EN 12209:2003

(Main)Building hardware - Locks and latches - Mechanically operated locks, latches and locking plates - Requirements and test methods

Building hardware - Locks and latches - Mechanically operated locks, latches and locking plates - Requirements and test methods

This European Standard specifies requirements and test methods for durability, strength, security, and function of mechanically operated locks and latches and their locking plates for use in doors, window doors and entrance doors in buildings.

Locks, latches and their locking plates used in fire resistant and/or smoke control door assemblies require additional attributes in order to comply with the Essential Requirement "Safety in case of fire" either independently or as a part of a complete assembly. Additional requirements for locks and latches and their locking plates used on fire resistant and/or smoke control door assemblies are specified in annex A.

The following locking devices and associated products are not covered by this European Standard: cylinders for locks, handles, electro-mechanically operated locks and striking plates, multi-point locks and their locking plates, locks for windows, padlocks, locks for safes, furniture locks and prison locks.

NOTE A lock meeting this standard can at the same time be part of an exit device according to EN 179 or EN 1125.

Schlösser und Baubeschläge - Schlösser - Mechanisch betätigte Schlösser und Schließbleche - Anforderungen und Prüfverfahren

Quincaillerie pour le bâtiment - Serrures - Serrures mécaniques et gâches - Exigences et méthodes d'essai

Stavbno okovje – Ključavnice in zapahi - Mehanske ključavnice, zapahi in prijemniki - Zahteve in preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 09-Dec-2003

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 33 - Doors, windows, shutters and building hardware

- Drafting Committee

- CEN/TC 33/WG 4 - Building hardware

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 16-Mar-2016

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 23-Mar-2016

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 12209:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Building hardware - Locks and latches - Mechanically operated locks, latches and locking plates - Requirements and test methods". This standard covers: This European Standard specifies requirements and test methods for durability, strength, security, and function of mechanically operated locks and latches and their locking plates for use in doors, window doors and entrance doors in buildings. Locks, latches and their locking plates used in fire resistant and/or smoke control door assemblies require additional attributes in order to comply with the Essential Requirement "Safety in case of fire" either independently or as a part of a complete assembly. Additional requirements for locks and latches and their locking plates used on fire resistant and/or smoke control door assemblies are specified in annex A. The following locking devices and associated products are not covered by this European Standard: cylinders for locks, handles, electro-mechanically operated locks and striking plates, multi-point locks and their locking plates, locks for windows, padlocks, locks for safes, furniture locks and prison locks. NOTE A lock meeting this standard can at the same time be part of an exit device according to EN 179 or EN 1125.

This European Standard specifies requirements and test methods for durability, strength, security, and function of mechanically operated locks and latches and their locking plates for use in doors, window doors and entrance doors in buildings. Locks, latches and their locking plates used in fire resistant and/or smoke control door assemblies require additional attributes in order to comply with the Essential Requirement "Safety in case of fire" either independently or as a part of a complete assembly. Additional requirements for locks and latches and their locking plates used on fire resistant and/or smoke control door assemblies are specified in annex A. The following locking devices and associated products are not covered by this European Standard: cylinders for locks, handles, electro-mechanically operated locks and striking plates, multi-point locks and their locking plates, locks for windows, padlocks, locks for safes, furniture locks and prison locks. NOTE A lock meeting this standard can at the same time be part of an exit device according to EN 179 or EN 1125.

EN 12209:2003 is classified under the following ICS (International Classification for Standards) categories: 91.190 - Building accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12209:2003 has the following relationships with other standards: It is inter standard links to EN 12209:2016, EN ISO 12217-2:2002, EN 1634-1:2014+A1:2018, EN 1670:1998, EN 1628:2011, EN 1629:2011, EN 1630:2011, EN 1628:2011+A1:2015, EN 16034:2014, EN 1629:2011+A1:2015, EN 1630:2011+A1:2015, EN 1627:2011, EN 14846:2008, EN 12209:2003/AC:2005, FprEN 12209 rev. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12209:2003 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/101. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12209:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Building hardware - Locks and latches - Mechanically operated locks, latches and locking plates - Requirements and test methodsQuincaillerie pour le bâtiment - Serrures - Serrures mécaniques et gâches - Exigences et méthodes d'essaiSchlösser und Baubeschläge - Schlösser - Mechanisch betätigte Schlösser und Schließbleche - Anforderungen und Prüfverfahren91.190Stavbna opremaBuilding accessoriesICS:SIST EN 12209:2004enTa slovenski standard je istoveten z:EN 12209:200301-oktober-2004SIST EN 12209:2004SLOVENSKI

STANDARD

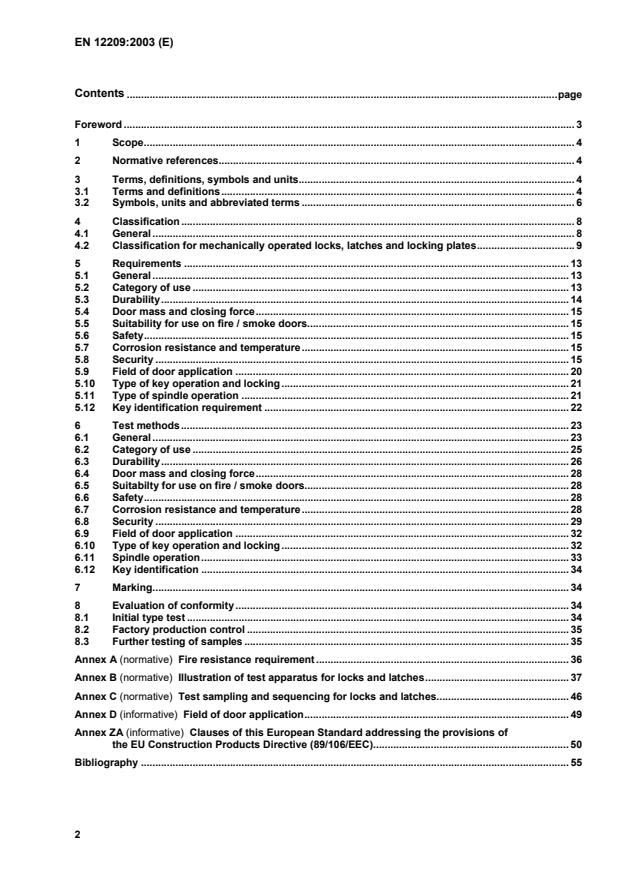

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12209December 2003ICS 91.190English versionBuilding hardware - Locks and latches - Mechanically operatedlocks, latches and locking plates - Requirements and testmethodsQuincaillerie pour le bâtiment - Serrures - Serruresmécaniques et gâches - Exigences et méthodes d'essaiSchlösser und Baubeschläge - Schlösser - Mechanischbetätigte Schlösser und Schließbleche - Anforderungen undPrüfverfahrenThis European Standard was approved by CEN on 27 June 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12209:2003 E

Fire resistance requirement.36Annex B (normative)

Illustration of test apparatus for locks and latches.37Annex C (normative)

Test sampling and sequencing for locks and latches.46Annex D (informative)

Field of door application.49Annex ZA (informative)

Clauses of this European Standard addressing the provisions ofthe EU Construction Products Directive (89/106/EEC).50Bibliography.55

for use by people with a high incentive to exercise care and with a small chance ofmisuse, e.g. residential doors.¾ grade 2:

for use by people with some incentive to exercise care but where there is some chanceof misuse, e.g. office doors.¾ grade 3 :

for use by the public where there is little incentive to exercise care and where there is ahigh chance of misuse, e.g. doors in public buildings.4.2.2 Durability (second digit)Twelve grades of durability and load on latch bolt are identified.¾ grade A:

50 000

test cycles;no

load on latch bolt;¾ grade B: 100 000

test cycles;no

load on latch bolt;¾ grade C: 200 000

test cycles;no

load on latch bolt;¾ grade F:

50 000

test cycles;10 N

load on latch bolt;¾ grade G: 100 000

test cycles;10 N

load on latch bolt;¾ grade H: 200 000

test cycles;10 N

load on latch bolt;¾ grade L:100 000

test cycles;25 N

load on latch bolt;¾ grade M: 200 000

test cycles;25 N

load on latch bolt;¾ grade R: 100 000

test cycles;50 N

load on latch bolt;¾ grade S: 200 000

test cycles;50 N

load on latch bolt;¾ grade W: 100 000

test cycles;120 N

load on latch bolt;

test cycles;120 N

load on latch bolt.NOTEThe above information relates to latch action only. Corresponding durability requirements based onnumber of cycles, apply to the dead bolt and snib mechanisms as shown in Table 4.4.2.3 Door mass and closing force (third digit)Nine grades of door mass and closing force are identified.¾ grade 1: up to 100 kg door mass;50 N maximum closing force;¾ grade 2: up to 200 kg door mass;50 N maximum closing force;¾ grade 3: above

200 kg door mass orspecified by the manufacturer;50 N maximum closing force;¾ grade 4: up to 100 kg door mass;25 N maximum closing force;¾ grade 5: up to 200 kg door mass;25 N maximum closing force;¾ grade 6: above

200 kg door mass or specified by the manufacturer;25 N maximum closing force;¾ grade 7: up to 100 kg door mass;15 N maximum closing force;¾ grade 8: up to 200 kg door mass;15 N maximum closing force;¾ grade 9: above

200 kg door mass or specified by the manufacturer; 15 N maximum closing force.4.2.4 Suitability for use on fire/smoke doors (fourth digit) Two grades of suitability for use on fire/smoke doors are identified.¾ grade 0: not approved for use on fire/smoke resisting door assemblies;¾ grade 1: suitable for use on fire/smoke resisting door assemblies, subject to satisfactoryassessment of the contribution of the lock or latch to the fire resistance of specified fire/smokeresisting door assemblies. Such assessment is beyond the scope of this European Standard.Annex A indicates additional requirements for locks and latches to this grade.4.2.5 Safety (fifth digit)Only one grade of safety is identified.¾ grade 0: no safety requirement.NOTESee EN 179 and EN 1125 for locks, latches and locking plates that are part of exit devices for use onemergency or panic exit doors.4.2.6 Corrosion resistance and temperature (sixth digit)Eight grades of corrosion resistance and temperature requirement are identified.¾ grade 0: no defined corrosion resistance;no temperature requirement;

Minimum security and no drill resistance;¾ grade 2:

Low security and no drill resistance;¾ grade 3:

Medium security and no drill resistance;¾ grade 4:

High security and no drill resistance;¾ grade 5:

High security with drill resistance;¾ grade 6:

Very high security and no drill resistance;¾ grade 7:

Very high security with drill resistance.4.2.8 Field of door application (eighth digit)15 grades of door application are identified in Table 3.Table 3 — Field of door applicationGradeTypeApplication 1Application 2Application 3AMorticeUnrestricted applicationBMorticeHinged doorCMorticeSliding doorDRimUnrestricted applicationERimHinged doorFRimSliding doorGBored lockUnrestricted applicationHMorticeHinged doorSupportedJRimHinged doorInwardsKMorticeHinged doorLocked from insideLMorticeSliding doorLocked from insideMRimHinged doorLocked from insideNRimSliding doorLocked from insidePMorticeHinged doorSupportedLocked from insideRRimHinged doorInwardsLocked from inside

D:lever lock or latch;manually locking;¾ grade E:lever lock or latch;automatically locking;¾ grade F:lever lock or latch;manually locking with intermediate locking;¾ grade G:lock or latch without key operation;manually locking;¾ grade H:lock without key operation;automatically locking.4.2.10 Type of spindle operation (tenth digit)Five grades of spindle operation are identified.¾grade 0:lock or latch without follower¾ grade 1: lock or latch for knob or sprung lever handle operation;¾ grade 2: lock or latch for unsprung lever handle operation;¾ grade 3: lock or latch for heavy duty unsprung lever handle operation;¾ grade 4:lock or latch for heavy duty unsprung lever handle operation specified by themanufacturer.4.2.11 Key identification requirement (eleventh digit)Nine grades are identified from 0 to H.¾ grade 0:

No requirements;¾ grade A:

Minimum three detaining elements;¾ grade B:

Minimum five detaining elements;¾ grade C

Minimum five detaining elements, extended number of effective differs;¾ grade D:

Minimum six detaining elements;¾ grade E:

Minimum six detaining elements, extended number of effective differs;

Minimum seven detaining elements;¾ grade G:

Minimum seven detaining g elements, extended number of effective differs;¾ grade H:

Minimum eight detaining elements, extended number of effective differs.4.2.12 Example for classification of locks, latches and their locking plates2H510E5AF2CThis indicates a mechanically operated lock and locking plate for use in an application where peoplehave an incentive to exercise care, able to withstand a durability of 200,000 cycles with a 10 N loadon the latch bolt, on a door with a mass of up to 200 kg and a maximum closing force of 25 N, suitablefor use on a fire/smoke resisting door assembly, no safety requirement, moderate corrosionresistance in temperatures ranging from – 20 0C to + 80 0C, with high security and drill resistance foruse in any mortice application, with a manual locking lever lock or latch, unsprung lever handleoperation, a minimum of five deadlocking elements and an extended number of effective differs.5 Requirements5.1 General5.1.1 Dangerous substancesMaterials in products shall not release any dangerous substances in excess of the maximum levelsspecified in any relevant European Standard for the material and in any national regulations in themember state of destination.5.1.2 Return force of latch boltWhen tested in accordance with 6.1.2, the return force of the latch bolt shall not be less thanF2 = 2,5 N (see Figure 1).5.2 Category of use5.2.1 Resistance to side load on latch bolt.When tested in accordance with 6.2.1, the lock or latch shall resist a side load of F1 (see Figure 1).¾ grade 1:2 kN¾ grade 2 3 kN¾ grade 3:3 kN5.2.2 Torque to operate deadboltWhen tested in accordance with 6.2.2:5.2.2.1the torque on the key to operate the deadbolt shall not exceed M3 = 1,5 Nm(see Figure 1).

F,50 00010 00050 00010 000B,

G,

L,

R,

W100 00025 000100 00025 000C,

H,

M,

S,

X200 00050 000200 00025 0005.3.3 Durability of locking snib mechanismWhen tested in accordance with 6.3.3, the locking snib mechanism shall complete the minimumnumber of cycles specified in Table 4. The mechanism shall operate after the test.

securityUnitSubclausenumberRequirementTestmethodTestParam.1234567Torque resistance of knob on bored1015-----Nmlock and latch sets5.8.1.1Torque resistance of lever handle on6.8.1.1M92030-----Nmbored lock and latch sets5.8.1.2Torque resistance of knob or lever6.8.1.2M1011111kNhandle on Rim nigth latches5.8.2.1- side load on deadbolt6.8.2.1F4135771010kN- net drilling time for sideload test----3-55.8.2.2- total drilling time for sideload test6.8.2.2t----5-10min5.8.3Deadbolt projection6.8.3L110121420202020mm- end loadF5124 a5a5a6a6akN5.8.4.1- resulting projection6.8.4.1L28101117171717mm- net drilling time for endload test----3-55.8.4.2- total drilling time for endload test6.8.4.2t----5-10min5.8.5Resistance to pulling of hook/claw6.8.5F6135771010kNbolt5.8.6Resistance to disengaging of6.8.6F7124a5a5a6 a6 akNhook/claw bolt5.8.7Resistance to forcing of locating6.8.7F81345566kNdevices in sliding door lock5.8.8Resistance to pulling off of knob on6.8.8F911,5-----kNbored lock and latch setsF545566kN5.8.9.1Resistance to end load on box6.8.9.1L3-- 131919 19 19mmprotected locking plates5.8.9.2Resistance to side load on locking6.8.9.2F4135771010kNplate5.8.9.3Resistance to pulling on locking plate6.8.9.3F6135771010kNResistance to lifting force on locking5.8.9.4plate6.8.9.4F81345566kNaWhere the deadbolt is protected by a box locking plate the end load on deadbolt requirement shall be 2 kN

with intermediate locking positionsWhen tested in accordance with 6.10.2.2 it shall not be possible to remove the key from the lockbefore the bolt is properly deadlocked.5.10.2.3 Automatic locking deadboltWhen a lock with an automatically locking deadbolt is tested in accordance with 6.10.2.3, it shall meetthe following requirements:¾ the deadbolt still has to be released automatically, when the distance between forend and lockingplate is up to 5 mm;¾ when retracting the deadbolt of a lock by key or handle operation, the deadbolt shall reach itsheld back position before the latch bolt disengages from the locking plate, when the distancebetween forend and locking plate is up to 5 mm.5.10.2.4 Automatic locking latch boltWhen a lock or latch with an automatically locking latch bolt is tested in accordance with 6.10.2.4, itshall meet the following requirements:¾ the latch bolt still has to be locked automatically (deadlocking function), when the distancebetween forend and locking plate is up to 5 mm;¾ it shall not be possible to release the dead locking function by manipulation of the elements whichare accessible between the forend and the locking plate.5.10.3 Torque to withdraw the latch bolt with keyWhen tested in accordance with 6.10.3, the torque on the key shall not exceed M1 = 1,5 Nm(see Figure 1).5.11 Type of spindle operation5.11.1 Torque to withdraw the latch boltWhen tested in accordance with 6.11.1, the torque M2 on the follower for operation the latch shall notexceed (see Figure 1):

0,5 Nm;¾ grade 2:

3 Nm;¾ grade 3:

5 Nm;¾ grade 4:

in accordance with manufacturers specification.5.11.2 Strength of bolt actionsWhen tested in accordance with 6.11.2, the deadbolt components shall resist a torque of 30 Nm andthe latch bolt components shall resist a torque of 20 Nm for all grades (see Figure 1).The lock or latch shall operate correctly after this test fulfilling the requirements of 5.11.1.5.11.3 Minimum follower restoring torqueWhen tested in accordance with 6.11.3, the restoring torque on the follower shall be at least M8 asappropriate.¾ grade 1:

0 Nm;¾ grade 2:

0,6 Nm;¾ grade 3:

0,6 Nm;¾ grade 4:

0,6 Nm.5.12 Key identification requirement5.12.1 Detaining elementsThe minimum number of detaining elements that form part of the deadbolt mechanism (or latch actionwhere there is direct operation by the key) shall be as specified in Table 6.5.12.2 Effective differsAssessed in accordance with 6.12.2, locks shall have the minimum number of effective differs that areindicated in Table 6.5.12.3 Differing step heights on keyAssessed as in 6.12.3, keys shall have the minimum number of different step heights that areindicated in Table 6.5.12.4 Non-interpassing of keys with just one interval differWhen tested in accordance with 6.12.4, it shall not be possible to open the lock with the next closestkey (as defined by the manufacturer’s coding system).5.12.5 Coding protectionExcept for grade 1, direct coding on the key is not permitted.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...