EN 14037-1:2016

(Main)Free hanging heating and cooling surfaces for water with a temperature below 120°C - Part 1: Pre-fabricated ceiling mounted radiant panels for space heating - Technical specifications and requirements

Free hanging heating and cooling surfaces for water with a temperature below 120°C - Part 1: Pre-fabricated ceiling mounted radiant panels for space heating - Technical specifications and requirements

This European Standard defines technical specifications and requirements of free hanging prefabricated ceil-ing mounted radiant panels with an air gap between construction and the emitter (not embedded) fed with water at temperatures below 120 °C connected with a centralized heating supply source intended to be in-stalled in buildings.

The panels should be installed with an upper insulation.

The European Standard does not apply to independent heating devices.

The European Standard also defines the additional common data that the manufacturer has to provide to the trade in order to ensure the correct application of the products.

This European standard does not cover the performance of hanging accessories.

An der Decke frei abgehängte Heiz- und Kühlflächen für Wasser mit einer Temperatur unter 120 °C - Teil 1: Vorgefertigte Deckenstrahlplatten zur Raumheizung - Technische Spezifikationen und Anforderungen

Diese Europäische Norm legt die technischen Spezifikationen und Anforderungen für vorgefertigte Deckenstrahlplatten mit einem Luftspalt zwischen dem Gebäudebauteil und den (nicht integrierten) Heizelementen fest. Die Deckenstrahlplatten werden mit Wasser versorgt das Temperaturen unter 120 °C hat und sind an eine zentrale Gebäude-Heizungsanlage angeschlossen.

Die Deckenstrahlplatten sollten an der Oberseite mit einer Wärmedämmung versehen sein.

Diese Europäische Norm gilt nicht für selbständige Heizgeräte.

Diese Europäische Norm legt außerdem die zusätzlichen allgemeinen Daten fest, die der Hersteller dem Markt zur Sicherstellung der ordnungsgemäßen Anwendung der Produkte bereitzustellen hat.

Diese Europäische Norm behandelt nicht die Ausführung des Befestigungsmaterials.

Panneaux rayonnants de chauffage et de rafraîchissement alimentés avec une eau à une température inférieure à 120 °C - Partie 1 : Panneaux rayonnants de plafond préfabriqués destinés au chauffage des locaux - Spécifications techniques et exigences

La présente Norme européenne définit les spécifications techniques et les exigences relatives aux panneaux rayonnants de plafond préfabriqués comportant une poche d'air entre la construction et l'émetteur (non intégré), alimentés avec une eau à une température inférieure à 120 °C à l'aide d'une source d'alimentation de chauffage central et destinés à être installés dans des bâtiments.

Il convient que les panneaux soient dotés d'une isolation supérieure.

La présente Norme européenne ne s’applique pas aux appareils de chauffage indépendants.

La présente Norme européenne définit également les données courantes supplémentaires que le fabricant doit inclure dans sa documentation commerciale afin d’assurer une utilisation correcte des produits.

La présente Norme européenne ne décrit pas les performances des accessoires d’accrochage.

Prosto viseče grelne in hladilne površine za vodo s temperaturo do 120 °C - 1. del: Predizdelane stropne sevalne plošče za ogrevanje prostora - Tehnične specifikacije in zahteve

Definicija tehničnih specifikacij in zahtev za predizdelane sevalne plošče, ki se iz oddaljenega vira toplote polnijo z vodo s temperaturo do 120 °C, in definicija dodatnih skupnih podatkov, ki jih mora proizvajalec zagotoviti za pravilno uporabo izdelkov. Ta dokument se ne uporablja za samostojne ogrevalne naprave.

General Information

- Status

- Published

- Publication Date

- 20-Sep-2016

- Technical Committee

- CEN/TC 130 - Space heating appliances without integral heat sources

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 14-Mar-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 23-Jul-2014

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 14037-1:2016 is a CEN European Standard that sets technical specifications and requirements for free hanging, pre‑fabricated ceiling‑mounted radiant panels intended for space heating and fed with water at temperatures below 120 °C. It covers panels installed with an air gap (not embedded) and requires an upper insulation layer. The standard applies to products connected to a centralized heating supply in buildings and excludes independent heating appliances and the performance of hanging accessories.

Key topics and technical requirements

This part of EN 14037 addresses manufacturer, design and conformity duties, including:

- Scope and definitions for prefabricated ceiling mounted radiant panels (width typically 0.3–1.5 m in model descriptions).

- Materials and surface protection, including surface emissivity requirements.

- Mechanical resistance criteria such as horizontal curvature and vertical deflection limits.

- Resistance to fixings, pressure tightness and pressure resistance for water circuits.

- Dimensional tolerances and requirements for upper insulation and water flow resistance.

- Thermal performance data: rated thermal output, characteristic equations and surface temperatures (used with test and rating methods in companion parts).

- Health & safety: release of dangerous substances and reaction to fire (referencing EN 13501‑1).

- Assessment and verification of constancy of performance (AVCP): type testing, factory production control (FPC), initial inspection and continuous surveillance.

- Technical documentation and mandatory manufacturer data to ensure correct application by trade and installers.

Normative references include EN 14037‑2, ‑3, ‑4 (test, rating and cooling test methods), EN 13501‑1 and EN ISO 2409.

Applications and who uses this standard

EN 14037‑1 is essential for stakeholders involved in design, manufacture, procurement and compliance of ceiling‑mounted radiant heating systems:

- Manufacturers - to design panels, set production controls, and supply required technical data.

- HVAC engineers and system designers - for selection, system integration and performance verification.

- Architects and building services consultants - to specify compliant ceiling radiant panels for buildings.

- Installers and contractors - to ensure correct installation with upper insulation and adherence to load/fixings guidance.

- Test laboratories and certification bodies - for type testing and AVCP procedures.

- Building owners and procurement teams - for product comparison and regulatory compliance (links to Regulation (EU) No. 305/2011 via Annex ZA).

Practical uses include performance comparison, specifying panels for commercial and residential spaces, compliance documentation and ensuring safe, durable installations of centralized low‑temperature water radiant ceilings.

Related standards

- EN 14037‑2:2016 - Test method for thermal output

- EN 14037‑3:2016 - Rating method and evaluation of radiant thermal output

- EN 14037‑4:2016 - Test method for cooling capacity

- EN 14037‑5 - Open/closed heated ceiling surfaces (test method)

- EN 13501‑1 - Reaction to fire classification

- EN ISO 2409 - Paints and varnishes - Cross‑cut test

Keywords: EN 14037‑1:2016, ceiling mounted radiant panels, free hanging heating and cooling surfaces, prefabricated ceiling panels, thermal output, CEN, water below 120 °C.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 14037-1:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Free hanging heating and cooling surfaces for water with a temperature below 120°C - Part 1: Pre-fabricated ceiling mounted radiant panels for space heating - Technical specifications and requirements". This standard covers: This European Standard defines technical specifications and requirements of free hanging prefabricated ceil-ing mounted radiant panels with an air gap between construction and the emitter (not embedded) fed with water at temperatures below 120 °C connected with a centralized heating supply source intended to be in-stalled in buildings. The panels should be installed with an upper insulation. The European Standard does not apply to independent heating devices. The European Standard also defines the additional common data that the manufacturer has to provide to the trade in order to ensure the correct application of the products. This European standard does not cover the performance of hanging accessories.

This European Standard defines technical specifications and requirements of free hanging prefabricated ceil-ing mounted radiant panels with an air gap between construction and the emitter (not embedded) fed with water at temperatures below 120 °C connected with a centralized heating supply source intended to be in-stalled in buildings. The panels should be installed with an upper insulation. The European Standard does not apply to independent heating devices. The European Standard also defines the additional common data that the manufacturer has to provide to the trade in order to ensure the correct application of the products. This European standard does not cover the performance of hanging accessories.

EN 14037-1:2016 is classified under the following ICS (International Classification for Standards) categories: 01.040.91 - Construction materials and building (Vocabularies); 91.140.10 - Central heating systems; 91.140.30 - Ventilation and air-conditioning systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14037-1:2016 has the following relationships with other standards: It is inter standard links to EN 14037-1:2003, EN ISO 2409:2020, EN 13501-1:2018, EN 14037-3:2016, EN 14037-2:2016, CEN/TR 15316-6-2:2017, EN 14037-4:2016, EN 14037-5:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14037-1:2016 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/129. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14037-1:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.þQHAn der Decke frei abgehängte Heiz- und Kühlflächen für Wasser mit einer Temperatur unter 120 °C - Teil 1: Vorgefertigte Deckenstrahlplatten zur Raumheizung - Technische Spezifikationen und AnforderungenPanneaux rayonnants de chauffage et de rafraîchissement alimentés avec une eau à une température inférieure à 120 °C - Partie 1 : Panneaux rayonnants de plafond préfabriqués destinés au chauffage des locaux - Spécifications techniques et exigencesFree hanging heating and cooling surfaces for water with a temperature below 120°C - Part 1: Pre-fabricated ceiling mounted radiant panels for space heating - Technical specifications and requirements91.140.10Sistemi centralnega ogrevanjaCentral heating systemsICS:Ta slovenski standard je istoveten z:EN 14037-1:2016SIST EN 14037-1:2017en01-april-2017SIST EN 14037-1:2017SLOVENSKI

STANDARDSIST EN 14037-1:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14037-1

September

t r s x ICS

{ sä s v rä s râ

{ sä s v rä u r Supersedes EN

s v r u yæ sã t r r uEnglish Version

Free hanging heating and cooling surfaces for water with a temperature below

s t r ¹C æ Part

sã Preæfabricated ceiling mounted radiant panels for space heating æ Technical specifications and requirements Panneaux rayonnants de chauffage et de rafraîchissement alimentés avec une eau à une température inférieure à

s t r

¹C æ Partie

s ã Panneaux rayonnants de plafond préfabriqués destinés au chauffage des locaux æ Spécifications techniques et exigences

An der Decke frei abgehängte Heizæ und Kühlflächen für Wasser mit einer Temperatur unter

s t r

¹C æ Teil

sã Vorgefertigte Deckenstrahlplatten zur Raumheizung æ Technische Spezifikationen und Anforderungen This European Standard was approved by CEN on

s { March

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s v r u yæ sã t r s x ESIST EN 14037-1:2017

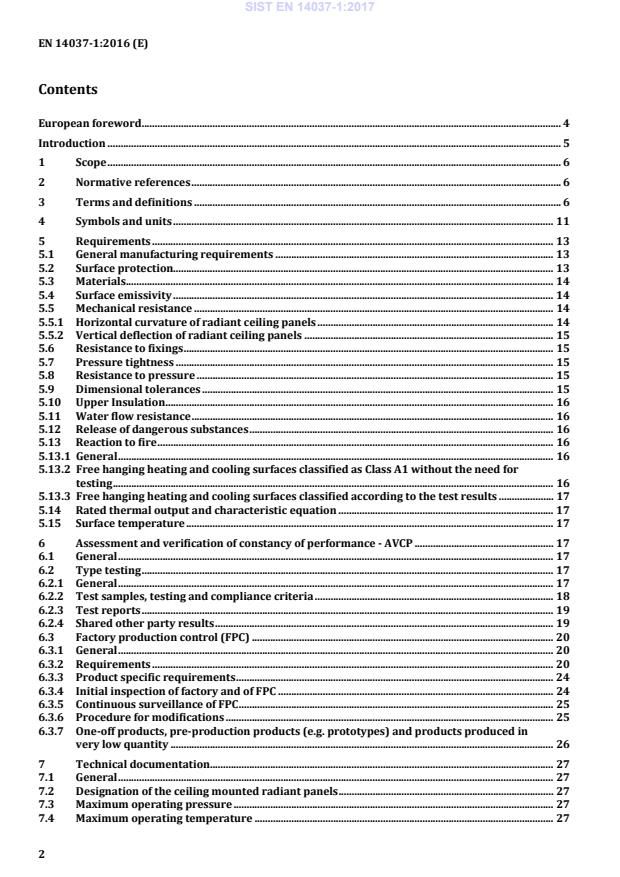

2 Contents European foreword . 4 Introduction . 5 1 Scope . 6 2 Normative references . 6 3 Terms and definitions . 6 4 Symbols and units . 11 5 Requirements . 13 5.1 General manufacturing requirements . 13 5.2 Surface protection. 13 5.3 Materials . 14 5.4 Surface emissivity . 14 5.5 Mechanical resistance . 14 5.5.1 Horizontal curvature of radiant ceiling panels . 14 5.5.2 Vertical deflection of radiant ceiling panels . 15 5.6 Resistance to fixings . 15 5.7 Pressure tightness . 15 5.8 Resistance to pressure . 15 5.9 Dimensional tolerances . 15 5.10 Upper Insulation . 16 5.11 Water flow resistance . 16 5.12 Release of dangerous substances . 16 5.13 Reaction to fire . 16 5.13.1 General . 16 5.13.2 Free hanging heating and cooling surfaces classified as Class A1 without the need for testing . 16 5.13.3 Free hanging heating and cooling surfaces classified according to the test results . 17 5.14 Rated thermal output and characteristic equation . 17 5.15 Surface temperature . 17 6 Assessment and verification of constancy of performance - AVCP . 17 6.1 General . 17 6.2 Type testing . 17 6.2.1 General . 17 6.2.2 Test samples, testing and compliance criteria . 18 6.2.3 Test reports . 19 6.2.4 Shared other party results . 19 6.3 Factory production control (FPC) . 20 6.3.1 General . 20 6.3.2 Requirements . 20 6.3.3 Product specific requirements . 24 6.3.4 Initial inspection of factory and of FPC . 24 6.3.5 Continuous surveillance of FPC . 25 6.3.6 Procedure for modifications . 25 6.3.7 One-off products, pre-production products (e.g. prototypes) and products produced in very low quantity . 26 7 Technical documentation . 27 7.1 General . 27 7.2 Designation of the ceiling mounted radiant panels . 27 7.3 Maximum operating pressure . 27 7.4 Maximum operating temperature . 27 SIST EN 14037-1:2017

3 7.5 Thermal output respectively cooling capacity . 27 7.6 Dimensions and technical data . 27 7.7 Reference data . 28 7.8 Installation manual . 28 Annex ZA (informative)

Relationship

of this European Standard with Regulation (EU) No. 305/2011 . 29 ZA.1 Scope and relevant characteristics . 29 ZA.2 System of Assessment and Verification of Constancy of Performance (AVCP) . 30 ZA.3 Assignment of AVCP tasks . 30 Bibliography . 32

4 European foreword This document (EN 14037-1:2016) has been prepared by Technical Committee CEN/TC 130 “Space heating appliances without integral heat sources”, the secretariat of which is held by UNI. This document supersedes EN 14037-1:2003. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by March 2017, and conflicting national standards shall be withdrawn at the latest by June 2018. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document has been prepared under a mandate given to CEN by the European Commission and the Eu-ropean Free Trade Association, and supports basic work requirements of Regulation (EU) No. 305/2011.

For relationship with Regulation (EU) No. 305/2011, see informative Annex ZA, which is an integral part of this document. The main changes are: — the title has been changed, — the introduction has been changed, — the scope has been changed, — new definitions have been added, — the Annex ZA has been adapted.

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portu-gal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 14037-1:2017

5 Introduction This European Standard results from the recognition, that heated and chilled ceiling radiant panels falling into the field of application hereinafter stated are traded on the basis of their thermal output. For evaluating and comparing different heated and chilled ceiling surfaces it is therefore necessary to refer to a heating stipulated value. As installations with ceiling mounted radiant panels can also be used in practice for space cooling, it is nec-essary to have a test method for evaluating the cooling capacity. Installations with different free hanging heating and cooling surfaces need, for the use of space heating a test method for evaluating the heating out-put. The test method differs from the method for ceiling mounted radiant panels. The European Standard EN 14037, Free hanging heating and cooling surfaces for water with a temperature below 120°C, consists of the following parts: — Part 1: Pre-fabricated ceiling mounted radiant panels for space heating - Technical specifications and re-quirements; — Part 2: Pre-fabricated ceiling mounted radiant panels for space heating - Test method for thermal output; — Part 3: Pre-fabricated ceiling mounted radiant panels for space heating - Rating method and evaluation of radiant thermal output; — Part 4: Pre-fabricated ceiling mounted radiant panels for space heating - Test method for cooling capacity; — Part 5: Open or closed heated ceiling surfaces - Test method for thermal output. SIST EN 14037-1:2017

6 1 Scope This European Standard defines technical specifications and requirements of free hanging pre-fabricated ceiling mounted radiant panels with an air gap between construction and the emitter (not embedded) fed with water at temperatures below 120 °C connected with a centralized heating supply source intended to be installed in buildings. The panels should be installed with an upper insulation. The European Standard does not apply to independent heating devices. The European Standard also defines the additional common data that the manufacturer has to provide to the trade in order to ensure the correct application of the products. This European standard does not cover the performance of hanging accessories. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indis-pensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 13501-1, Fire classification of construction products and building elements - Part 1: Classification using da-ta from reaction to fire tests EN 14037-2:2016, Free hanging heating and cooling surfaces for water with a temperature below 120°C – Part 2: Pre-fabricated ceiling mounted radiant panels for space heating - Test method for thermal output EN 14037-3:2016, Free hanging heating and cooling surfaces for water with a temperature below 120°C - Part 3: Pre-fabricated ceiling mounted radiant panels for space heating - Rating method and evaluation of radiant thermal output EN ISO 2409, Paints and varnishes - Cross-cut test (ISO 2409) 3 Terms and definitions For the purposes of this document, the terms and definitions given below apply. 3.1 heating appliance device having the purpose of transferring heat in order to provide specific temperature conditions inside buildings 3.2 independent heating appliance self-contained heating appliance which does not need to be connected to a remote heat source (e. g. a boiler) as it contains its own heat source (e. g. gas fired appliances, electric appliances, heat pump appliances) 3.3 pre-fabricated ceiling mounted radiant panel pre-fabricated heat-transmitting device in the form of a heating or cooling element with width of 0,3 m up to 1,5 m fitted with connection components or open pipes for in-side-assembling and designed to operate on water flow heating and/or cooling facilities SIST EN 14037-1:2017

7 3.4 model ceiling mounted radiant panel or heated ceiling surface of defined construction, e.g. width, height, number and diameter of the tubes 3.5 type group of models with identical modular cross section 3.6 sample ceiling mounted radiant panel or heated ceiling surface, used for testing 3.7 inlet water temperature bulk temperature of the water entering the ceiling mounted radiant panel 3.8 outlet water temperature bulk temperature of the water leaving the ceiling mounted radiant panel 3.9 mean water temperature arithmetical mean of inlet and outlet water temperature 3.10 water temperature drop temperature difference between the inlet and outlet water temperature of the pre-fabricated ceiling mount-ed radiant panel 3.11 mean radiant temperature temperature in a defined point of the room resulting from the radiation of all surrounding surfaces and of the pre-fabricated ceiling mounted radiant panel respectively heated ceiling surface 3.12 reference room temperature temperature measured with a globe thermometer 3.13 temperature difference temperature difference between mean water temperature and reference room temperature 3.14 standard temperature difference of ceiling mounted radiant panels (EN 14037-2) mean water temperature 75°C and reference room temperature 20°C, determined temperature difference 55 K 3.15 surface temperatures of the inside surfaces of the test room mean temperatures of the inside surfaces of the test room 3.16 mean surface temperature of the pre-fabricated ceiling mounted radiant panel mean temperature on the heating or cooling surfaces of the ceiling mounted radiant panel facing the room below SIST EN 14037-1:2017

8 3.17 surface temperature maximum inlet water temperature Note 1 to entry: This definition is given for safety requirements only. 3.18 air temperature indoor air temperature measured by using radiation shields 3.19 active length of the pre-fabricated ceiling mounted radiant panel length of the usable heating and cooling panels with identical cross section and without connection compo-nents and covers, which are bonded together with the water flow components 3.20 connection components all other components attached to the active length of the ceiling mounted radiant panel which are used for connecting to the distribution system or for venting and draining (see Figure 1) 3.21 indirect heating surface (dry surface) portion of the heating surface of the panel which is in contact with air only (e.g. radiant sheet between the tubes) 3.22 direct heating surface (wet surface) portion of the heating surface of the panel which is in contact with the water 3.23 active surface of the pre-fabricated ceiling mounted radiant panel lower panel surface, the lateral edges are not included 3.24 air pressure pressure of air measured by a barometer at the testing place 3.25 standard air pressure pressure of air which is defined as 101,325 kPa (1,01325 bar) 3.26 water flow rate amount of water flowing through the ceiling mounted radiant panel resp. heating and cooling surface, per unit of time 3.27 total thermal output thermal output of the active length and of the connection components 3.28 radiant output thermal output emitted downwards by radiation of the active length SIST EN 14037-1:2017

9 3.29 standard thermal output thermal output at standard temperature difference, standard air pressure and upper insulation as defined in EN 14037-2 3.30 characteristic equation equation that gives the thermal output as a function of the temperature difference at constant water flow rate 3.31 construction dimensions 3.31.1 construction length length of the ceiling mounted radiant panel including the collectors/ headers but excluding the connecting pieces to the heating pipe work 3.31.2 outside diameter of circular tubes nominal diameter according to standard tube dimensions 3.31.3 dimensions of non-circular tubes shape and all dimensions necessary to describe exactly the cross section of the tube 3.31.4 distance between tubes distance between the centre lines of two tubes in parallel 3.31.5 length of tube length of tubes between collectors / headers 3.31.6 length of radiant sheet length of the heat transferring sheets Note 1 to entry: Generally identical with the active length according to 3.19 3.31.7 width of pre-fabricated ceiling mounted radiant panel width of ceiling mounted radiant panels measured over the outsides of lateral edges 3.31.8 thickness of sheet thickness of the radiant sheet 3.31.9 height of lateral edges height of lateral edges of the radiant sheet to hold the upper insulation 3.32 module 1 m of the active length of a pre-fabricated ceiling mounted radiant panel SIST EN 14037-1:2017

10 3.33 modular thermal output thermal output of one module calculated from the thermal output of the active length of a pre-fabricated ceil-ing mounted radiant panel, resp. the active surface of a heated ceiling surface 3.34 standard modular thermal output thermal output of one module at standard conditions including upper insulation as defined in EN 14037-2 3.35 rated thermal output of a pre-fabricated ceiling mounted radiant panel thermal output evaluated in accordance to EN 14037-3:2016, Clause 5 and referred to the value of the standard modular output of a ceiling mounted radiant panel 3.36 maximum operating pressure maximum system pressure, to which the panel may be submitted as stated by the manufacturer 3.37 factory test pressure (leak test) pressure to which the panel is submitted during the manufacturing process 3.38 emissivity ratio of emissive power of a surface at a given temperature to that of the black body at the same temperature and with the same surroundings SIST EN 14037-1:2017

11 4 Symbols and units For quantities defined in a different part of this standard reference to this part of the standard is made. Table 1 — Symbols and units No. Quantity Symbol Unit 1 Surface area of the non insulated walls

A m2 2 Active surface of a heated ceiling surface module Aa m2 3 Active surface of the ceiling mounted radiant panel b Arp b m2 4 Specific heat capacity cp J/kg K 5 Diameter for connection of inlet/outlet DI/O mm 6 Outside diameter of tubes DO mm 7 Distance between tubes dtub mm 8 Specific enthalpy h J/kg 9 Inlet water enthalpy h1 J/kg 10 Outlet water enthalpy h2 J/kg 11 Height of the void including the height of the test sample hv mm 12 Constant of the characteristic equation of the active length Kact W/ K nact 13 Constant of the characteristic equation of the module KactM W/(m K nact) 14 Constant of the characteristic equation of the connection com-ponents Kcomp W/K ncomp 15 Constant of the characteristic equation of the module based on the rated thermal output Krto W/(m K nact) 16 Constant of the characteristic equation of the construction length Ktot W/K ntot 17 Active length of the ceiling mounted radiant panel Lact mm 18 Height of lateral edges Lle mm 19 Length of radiant sheet Lsh mm 20 Construction length Ltot mm 21 Length of tubes Ltub mm 22 Dry mass M kg 23 Water content mv dm3 24 Exponent of the characteristic equation of the active length nact - 25 Exponent of the characteristic equation of the connection components ncomp - 26 Exponent of the characteristic equation of the construction length ntot - 27 Air pressure p kPa 28 Factory test pressure pfact kPa 29 Maximum operating pressure pmax kPa 30 Standard air pressure ps a kPa SIST EN 14037-1:2017

12 31 Water flow rate qm kg/s 32 Percentage of radiant output R % 33 Thickness of upper insulation si mm 34 Reproducibility tolerance sm W 35 Repeatability tolerance so W 36 Thickness of sheet ssh mm 37 Thermodynamic temperature T K 38 Temperature t °C 39 Inlet water temperature t1 °C 40 Outlet water temperature t2 °C 41 Air temperature ta °C 42 Mean water temperature tm °C 43 Mean radiant temperature tmrad °C 44 Reference room temperature tref °C 45 Mean surface temperature of the ceiling mounted radiant pan-el trp b °C 46 Surface temperature of the inside surfaces of the test booth tw °C 47 Width of ceiling mounted radiant panel Wrp b mm 48 Stephan Boltzmann constant (5,67 × 108)

W/(m2 K4) 49 Emissivity of the test sample

- 50 Time interval

s 51 Output of the active length act W 52 Output of connection components comp W 53 Rated thermal output D W/m 54 Modular thermal output L W/m 55 Standard modular thermal output a Ls W/m 56 Measured output me W 57 Standard output of a master panel of the primary set for Inter-laboratory comparisons M,s W 58 Standard output of a master panel O,s W 59 Radiant output rad W 60 Total output tot W 61 Temperature difference T K 62 Measured temperature difference Tme K 63 Standard temperature difference of a ceiling mounted radiant panel when heating

Ts K a “s” indicates that the value is in standard conditions. b “rp” indicates that the symbol is referred to the ceiling mounted radiant panel. SIST EN 14037-1:2017

13 5 Requirements 5.1 General manufacturing requirements The thermal output of a pre-fabricated ceiling mounted radiant panel is mainly transferred downwards to the space by radiation. The thermal output upwards shall be minimized by insulation. The maximum surface temperature of the lateral edges shall not exceed the minimum surface temperature of the radiant sheet between the last two wet surfaces. For ceiling panels with a construction according to Figure 1 with a tube pitch of X (mm), the distance between the axis of the outside tubes and the edges has to have a minimum distance of 0,5X (mm). The panel is freely suspended above the useful space and designed to be a permanent part of the building although not a part incorporated in the building structure Air flow across the panel is to be prevented. 5.2 Surface protection If the material in use requires protection, measures for protection against corrosion should be provided. Paint and varnishes used for protection are considered as part of the free hanging heating surface and are, therefore subject to requirement to dangerous substance. When and where required the surface protection of the pre-fabricated ceiling mounted radiant panel shall be in accordance with EN ISO 2409 and its performance declared by the manufacturer by referring to class 0 or 1 given in EN ISO 2409. SIST EN 14037-1:2017

longitudinal section Key 1 connection components 5 upper insulation 2 inlet / outlet 6 radiant sheet 3 drain 7 lateral edge 4 vent

8 fixing for suspension

Lact = Lsh

(only for this example) Figure 1 — Example for a typical ceiling mounted radiant panel 5.3 Materials The manufacturers shall declare the materials used for producing the pre-fabricated ceiling mounted radiant panels 5.4 Surface emissivity The radiating surface of the active heating surface should have an emissivity not lower than 0,8. 5.5 Mechanical resistance 5.5.1 Horizontal curvature of radiant ceiling panels Horizontal curvature should be no more than 10 mm for a 6 m panel when cold. Shorter ceiling panels should have a maximum curvature in proportion. SIST EN 14037-1:2017

15 NOTE These tolerances apply only to manufactured panels before installation, since site welding can cause distor-tion. 5.5.2 Vertical deflection of radiant ceiling panels The maximum vertical deflection between fixing points should be no more than the distance between the fixing points divided by 300 (thus the maximum vertical deflection would be 7 mm for a 2 m distance be-tween fixing points, 10 mm for 3 m between fixing points, etc.) NOTE These tolerances apply only to manufactured panels before installation, since site welding can cause distor-tion. 5.6 Resistance to fixings The fixing points on the pre-fabricated ceiling mounted radiant panel shall be designed to withstand a load of 5 times the allocated mass of the panel, including water, without failure. A loading up to 3 times of the al-located filled mass shall be achieved without any occurrence of permanent deformation. The manufacturer shall submit a statement for the suitability and stability of the fixing points in accordance with pass/fail-criteria. 5.7 Pressure tightness The headers and their connections to the tubes of the active length (wet surface) of all products leaving the factory shall be tested for leaks with a test pressure equal to at least 1,3 times the maximum operating pres-sure stated by the manufacturer and declared in accordance with pass/fail-criteria. The test has to be carried out by using air as pressurizing fluid and be realized by means of a water tank or by leakage indicating mediums and a pneumatic circuit that provides the pressurized air. 5.8 Resistance to pressure A sample of a panel in accordance with EN 14037-2 shall be tested to ensure that no leakage or permanent deformation will occur at the maximum test pressure, which is a factor of 1,69 times the maximum operating pressure stated by the manufacturer and declared in accordance with pass/fail-criteria. 5.9 Dimensional tolerances The dimensional deviations of parts of the panel having an influence on the thermal output shall not be greater than the tolerances indicated in the manufacturer's drawings supplied to the laboratory with the testing samples. Under no circumstances shall they be greater than those stated in Table 2. The adherence of the dimensional tolerances of the test samples shall be verified by the test laboratory before the test of the thermal output. Table 2 — Dimensional tolerances Dimension Tolerances Outside diameter of tubes ±0,50 mm Distance between tubes ±2 % of the distance Length of tubes ±3,00 mm Length of radiant sheet ±3,00 mm Width of ceiling mounted radiant panel ±6,00 mm Thickness of sheet ±0,08 mm Height of lateral edges ±3,00 mm SIST EN 14037-1:2017

16 5.10 Upper Insulation The upper side of the ceiling mounted heating radiant panels shall be provided with insulation. The thermal resistance of the insulation has a substantial influence on the thermal output upwards. Ceiling panels used only for cooling can be realized without upper insulation. For the insulation of the pre-fabricated ceiling mounted radiant panel used by the manufacturer the follow-ing information shall be given: — thermal resistance in m2 K/W and specific mass in kg/m3 at 20 °C; — material for the top cover of the insulation; — reaction to fire of the materials. 5.11 Water flow resistance The manufacturer shall provide documentation containing the pressure losses under different mass flow conditions to calculate water flow resistance for differing types of connections and internal circulations. 5.12 Release of dangerous substances National regulations on dangerous substances may require, verification and declaration on release, and sometimes content, of dangerous substances, when construction products covered by this standard are placed on those markets. In the absence of European harmonized test methods, verification and declaration on release/content should be done taking into account national provisions in the place of use. NOTE An informative database covering European and national provisions on dangerous substances is available at the Construction website on EUROPA accessed through: http://ec.europa.eu/enterprise/construction/cpd-ds/ 5.13 Reaction to fire 5.13.1 General Where use of a pre-fabricated ceiling mounted radiant panels is subject to national regulatory requirements on reaction to fire, its reaction to fire performance shall be considered as the one of its components (i.e. ma-terial approach) and shall be declared as one of the following classes, according to EN 13501-1: a) Class A1, without the need for testing (CWT), when meeting the requirements, specified in 5.13.2, or otherwise, or b) class, defined according to the results of testing of the material(s) used in the unit, according to the standard(s) referred to in EN 13501-1, as specified in 5.13.3. Conversely, where use of such a unit is not subject to national regulatory requirements on reaction to fire, either class, determined according to a) or b) or “No Performance Determined” (NPD) may be declared. 5.13.2 Pre-fabricated ceiling mounted radiant panels classified as Class A1 without the need for testing The reaction to fire performance of pre-fabricated ceiling mounted radiant panels shall be declared as Class A11 without the need for testing, provided that the pre-fabricated ceiling mounted radiant panels are non-coated metallic material or coated metallic material where the coating does not exceed 1,0 mm of thickness

See Decision of the Commission 96/603/EC of 1996-10-04 (see OJEU L 267 of 1996-10-19), as twice amended by 2000/605/EC of 2000-09-26 (see OJEU L 258 of 2000-10-12) and by 2003/424/EC of 2003-06-06 (see OJEU L 144 of 2003-06-12). SIST EN 14037-1:2017

17 and 1,0 kg/m2 of mass per unit area2 and where relevant the insulation material is of class A1 without test-ing. 5.13.3 Pre-fabricated ceiling mounted radiant panels classified according to the test results For the purpose of the reaction to fire performance of the pre-fabricated ceiling mounted radiant panels each of its constituent materials including the insulating material if relevant, shall be classified according to EN 13501-1 and only the lowest class of such materials shall be declared. The class of an individual constitu-ent material shall be obtained as the result of the test method(s), relevant to this class, and as specified in the standards referred to in EN 13501-1. Test specimens used for the test methods, applicable for this classification, shall be prepared according to EN 13501-1 and to the relevant standards referred therein. Only one model is to be tested to assess the reaction to fire of a type. 5.14 Rated thermal output and characteristic equation The rated thermal output as defined in 3.35 and the thermal output under different operating conditions have to be determined according to EN 14037-3:2016. The value of the rated thermal output has to be given in W/m as well as K and n of the characteristic equation

= K „ tn [in W/m] as defined in EN 14037-2:2016, 8.12. 5.15 Surface temperature The maximum surface temperature is assumed equal to the system design inlet water temperature3. 6 Assessment and verification of constancy of performance - AVCP 6.1 General The compliance of pre-fabricated ceiling mounted radiant panels with the requirements of this standard and with the performances declared by the manufacturer in the Declaration of Performance (DoP) shall be demonstrated by: - determination of the product-type on the basis of type testing - factory production control by the manufacturer, including product assessment. The manufacturer shall always retain the overall control and shall have the necessary means to take respon-sibility for the conformity of the product with its declared performance(s). 6.2 Type testing 6.2.1 General All performances related to characteristics included in this standard shall be determined when the manufac-turer intends to declare the respective performances unless the standard gives provisions for declaring them without performing tests. (e.g. use of previously existing data, classification without further testing –CWFT- and conventionally accepted performance).

See Decision 2000/147 EC for non-substantial components. (add the reference to the Official Journal) 3

Pre-fabricated ceiling mounted radiant panels are heat emitters without internal heat source. The maximum water temperature is decided by the system designer and controlled by safety devices in the heating system. SIST EN 14037-1:2017

18 Assessment previously performed in accordance with the provisions of this standard, may be taken into ac-count provided that they were made to the same or a more rigorous test method, under the same AVCP sys-tem on the same product such that the results are applicable to the product in question. For the purposes of assessment, the manufacturer's products may be grouped into families, where it is con-sidered that the results for one or more characteristics from any one product within the family are repre-sentative for that same characteristics for all products within that same family In addition, the determination of the product type shall be performed for all characteristics included in the standard for which the manufacturer declares the performance: — at the beginning of the production of a new or modified pre-fabricated ceiling mounted radiant panels (unless it is a member of the same product range); or — at the beginning of a new or modified method of production (where this may affect the stated proper-ties); or — they shall be repeated for the appropriate characteristic(s), whenever a change occurs in the free hang-ing ceiling mounted radiant panels design, in the raw material, in the supplier of the components (acces-sories) or in the method of production (subject to the definition of a family), which would affect signifi-cantly one or more of the characteristics. Where components are used whose characteristics have already been determined, by the component manu-facturer, on the basis of assessment methods of other product standards, these characteristics need not be re-assessed. The specifications of these components shall be documented. Products bearing regulatory marking in accordance with appropriate harmonized European specifications may be presumed to have the performances declared in the Declaration of Performance (DoP), although this does not replace the responsibility on the pre-fabricated ceiling mounted radiant panels manufacturer to ensure that the pre-fabricated ceiling mounted radiant panels as a whole are correctly manufactured and their component products (accessories) have the declared performance values. 6.2.2 Test samples, testing and compliance criteria The number of samples of pre-fabricated ceiling mounted radiant panels to be tested/assessed shall be in accordance with Table 3. SIST EN 14037-1:2017

19 Table 3 — Number of samples to be tested and compliance criteria Characteristic Requirement

Assessment method

No. of samples

Compliance criteria

Reaction to fire 5.13 5.13 1 per type Meet the intended declared class according to 5.13 Release of dangerous sub-stances 5.12 5.12 In accordance with na-tional regulations in use. According to 5.12 Pressure tightness 5.7 5.7 1 per type. No leakage as pass/fail ac-cording to 5.7 Surface temperature a) 5.15 5.15 Not applicable According to the design of the heating system and never higher than 120 °Ca according to 5.15. Resistance to pressure 5.8 5.8 1 per type No breakage as pass/fail ac-cording to 5.8. Rated thermal output 5.14 5.14 Each model according to EN 14037–2:2016, 8.2 Declared value in W at

= 55 K according to 5.14. Thermal output in different operating conditions (characteristic curve) 5.14 5.14 Each model according to EN 14037–2:2016, 8.2 Declared value for the expo-nent n and the coefficient k of the characteristic equation according to 5.14. Durability against corrosion (surface protection) 5.2 5.2 1 per type 5.2 Resistance to fixings 5.6 5.6 1 per model 5.6 a) Pre-fabricated ceiling mounted radiant panels are heat emitters without internal heat source. The maximum water temperature is decided by the system designer and controlled by safety devices in the heating system. 6.2.3 Test reports The results of the determination of the product type shall be documented in test reports. All test reports shall be retained by the manufacturer for at least 10 years after the last date of production of the pre-fabricated ceiling mounted radiant panels to which they relate. 6.2.4 Shared other party results A manufacturer may use the results of the product type determination obtained by someone else (e.g. by an-other manufacturer, as a common service to manufacturers, or by a product developer), to justify his own declaration of performance regarding a product that is manufactured according to the same design (e.g. di-mensions) and with raw materials, constituents and manufacturing methods of the same kind, provided that: –

the results are known to be valid for products with the same essential characteristics relevant for the product performance; SIST EN 14037-1:2017

20 –

in addition to any information essential for confirming that the product has such same performances related to specific essential characteristics, the other party who has carried out the determination of the product type concerned or has had it carried out, has expressly accepted4 to transmit to the manufac-turer the results and the test report to be used for the latter’s product type determination, as well as in-formation regarding production facilities and the production control process that can be taken into ac-count for FPC; –

the manufacturer using other party results accepts to remain responsible for the product having the de-clared performances and he also: –

ensures that the product has the same characteristics relevant for performance as the one that has been subjected to the determination of the product type, and that there are no significant dif-ferences with regard to production facilities and the production control process compared to that used for the product that was subjected to the determination of the product type; and –

keeps available a copy of the determination of the product type report that also contains the infor-mation needed for verifying that the product is manufactured according to the same design and with raw materials, constituents and manufacturing methods of the same kind. 6.3 Factory production control (FPC) 6.3.1 General The manufacturer shall establish, document and maintain an FPC system to ensure that the products placed on the market comply with the declared performance of the essential characteristics. The FPC system shall consist of procedures, regular inspections and tests and/or assessments and the use of the results to control raw and other incoming materials or components, equipment, the production process and the product. All the elements, requirements and provisions adopted by the manufacturer shall be documented in a sys-tematic manner in the form of written policies and procedures. This factory production control system documentation s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...