for the preparation of concrete and mortar, when they are used as intended and under the conditions foreseen by the manufacturer (see Clause 4). The exceptions are explosion hazards when using flammable or explosive materials that are significant but not dealt with. This document specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. Maintenance is dealt with but not noise during maintenance. 1.3 This document is not applicable to machinery and plants which are manufactured before the date of publication of this document by CEN. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 294:1992, Safety of machinery — Safety distances to prevent danger zones being reached by the upper limbs EN 349:1993, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body EN 360:2002, Personal protective equipment against falls from a height — Retractable type fall arresters EN 361:2002, Personal protective equipment against falls from a height — Full body harnesses EN 363:2002, Personal protective equipment against falls from a height — Fall arrest systems EN 547-1:1996, Safety of machinery — Human body measurements — Part 1: Principles for determining the dimensions required for openings for whole body access into machinery EN 547-2:1996, Safety of machinery — Human body measurements — Part 2: Principles for determining the dimensions required for access openings EN 547-3:1996, Safety of machinery — Human body measurements — Part 3: Anthropometric data EN 574:1996, Safety of machinery — Two-hand control devices — Functional aspects — Principles for design EN 614-1:2006, Safety of machinery — Ergonomic design principles — Part 1: Terminology and general principles EN 617:2001, Continuous handling equipment and systems — Safety and EMC requirements for the equipment for the storage of bulk materials in silos, bunkers, bins and hoppers SIST EN 12151:2009

Figure B.10) 3.15 scraper power operated machine used for loosening, collecting and conveying gravel, sand, pumice and similar material. Operation is manually or automatically sequenced (see Figure B.3, Key number 6) 3.16 discharge system device to remove the contents of the mixer 3.17 concrete and mortar homogeneous blends of raw material, cement, water and optional additives 3.18 additives materials which may be added to the concrete or mortar to modify appearance or working characteristics 3.19 waste concrete reprocessing plant plant which permits the separation of raw material from water and cement to allow their reuse (see Figures B.20, B.21 and B.22) SIST EN 12151:2009

Hazards Locations/circumstances/consequencesEN 12151 4.1 Mechanical hazards (according to

EN ISO 12100-1:2003, 4.2)

4.1.1 Crushing Access to drive pinions Access between mixer body and lid when lid is open Access to fixed and moving parts of mixer plant 5.1.3, 5.1.4, 5.1.8, 5.2.3.1, 5.2.3.2, 5.2.3.3, 5.2.3.4, 5.2.3.5, 5.2.3.6, 5.2.3.7, 5.2.4.1, 5.2.4.2, 5.2.5.1, 5.2.5.2, 5.2.5.3, 5.2.6.3, 5.2.6.4, 5.2.6.5, 5.2.7.5, 5.2.8, 5.2.10.1, 5.2.10.2, 5.2.10.5 4.1.2 Shearing Access to the fixed and moving parts inside the mixer from either the inlet, discharge or any other access position Access to the inside of the mixer for making additions or for sampling Access to fixed and moving parts external to the mixer Access to the fixed chassis through the wheel of the drum tilting mechanism 5.1.3, 5.1.4, 5.1.9, 5.2.2.4, 5.2.3.1, 5.2.3.2, 5.2.3.5, 5.2.5.1, 5.2.6.2, 5.2.6.4, 5.2.7.1, 5.2.7.4, 5.2.7.5, 5.2.10.1, 5.2.10.2, 5.2.10.5 4.1.3 Cutting and severing Cutting and severing action of the discharge door and fixed parts 5.1.3, 5.1.4, 5.1.9, 5.2.2.1, 5.2.5.1 4.1.4 Entanglement Access to external moving drive units 5.1.3, 5.1.4, 5.1.9, 5.2.7.1, 5.2.7.4, 5.2.10.1 4.1.5 Drawing-in or trapping hazard Access to drive pinions Access to all rotating parts where the risk of drawing-in is given Access to protruding parts on rotating mixer body Access to the in running nips of V-Belt drives or chain sprocket drives 5.1.3, 5.1.4, 5.1.9, 5.2.2.1, 5.2.2.2, 5.2.2.3, 5.2.2.4, 5.2.3.1, 5.2.3.3, 5.2.3.4, 5.2.5.2, 5.2.5.3, 5.2.6.1, 5.2.6.4, 5.2.7.1, 5.2.7.2, 5.2.7.3, 5.2.7.4, 5.2.7.5, 5.2.9, 5.2.10.1 SIST EN 12151:2009

Hazards Locations/circumstances/consequences EN 12151 4.1.6 Impact Access to protruding parts on the outside of the rotating mixer body Access to the discharge doors Access to the inside of the mixer to make additions or for sampling 5.1.3, 5.1.4, 5.1.9, 5.2.2.1, 5.2.5.1, 5.2.6.4, 5.2.7.5 4.1.7 Friction or abrasion Access to mixer drive shafts or power take off units 5.1.3, 5.1.4, 5.1.9 4.1.8 High pressure fluid ejection Access to hydraulic systems 5.1.1 4.1.9 Ejection of parts or material Proximity to hoppers fed with materials 5.2.7.5 4.1.10 Loss of stability Instability of mixer and/or equipment 5.2.2.5, 5.2.5.4, 5.2.10.4 4.1.11 Slips, trips and falls Access to areas where slips, trips and falls are possible 5.2.4.1, 5.2.4.2, 5.2.4.3, 5.2.7.6, 5.2.8, 5.2.10.3, 5.2.10.5 4.2 Electrical hazards (according to

EN ISO 12001-1:2003, 4.3) Electrocution, electric shocks or burns 5.1.2, 5.2.2.1, 5.2.2.5, 5.2.3.8, 5.2.9 4.3 Thermal hazards (according to

EN ISO 12100-1:2003, 4.4) Steam ejection Access to hot machinery parts (e.g. combustion engine, exhaust pipe) 5.1.5

4.4 Hazardous generated by noise (according to

EN ISO 12100-1:2003, 4.5) Hearing loss and other physiological damage. Impaired oral communication and perception of warning signals 5.1.6 4.5 Hazardous generated by vibration (according to

EN ISO 12100-1:2003, 4.6) Blood circulation disorder due to the use of vibratory equipment Not relevant for this type of machines 4.6 Hazards generated by radiation (according to

EN ISO 12100-1:2003, 4.7) Level gauges and other radiation instrumentation Radiation anti static devices 5.2.7.5 4.7 Hazards generated by material and substances processed, used or exhausted by machinery (according to

EN ISO 12100-1:2003, 4.8) Contact, inhalation or ingestion of harmful fluids, gases, fumes, dusts or aerosols, including use in an enclosed space Inhalation of exhaust gases Not applicable 4.8 Hazards generated by neglecting ergonomic principles in machine design (according to EN ISO 12100-1:2003, 4.9) Personnel injury due to poor design of ergonomic principles Working environment - comfort of the working station: temperature, lighting, postures, ventilation etc. 5.1.7, 5.2.3.8 4.9 Failure of electrical installation and control systems Power supply failure

5.1.2, 5.1.9, 5.2.7.5 4.10 Hazards generated by fire Burns and fire 5.1.10 4.11 Hazards caused by assembly/disassembly Loss of stability 5.1.11 4.12 Hazards caused by EMC Unexpected malfunctions 5.1.12

EN 60204-1:2006. Each of the following parts of a plant shall be equipped with a switch for stop and protection for unintended start according to 5.3 and 5.4 of EN 60204-1:2006: each of the mixers; each of the skip hoist systems; scraper; conveyor transporting the aggregates to the silos; equipment for discharging and distribution the aggregates and cement. The control stand shall be designed to ergonomic principles as defined in EN 614-1:2006. The operator shall have good visibility to the discharge area. SIST EN 12151:2009

EN ISO 14122-3:2001. SIST EN 12151:2009

EN ISO 12100-2:2003 for hazards relevant but not significant which are not dealt with by this document (e.g. sharp edges). For the application of EN 294:1992, EN 349:1993, EN 547-1:1996, EN 547-2:1996, EN 547-3:1996, EN 574:1996, EN 614-1:2006, EN 617:2001, EN 618:2002, EN 620:2002, EN 795:1996, EN 953:1997, EN 954-1:1996, EN 982:1996, EN 983:1996, EN 999:1998, EN 1050:1996, EN 1088:1995, EN 60204-1:2006, EN 60335-1:2002,

EN 60335-2-69:2003, EN 60529:1991, EN 62262:1995, EN ISO 12100-1:2003, EN ISO 13732-1:2006,

EN ISO 13850:2006, EN ISO 14122-1:2001, EN ISO 14122-2:2001, EN ISO 14122-3:2001, the manufacturer shall carry out an adequate risk assessment for the requirements thereof where choice is necessary. NOTE This specific risk assessment is part of the general risk assessment relating to the hazards not covered by this C standard. 5.2 Specific requirements relating to different types of machines 5.2.1 General This part of the standard is organized by machinery type/machinery group(s). Machinery Group: 5.2.2 Small mobile tipping drum mixers for domestic and industrial use (see Annex B) SIST EN 12151:2009

Machinery part Hazard Group Hazard Reference EN ISO

12100-1:2003 Safety measures 5.2.2.1 Electrical motor and combustion engine Mechanical Drawing–in or trapping from drive belt; from cooling fan belt 4.2.1 A fixed guard shall be fitted, according to EN 953:1997.

Impact from rotating fan blade 4.2.1 A fixed guard shall be fitted, according to EN 953:1997.

Cutting and severing from motor housing or door falling 4.2.1 The motor housing or door shall be secured in the open position and prevented from unintentional closing by a positive locking latch, except where it is hinged to open in a downwards direction.

Electrical Electric shock or burns 4.3 Protection against indirect contact. Mixers shall be protected in accordance with EN 60204-1:2006. The mechanical resist shall comply with IP 44 of EN 62262:1995. Mixers below 0,9 kW absorbed motor rating shall be protected with class II equipment (double insulation), according to EN 60204-1:2006, according to EN 60335-1:2002 and for the mechanical strength according to EN 60335-2-69:2003 chapter 21.101 or with a safety low voltage system powered by a transformer with safety low voltage.

These mixers shall be permanently identified by the symbol "protective insulation" according to ISO 7000:2004.

An easily detectable indication plate good legible and indelible shall be fixed on the exterior enclosure of the mixer; it shall read as follows:

"Disconnect electrical power supply before opening the enclosure. Operation is permitted only if the enclosure is fully closed”.

The following indication shall be given

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...