EN 10304:2001

(Main)Magnetic materials (iron and steel) for use in relays

Magnetic materials (iron and steel) for use in relays

This European Standard specifies the magnetic materials used principally for relays. In particular it specifies general requirements, the magnetic properties, geometric characteristics and tolerances.

This European Standard applies to pure iron and steel products generally delivered in the semi-processed state.

These materials correspond to clauses A, B, C1 and C2 of IEC 60404-1.

Magnetische Relaiswerkstoffe (Eisen und Stahl)

Diese Europäische Norm legt die allgemeinen Anforderungen, magnetischen Eigenschaften, geome-trischen

Daten und Grenzabmaße ebenso wie Prüfverfahren für magnetische Werkstoffe fest, die in

erster Linie für Relais eingesetzt werden.

Diese Europäische Norm bezieht sich auf im Allgemeinen im nicht-schlussgeglühten Zustand gelieferte

Reineisen- und Stahlerzeugnisse.

Diese Werkstoffe entsprechen den Abschnitten A, B, C1 und C2 von IEC 60404-1.

Matériaux magnétiques pour relais (fer et acier)

Domaine d'application

La présente Norme européenne spécifie les matériaux magnétiques employés principalement pour les relais. Elle spécifie en particulier les prescriptions générales, les caractéristiques magnétiques, les caractéristiques géométriques et les tolérances.

La présente Norme européenne est applicable aux produits en fer pur et en acier livrés à l'état semi-fini.

Ces matériaux correspondent aux articles A, B, C1 et C2 de la CEI 60404-1.

Magnetni materiali (železo in jeklo) za releje

General Information

- Status

- Published

- Publication Date

- 24-Apr-2001

- Withdrawal Date

- 30-Oct-2001

- Technical Committee

- ECISS/TC 108 - Steel sheet and strip for electrical applications

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 18-Oct-2005

- Completion Date

- 18-Oct-2005

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 10029:2010 - Hot-rolled steel plates 3 mm thick or above - Tolerances on dimensions and shape - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 10304:2001 - published by CEN - is the European standard that specifies magnetic materials (iron and steel) for use in relays. It defines general requirements, magnetic properties, geometric characteristics and tolerances for pure iron and steel products typically supplied in a semi-processed state (strip, sheet, plate, flats, bars, wire rod and wire). EN 10304:2001 aligns with clauses A, B, C1 and C2 of IEC 60404-1 and is based on IEC 60404-8-10.

Key topics

- Scope and product forms: covers hot- and cold-rolled strip, sheet, plate, flats, bars, wire rod and wire intended for relay components.

- Magnetic properties: classification by maximum coercivity (e.g., M40, M60, M80, M120, M240 with coercivity values in A/m). Requirements for aged-condition properties are subject to agreement.

- Geometric characteristics & tolerances: detailed thickness, width, diameter/size and flatness (wave factor) tolerances for hot- and cold-rolled products; specific tables provide numeric limits per product type.

- Surface & delivery conditions: surface quality (clean, free from grease/rust), forms of supply (coils, trimmed/untrimmed edges), internal coil diameter and weld/repair rules.

- Production, inspection & testing: production process left to manufacturer’s discretion but inspection, sampling, specimen preparation and test methods are specified; includes marking, labelling, packaging, complaints and ordering information.

- Designation system: conventional material ID format (letter M + coercivity value + material symbol + condition, e.g., M80 TH).

Applications and users

EN 10304:2001 is intended for professionals involved with magnetic components in electromechanical devices, especially:

- Relay designers and electrical engineers selecting core or armature materials.

- Steelmakers and magnetic-material manufacturers supplying semi-processed iron/steel for relays.

- Quality and production engineers who need to verify coercivity, dimensional tolerances and surface condition.

- Purchasing and procurement teams specifying material grades and delivery conditions for relay production.

- Test laboratories and conformity assessors applying the standard’s inspection and sampling rules.

Practical uses include ensuring consistent magnetic performance of relay cores, guaranteeing dimensional fit for stamping/assembly, and defining acceptance criteria for incoming materials.

Related standards

EN 10304 references and complements other standards such as:

- IEC 60404-1 / IEC 60404-7 (magnetic materials terminology and coercivity measurement)

- EN 10021, EN 10029, EN 10051, EN 10131 (dimensions/tolerances)

- EN 10204 (inspection documents)

- ISO/EN documents on tolerances and wire/wire-rod dimensions

Using EN 10304:2001 helps manufacturers and specifiers achieve reliable magnetic performance, consistent tolerancing and interoperable supply chains for relay applications.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 10304:2001 is a standard published by the European Committee for Standardization (CEN). Its full title is "Magnetic materials (iron and steel) for use in relays". This standard covers: This European Standard specifies the magnetic materials used principally for relays. In particular it specifies general requirements, the magnetic properties, geometric characteristics and tolerances. This European Standard applies to pure iron and steel products generally delivered in the semi-processed state. These materials correspond to clauses A, B, C1 and C2 of IEC 60404-1.

This European Standard specifies the magnetic materials used principally for relays. In particular it specifies general requirements, the magnetic properties, geometric characteristics and tolerances. This European Standard applies to pure iron and steel products generally delivered in the semi-processed state. These materials correspond to clauses A, B, C1 and C2 of IEC 60404-1.

EN 10304:2001 is classified under the following ICS (International Classification for Standards) categories: 77.140.40 - Steels with special magnetic properties; 77.140.50 - Flat steel products and semi-products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10304:2001 has the following relationships with other standards: It is inter standard links to EN 10060:2003, EN 10251:2024, EN 10021:2006, EN 10204:2004, EN 10058:2003, EN 12606-2:1999, EN 10029:2010, EN 10059:2003, EN 10051:2024, EN ISO 286-1:2010, EN ISO 15653:2010, EN 10131:2006, EN 2044:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10304:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Magnetni materiali (železo in jeklo) za relejeMagnetische Relaiswerkstoffe (Eisen und Stahl)Matériaux magnétiques pour relais (fer et acier)Magnetic materials (iron and steel) for use in relays77.140.40Jekla s posebnimi magnetnimi lastnostmiSteels with special magnetic properties29.120.70RelejiRelaysICS:Ta slovenski standard je istoveten z:EN 10304:2001SIST EN 10304:2002en01-september-2002SIST EN 10304:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10304April 2001ICS 77.140.40; 77.140.50English versionMagnetic materials (iron and steel) for use in relaysMatériaux magnétiques pour relais (fer et acier)Magnetische Relaiswerkstoffe (Eisen und Stahl)This European Standard was approved by CEN on 8 March 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2001 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10304:2001 ESIST EN 10304:2002

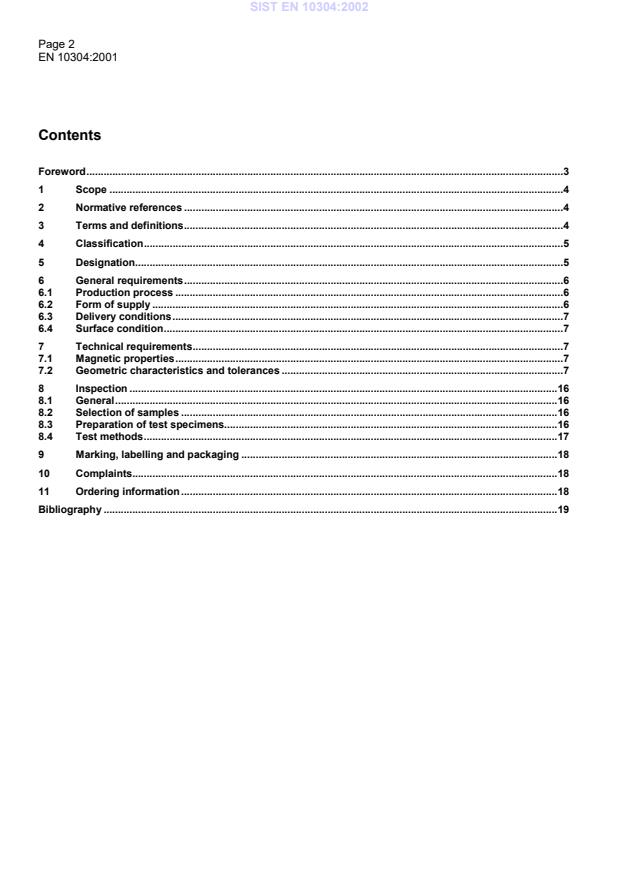

Page 2EN 10304:2001ContentsForeword.31Scope.42Normative references.43Terms and definitions.44Classification.55Designation.56General requirements.66.1Production process.66.2Form of supply.66.3Delivery conditions.76.4Surface condition.77Technical requirements.77.1Magnetic properties.77.2Geometric characteristics and tolerances.78Inspection.168.1General.168.2Selection of samples.168.3Preparation of test specimens.168.4Test methods.179Marking, labelling and packaging.1810Complaints.1811Ordering information.18Bibliography.19SIST EN 10304:2002

Page 3EN 10304:2001ForewordThis European Standard has been prepared by Technical Committee ECISS/TC 24 "Electrical steel sheet and stripqualities - Qualities, dimensions, tolerances and specific tests", the secretariat of which is held by DIN.This European Standard shall be given the status of a national standard, either by publication of an identical text orby endorsement, at the latest by October 2001, and conflicting national standards shall be withdrawn at the latestby October 2001.This Standard is based on IEC 60404-8-10.According to the CEN/CENELEC Internal Regulations, the national standards organizations of the followingcountries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark, Finland,France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden,Switzerland and the United Kingdom.SIST EN 10304:2002

Page 4EN 10304:20011 ScopeThis European Standard specifies the magnetic materials used principally for relays. In particular it specifiesgeneral requirements, the magnetic properties, geometric characteristics and tolerances.This European Standard applies to pure iron and steel products generally delivered in the semi-processed state.These materials correspond to clauses A, B, C1 and C2 of IEC 60404-1.2 Normative referencesThis European Standard incorporates by dated or undated reference, provisions from other publications. Thesenormative references are cited at the appropriate places in the text and the publications are listed hereafter. Fordated references, subsequent amendments to or revisions of any of these publications apply to this EuropeanStandard only when incorporated in it by amendment or revision. For undated references the latest edition of thepublication referred to applies (including amendments).EN 10021, General technical delivery requirements for steel and steel products.EN 10029, Hot rolled steel plates 3 mm thick and above - Tolerances on dimensions, shape and mass.EN 10051, Continuously hot-rolled uncoated plate, sheet and strip of non-alloy and alloy steels - Tolerances ondimensions and shape.EN 10131, Cold rolled uncoated low carbon and high yield strength steel flat products for cold forming - Toleranceson dimensions and shape.EN 10204, Metallic products - Types of inspection documents.EN 10251, Magnetic materials - Methods of determination of the geometrical characteristics of magnetic steel sheetand strip.prEN 10058:2000, Hot rolled flat for general purposes.prEN 10059:2000, Hot rolled square for general purposes.prEN 10060:2000, Hot rolled round for general purposes.IEC 60050 (221), International Electrotechnical Vocabulary (IEV) - Chapter 221 : Magnetic materials andcomponents.IEC 60404-7, Magnetic materials - Part 7 : Method of measurement of the coercivity of magnetic materials in anopen magnetic circuit.EN 20286-1, ISO system of limits and fits - Part 1: Bases of tolerances, deviations and fits (ISO 286-1:1988)ISO 8457-1, Steel wire rod : Part 1 : Dimensions and tolerances.3 Terms and definitionsFor the purposes of this European Standard the terms and definitions given in IEC 60050 (221) and the followingapply.3.1sheet and plateflat rolled product with a width of 600 mm or overNOTE 1The edges are as rolled, sheared or flame cut.SIST EN 10304:2002

Page 5EN 10304:2001NOTE 2A distinction is made between sheets which have a thickness up to 3 mm and plates which have a thickness of3 mm or over.3.2stripflat rolled product which immediately after the final rolling pass or after pickling or continuous annealing is woundinto a regular coilNOTEAs rolled strip has slightly convex edges, but may also be supplied with sheared edges or slit from wider strip3.3flatsproducts of rectangular cross section rolled on the four faces of thickness generally 5 mm or greater and width notgreater than 150 mm3.4roundsproducts having a circular cross section of diameter generally 8 mm or greater3.5squaresproducts having a square cross section whose side is generally 8 mm or greater3.6wire rodhot rolled long product having a nominal size generally of 5 mm or greater and wound into irregular coilsNOTEThe cross section may be round, oval, square, rectangular, hexagonal, octagonal, half round or of any similarshape.3.7wireproduct of constant full cross section along its length, obtained by cold drawing and which can be wound intoirregular or regular coilsNOTEIt is obtained by cold drawing wire rod through a reducing die or passing under pressure between rollers andrewinding the drawn product.3.8edge cambergreatest distance between a longitudinal edge of the sheet and the line joining the two extremities of the measuredlength of this edge4 ClassificationThe materials covered by this standard are classified according to the maximum value of coercivity, the shape anddimensions of the material and its final condition. Not all materials are available in the cold rolled conditionthroughout the thickness range.5 DesignationThe conventional designation of the material comprises the following in the order given :the letter M ;the specified maximum value of coercivity in A/m ;one of the following symbols :F : for pure iron ;SIST EN 10304:2002

Page 6EN 10304:2001T : for alloy steel ;U : for non-alloy steel ;the final condition as indicated below :H : hot rolled ;C : cold rolled or cold drawn ;for example :M 80 TH: alloy steel with a specified maximum coercivity of 80 A/m in the hot rolled condition.6 General requirements6.1 Production processThe production process of the products defined by this standard is left to the discretion of the manufacturer.6.2 Form of supply6.2.1 StripThe materials are supplied in the hot or cold rolled conditions.The coils shall have a minimum internal diameter of approximatively 500 mm. The strip shall be of constant widthand wound in such a manner that the edges are superimposed in a regular manner and that the side faces of coilare substantially flat.The coils shall be sufficiently tightly wound so that they do not collapse under their own weight.The strip can occasionally exhibit welds or interleaves resulting from the removal of defective zones subject to prioragreement between the parties. The value of the additional thickness due to the weld is subject to agreement. Ifnecessary the marking of welds or interleaves may form the subject of a special agreement.For coils containing repair welds or interleaves, each part of the strip shall be of the same quality material.The edges of parts welded together shall not be so much out of alignment as to affect the further processing of thematerial.The mass of coils shall be agreed at the time of ordering.6.2.2 Sheet and plateThis material may be supplied in the hot or cold rolled conditions.The edges of the sheet or plate, parallel to the rolling direction shall be as rolled, mechanically sheared or flamecut.6.2.3 Flats and barsThe material may be supplied in the hot or cold rolled conditions or cold drawn condition.6.2.4 Wire rod and wiresWire rod and wires are delivered respectively in the hot rolled condition and in the drawn condition.These products are delivered in the form of coils ; the mass of the coils shall be defined at the time of ordering.SIST EN 10304:2002

Page 7EN 10304:20016.3 Delivery conditionsThe different types of delivery condition are given in Table 1.Table 1 - Delivery conditionsType of productHot rolledCold rolledCold drawnSemi-processed condition aStripxxxSheetxxxPlatexxFlat and barxxxWire rodxxWirexxa The products may be supplied in the fully processed condition, if agreed at time of ordering.6.4 Surface conditionThe surfaces of the product shall be smooth, clean and free from grease and rust.Isolated imperfections such as scratches, blisters etc may be tolerated if the thickness remains within the tolerancelimits.The nature of the surface condition will depend on the final treatment. For material in the hot rolled condition, thematerial exhibits a hot mill scale.7 Technical requirements7.1 Magnetic propertiesThe specified maximum value of coercivity shall be as given in Table 2.Table 2 - CoercivityGradeMaximum coercivityin A/mM 4040M 6060M 8080M 120120M 240240If properties in the aged condition are required, they shall be the subject of prior agreement together with theconditions of the ageing treatment.7.2 Geometric characteristics and tolerances7.2.1 Thickness7.2.1.1 Hot rolled flat productsThe tolerances on thickness shall be as given in Table 3 for strip and sheet and in Table 4 for plate.SIST EN 10304:2002

Page 8EN 10304:2001Table 3 - Tolerances on thickness for continuously hot rolled strip and sheet aDimensions in millimetresNominal thicknessTolerances for a nominal width of 1 200> 1 200 1 500> 1 500 1 800> 1 800 2,00± 0,17± 0,19± 0,21-> 2,00

2,50± 0,18± 0,21± 0,23± 0,25> 2,50

3,00± 0,20± 0,22± 0,24± 0,26> 3,00

4,00± 0,22± 0,24± 0,26± 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...