EN 10131:2006

(Main)Cold rolled uncoated and zinc or zinc-nickel electrolytically coated low carbon and high yield strength steel flat products for cold forming - Tolerances on dimensions and shape

Cold rolled uncoated and zinc or zinc-nickel electrolytically coated low carbon and high yield strength steel flat products for cold forming - Tolerances on dimensions and shape

This European Standard applies to cold rolled uncoated and electrolytically zinc or zinc-nickel coated low carbon and high yield strength steel flat products for cold forming with a minimum thickness of 0,35 mm and, unless otherwise agreed at the time of ordering, less than or equal to 3 mm thick, delivered in sheet, wide strip, slit wide strip or cut lengths obtained from slit wide strip or sheet. The concerned standards are EN 10130, EN 10152, EN 10271, EN 10209, EN 10268 and prEN 10338.

It does not apply to cold rolled strip (rolled width < 600 mm) or to flat cold rolled products for which there is a specific standard, in particular the following:

cold rolled non-grain oriented magnetic steel sheet and strip (EN 10106);

semi-processed steel strip for the construction of magnetic circuits (EN 10126 and 10165);

tinplate and ECCS (EN 10202);

blackplate in coils (EN 10205);

cold rolled uncoated non-alloy mild steel narrow strip for cold forming (EN 10139).

Kaltgewalzte Flacherzeugnisse ohne Überzug und mit elektrolytischem Zink- oder Zink-Nickel-Überzug aus weichen Stählen sowie aus Stählen mit höherer Streckgrenze zum Kaltumformen - Grenzabmaße und Formtoleranzen

La présente Norme européenne s’applique aux produits plats laminés à froid, non revêtus et revêtus de zinc ou de zinc-nickel par voie électrolytique, en acier doux ou en acier à haute limite d’élasticité pour formage à froid, d’épaisseur au moins égale à 0,35 mm et, sauf accord à la commande, inférieure ou égale à 3 mm, livrés en tôles, larges bandes, larges bandes refendues ou bandes coupées à longueur obtenues à partir de larges bandes refendues ou de tôles.

Elle ne s’applique pas aux feuillards (largeur de laminage < 600 m) laminés à froid ni aux produits laminés à froid pour lesquels il existe une norme spécifique, en particulier aux produits suivants :

- bandes et tôles magnétiques à grains non orientés laminées à froid (EN 10106) ;

- bandes semi-finies destinées à la construction des circuits magnétiques (EN 10126 et 10165) ;

- fer blanc et fer chromé (prEN 10202) ;

- fer noir en bobines (EN 10205) ;

- feuillards non revêtus laminés à froid en aciers doux non alliés, pour formage à froid (EN 10139).

Produits plats laminés à froid, non revêtus ou revêtus de zinc ou de zinc-nickel par voie électrolytique, en acier à bas carbone et en acier à haute limite d'élasticité pour formage à froid - Tolérances sur les dimensions et sur la forme

La présente Norme européenne s'applique aux produits plats laminés à froid, non revêtus et revêtus de zinc (EN 10152) ou de zinc-nickel (EN 10271) par voie électrolytique, en acier doux ou en acier à haute limite d'élasticité pour formage à froid, d'épaisseur au moins égale à 0,35 mm et, sauf accord à la commande, inférieure ou égale à 3 mm, livrés en tôles, larges bandes, larges bandes refendues ou bandes coupées à longueur obtenues à partir de larges bandes refendues ou de tôles.

Elle ne s'applique pas aux feuillards (largeur de laminage < 600 m) laminés à froid ni aux produits laminés à froid pour lesquels il existe une norme spécifique, en particulier aux produits suivants :

¾ bandes et tôles magnétiques à grains non orientés laminées à froid (EN 10106) ;

¾ bandes semi-finies destinées à la construction des circuits magnétiques (EN 10126 et 10165) ;

¾ fer blanc et fer chromé (prEN 10202) ;

¾ fer noir en bobines (EN 10205) ;

feuillards non revêtus laminés à froid en aciers doux non alliés, pour formage à froid (EN 10139).

Hladno valjani ploščati proizvodi za hladno oblikovanje, neprevlečeni in pocinkani ali prevlečeni s cink-nikljem, iz maloogljičnega jekla z veliko napetostjo tečenja – Mejni odstopki mer in tolerance oblike

General Information

- Status

- Published

- Publication Date

- 11-Jul-2006

- Withdrawal Date

- 30-Jan-2007

- Technical Committee

- ECISS/TC 109 - Coated and uncoated flat products to be used for cold forming

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 20-May-2022

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 10131:2006 is a CEN European Standard that specifies tolerances on dimensions and shape for cold rolled, uncoated and electrolytically zinc or zinc‑nickel coated low‑carbon and high‑yield‑strength steel flat products intended for cold forming. It covers products with a nominal thickness ≥ 0.35 mm and, unless agreed otherwise, ≤ 3.0 mm, delivered as sheet, wide strip, slit wide strip or cut lengths. The standard was approved in 2006 and supersedes EN 10131:1991.

Key topics

- Scope & exclusions

- Applies to cold‑rolled flat products for cold forming (sheets, wide strip, slit wide strip, cut lengths).

- Excludes cold rolled strip with rolled width < 600 mm and products covered by specific standards (e.g. EN 10106, EN 10139, EN 10202, EN 10205, EN 10341).

- Cross‑references: EN 10130, EN 10152, EN 10271, EN 10209, EN 10268, prEN 10338.

- Designation & delivery conditions

- Product designation format (type, EN 10131 reference, nominal thickness/width/length, flags for special tolerances).

- Delivery may be with normal or special tolerances for thickness, width, length, flatness and camber - if not specified, normal tolerances apply.

- Measurement rules

- Thickness measured > 40 mm from edges (mid‑axis for slit coils ≤ 80 mm).

- Width measured perpendicular to the longitudinal axis.

- Length measured along a long side; flatness defined as max distance between sheet and horizontal plane.

- Tolerances covered

- Thickness tolerances vary by nominal thickness, nominal width and specified minimum yield strength (separate tables for Re < 260 MPa, 260 ≤ Re < 340 MPa, 340 ≤ Re ≤ 420 MPa, Re > 420 MPa).

- Width: tables for sheet/wide strip and for slit wide strip (<600 mm).

- Length: fixed under/over limits for <2000 mm and percentage values for ≥2000 mm.

- Flatness, camber, out‑of‑squareness: definitions and limits (special flatness requirements can be ordered).

Applications and users

- Who uses it:

- Steel producers and mill QA teams for production and labeling.

- Purchasers/specifiers who require consistent dimensional quality for cold forming.

- OEMs and fabricators in automotive, household appliances, HVAC, electronics enclosures and other stampings or deep‑drawn parts.

- Inspection laboratories and compliance auditors.

- Practical use:

- Ensure material conforms to stamping/forming process needs (thickness uniformity, flatness and camber affect tool performance and part accuracy).

- Establish acceptance criteria in purchase orders and supplier contracts - special tolerances should be agreed at time of ordering.

Related standards

- EN 10130, EN 10152, EN 10271, EN 10209, EN 10268, prEN 10338

- Standards excluded or complementary: EN 10106, EN 10139, EN 10202, EN 10205, EN 10341

Keywords: EN 10131:2006, cold rolled steel, zinc coated, zinc‑nickel, tolerances, thickness tolerance, width tolerance, flatness, camber, cold forming.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 10131:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Cold rolled uncoated and zinc or zinc-nickel electrolytically coated low carbon and high yield strength steel flat products for cold forming - Tolerances on dimensions and shape". This standard covers: This European Standard applies to cold rolled uncoated and electrolytically zinc or zinc-nickel coated low carbon and high yield strength steel flat products for cold forming with a minimum thickness of 0,35 mm and, unless otherwise agreed at the time of ordering, less than or equal to 3 mm thick, delivered in sheet, wide strip, slit wide strip or cut lengths obtained from slit wide strip or sheet. The concerned standards are EN 10130, EN 10152, EN 10271, EN 10209, EN 10268 and prEN 10338. It does not apply to cold rolled strip (rolled width < 600 mm) or to flat cold rolled products for which there is a specific standard, in particular the following: cold rolled non-grain oriented magnetic steel sheet and strip (EN 10106); semi-processed steel strip for the construction of magnetic circuits (EN 10126 and 10165); tinplate and ECCS (EN 10202); blackplate in coils (EN 10205); cold rolled uncoated non-alloy mild steel narrow strip for cold forming (EN 10139).

This European Standard applies to cold rolled uncoated and electrolytically zinc or zinc-nickel coated low carbon and high yield strength steel flat products for cold forming with a minimum thickness of 0,35 mm and, unless otherwise agreed at the time of ordering, less than or equal to 3 mm thick, delivered in sheet, wide strip, slit wide strip or cut lengths obtained from slit wide strip or sheet. The concerned standards are EN 10130, EN 10152, EN 10271, EN 10209, EN 10268 and prEN 10338. It does not apply to cold rolled strip (rolled width < 600 mm) or to flat cold rolled products for which there is a specific standard, in particular the following: cold rolled non-grain oriented magnetic steel sheet and strip (EN 10106); semi-processed steel strip for the construction of magnetic circuits (EN 10126 and 10165); tinplate and ECCS (EN 10202); blackplate in coils (EN 10205); cold rolled uncoated non-alloy mild steel narrow strip for cold forming (EN 10139).

EN 10131:2006 is classified under the following ICS (International Classification for Standards) categories: 77.140.50 - Flat steel products and semi-products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10131:2006 has the following relationships with other standards: It is inter standard links to EN 10131:1991, EN 10079:1992, EN 10338:2025, EN 10304:2001, EN 10120:2017, EN 10359:2023, EN 1090-2:2018, EN 10130:2006, EN 912:2011, EN 10271:1998, EN 10152:2009, EN 13025-3:2005, EN 10169:2010+A1:2012, EN 10359:2015, EN 13025-2:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10131:2006 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071, M/BC/CEN/87/15, M/BC/CEN/89/10. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10131:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Cold rolled uncoated and zinc or zinc-nickel electrolytically coated low carbon and high yield strength steel flat products for cold forming - Tolerances on dimensions and shapeProduits plats laminés a froid, non revetus ou revetus de zinc ou de zinc-nickel par voie électrolytique, en acier a bas carbone et en acier a haute limite d'élasticité pour formage a froid - Tolérances sur les dimensions et sur la formeKaltgewalzte Flacherzeugnisse ohne Überzug und mit elektrolytischem Zink- oder Zink-Nickel-Überzug aus weichen Stählen sowie aus Stählen mit höherer Streckgrenze zum Kaltumformen - Grenzabmaße und FormtoleranzenTa slovenski standard je istoveten z:EN 10131:2006SIST EN 10131:2006en77.140.50ICS:SIST EN 10131:19971DGRPHãþDSLOVENSKI

STANDARDSIST EN 10131:200601-september-2006

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 10131July 2006ICS 77.140.50Supersedes EN 10131:1991

English VersionCold rolled uncoated and zinc or zinc-nickel electrolyticallycoated low carbon and high yield strength steel flat products forcold forming - Tolerances on dimensions and shapeProduits plats laminés à froid, non revêtus ou revêtus dezinc ou de zinc-nickel par voie électrolytique, en acier à bascarbone et en acier à haute limite d'élasticité pour formageà froid - Tolérances sur les dimensions et sur la formeKaltgewalzte Flacherzeugnisse ohne Überzug und mitelektrolytischem Zink- oder Zink-Nickel-Überzug ausweichen Stählen sowie aus Stählen mit höhererStreckgrenze zum Kaltumformen - Grenzabmaße undFormtoleranzenThis European Standard was approved by CEN on 12 June 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 10131:2006: E

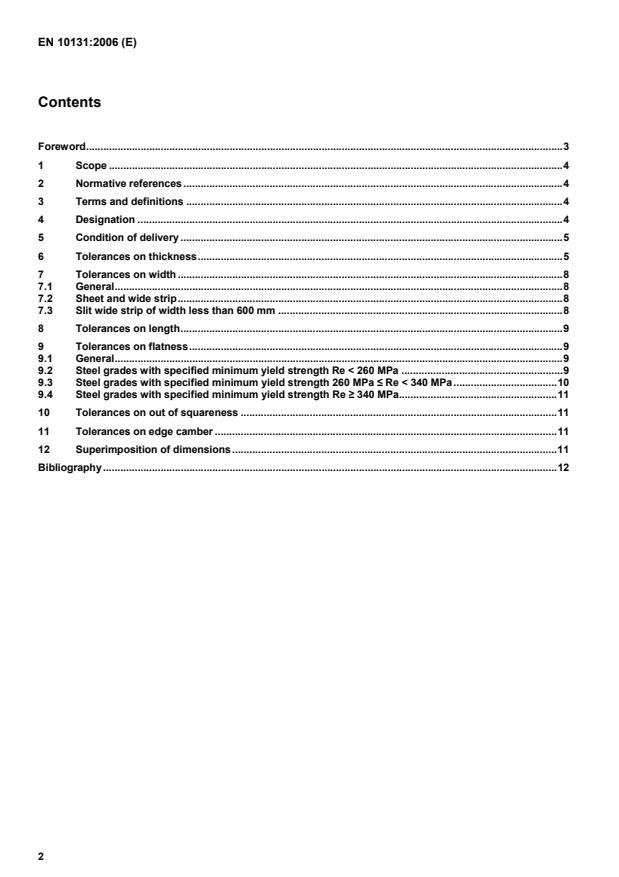

Foreword.3 1 Scope.4 2 Normative references.4 3 Terms and definitions.4 4 Designation.4 5 Condition of delivery.5 6 Tolerances on thickness.5 7 Tolerances on width.8 7.1 General.8 7.2 Sheet and wide strip.8 7.3 Slit wide strip of width less than 600 mm.8 8 Tolerances on length.9 9 Tolerances on flatness.9 9.1 General.9 9.2 Steel grades with specified minimum yield strength Re < 260 MPa.9 9.3 Steel grades with specified minimum yield strength 260 MPa ≤ Re < 340 MPa.10 9.4 Steel grades with specified minimum yield strength Re ≥ 340 MPa.11 10 Tolerances on out of squareness.11 11 Tolerances on edge camber.11 12 Superimposition of dimensions.11 Bibliography.12

This document (EN 10131:2006) has been prepared by Technical Committee ECISS/TC 13 “Flat products for cold working - Qualities, dimensions, tolerances and specific tests”, the secretariat of which is held by IBN. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by January 2007, and conflicting national standards shall be withdrawn at the latest by January 2007. This document supersedes EN 10131:1991. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

tinplate and ECCS (EN 10202); blackplate in coils (EN 10205); cold rolled uncoated non-alloy mild steel narrow strip for cold forming (EN 10139). 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references the latest edition of the referenced document (including any amendments) applies. EN 10079:1992, Definition of steel products 3 Terms and definitions For the purposes of this European Standard, the terms and definitions given in EN 10079:1992 and the following apply. 3.1 nominal thickness whole specified thickness of the coated or uncoated product NOTE In the case of coated products, it includes both substrate and coating.

4 Designation 4.1 Products conforming to this European standard shall be designated in the following order (see also clause 5): a) type of product (sheet, wide strip, slit wide strip or cut length); b) reference to this European Standard (EN 10131); c) nominal thickness in millimetres; d) letter S for products ordered with special tolerances on thickness; e) nominal width in millimetres;

Wide strip EN 10131-1,20x1500 Steel EN 10130-DC04-A-m EXAMPLE 2 Sheet according to this European standard of nominal thickness 0,80 mm ordered with special thickness tolerance (S), nominal width of 1200 mm with special tolerances on width (S), nominal length of 2500 mm and with special tolerances on flatness in steel DC06-B-g as specified in EN 10130:

Sheet EN 10131-0,80Sx1200Sx2500FS Steel EN 10130-DC06-B-g 5 Condition of delivery 5.1 Flat products according to this European standard may be delivered as follows: a) with normal or special thickness tolerances (see Tables 1 to 4); b) with normal or special width tolerances (see Tables 5 and 6); c) with normal or special length tolerances for sheet or cut lengths (see Table 7); d) with normal or special flatness tolerances for sheet or cut lengths (see Tables 8 and 9); e) with normal or special tolerances on camber for slit strip of width less than 600 mm (see clause 11). 5.2 In the absence of information on the order in respect of the condition of delivery given in 5.1 the flat products shall be delivered with normal tolerances on thickness, width, length, flatness and camber.

6 Tolerances on thickness The thickness may be measured at any point located more than 40 mm from the edges. In the case of slit coils or cut lengths having a width of 80 mm or below, the position of the measurement shall be at the middle axis. The tolerances on thickness shall be as given in Tables 1 to 4 and apply over the whole length. Tolerances more severe than special tolerances may be agreed at the time of the order.

Re < 260 MPa1)

D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...