EN 16286-1:2024

(Main)Railway applications - Gangway systems between vehicles - Part 1: Main applications

Railway applications - Gangway systems between vehicles - Part 1: Main applications

This document specifies the technical and safety requirements applicable to gangway systems used in heavy rail and urban rail vehicles that are designed to allow passengers or staff to move between adjacent vehicles.

It also specifies:

- the requirements for the safety for passengers and/or staff in the gangway while the train is running,

- the assessment methods as well as pass/fail criteria for gangways installed on vehicles.

NOTE Some requirements in this document may not be applicable for gangways designed for use by staff only.

This document is not intended to specify requirements for articulation systems which can be an integral part of gangway systems.

This document is not applicable for rubber tube gangways and interconnecting gangways for coaches travelling at speeds of up to 200 km/h on high-speed lines with tunnel sections. Information about these types of gangway systems are given in Annex A and Annex B.

Bahnanwendungen - Übergangssysteme zwischen Fahrzeugen - Teil 1: Hauptanwendungen

Dieses Dokument legt die technischen und sicherheitsrelevanten Anforderungen für Übergangssysteme fest, die in Vollbahnen und Fahrzeugen städtischer Schienenbahnen verwendet werden, um Fahrgästen oder Personal den Übergang zwischen angrenzenden Fahrzeugen zu ermöglichen.

Es legt auch Folgendes fest:

die Anforderungen an die Sicherheit für Fahrgäste und/oder Personal im Übergang, während der Zug fährt;

die Bewertungsverfahren sowie Abnahmekriterien für die am Fahrzeug installierten Übergangssysteme.

ANMERKUNG Einige der Anforderungen in diesem Dokument sind möglicherweise nicht für Übergänge anwendbar, die für die ausschließliche Nutzung durch Personal vorgesehen sind.

Dieses Dokument ist nicht dafür vorgesehen, Anforderungen an Gelenksysteme festzulegen, die Bestandteil von Übergangssystemen sein können.

Dieses Dokument ist nicht für Wulstübergänge und Übergangseinrichtungen von Reisezugwagen anwendbar, die mit einer Geschwindigkeit von bis zu 200 km/h auf Hochgeschwindigkeitsstrecken mit Tunnelabschnitten fahren. Informationen zu diesen Arten von Übergangssystemen sind in Anhang A und Anhang B enthalten.

Applications ferroviaires - Systèmes d'intercirculation entre véhicules - Partie 1: Applications générales

Železniške naprave - Prehodni sistemi med vozili - 1. del: Glavne vrste uporabe

Ta evropski standard določa tehnične in varnostne zahteve prehodnih sistemov, ki se uporabljajo za vsa železniška vozila, kot so tramvaji, tramvajski vlaki, vagoni, metroji, vlaki na primestnih in glavnih progah ter vlaki za visoke hitrosti, ki prevažajo potnike. Prehodni sistem omogoča udoben prehod z enega vozila na drugega in vključuje upogljiv sestavni del, ki dopušča relativno gibanje med vozili.

Standard določa tudi:

– zahteve za varnost potnikov in/ali osebje v prehodu med obratovanjem vlaka;

– metode za oceno in merila za sprejem/zavrnitev za prehode, nameščene na vozila.

General Information

- Status

- Published

- Publication Date

- 29-Oct-2024

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/WG 41 - Passenger Gangways

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 30-Oct-2024

- Due Date

- 21-Sep-2023

- Completion Date

- 30-Oct-2024

Relations

- Effective Date

- 15-Jul-2020

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 45545-1:2013 - Railway applications - Fire protection on railway vehicles - Part 1: General - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16286-1:2024 - Railway applications - Gangway systems between vehicles - Part 1: Main applications (CEN) defines technical and safety requirements for gangway systems used on heavy rail and urban rail vehicles that allow passengers or staff to move between adjacent vehicles. The standard covers design limits, safety during train movement, assessment methods and pass/fail criteria for installed gangways. It supersedes EN 16286-1:2013 and updates scope, tests and several technical clauses to reflect current practice.

Key exclusions:

- Not intended to specify articulation systems (even if integral to some gangways).

- Not applicable to rubber tube gangways and certain interconnecting gangways for coaches up to 200 km/h on high‑speed tunnels (informative Annex A and B provide background).

Key Topics and Requirements

EN 16286-1:2024 sets out requirements across design, testing and maintenance, including:

- Geometry and clearway: outer gangway dimensions, clearway for general use and for wheelchairs, length, steps and ramps.

- Loads and structural requirements: vertical, horizontal and dynamic loads, aerodynamic effects, and fixation strength.

- Relative movements: allowable movements between vehicles and required accommodation in gangway design.

- Environmental and safety performance: water tightness, pressure tightness, thermal insulation, acoustic behavior, fire protection, earthing and vandalism resistance.

- Human factors: handrails, safe passage for passengers and staff, wheelchair and service trolley accessibility.

- Crash behaviour and lifetime: durability, endurance testing and pass/fail criteria for reliable in-service performance.

- Interfaces and integration: mechanical interfaces with vehicle bodies, gangway doors, lighting and adjoining components.

- Testing and validation: mass measurement, movement tests, wheelchair/service trolley tests, pressure and water tightness tests, acoustic measurements and new endurance tests (Annex C provides test parameters and criteria).

- Maintenance and documentation: installation, operational handling, cleaning, graffiti removal, and repair instructions.

Applications and Users

This standard is intended for:

- Rail vehicle designers and manufacturers specifying or integrating gangway systems on multiple units, metro trains, trams and coaches.

- Railway undertakings and operators assessing safety and interoperability of gangways in passenger service.

- Certification bodies and testing laboratories performing conformity and endurance testing.

- Maintenance teams and procurement specialists establishing maintenance regimes, repair instructions and procurement specifications.

Practical use cases include designing accessible inter-car connections, validating gangways for mixed urban/heavy rail fleets, and creating contract and acceptance test criteria.

Related Standards

- EN 16286-2 (Part 2): Acoustic measurements - complements Part 1 for sound performance.

- EN 17343 and other referenced normative documents (see Annex ZA for relationship with EU Directive 2016/797).

Keywords: EN 16286-1:2024, gangway systems, railway gangways, rail vehicle interconnection, safety requirements, testing and validation, wheelchair access, CEN.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 16286-1:2024 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Gangway systems between vehicles - Part 1: Main applications". This standard covers: This document specifies the technical and safety requirements applicable to gangway systems used in heavy rail and urban rail vehicles that are designed to allow passengers or staff to move between adjacent vehicles. It also specifies: - the requirements for the safety for passengers and/or staff in the gangway while the train is running, - the assessment methods as well as pass/fail criteria for gangways installed on vehicles. NOTE Some requirements in this document may not be applicable for gangways designed for use by staff only. This document is not intended to specify requirements for articulation systems which can be an integral part of gangway systems. This document is not applicable for rubber tube gangways and interconnecting gangways for coaches travelling at speeds of up to 200 km/h on high-speed lines with tunnel sections. Information about these types of gangway systems are given in Annex A and Annex B.

This document specifies the technical and safety requirements applicable to gangway systems used in heavy rail and urban rail vehicles that are designed to allow passengers or staff to move between adjacent vehicles. It also specifies: - the requirements for the safety for passengers and/or staff in the gangway while the train is running, - the assessment methods as well as pass/fail criteria for gangways installed on vehicles. NOTE Some requirements in this document may not be applicable for gangways designed for use by staff only. This document is not intended to specify requirements for articulation systems which can be an integral part of gangway systems. This document is not applicable for rubber tube gangways and interconnecting gangways for coaches travelling at speeds of up to 200 km/h on high-speed lines with tunnel sections. Information about these types of gangway systems are given in Annex A and Annex B.

EN 16286-1:2024 is classified under the following ICS (International Classification for Standards) categories: 45.060.20 - Trailing stock. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16286-1:2024 has the following relationships with other standards: It is inter standard links to EN 16286-1:2013, EN 50125-1:2014, EN 45545-2:2020+A1:2023, EN 45545-1:2013, EN 12663-1:2010+A2:2023, EN 16286-2:2023, EN 15663:2017+A1:2018, EN 14067-5:2021, EN 16585-3:2017, EN ISO 6946:2017, EN 45545-4:2013, EN 45545-3:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16286-1:2024 is associated with the following European legislation: EU Directives/Regulations: 2016/797/EU; Standardization Mandates: M/483, M/591. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16286-1:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2024

Železniške naprave - Prehodni sistemi med vozili - 1. del: Glavne vrste uporabe

Railway applications - Gangway systems between vehicles - Part 1: Main applications

Bahnanwendungen - Übergangssysteme zwischen Fahrzeugen - Teil 1:

Hauptanwendungen

Applications ferroviaires - Systèmes d'intercirculation entre véhicules - Partie 1:

Applications générales

Ta slovenski standard je istoveten z: EN 16286-1:2024

ICS:

45.060.01 Železniška vozila na splošno Railway rolling stock in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16286-1

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2024

EUROPÄISCHE NORM

ICS 45.060.20 Supersedes EN 16286-1:2013

English Version

Railway applications - Gangway systems between vehicles

- Part 1: Main applications

Applications ferroviaires - Systèmes d'intercirculation Bahnanwendungen - Übergangssysteme zwischen

entre véhicules - Partie 1: Applications générales Fahrzeugen - Teil 1: Hauptanwendungen

This European Standard was approved by CEN on 2 September 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16286-1:2024 E

worldwide for CEN national Members.

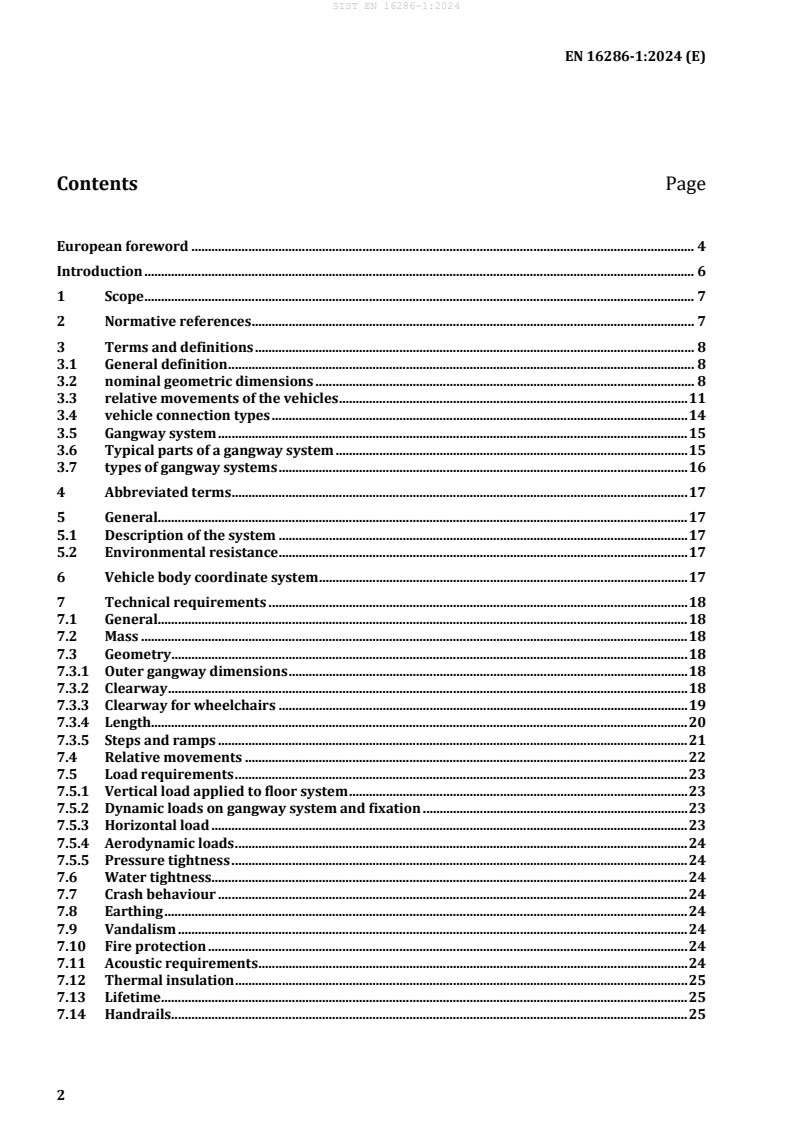

Contents Page

European foreword . 4

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

3.1 General definition . 8

3.2 nominal geometric dimensions . 8

3.3 relative movements of the vehicles . 11

3.4 vehicle connection types . 14

3.5 Gangway system . 15

3.6 Typical parts of a gangway system . 15

3.7 types of gangway systems . 16

4 Abbreviated terms . 17

5 General. 17

5.1 Description of the system . 17

5.2 Environmental resistance . 17

6 Vehicle body coordinate system . 17

7 Technical requirements . 18

7.1 General. 18

7.2 Mass . 18

7.3 Geometry . 18

7.3.1 Outer gangway dimensions . 18

7.3.2 Clearway . 18

7.3.3 Clearway for wheelchairs . 19

7.3.4 Length. 20

7.3.5 Steps and ramps . 21

7.4 Relative movements . 22

7.5 Load requirements . 23

7.5.1 Vertical load applied to floor system . 23

7.5.2 Dynamic loads on gangway system and fixation . 23

7.5.3 Horizontal load . 23

7.5.4 Aerodynamic loads . 24

7.5.5 Pressure tightness . 24

7.6 Water tightness. 24

7.7 Crash behaviour . 24

7.8 Earthing . 24

7.9 Vandalism . 24

7.10 Fire protection . 24

7.11 Acoustic requirements . 24

7.12 Thermal insulation . 25

7.13 Lifetime . 25

7.14 Handrails. 25

7.15 Other requirements . 25

8 Interfaces with the vehicle . 25

8.1 General . 25

8.2 Mechanical interfaces . 25

8.3 Adjoining components . 27

8.3.1 General . 27

8.3.2 Inter-vehicle connections . 27

8.3.3 Gangway doors and separating elements . 28

8.3.4 Tail and head lights . 28

9 Testing . 28

9.1 Mass measurement . 28

9.2 Movement test . 28

9.3 Wheelchair and service trolley test . 34

9.4 Pressure tightness test . 34

9.5 Water tightness test . 35

9.6 Acoustic measurements . 35

9.7 Endurance test . 35

10 Maintenance . 36

10.1 General . 36

10.2 Installation . 36

10.3 Operational handling . 36

10.4 Cleaning of a gangway . 36

10.5 Removal of graffiti . 36

10.6 Repair instructions . 36

Annex A (informative) Rubber tube gangways . 37

A.1 General . 37

A.2 Construction requirements . 37

Annex B (informative) Interconnecting gangways for coaches travelling at speeds of up to

200 km/h on high-speed lines with tunnel sections . 42

Annex C (informative) Endurance test parameters and test criteria . 43

C.1 General . 43

C.2 Pass/fail criteria . 44

Annex ZA (informative) Relationship between this European Standard and the Essential

requirements of Directive (EU) 2016/797 aimed to be covered . 46

Bibliography . 48

European foreword

This document (EN 16286-1:2024) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2025, and conflicting national standards shall be

withdrawn at the latest by April 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 16286-1:2013.

1:2013:

— Scope has been modified and adopted to current wording of EN 17343;

— Normative references have been updated;

— Terms and definitions have been revised;

— 7.3.1 “Outer gangway dimensions” has been revised;

— 7.3.2 “Clearway” has been revised;

— 7.3.3 “Clearway for wheelchairs” has been revised;

— 7.3.5 “Steps and ramps” has been revised;

— 7.4 “Relative movements” has been revised;

— 7.5.1 “Vertical load applied to floor system” has been revised;

— 7.5.4 “Aerodynamic loads” has been revised;

— New 7.14 “Handrails” has been added;

— 7.15 “Other requirements” (former 7.9) has been revised;

— 8.2 “Mechanical interfaces” has been revised;

— 9.2 “Movement test” has been revised;

— 9.3 “Wheelchair and service trolley test” has been revised;

— 9.4 “Pressure tightness test” has been revised;

— 9.5 “Water tightness” has been revised;

— New 9.7 “Endurance test” has been added;

— 10.4 “Cleaning of a gangway” has been revised;

— New 10.6 “Repair instructions” has been added;

— Annex A has been and changed to “informative”;

— New informative Annex C “Endurance test parameters and test criteria” has been added;

— Update of Annex ZA.

This series of European Standards EN 16286, Railway applications — Gangway systems between vehicles,

consists of the following parts:

— Part 1: Main applications

— Part 2: Acoustic measurements

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

Introduction

The railway system requires technical rules for train concepts with flexible connections which allow

passage from one vehicle to the next vehicle (or between vehicle modules). This document describes

main requirements for the design and validation of gangway systems.

The requirements set out in this document are based on long-term existing practices and procedures

developed and currently in use by railway undertakings and industry. The application of these systems

has changed over the years.

For many years the majority of gangway systems consisted of rubber tubes pressed together when

coaches were coupled. This solution was standardized in UIC leaflet 561:1991 with the aim to

reconfigure train sets. Information about the main requirements of this leaflet has been incorporated in

this document as Annex A.

The aim of EN 16286-1 is to cover project-specific solutions, which have been developed for each train

set; for example, for multiple units, metro vehicles or tram vehicles.

1 Scope

This document specifies the technical and safety requirements applicable to gangway systems used in

heavy rail and urban rail vehicles that are designed to allow passengers or staff to move between

adjacent vehicles.

It also specifies

— the requirements for the safety for passengers and/or staff in the gangway while the train is

running,

— the assessment methods as well as pass/fail criteria for gangways installed on vehicles.

NOTE Some requirements in this document may not be applicable for gangways designed for use by staff

only.

This document is not intended to specify requirements for articulation systems which can be an integral

part of gangway systems.

This document is not applicable for rubber tube gangways and interconnecting gangways for coaches

travelling at speeds of up to 200 km/h on high-speed lines with tunnel sections. Information about

these types of gangway systems are given in Annex A and Annex B.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12663-1:2010+A2:2023, Railway applications - Structural requirements of railway vehicle bodies -

Part 1: Locomotives and passenger rolling stock (and alternative method for freight wagons)

EN 14067-5:2021, Railway applications - Aerodynamics - Part 5: Requirements and assessment

procedures for aerodynamics in tunnels

EN 15663:2017+A1:2018, Railway applications - Vehicle reference masses

EN 16286-2:2023, Railway applications - Gangway systems between vehicles - Part 2: Acoustic

measurements

EN 16585-3:2017, Railway applications - Design for PRM use - Equipment and components on board

rolling stock - Part 3: Clearways and internal doors

EN 45545-1:2013, Railway applications - Fire protection on railway vehicles - Part 1: General

EN 45545-2:2020+A1:2023, Railway applications - Fire protection on railway vehicles - Part 2:

Requirements for fire behaviour of materials and components

EN 45545-3:2013, Railway applications - Fire protection on railway vehicles - Part 3: Fire resistance

requirements for fire barriers

EN 45545-4:2013, Railway applications - Fire protection on railway vehicles - Part 4: Fire safety

requirements for rolling stock design

EN 50125-1:2014, Railway applications - Environmental conditions for equipment - Part 1: Rolling stock

and on-board equipment

EN ISO 6946:2017, Building components and building elements - Thermal resistance and thermal

transmittance - Calculation methods (ISO 6946:2017, Corrected version 2021-12)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1 General definition

3.1.1

nominal position

gangway position on straight level track where all relative movements of the vehicles are zero

Note 1 to entry: See 7.4 for relative movements.

3.2 nominal geometric dimensions

NOTE Nominal dimensions are defined on straight level track, vehicle suspension in nominal condition, and

mass of the vehicle in the “as built” condition (dead mass), as defined in EN 15663.

3.2.1

length

distance between the vehicle-connection surfaces of a gangway with the coupler or articulation at the

nominal position

3.2.2

width

distance between lateral inner face of the gangway

Note 1 to entry: The width is often measured at shoulder height.

Note 2 to entry: See Figure 1.

3.2.3

horizontal clearway

unobstructed distance between lateral inner faces of the gangway at floor level

Note 1 to entry: See Figure 1.

Note 2 to entry: The horizontal clearway may be reduced above the floor level provided it maintains the

minimum dimensions in 7.3.2.

3.2.4

vertical clearway

unobstructed distance between gangway floor level and the interior ceiling or panel of the gangway

Note 1 to entry: See Figure 1.

3.2.5

outer gangway width

maximum overall outer width of the gangway

Note 1 to entry: See Figure 1.

3.2.6

outer gangway height

overall outer height of the gangway

Note 1 to entry: See Figure 1.

3.2.7

gangway floor height

distance between floor level of the gangway and top of the rail

Note 1 to entry: See Figure 1.

3.2.8

reference point

intersection of floor level with vehicle centre plane at the vehicle end

Key

1 horizontal clearway 6 outer gangway height

2 width 7 gangway floor height

3 vertical clearway 8 top of the rail

4 skirts, inner panel, etc. 9 vehicle centre plane

5 outer gangway width 10 reference point

Figure 1 — Gangway – design example

3.3 relative movements of the vehicles

NOTE Real relative movements of the vehicles typically consist of any combination of the movements defined

in 3.3.1 to 3.3.7.

3.3.1

longitudinal displacement

x

deflection of the length of the gangway in longitudinal direction on track

Note 1 to entry: Longitudinal displacement is the extension or compression of the nominal length, see Figure 2.

Note 2 to entry: Longitudinal displacement is generated, for example, by buff and draw of the connected coupling

system.

Key

1 nominal length

2 compressed length

3 extended length

xb longitudinal displacement (buff)

xd longitudinal displacement (draw)

Figure 2 — Longitudinal displacement

3.3.2

vertical displacement

z

vertical distance between reference point of vehicle 1 and reference point of vehicle 2

Note 1 to entry: See Figure 3.

Key

1 vehicle 1

2 vehicle 2

3 reference points

z vertical displacement

Figure 3 — Vertical displacement

3.3.3

lateral displacement

y

lateral distance between reference point of vehicle 1 and reference point of vehicle 2

Note 1 to entry: See Figure 4.

Key

1 vehicle 1

2 vehicle 2

3 reference points

y lateral displacement

Figure 4 — Lateral displacement

3.3.4

yaw angle

α

z

angle between the vehicle ends measured around z-axis

Note 1 to entry: See Figure 5

Key

1 vehicle 1

2 vehicle 2

α yaw angle

z

Figure 5 — Yaw angle

3.3.5

pitch angle

α

y

negative or positive angle between vehicle ends, measured around the y-axis

Note 1 to entry: See Figure 6.

a) negative angle (concave) b) positive angle (convex)

Key

1 vehicle 1

2 vehicle 2

αy pitch angle

Figure 6 — Pitch angle

3.3.6

roll angle

α

x

rotation around the longitudinal x-axis (roll centre) that defines the angle between vehicle centre

plane 1 (vehicle 1) and vehicle centre plane 2 (vehicle 2)

Note 1 to entry: See Figure 7.

3.3.7

roll centre height

h

vertical distance from top of rail to the roll centre

Note 1 to entry: See Figure 7.

Key

h roll centre height

αx roll angle

Figure 7 — Roll angle

3.4 vehicle connection types

3.4.1

vehicle connection by coupling system

type of vehicle connection in which the relative movements of the connected vehicles are influenced by

two or more pivot points

3.4.2

vehicle connection by articulation

type of vehicle connection in which the relative movements of the connected vehicles are influenced by

only one pivot point

3.5 Gangway system

3.5.1

gangway system

flexible assembly between adjacent rail vehicles or vehicle segments designed to allow transit from one

vehicle to another

Note 1 to entry: Such gangway systems are often simply called gangway.

Note 2 to entry: In this document the term “vehicle” is used for “rail vehicle” and “rail vehicle segment” as defined

in EN 17343:2023.

[SOURCE: EN 17343:2023, 3.1.8.5.2, modified – “rail” deleted in the second occurrence, Note 1 to entry

and Note 2 to entry added.]

3.6 Typical parts of a gangway system

3.6.1

bellows

articulating environmental envelope surrounding the passageway which is typically comprised of

bellows fabric and bellows frames

Note 1 to entry: This can also describe the flexible elements of a rubber tube gangway.

3.6.1.1

bellows fabric

flexible material which enables the movements of the bellows and which provides protection against

external environmental conditions

Note 1 to entry: Typically made by a laminate which comprises fabric and elastomer layers.

3.6.1.2

bellows frame

intermediate mechanical structure which provides stability in shape and which is connected to the

bellows fabric

Note 1 to entry: This is also called clamp, crimp or hoop.

3.6.1.3

skirt

projection from the inner sidewall above floor level preventing gapping hazards

3.6.2

end frame

mechanical structure which connects the bellows to the carbody structure

Note 1 to entry: This is also called screw-on frame, mounting frame, couple frame.

Note 2 to entry: The end frame can consist of two individual frames in case of latching requirement.

3.6.3

centre frame

intermediate mechanical structure which provides stability in shape and which is connected to the

bellows typically providing a higher stiffness and a larger cross-section than a bellows frame

Note 1 to entry: A centre frame is typically located in central position of the bellows (in the direction of the x-axis)

and can be supported, e.g. by the coupler.

Note 2 to entry: The centre frame can consist of two individual frames in case of latching requirement.

3.6.4

floor system

floor structure capable of carrying passengers and staff and accommodating relative movements

between vehicles

Note 1 to entry: This is also called tread plate, bridge plate, rubber bridge system, turntable, chain bridge or

linking bridge.

3.6.5

side panel

vertical cover of the inner sidewall

3.6.6

ceiling panel

horizontal cover of the inner ceiling surface

3.7 types of gangway systems

3.7.1

intermediate gangway system

gangway system, which is located between vehicles of a dedicated train set

3.7.2

front end gangway system

gangway system, which is located on the outer end of the end vehicle of a dedicated train set

Note 1 to entry: The front end gangway system is located on the same vehicle end as the driver’s cab.

4 Abbreviated terms

For the purposes of this document, the following abbreviated terms apply.

DP depot position = movement position under depot condition

HVAC heating, ventilation and air conditioning

MSP maximum service position = movement position under maximum operational service

condition (in accordance with Table 1 and in accordance with Table 2 (I))

M-I vehicle category “high speed and long distance units” in accordance with

EN 15663:2017+A1:2018

M-II vehicle category “passenger vehicles other than high speed and long distance units” in

accordance with EN 15663:2017+A1:2018

PND normal design payload in accordance with EN 15663:2017+A1:2018

PRM people with reduced mobility

PXD exceptional payload in accordance with EN 15663:2017+A1:2018

RSP reduced service position = movement position under reduced operational service condition

(70 % of MSP)

TOF top of floor

TOR top of rail

5 General

5.1 Description of the system

A gangway is a system located between two rail vehicles that allows passage between those vehicles by

passengers and/or staff. The gangway prevents users from falling from the train and provides a

specified and agreed level of protection from external environmental conditions. The gangway system

accommodates all relative movements between the vehicles it connects.

Additional features may be added according to the specification.

5.2 Environmental resistance

The design of gangways shall take into account the environmental conditions to which they will be

subjected. Environmental parameters, described in EN 50125-1:2014, shall be considered in the

specification for the gangway.

6 Vehicle body coordinate system

The coordinate system is shown in Figure 8. The positive direction of the x-axis (corresponding to

vehicle body longitudinal axis) is in the direction of movement. The positive direction of the z-axis

(corresponding to vehicle body vertical axis) points upwards. The y-axis (corresponding to vehicle body

transverse axis) is in the horizontal plane completing a right hand coordinate system.

NOTE Conventional coach pictured, but gangways can also connect modules of a multi-moduled vehicle

typically in tram applications.

Key

1 direction of movement

x longitudinal axis

y lateral axis

z vertical axis

Figure 8 — Vehicle body coordinate system

7 Technical requirements

7.1 General

A specification for the gangway with the following minimum requirements shall be established.

7.2 Mass

The maximum mass of the gangway system should be specified in the specification.

NOTE 1 System architecture, dimensional and acoustic requirements have an important influence on the mass.

NOTE 2 Weight is a commonly used term to describe mass.

7.3 Geometry

7.3.1 Outer gangway dimensions

The outer gangway dimensions shall respect the vehicle gauge.

For front end gangway systems the driver’s viewing requirements also influence the outer gangway

dimensions, as the gangway shall not obstruct any required viewing angles. Any assessment of the

driver's view shall be carried out with the gangway uncoupled, folded back and locked.

7.3.2 Clearway

The dimensions of the clearway shall be in accordance with EN 16585-3:2017 for the clearway between

connecting vehicles on straight and level track condition as shown in Figure 9.

NOTE 1 EN 16585-3:2017, 5.3, allows exceptions to the dimensions shown in Figure 9.

NOTE 2 For front end gangway systems, the essential requirement for drivers' sight line in combination with

small vehicle profiles can necessitate a reduction of these values.

Dimensions in millimetres

Key

1 TOF

2 gangway shape

x length of the gangway

Figure 9 — Volume representing the clearway between connected vehicles

7.3.3 Clearway for wheelchairs

It shall be specified in the specification, if the gangway is a wheelchair accessible area. If the gangway is

a wheelchair accessible area the volume as shown in Figure 10 shall be maintained as clearway over the

length of the gangway, as well as in associated gangway doors, in nominal position and should be

maintained in each service condition.

NOTE 1 The required free width can be reduced to no less than 700 mm up to a level of 400 mm above floor

during the operational service conditions as specified in Table 2 (see also prEN 16585-2:2022, Figure B.4).

NOTE 2 To verify the accessibility for a wheelchair a representative obstacle according to prEN 16585-2:2022,

Figure B.3 and Figure B.4 (but with a length not longer than the gangway length) can be positioned in the gangway

passenger area.

Dimensions in millimetres

Key

1 TOF

2 gangway shape

x length of the gangway

Figure 10 — Volume representing the clearway between connected vehicles for wheelchairs

7.3.4 Length

The length of the gangway shall be chosen so that the gangway has the capability to accommodate all

relative movements of the vehicles.

7.3.5 Steps and ramps

Discontinuities within the gangway floor and the floor transition from one vehicle to the gangway, as

well as from the gangway to the connected vehicle, should be minimized to facilitate passage without

trip and stumble hazards. Height changes ≤ 15 mm in nominal position can be considered to be a step

and do not have to comply with EN 16585-3:2017.

Height changes ≤ 3 mm do not need to have chamfered or rounded edges, see Figure 11.

Dimensions in millimetres

Figure 11 — Example for a height change ≤ 3 mm

Height changes > 3 mm and ≤ 15 mm in nominal position shall have chamfered or rounded edges.

Figure 12 gives examples for chamfered and rounded edges.

Dimensions in millimetres

a) Example for a chamfered edge

b) Example for a rounded edge

Key

1 tangential transitions

a recommended

Figure 12 — Examples for height change > 3 mm and ≤ 15 mm

For height changes > 15 mm, the first ≤ 15 mm can be considered to be a step but any additional

increase in height shall be considered to be a ramp in accordance with EN 16585-3:2017, see Figure 13.

The minimum horizontal walking floor length between successive ramps, as specified in

EN 16585-3:2017, 5.4 (4), is not applicable for the gangway system.

Dimensions in millimetres

Key

1 vertical discontinuity in accordance with Figure 11 or Figure 12

2 ramp in accordance with EN 16585-3:2017

Figure 13 — Example for a height change > 15 mm

It shall be specified in the specification, if the gangway is a wheelchair accessible area. If the gangway is

a wheelchair accessible area, any ramps shall comply with EN 16585-3:2017, Table 4. If the gangway is

not a wheelchair accessible area, any ramps shall comply with EN 16585-3:2017, Table 5.

7.4 Relative movements

Maximum movements shall be specified in the specification. It is recommended to record the derivation

of the corresponding values.

During the design phase, movement studies for all movement conditions shall be carried out in

accordance with Table 2.

NOTE 1 In depot conditions, interior safety requirements can be relaxed considering that no passengers but

trained staff can be present.

A movement study shall be carried out to ensure that the gangway system performs all required

movements without any damage. The requirements described in 7.3 shall be verified.

Table 1 gives relevant relative movements for different types of vehicle connections.

Table 1 — Relevant relative movements for types of vehicle connections

Longitudinal

displacement

Vertical Lateral Yaw Pitch Roll

Connection Combi-

displacement displacement angle angle angle

Compressed Extended

types nations

length length

xb xd z y az ay ax

Vehicle

connection

X X X X X X X X

by coupling

system

Vehicle

connection

a a a

0 0 0 0 X X X X

by

articulation

X = applicable

0 = not applicable

a

In some articulations movements can appear (e.g. as a result of energy absorption), so that the value is no longer 0.”

The movements to be considered are, for example

— longitudinal displacements caused by coupler and energy absorbing systems,

— vertical displacements caused by loading, wheel wear, degraded suspension conditions,

— lateral displacements caused by s-curves and lateral clearance of bogies and wheel/rail,

NOTE 2 For vehicles connected by coupling systems, EN 16839:2022, Annex B provides some positions for

the vehicles that can be used for the assessment of the lateral displacements.

— yaw angle caused by curve negotiation, curve entrance,

— pitch angle caused by crest and hollow and uneven wheel wear in one vehicle,

— roll angle caused by cant in curves or lateral acceleration,

— derailment and rerailment, lifting scenarios,

— dynamic effects.

NOTE 3 This list is not exhaustive.

7.5 Load requirements

7.5.1 Vertical load applied to floor system

A static passenger load on the floor area shall be specified in the specification in accordance with

EN 15663:2017+A1:2018 for service condition. Loading capability of the floor may be demonstrated by

calculation or test, typically in nominal position, unless otherwise specified.

The floor system shall withstand a static load of 800 N applied over a surface of 100 mm × 200 mm at

any point of the floor system.

The relevant acceptance criteria are

— to verify the strength of the structure when subjected to the maximum loads,

— to verify that no significant permanent deformation is present after removal of the maximum loads.

NOTE Additional, special loads and accelerations in accordance with EN 12663-1 can be specified in the

specification.

7.5.2 Dynamic loads on gangway system and fixation

Accelerations, specified in EN 12663-1:2010+A2:2023 for equipment attachments, as well as forces

generated by the relative movements shall be taken into account.

7.5.3 Horizontal load

The gangway sidewall of the clearway shall carry a load simulating a person leaning against the

sidewall. Perpendicular surface loads acting from within the gangway shall be applied without causing

any permanent deformation:

— a load of 15 % × 80 kg × 9,81 m/s = 120 N representing a hand of a person over an area of

0,1 m × 0,1 m on any area of the surface of the gangway;

— a load of 80 kg × 9,81 m/s = 800 N representing the shoulders of a person over an area of vertical

extension of 0,2 m and a horizontal extension of 0,5 m centred at 1,3 m above floor level anywhere

on that line.

The gangway shall stay in the gauge of the vehicle when the loads are applied.

7.5.4 Aerodynamic loads

The gangway shall be capable of resisting against aerodynamic loads that occur when trains are

crossing in open air and tunnels, without infringing the vehicle gauge requirements or showing any

permanent deformation.

The aerodynamic loads shall be specified in the specification. Verification shall be demonstrated by test

or by analogy. The requirements given in EN 14067-5:2021 shall be considered including simplified

load cases for low speeds.

7.5.5 Pressure tightness

If pressure tightness is required, the pressure P and the pressure difference ΔP per time interval shall

be specified to meet the overall vehicle requirements. The values for over pressure and under pressure

shall be specified.

7.6 Water tightness

There shall be no ingress of water caused by rain, melting snow and cleaning procedures from outside

through the gangway systems and its interface with the vehicle into the passenger area.

Vehicles with gangway systems which are not able to fulfil these requirements (e.g. rubber tube

gangways, see Annex A) shall be equipped with water tight gangway doors or other measures to avoid

problems with water that enters via the gangway.

Drainage may be provided to prevent accumulation of liquids within the gangway.

7.7 Crash behaviour

In case of crash scenarios, the components of the gangway system shall not prevent the function of the

crash protection equipment (e.g. energy absorber elements or anti climbers). The minimum length of

compressed gangway components shall be taken into account.

7.8 Earthing

If the earthing concept for the vehicle has requirements for the gangway, they shall be included in the

specification.

7.9 Vandalism

If there are requirements for vandalism resistance they shall be specified in the specification.

7.10 Fire protection

The gangway shall be designed in accordance with EN 45545-1:2013, EN 45545-2:2020+A1:2023,

EN 45545-3:2013 and EN 45545-4:2013.

7.11 Acoustic requirements

Sound reduction index R shall be specified in the specification in accordance with EN 16286-2:2023.

No squeaks, whistles, bangs or rattles shall be generated by the gangway system in operation.

7.12 Thermal insulation

If required, the calculation of the coefficient for thermal insulation shall be performed according to

EN ISO 6946:2017 or other internationally accepted standards.

7.13 Lifetime

The lifetime of a gangway shall be specified and ensured by a maintenance program.

7.14 Handrails

It shall be specified in the specification, if and what kind of a handrail shall be located inside the

ga

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...