prEN 341

(Main)Personal fall protection equipment - Descender devices for rescue

Personal fall protection equipment - Descender devices for rescue

This document specifies requirements, test methods, marking and manufacturer’s instructions and information for descender devices fitted with a built-in speed-regulating system, which include descent lines (hereinafter referred to as lines). These descender devices are intended to be used in a rescue system to provide protection against falling from a height when accessing/leaving positions at a height.

This document does not specify requirements for descender devices that are used for descending in mountaineering, rope access or work positioning systems.

Persönliche Absturzschutzausrüstung - Abseilgeräte zum Retten

Dieses Dokument legt Anforderungen, Prüfverfahren, Kennzeichnungen und Herstelleranweisungen und Informationen für Abseilgeräte mit eingebautem Geschwindigkeitssteuerungssystem fest, was Abseiltragmittel (im weiteren Verlauf Tragmittel genannt) beinhaltet. Diese Abseilgeräte sind zur Verwendung in Rettungssystemen als Schutz gegen Sturz aus der Höhe beim Zugang zu oder dem Verlassen von hohen Lagen vorgesehen. In diesem Dokument sind keine Anforderungen an Abseilgeräte vorgesehen, die zum Abseilen beim Bergsteigen, seilunterstütztem Zugang oder Arbeitsplatzpositionierungssystemen verwendet werden.

Équipement de protection individuelle contre les chutes - Descendeurs pour sauvetage

Osebna varovalna oprema za zaščito pred padci z višine - Naprave za spuščanje ob reševanju

General Information

- Status

- Not Published

- Publication Date

- 05-Nov-2026

- Technical Committee

- CEN/TC 160 - Protection against falls from height including working belts

- Current Stage

- 4060 - Closure of enquiry - Enquiry

- Start Date

- 24-Apr-2025

- Due Date

- 21-Mar-2025

- Completion Date

- 24-Apr-2025

Relations

- Effective Date

- 19-Jan-2023

Overview

prEN 341 (CEN) - Personal fall protection equipment - Descender devices for rescue - specifies requirements, test methods, marking and manufacturer’s information for descender devices fitted with a built‑in speed‑regulating system (including the descent line). The standard covers devices intended for use in rescue systems to protect persons from falling when accessing or leaving positions at height. It does not cover descenders used for mountaineering, rope access or work‑positioning systems.

Key topics and technical requirements

- Device types

- Type 1 (automatic): built‑in speed regulation that requires no user intervention once descent starts.

- Type 2 (manually‑operated): speed regulation requires user input (includes descent control elements; panic locking also defined).

- Performance classes

- Devices are classified (A, B, C, D) by their descent energy capability and intended number of descents; class D is limited to a single descent. Exact energy thresholds and classification rules are defined in the standard.

- Lines (descent ropes/webbing)

- Permitted line materials: steel or stainless‑steel wire rope, textile kernmantel rope, or webbing. Terminations and end stops, protection against unintended slipping, and inspection requirements are specified.

- Loads

- Manufacturers must specify minimum rated load and maximum rated load (maximum shall be at least 100 kg when tested).

- Design, materials and user safety

- Materials in contact with skin must not cause harm. Edges must not damage ropes or users. Where a rescue lifting function exists, additional conformity to EN 1496:2017 (class A) is required.

- Tests and verification

- The standard defines dynamic strength, static strength, function tests (including conditioning), descent energy tests, line integrity, operating and blocking forces, and corrosion resistance (e.g., salt spray).

- Marking and documentation

- Required marking, user instructions, maintenance, inspection guidance and manufacturer information are specified.

Practical applications

- Use prEN 341 to design, evaluate, certify or procure rescue descender devices for emergency evacuation or rescue at height (e.g., emergency descent systems on industrial installations, cable cars, or building evacuation systems).

- Valuable for manufacturers, product designers, testing laboratories, conformity assessment bodies, health & safety managers and procurement teams responsible for fall protection equipment and rescue planning.

Who should use this standard

- Manufacturers of descender devices and descent lines

- Test laboratories and certification bodies

- Safety engineers, rescue teams and asset owners specifying rescue equipment

- Procurement officers ensuring compliance with CEN requirements

Related standards

- EN 363 (personal fall protection systems)

- EN 1496 (rescue lifting devices)

- EN 1891 (low‑stretch ropes)

- EN 362 (connectors)

- EN ISO 9227 (corrosion/salt spray tests)

Keywords: prEN 341, descender devices, personal fall protection, rescue descender, built‑in speed‑regulating system, descent lines, CEN standard, fall protection equipment.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

prEN 341 is a draft published by the European Committee for Standardization (CEN). Its full title is "Personal fall protection equipment - Descender devices for rescue". This standard covers: This document specifies requirements, test methods, marking and manufacturer’s instructions and information for descender devices fitted with a built-in speed-regulating system, which include descent lines (hereinafter referred to as lines). These descender devices are intended to be used in a rescue system to provide protection against falling from a height when accessing/leaving positions at a height. This document does not specify requirements for descender devices that are used for descending in mountaineering, rope access or work positioning systems.

This document specifies requirements, test methods, marking and manufacturer’s instructions and information for descender devices fitted with a built-in speed-regulating system, which include descent lines (hereinafter referred to as lines). These descender devices are intended to be used in a rescue system to provide protection against falling from a height when accessing/leaving positions at a height. This document does not specify requirements for descender devices that are used for descending in mountaineering, rope access or work positioning systems.

prEN 341 is classified under the following ICS (International Classification for Standards) categories: 13.340.60 - Protection against falling and slipping; 13.340.99 - Other protective equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 341 has the following relationships with other standards: It is inter standard links to EN 341:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 341 is associated with the following European legislation: EU Directives/Regulations: 2016/425; Standardization Mandates: M/571, M/571 AMD 1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 341 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2025

Osebna varovalna oprema za zaščito pred padci z višine - Naprave za spuščanje

ob reševanju

Personal fall protection equipment - Descender devices for rescue

Persönliche Absturzschutzausrüstung - Abseilgeräte zum Retten

Équipement de protection individuelle contre les chutes - Descendeurs pour sauvetage

Ta slovenski standard je istoveten z: prEN 341

ICS:

13.340.60 Zaščita pred padci in zdrsi Protection against falling and

slipping

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

January 2025

ICS 13.340.99 Will supersede EN 341:2011

English Version

Personal fall protection equipment - Descender devices for

rescue

Persönliche Absturzschutzausrüstung - Abseilgeräte

zum Retten

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 160.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 341:2025 E

worldwide for CEN national Members.

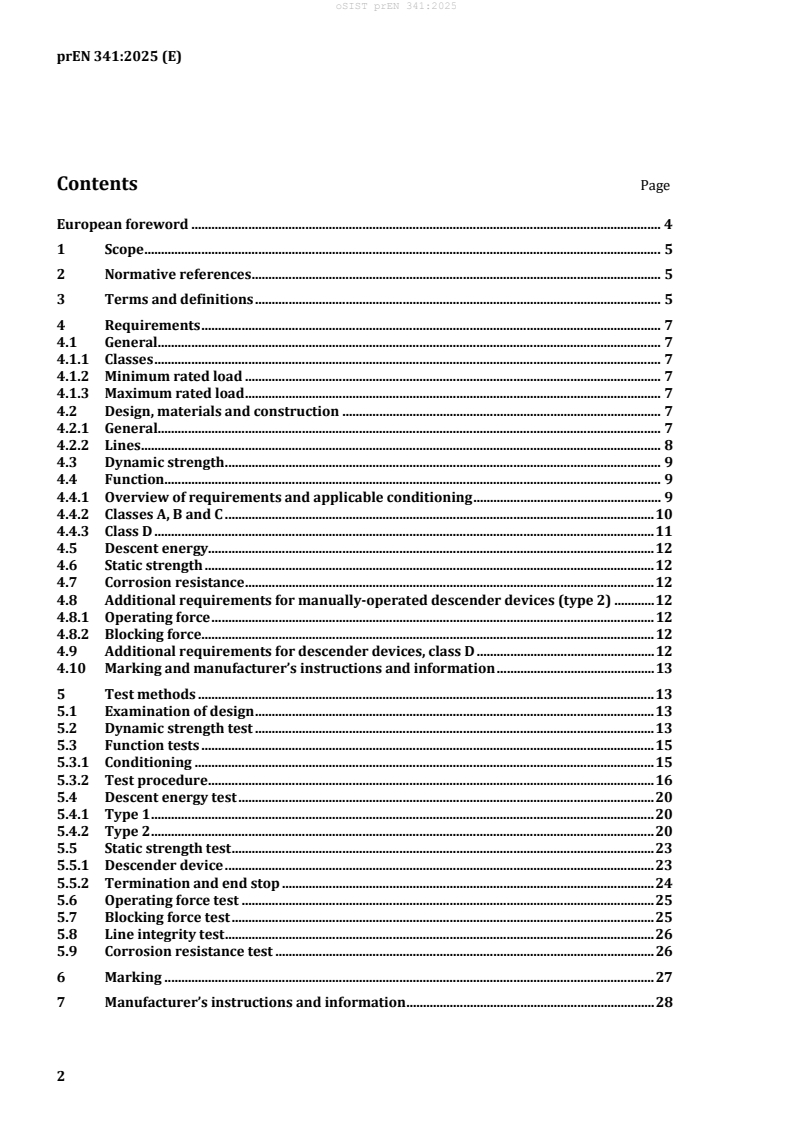

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Requirements . 7

4.1 General. 7

4.1.1 Classes . 7

4.1.2 Minimum rated load . 7

4.1.3 Maximum rated load . 7

4.2 Design, materials and construction . 7

4.2.1 General. 7

4.2.2 Lines . 8

4.3 Dynamic strength . 9

4.4 Function . 9

4.4.1 Overview of requirements and applicable conditioning . 9

4.4.2 Classes A, B and C . 10

4.4.3 Class D . 11

4.5 Descent energy. 12

4.6 Static strength . 12

4.7 Corrosion resistance . 12

4.8 Additional requirements for manually-operated descender devices (type 2) . 12

4.8.1 Operating force . 12

4.8.2 Blocking force. 12

4.9 Additional requirements for descender devices, class D . 12

4.10 Marking and manufacturer’s instructions and information . 13

5 Test methods . 13

5.1 Examination of design . 13

5.2 Dynamic strength test . 13

5.3 Function tests . 15

5.3.1 Conditioning . 15

5.3.2 Test procedure . 16

5.4 Descent energy test . 20

5.4.1 Type 1 . 20

5.4.2 Type 2 . 20

5.5 Static strength test . 23

5.5.1 Descender device . 23

5.5.2 Termination and end stop . 24

5.6 Operating force test . 25

5.7 Blocking force test . 25

5.8 Line integrity test . 26

5.9 Corrosion resistance test . 26

6 Marking . 27

7 Manufacturer’s instructions and information . 28

Annex A (informative) Significant technical changes between this document and EN 341:2011

................................................................................................................................................................... 29

Annex B (informative) Background and rationale about the changes between this document

and EN 341:2011 . 31

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Regulation (EU) 2016/425 aimed to be covered . 33

Bibliography . 35

European foreword

This document (prEN 341:2025) has been prepared by Technical Committee CEN/TC 160 Protection

against falls from height including working belts”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 341:2011.

A list of technical changes between this edition and EN 341:2011 is given in Annex A. Background and

rationale about the changes between this edition and EN 341:2011 is given in Annex B.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

1 Scope

This document specifies requirements, test methods, marking and manufacturer’s instructions and

information for descender devices fitted with a built-in speed-regulating system, which include descent

lines (hereinafter referred to as lines). These descender devices are intended to be used in a rescue

system to provide protection against falling from a height when accessing/leaving positions at a height.

This document does not specify requirements for descender devices that are used for descending in

mountaineering, rope access or work positioning systems.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 363:2018, Personal fall protection equipment — Personal fall protection systems

EN 364:1992, Personal protective equipment against falls from a height — Test methods

EN 365:2004, Personal protective equipment against falls from a height — General requirements for

instructions for use, maintenance, periodic examination, repair, marking and packaging

EN 1496:2017, Personal fall protection equipment — Rescue lifting devices

EN 1891:1998, Personal protective equipment for the prevention of falls from a height — Low stretch

kernmantel ropes

EN 12385-1:2002+A1:2008, Steel wire ropes — Safety — Part 1: General requirements

EN ISO 9227:2022, Corrosion tests in artificial atmospheres — Salt spray tests (ISO 9227:2022)

3 Terms and definitions

For the purposes of this document, the terms and definitions of EN 363:2018 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

descender device

automatic (type 1) or manually-operated (type 2) device, including a line, by which persons can, at a

limited velocity, rescue themselves, themselves and others or solely others from a higher to a lower

position in such a way that a free fall is prevented

Note 1 to entry: In this document the term “device” is used to refer to the descender device without the line.

Note 2 to entry: The device can be designed for a line made from e.g. wire rope, textile rope, or webbing.

As impacted by EN 364:1992/AC:1993

As impacted by EN 365:2004/AC:2006

As impacted by EN ISO 9227:2022/A1:2024

3.1.1

automatic descender device (type 1)

descender device with a built-in speed-regulating system that does not require an intervention by the

user once the descent has commenced

3.1.2

manually-operated descender device (type 2)

descender device with a built-in speed-regulating system that requires an intervention by the user

3.1.3

built-in speed-regulating system

integral braking system of the descender device used to control the velocity of the descent for type 1 and

to stop the descent with hands-off for type 2

3.1.4

descent control element

integral element of the manually-operated descender device, used to control the built-in speed regulating

system

Note 1 to entry: A handle is an example for a descent control element.

3.1.5

panic locking element

integral part or function of the control device which stops the descent and thereby prevents an

uncontrolled descent or a fall if the user panics and operates the descender device beyond its intended

control parameters

3.1.6

attachment point

point at the descender device for connection of the user or to the anchor point

3.2

descent energy

energy measured in joules and expressed as W, which results from the product of the descent load, the

gravity, the descent height and the number of descents

Note 1 to entry: Descent energy W = m × g × h × n

where

W is the descent energy, expressed in joules (J);

m is the descent load, expressed in kilograms (kg);

g is the gravity 9,81 m/s ;

h is the descent height, expressed in metres (m);

n is the number of descents.

3.3

minimum rated load

minimum mass of the person(s), excluding tools and equipment, for the descender device, as specified by

the manufacturer

Note 1 to entry: Minimum rated load is expressed in kilograms.

3.4

maximum rated load

maximum mass of the person(s), including tools and equipment, for the descender device, as specified by

the manufacturer

Note 1 to entry: Maximum rated load is expressed in kilograms.

3.5

man-made fibre

fibre obtained by a manufacturing process

Note 1 to entry: For more information on man-made fibres, refer to ISO/TR 11827:2012.

4 Requirements

4.1 General

4.1.1 Classes

Descender devices are classified as follows:

a) class A: descent energy W ≥ 7,5 × 10 J;

b) class B: descent energy W ≥ 1,5 × 10 J;

c) class C: descent energy W ≥ 0,5 × 10 J;

d) class D: For only one descent. Descent energy depends on the maximum descent height and the

maximum rated load.

NOTE In practice, descender devices are subjected to different loads. A descender device for descending, e.g.

100 passengers from a cable car at a height of 100 m, has to meet more severe requirements than a descender device

used by a crane driver to descend by himself from a height of 20 m only once.

4.1.2 Minimum rated load

The minimum rated load shall be specified by the manufacturer when tested in accordance with 5.1.

4.1.3 Maximum rated load

The maximum rated load shall be specified by the manufacturer and shall be at least 100 kg when tested

in accordance with 5.1.

4.2 Design, materials and construction

4.2.1 General

Materials which can come into contact with the skin of a user shall not be known to, or suspected to,

adversely affect user hygiene or health, e.g. cause irritating or sensitization effects, during normal use of

the descender device.

Descender devices shall not have sharp or rough edges that can cut, abrade or otherwise damage rope or

webbing or cause injury to the user.

When descender devices in accordance with this standard have a rescue lifting function, they shall in

addition to this document conform to EN 1496:2017, class A.

Suitable connectors shall be used (e.g. a connector conforming to EN 362:2004).

These requirements shall be tested in accordance with 5.1.

4.2.2 Lines

4.2.2.1 General

Lines shall be made from steel or stainless steel wire rope, textile rope or webbing.

Lines shall have at least one termination. Line ends that do not have a termination shall have an end stop.

The ends of the lines shall be protected against slipping through the device unintentionally.

Lines including their termination(s) shall be of a type capable of visual inspection or else subject to

manufacturers’ guidance for appropriate examination.

These requirements shall be tested in accordance with 5.1.

4.2.2.2 Wire rope lines

Wire rope lines shall be made from one piece and shall be stress and torsion relieved.

Wire rope lines made from steel except stainless steel shall be galvanized according to

EN 12385-1:2002+A1:2008.

The nominal tensile strength of the wires of the steel or stainless steel wire rope shall not exceed

1960 N/mm .

NOTE A limit of the nominal tensile strength is necessary, because the wires become too brittle with a higher

nominal tensile strength.

Manufacturers of descender devices should be particularly careful when selecting lines made from

stainless steel as some types of stainless steel can have unpredictable fatigue and corrosion

characteristics.

These requirements shall be tested in accordance with 5.1.

4.2.2.3 Textile rope lines

When tested in accordance with 5.1 textile rope lines for descender devices, class A, B or C shall be of

kernmantel construction and shall conform to EN 1891:1998, 4.1 to 4.10, with the requirements of type A.

4.2.2.4 Webbing lines

Webbing lines shall meet the requirements of EN 1891:1998, 4.5, 4.6 and 4.10, with the requirements of

type A.

Webbing lines shall be made from man-made fibres suitable for the use intended. The breaking tenacity

of the man-made fibre shall be known to be at least 0,6 N/tex.

The materials used for the construction of the webbing line shall be known to have a melting point of

more than 195 °C. Webbing lines made from polypropylene or polyethylene shall not be used.

These requirements shall be tested in accordance with 5.1.

4.2.2.5 Line integrity

When tested in accordance with 5.8, lines made of stainless steel wire rope or made of textiles containing

aramid fibres shall withstand a test force as given in 4.6, applied for 3 min.

4.2.2.6 Terminations, end stops

Lines shall be terminated in such a manner that they can be connected, directly or by an appropriate

connector as specified by the manufacturer, to a body holding device, e.g. a rescue harness or a rescue

loop, or to an anchor device.

Reinforcement or another method shall be used to protect terminations from concentrated wear at all

webbing-to-metal fitting interfaces.

All splices shall be secured to prevent the splice from coming open in use.

Eye splices in laid fibre rope shall consist of at least four tucks using all the yarns in the strands. The

length of the splicing tails emerging after the last tuck shall be at least one rope diameter.

Threads used for sewing shall be physically compatible with the webbing/rope, and the quality shall be

compatible to that of the webbing/rope. They shall, however, be of a contrasting shade or colour in order

to facilitate visual inspection.

When using a knot for forming a termination or as an end stop, the knot shall be secured so that it cannot

be opened without the use of a tool. The tail end of the knot shall have a minimum length of 100 mm after

testing in accordance with 5.5.2.

Webbing ends shall be sealed or otherwise prevented from unravelling.

Eye terminations of wire ropes shall be made with thimbles and by splices or with thimbles and by

pressed ferrules.

4.3 Dynamic strength

When tested in accordance with 5.2, the descender device shall not release the test mass and no part of

the descender device shall show any signs of breaking or tearing.

4.4 Function

4.4.1 Overview of requirements and applicable conditioning

An overview for the conditionings and function requirements for the different Classes and Types is given

in Table 1.

Table 1 — Overview of conditioning and function requirements

Classes A, B, C Class D

Type 1 Type 2 Type 1 Type 2

Conditioning

Full Full Full Full

5 m 5 m 5 m 5 m

length length length length

Clause 4.4.2.1.1 4.4.2.1.2 4.4.2.2.1 4.4.2.2.2 4.4.3.1.1 4.4.3.1.2 4.4.3.2.1 4.4.3.2.2

Dry

5.3.1.2 No Yes Yes Yes No Yes No Yes

conditioning

Wet

5.3.1.3 No Yes Yes Yes No O No O

conditioning

Cold

5.3.1.4 Yes No Yes No O No O No

conditioning

Wet and cold

5.3.1.5 O No O No O No O No

conditioning

O = required, if claimed by the manufacturer.

4.4.2 Classes A, B and C

4.4.2.1 Type 1

4.4.2.1.1 Type 1 — 5 m

When tested in accordance with 5.3.2.1.1.1, after cold conditioning in accordance with 5.3.1.4, the descent

shall be continuous. If the manufacturer claims the use at temperatures lower than −4 °C, the lowest

claimed temperature shall be used.

If claimed by the manufacturer, for use at wet and cold conditions, the descent shall be continuous when

conditioned in accordance with 5.3.1.5 and tested in accordance with 5.3.2.1.1.1.

If the manufacturer claims the possibility to carry out alternating descents the descender device shall be

conditioned in accordance with 5.3.1.3 and the descent shall start when tested in accordance with

5.3.2.1.1.2.

NOTE For alternating descents the wet conditioning is the most severe configuration for the weight of the line.

4.4.2.1.2 Type 1 — Full length

When tested in accordance with 5.3.2.1.2, after dry conditioning in accordance with 5.3.1.2, the average

descent velocity shall be between 0,5 m/s and 2 m/s.

When tested in accordance with 5.3.2.1.2, after wet conditioning in accordance with 5.3.1.3, the average

descent velocity shall be between 0,5 m/s and 2 m/s.

4.4.2.2 Type 2

4.4.2.2.1 Type 2 — 5 m

When tested in accordance with 5.3.2.2.1.1, after dry conditioning in accordance with 5.3.1.2, the descent

shall be controllable, and the descender device shall stop in a hands-off or any panic-grab position.

When tested in accordance with 5.3.2.2.1.1, after wet conditioning in accordance with 5.3.1.3, the descent

shall be controllable, and the descender device shall stop in a hands-off or any panic-grab position.

When tested in accordance with 5.3.2.2.1.1, after cold conditioning in accordance with 5.3.1.4, the descent

shall be controllable, and the descender device shall stop in a hands-off or any panic-grab position. If the

manufacturer claims the use at temperatures lower than −4°C, the lowest claimed temperature shall be

used.

If claimed by the manufacturer, for use at wet and cold conditions, the descent shall be controllable, and

the descender device shall stop in a hands-off or any panic-grab position when conditioned in accordance

with 5.3.1.5 and tested in accordance with 5.3.2.2.1.1.

If the manufacturer claims the possibility to carry out alternating descents the descender device shall be

conditioned in accordance with 5.3.1.3 and the descent shall start when tested in accordance with

5.3.2.2.1.2.

NOTE For alternating descents the wet conditioning is the most severe configuration for the weight of the line.

4.4.2.2.2 Type 2 — Full length

When tested in accordance with 5.3.2.2.2, after dry conditioning in accordance with 5.3.1.2, the descent

shall be adjustable and controllable.

When tested in accordance with 5.3.2.2.2, after wet conditioning in accordance with 5.3.1.3, the descent

shall be adjustable and controllable.

The parts of the descender device that are touched to control the descent shall not develop a temperature

higher than 48 °C during the descent. The descent control element shall not break.

4.4.3 Class D

4.4.3.1 Type 1

4.4.3.1.1 Type 1 — 5 m

If claimed by the manufacturer for use at cold condition or for use at temperatures lower than −4 °C, the

descent shall be continuous, and the average velocity shall be between 0,5 m/s and 2 m/s when

conditioned in accordance with 5.3.1.4 and tested in accordance with 5.3.2.1.1.1.

If claimed by the manufacturer, for use at wet and cold conditions, the descent shall be continuous, and

the average velocity shall be between 0,5 m/s and 2 m/s when conditioned in accordance with 5.3.1.5

and tested in accordance with 5.3.2.1.1.1.

When checked in accordance with 5.3.2.1.1.1 the descender device shall indicate that it has been used.

4.4.3.1.2 Type 1 — Full length

When tested in accordance with 5.3.2.1.2, after dry conditioning in accordance with 5.3.1.2, the average

descent velocity shall be between 0,5 m/s and 2 m/s.

If claimed by the manufacturer for use at wet condition the average descent velocity shall be between

0,5 m/s and 2 m/s when conditioned in accordance with 5.3.1.3 and tested in accordance with 5.3.2.1.2.

When checked in accordance with 5.3.2.1.2 the descender device shall indicate that it has been used.

4.4.3.2 Type 2

4.4.3.2.1 Type 2 — 5 m

If claimed by the manufacturer for use at cold condition or for use at temperatures lower than −4 °C, the

descent shall be controllable, the descender device shall stop in a hands-off or any panic-grab position

and shall indicate that it has been used when conditioned in accordance with 5.3.1.4 and tested in

accordance with 5.3.2.2.1.1.

If claimed by the manufacturer, for use at wet and cold conditions, the descent shall be controllable, the

descender device shall stop in a hands-off or any panic-grab position and shall indicate that it has been

used when conditioned in accordance with 5.3.1.5 and tested in accordance with 5.3.2.2.1.1.

4.4.3.2.2 Type 2 — Full length

When tested in accordance with 5.3.2.2.2, after dry conditioning in accordance with 5.3.1.2 the descent

shall be controllable.

If claimed by the manufacturer for use at wet condition the descent shall be controllable when

conditioned in accordance with 5.3.1.3 and tested in accordance with 5.3.2.2.2.

The parts of the descender device that are touched to control the descent shall not develop a temperature

higher than 48 °C during the descent. The descent control element shall not break.

4.5 Descent energy

When tested in accordance with 5.4, with the descents being carried out in succession, descender devices,

class A, B and C shall meet the following requirements:

a) The descender devices shall withstand the descent energy determined for their class;

b) for type 1 the average descent velocity shall be between 0,5 m/s and 2 m/s;

c) for type 2 it shall be possible to maintain the mass within a range of ±1 m from its initial position.

NOTE This test is not required for Class D descender devices, as they are intended for a single use only.

4.6 Static strength

When tested in accordance with 5.5.1, descender devices, class A, B and C shall withstand a test force of

5 times the maximum rated load, but at least 15 kN.

When tested in accordance with 5.5.1, descender devices, class D shall withstand a test force of twice the

maximum impact force recorded in the dynamic test of 5.2, but at least 5 times the maximum rated load.

If manually-operated descender devices are tested in several locked positions, the highest of the

measured values shall be used as a basis for establishing the static strength test force.

When tested in accordance with 5.5.2, descender devices, classes A, B, C and D shall withstand a test force

of 6 kN.

4.7 Corrosion resistance

After testing in accordance with 5.9, metal parts of the descender device shall show no evidence of

corrosion of the base metal which could affect its function, e.g. the correct operation of moving elements

and locking function. White scaling or tarnishing is acceptable if the function is not impaired.

NOTE Conformity to this requirement does not imply suitability for use in highly corrosive environments, e.g.

offshore, chemical plants.

4.8 Additional requirements for manually-operated descender devices (type 2)

4.8.1 Operating force

When tested in accordance with 5.6, with a force equal to the maximum rated load, the force required to

start the descent shall not exceed 450 N.

4.8.2 Blocking force

Descender devices, with the descent control element in blocking mode, shall withstand a force of 3 kN or

1,4-times the maximum rated load, whichever is higher, for 3 min with a maximum slippage of 300 mm

when tested in accordance with 5.7.

No part of the device shall show any signs of permanent deformation that would affect its function, and

the line shall not show any signs of tearing or breaking.

For descender device that have more than one attachment point specified by the manufacturer, each

attachment point shall be tested to this requirement.

4.9 Additional requirements for descender devices, class D

After testing in accordance with 5.3, Class D descender devices shall indicate clearly that they have been

used.

4.10 Marking and manufacturer’s instructions and information

Marking of the descender device shall be in accordance with Clause 6.

Manufacturer’s instructions and information shall be supplied with the descender device in accordance

with Clause 7.

5 Test methods

5.1 Examination of design

Confirm by reference to appropriate documentation accompanying the descender device and by

measurement and by normal or corrected vision and/or tactile examination of the descender device that

it conforms to 4.1, 4.2.1, 4.2.2.1, 4.2.2.2, 4.2.2.3 and 4.2.2.4. If necessary to examine internal parts,

dismantle the device.

5.2 Dynamic strength test

The test apparatus shall conform to EN 364:1992, 4.4.1, 4.5, 4.6 and, if applicable, to EN 364:1992, 4.4.2.

Attach a new descender device by its attachment point or the termination of the line, as appropriate, to

the anchor point of the test apparatus, in accordance with the manufacturer’s instructions and

information, see Figure 1 or Figure 2. Manually-operated descender devices shall be tested in each locked

position intended by the manufacturer and described in the manufacturer’s instructions and information.

+50

Withdraw the line by (4 000 ) mm from the descender device and attach the rigid steel test mass in

accordance with the maximum rated load to the termination of the line or to the device, as appropriate.

In the case of descender devices with an automatic retraction function, prevent the line from retracting

by a clamp.

For descender devices, class D, attach a load cell between the device and the anchor point of the test

apparatus.

+50

Raise the test mass by (600 ) mm, with a maximum horizontal distance of 300 mm from the anchor

point.

Hold th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...