EN 341:2011

(Main)Personal fall protection equipment - Descender devices for rescue

Personal fall protection equipment - Descender devices for rescue

This European Standard specifies requirements, test methods, marking and information to be supplied by the manufacturer for descender devices, which include descent lines (hereinafter referred to as lines), intended for rescue and to protect against falls in a rescue system, which is a personal fall protection system. This European Standard does not specify requirements for descender devices that are used for descending in mountaineering, rope access or work positioning systems.

NOTE A descender device which enables the user to rescue himself and which conforms to this European Standard is personal protective equipment (PPE).

Persönliche Absturzschutzausrüstung - Abseilgeräte zum Retten

Diese Europäische Norm legt Anforderungen, Prüfverfahren, Kennzeichnung und Informationen des Herstellers für Abseilgeräte, einschließlich des Tragmittels zum Abseilen (im Folgenden kurz als Tragmittel bezeichnet), zur Rettung und zum Schutz gegen Absturz in einem Rettungssystem, das ein persönliches Absturzschutzsystem ist, fest. Diese Europäische Norm legt keine Anforderungen für Abseilgeräte fest, die im Bergsport, bei seilunterstützten Arbeiten oder bei Systemen der Arbeitsplatzpositionierung benutzt werden. ANMERKUNG Ein Abseilgerät, das es dem Benutzer ermöglicht, sich selbst zu retten, und das dieser Europäischen Norm entspricht, ist eine persönliche Schutzausrüstung (PSA).

Équipement de protection individuelle contre les chutes - Descendeurs pour sauvetage

La présente Norme européenne prescrit les exigences, les méthodes d’essai, le marquage et les informations à fournir par le fabricant (notice d’information du fabricant) relatifs aux descendeurs, lesquels comprennent les supports d’assurage pour la descente (appelés ci-après supports d’assurage), destinés au sauvetage et à assurer une protection contre les chutes dans un système de sauvetage, qui constitue un système de protection individuelle contre les chutes. La présente Norme européenne ne spécifie aucune exigence concernant les descendeurs qui sont utilisés en alpinisme/en escalade ou avec les systèmes d'accès par corde ou de maintien au poste de travail.

NOTE Un descendeur qui permet à l'utilisateur de se sauver lui-même et qui est conforme à la présente Norme européenne est un équipement de protection individuelle (EPI).

Osebna varovalna oprema za zaščito pred padci z višine - Naprave za spuščanje ob reševanju

Ta evropski standard določa zahteve, preskusne metode, označevanje in informacije, ki jih mora zagotoviti proizvajalec za naprave za spuščanje, vključno z vodom za spuščanje, namenjenim izključno za reševanje, ki se uporabljajo v povezavi z drugo opremo, npr. pasovi za celo telo (EN 361), reševalnimi pasovi (EN 1497). Ta evropski standard ne določa zahtev za naprave za spuščanje, ki se uporabljajo za druge namene kot reševanje, npr. za gorništvo, dostopanje z vrvjo in delovne namestitvene sisteme. Naprave za spuščanje so lahko namenjene uporabi za eno ali dve osebi hkrati.

General Information

- Status

- Published

- Publication Date

- 21-Jun-2011

- Withdrawal Date

- 30-Dec-2011

- Technical Committee

- CEN/TC 160 - Protection against falls from height including working belts

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 09-May-2017

- Completion Date

- 11-Feb-2026

Relations

- Replaces

EN 341:1992/AC:1993 - Personal protective equipment against falls from a height - Descender devices - Effective Date

- 29-Jun-2011

- Replaces

EN 341:1992/A1:1996 - Personal protective equipment against falls from a height - Descender devices - Effective Date

- 29-Jun-2011

- Effective Date

- 29-Jun-2011

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 528:2021 - Rail dependent storage and retrieval equipment - Safety requirements for S/R machines - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 19-Jan-2023

Overview

EN 341:2011 - Personal fall protection equipment - Descender devices for rescue (CEN) defines safety, testing, marking and user information requirements for descender devices that include descent lines (wire, textile rope or webbing) intended for rescue and for fall protection within a rescue system. The standard applies to devices used to lower people safely from a higher to a lower position and explicitly excludes descender devices intended for mountaineering, rope access or work positioning. A descender device enabling self-rescue and conforming to EN 341:2011 is classified as personal protective equipment (PPE).

Key topics and technical requirements

- Scope and classification

- Covers automatic (type 1) and manually‑operated (type 2) descender devices.

- Devices are classified by descent energy: Class A (up to 7.5×10^6 J), B (up to 1.5×10^6 J), C (up to 0.5×10^6 J) and D (single descent; energy depends on height/load).

- Design, materials and construction

- Lines may be steel/stainless steel wire rope, textile kernmantel rope or webbing; specific construction and termination rules apply.

- Materials in contact with skin must not cause irritation; no sharp edges that could damage rope or harm the user.

- Minimum and maximum rated loads must be specified (maximum rated load ≥ 100 kg).

- Performance and function

- Descent velocity requirements: continuous descent between 0.5 m/s and 2 m/s (class‑dependent and subject to wet/cold test conditions).

- Temperature limits for user‑handled parts: surface heat must not exceed 48 °C during descent.

- Panic‑locking and control device behaviour are specified for user safety.

- Strength and durability testing

- Dynamic strength, static strength, descent energy and line integrity tests are defined.

- Corrosion resistance and environmental tests (wet, cold) are included.

- Marking and information

- Mandatory manufacturer marking, instructions for use, maintenance and periodic examination requirements.

Applications and users

- Practical uses: emergency evacuation systems, rescue lowering from towers, cable cars, industrial plant rescue, and other organized rescue scenarios where controlled lowering is required.

- Primary users and stakeholders:

- PPE manufacturers and designers of descender devices

- Safety managers, rescue coordinators and procurement officers specifying rescue equipment

- Test laboratories, notified bodies and conformity assessors

- Inspectors and maintenance personnel responsible for periodic examination and user training

Related standards (normative references)

- EN 362 (connectors), EN 363 (personal fall protection systems), EN 364 (test methods), EN 365 (instructions/maintenance), EN 1496 (rescue lifting devices), EN 1891 (low stretch ropes), EN 12385‑1 (steel wire ropes), EN ISO 9227 (salt spray corrosion tests).

Keywords: EN 341:2011, descender devices, personal fall protection, rescue, PPE, descent lines, descent energy, CEN, rescue lowering, testing and marking.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 341:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Personal fall protection equipment - Descender devices for rescue". This standard covers: This European Standard specifies requirements, test methods, marking and information to be supplied by the manufacturer for descender devices, which include descent lines (hereinafter referred to as lines), intended for rescue and to protect against falls in a rescue system, which is a personal fall protection system. This European Standard does not specify requirements for descender devices that are used for descending in mountaineering, rope access or work positioning systems. NOTE A descender device which enables the user to rescue himself and which conforms to this European Standard is personal protective equipment (PPE).

This European Standard specifies requirements, test methods, marking and information to be supplied by the manufacturer for descender devices, which include descent lines (hereinafter referred to as lines), intended for rescue and to protect against falls in a rescue system, which is a personal fall protection system. This European Standard does not specify requirements for descender devices that are used for descending in mountaineering, rope access or work positioning systems. NOTE A descender device which enables the user to rescue himself and which conforms to this European Standard is personal protective equipment (PPE).

EN 341:2011 is classified under the following ICS (International Classification for Standards) categories: 13.340.99 - Other protective equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 341:2011 has the following relationships with other standards: It is inter standard links to EN 341:1992/AC:1993, EN 341:1992/A1:1996, EN 341:1992, EN 362:2004, EN 363:2008, EN 14140:2014, EN 1496:2017, EN 1891:1998, EN 365:2004, EN 12385-1:2002+A1:2008, EN 528:2021+A1:2022, EN 619:2022, EN 528:2021, EN 619:2002+A1:2010, prEN 341. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 341:2011 is associated with the following European legislation: EU Directives/Regulations: 89/686/EEC; Standardization Mandates: M/031. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 341:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Persönliche Absturzschutzausrüstung - Abseilgeräte zum RettenÉquipement de protection individuelle contre les chutes - Descendeurs pour sauvetagePersonal fall protection equipment - Descender devices for rescue13.340.60Protection against falling and slippingICS:Ta slovenski standard je istoveten z:EN 341:2011SIST EN 341:2011en01-december-2011SIST EN 341:2011SLOVENSKI

STANDARDSIST EN 341:2002SIST EN 341:2002SIST EN 341:1996/AC:19981DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 341

June 2011 ICS 13.340.99 Supersedes EN 341:1992English Version

Personal fall protection equipment - Descender devices for rescue

Équipement de protection individuelle contre les chutes - Descendeurs pour sauvetage

Persönliche Absturzschutzausrüstung - Abseilgeräte zum Retten This European Standard was approved by CEN on 25 May 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 341:2011: ESIST EN 341:2011

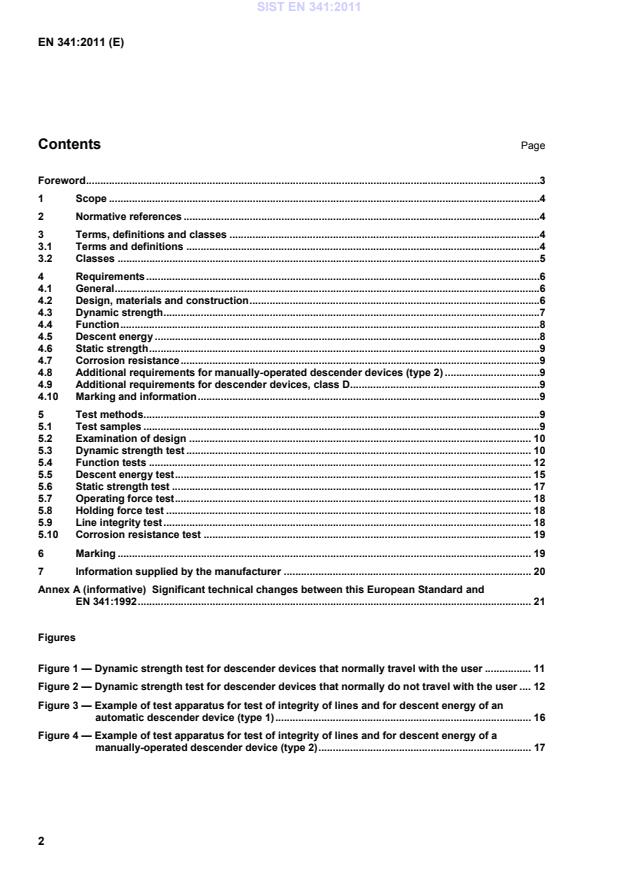

Significant technical changes between this European Standard and EN 341:1992 . 21 Figures Figure 1 — Dynamic strength test for descender devices that normally travel with the user . 11 Figure 2 — Dynamic strength test for descender devices that normally do not travel with the user . 12 Figure 3 — Example of test apparatus for test of integrity of lines and for descent energy of an

automatic descender device (type 1) . 16 Figure 4 — Example of test apparatus for test of integrity of lines and for descent energy of a

manually-operated descender device (type 2) . 17

EN 364:1992, Personal protective equipment against falls from a height — Test methods EN 365:2004, Personal protective equipment against falls from a height — General requirements for instructions for use, maintenance, periodic examination, repair, marking and packaging EN 1496:2006, Personal fall protection equipment — Rescue lifting devices EN 1891:1998, Personal protective equipment for the prevention of falls from a height — Low stretch kernmantel ropes EN 12385-1, Steel wire ropes — Safety — Part 1: General requirements

EN ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests (ISO 9227:2006) 3 Terms, definitions and classes For the purposes of this document, the terms and definitions of EN 363:2008 and the following apply. 3.1 Terms and definitions 3.1.1 descender device automatic (type 1) or manually-operated (type 2) device, including a line, by which persons can, at a limited velocity, rescue themselves or others from a higher to a lower position in such a way that a free fall is prevented NOTE

A line could be e.g. wire rope, textile rope, or webbing. 3.1.1.1 automatic descender device (type 1) descender device with a braking system that does not require an intervention by the user once the descent has commenced SIST EN 341:2011

Descent energy W = m × g × h × n

where

W

is the descent energy, expressed in joules (J);

m

is the descent load, expressed in kilograms (kg);

g

is the gravity 9,81 m/s2;

h

is the descent height, expressed in metres (m);

n

is the number of descents. 3.1.3 minimum rated load minimum mass of the person(s), including tools and equipment, for the descender device, as specified by the manufacturer

NOTE Minimum rated load is expressed in kilograms. 3.1.4 maximum rated load maximum mass of the person(s), including tools and equipment, for the descender device, as specified by the manufacturer

NOTE Maximum rated load is expressed in kilograms. 3.2 Classes Descender devices are classified as follows: a) class A: descent energy W

up to 7,5 × 106 J; b) class B: descent energy W

up to 1,5 × 106 J; c) class C: descent energy W

up to 0,5 × 106 J; SIST EN 341:2011

4.2 Design, materials and construction 4.2.1 General Materials which may come into contact with the skin of a user shall not be known to, or suspected to, adversely affect user hygiene or health, e.g. cause irritating or sensitization effects, during normal use of the descender device. Descender devices shall not have sharp or rough edges that may cut, abrade or otherwise damage rope or webbing or cause injury to the user.

When descender devices in accordance with this standard have a rescue lifting function, they shall in addition to this European Standard conform to EN 1496:2006, class A. Connectors shall conform to EN 362. 4.2.2 Lines Lines shall be made from steel or stainless steel wire rope, textile rope or webbing. Lines shall have at least one termination. Line ends that do not have a termination shall have an end stop. The ends of the lines shall be protected against slipping through the descender device unintentionally.

Lines including their termination(s) shall be of a type capable of visual inspection or else subject to manufacturers' guidance for appropriate examination. 4.2.2.1 Wire rope lines Wire rope lines shall be made from one piece and shall be stress and torsion relieved.

Wire rope lines made from steel except stainless steel shall be galvanized to EN 12385-1. The nominal tensile strength of the wires of the steel or stainless steel wire rope shall not exceed 1960 N/mm2. SIST EN 341:2011

4.2.2.2 Textile rope lines Textile rope lines for descender devices, class A, B or C shall be of kernmantel construction and shall conform to EN 1891:1998, type A, 4.1 to 4.10.

4.2.2.3 Webbing lines Webbing lines shall meet the requirements of EN 1891:1998, 4.5, 4.6 and 4.10. Webbing lines shall be made from virgin filament or multi-filament synthetic fibres suitable for the use intended. The breaking tenacity of the synthetic fibre shall be known to be at least 0,6 N/tex.

The materials used for the construction of the webbing line shall be known to have a melting point of more than 195 °C. Webbing lines made from polypropylene or polyethylene shall not be used. 4.2.2.4 Line integrity When tested in accordance with 5.9, lines made of stainless steel wire rope or made of textiles containing aramid fibres shall withstand a test force as given in 4.6, applied for 3 min. 4.2.2.5 Terminations, end stops Lines shall be terminated in such a manner that they can be connected, directly or by an appropriate connector as specified by the manufacturer, to a body holding device, e.g. a rescue harness or a rescue loop, or to an anchor device.

Reinforcement or another method shall be used to protect terminations from concentrated wear at all webbing-to-metal fitting interfaces.

All splices shall be secured to prevent the splice from coming open in use.

Eye splices in laid fibre rope shall consist of at least four tucks using all the yarns in the strands. The length of the splicing tails emerging after the last tuck shall be at least one rope diameter. Threads used for sewing shall be physically compatible with the webbing/rope, and the quality shall be compatible to that of the webbing/rope. They shall, however, be of a contrasting shade or colour in order to facilitate visual inspection. When using a knot for forming a termination or as an end stop, the knot shall be secured so that it cannot be opened without the use of a tool. When tested in accordance with 5.6, the tail end of the knot shall have a minimum length of 100 mm. Webbing ends shall be sealed or otherwise prevented from unravelling. Eye terminations of wire ropes shall be made with thimbles and by splices or with thimbles and by pressed ferrules. 4.3 Dynamic strength When tested in accordance with 5.3, the descender device shall not release the test mass and no part of the descender device shall show any signs of breaking or tearing.

a) it shall be possible to maintain a continuous descent velocity between 0,5 m/s and 2 m/s; b) in the case of a manually-operated descender device, the velocity shall not exceed 2 m/s when the control device is in a hands-off position or if applicable any panic locking element is engaged;

c) none of the parts of the descender device handled by the user to control the descents shall develop a temperature higher than 48 °C during the descents. When tested in wet and cold conditions in accordance with 5.4.3, it shall be possible to maintain a continuous descent velocity between 0,5 m/s and 2 m/s. If the manufacturer claims that the descender device can be used at temperatures lower than – 4 °C, it shall be possible to maintain a continuous descent velocity between 0,5 m/s and 2 m/s when tested in very cold conditions in accordance with 5.4.4. 4.4.2 Class D When tested in the dry condition in accordance with 5.4.1:

a) it shall be possible to maintain a continuous descent velocity at a maximum of 2 m/s; b) in the case of a manually-operated descender device, the velocity shall not exceed 2 m/s when the control device is in a hands-off position or if applicable any panic locking element is engaged;

c) none of the parts of the descender device handled by the user to control the descent shall develop a temperature higher than 48 °C during the descent. If the manufacturer claims that the descender device can be used in wet conditions, it shall be possible to maintain the descent velocity at a maximum of 2 m/s when tested in the wet conditions in accordance with 5.4.2. If the manufacturer claims that the descender device can be used in the temperature range of (- 4 to + 2) °C, it shall be possible to maintain the descent velocity at a maximum of 2 m/s when tested in the wet and cold conditions in accordance with 5.4.3. If the manufacturer claims that the descender device can be used at temperatures lower than – 4 °C, it shall be possible to maintain a continuous descent velocity at a maximum of 2 m/s when tested in the very cold conditions in accordance with 5.4.4. 4.5 Descent energy When tested in accordance with 5.5, with the descents being carried out in succession, descender devices, class A, B and C shall meet the following requirements: a) they shall resist the descent energy determined for their class; b) the temperature due to friction shall not affect the function of the descender device; c) it shall be possible to maintain the descent velocity between 0,5 m/s and 2 m/s; d) none of the parts of the descender device handled by the user to control the descents shall develop a temperature higher than 48 °C during the descents. SIST EN 341:2011

4.9 Additional requirements for descender devices, class D After testing in accordance with 5.4, Class D descender devices shall indicate clearly that they have been used. 4.10 Marking and information Marking of the descender device shall be in accordance with Clause 6. Information shall be supplied with the descender device in accordance with Clause 7. 5 Test methods 5.1 Test samples A minimum of two new descender devices shall be provided: one for the purposes of the tests specified in 5.2 and 5.10 and one for the purposes of the tests specified in 5.3, 5.4, 5.5, 5.6, 5.7 and 5.8. SIST EN 341:2011

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...