EN 1807:1999+A1:2009

(Main)Safety of woodworking machines - Band sawing machines

Safety of woodworking machines - Band sawing machines

This document specifies all significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to stationary and displaceable band sawing machines with either manual or automatic loading and/or unloading, hereinafter referred to as "machines" designed to cut solid wood, chipboard, fibreboard, plywood and also these materials where they are covered with plastic laminate or edgings.

This European Standard does not cover the hazards related to Electromagnetic Compatibility (EMC) as required by the EMC Directive 89/336/EEC of 03-05-89.

This European Standard does not apply to:

- hand held motor-operated electric tools or any adaptation permitting their use in a different mode, i.e. bench mounting;

NOTE 1 Hand-held motor operated electric tools are covered by the requirements of

EN 60745-1:2006 together with EN 60745-2-20:2003.

- transportable machines set up on a bench or a table similar to a bench, which are intended to carry out work in a stationary position, capable of being lifted by one person by hand.

NOTE 2 Transportable electrically driven machines are covered by the requirements of EN 61029-1:2000 together with EN 61029-2-5:2002.

This European Standard does not cover the hazards arising from machining processes (e.g. milling and sawing) of related to associated machines e.g. canters and circular saws.

This European Standard is primarily directed at machines which are manufactured after the date of issue of this standard.

Sicherheit von Holzbearbeitungsmaschinen - Bandsägemaschinen

Dieses Dokument spezifiziert alle in Abschnitt 4 aufgeführten signifikanten Gefährdungen, Gefährdungssituationen

und Gefährdungsereignisse, die auf stationäre und verschiebbare Bandsägemaschinen entweder

mit Handbeschickung und/oder Handentnahme oder automatischer Beschickung und/oder Entnahme

zutreffen — im Folgenden als „Maschinen“ bezeichnet —, die bestimmt sind zum Schneiden von Massivholz,

Spanplatten, Faserplatten und Sperrholz sowie diesen Werkstoffen, wenn sie mit Kunststoff beschichtet oder

mit Kunststoffkanten versehen sind."

!gelöschter Text"

!gelöschter Text" Diese Europäische Norm behandelt nicht die Gefährdungen bezüglich elektromagnetischer

Verträglichkeit (EMV), die in der EMV-Richtlinie 89/336/EWG vom 05-03-89 aufgeführt sind.

Diese europäische Norm gilt nicht für:

handgeführte motorbetriebene Elektrowerkzeuge oder irgendwelche Einrichtungen, die ihre Verwendung

in einer anderen Weise, d. h. in einem Gestell montiert, ermöglichen;"

!ANMERKUNG 1 Handgeführte motorbetriebene Elektrowerkzeuge sind durch die Anforderungen in

EN 60745-1:2006 zusammen mit EN 60745-2-20:2003 erfasst."

transportable Maschinen, die auf ein Gestell oder auf einen Tisch, der einem Gestell ähnlich ist,

aufgesetzt sind und die vorgesehen sind, während des Betriebs stationär verwendet zu werden, und die

von einer Person von Hand angehoben werden können."

!ANMERKUNG 2 Transportable, elektrisch angetriebene Maschinen sind durch die Anforderungen in

EN 61029-1:2000 zusammen mit prEN 61029-2-5:2002 erfasst."

Diese europäische Norm behandelt nicht die Gefährdungen, die von Bearbeitungsvorgängen (z. B. Fräsen

und Sägen) verbundener Maschinen wie z. B. Spanern und Kreissägen ausgehen.

Diese Norm ist in erster Linie auf Maschinen anzuwenden, die nach dem Ausgabedatum dieser Norm

hergestellt werden.

Sécurité des machines pour le travail du bois - Machines à scier à ruban

!Le présent document traite de tous les phénomènes, situations et événements dangereux significatifs tels qu’énumérés dans l'Article 4 qui sont pertinents pour les machines à scier à ruban fixes et déplaçables munies d'un système de chargement et/ou de déchargement soit manuel, soit automatique (ci-après désignées «machines»), conçues pour la coupe de bois massif, de panneaux de particules, de panneaux de fibres, de contreplaqué, ainsi que ces matériaux lorsque leur surface ou leurs chants sont recouverts de plastique."

!texte supprimé"

!texte supprimé" La présente norme européenne ne traite pas les risques relatifs à la compatibilité électromagnétique (CEM) tels que prescrits dans la Directive CEM 89/336/CEE du 89-05-03.

La présente norme européenne ne s'applique pas aux :

- !outils électriques à moteur portatifs ou toute adaptation permettant leur utilisation de manière différente, c'est-à-dire fixés sur un établi ;"

NOTE 1 !Les outils électriques portatifs à moteur sont couverts par les exigences de l'EN 60745-1:2006 et de l'EN 60745-2-20:2003."

- !machines déplaçables installées sur un établi ou une table similaire à un établi, destinées à exécuter des travaux dans une position fixe, pouvant être soulevées à la main par une personne."

NOTE 2 !Les machines déplaçables à entraînement électrique sont couvertes par les exigences de l'EN 61029-1:2000 et de l'EN 61029-2-5:2002."

La présente norme européenne ne traite pas des phénomènes dangereux produits par les procédés d'usinage (par exemple fraisage et sciage) dus aux machines associées (par exemple scie circulaire à chanfreiner).

La présente norme est applicable avant tout aux machines fabriquées après la date de publication de la présente norme.

Varnost lesnoobdelovalnih strojev - Tračne žage

General Information

- Status

- Withdrawn

- Publication Date

- 01-Sep-2009

- Withdrawal Date

- 26-Mar-2013

- Technical Committee

- CEN/TC 142 - Woodworking machines - Safety

- Drafting Committee

- CEN/TC 142/WG 3 - Bandsawing machines

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 27-Mar-2013

- Completion Date

- 27-Mar-2013

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 309, C 309, C 309, C 309, C 309, C 309, C 309, C OJ Date: 18-Dec-2009

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Replaced By

EN 1807-2:2013 - Safety of woodworking machines - Band sawing machines - Part 2: Log sawing machines - Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Refers

EN 60825-1:2007 - Safety of laser products - Part 1: Equipment classification and requirements - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 1807:1999+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of woodworking machines - Band sawing machines". This standard covers: This document specifies all significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to stationary and displaceable band sawing machines with either manual or automatic loading and/or unloading, hereinafter referred to as "machines" designed to cut solid wood, chipboard, fibreboard, plywood and also these materials where they are covered with plastic laminate or edgings. This European Standard does not cover the hazards related to Electromagnetic Compatibility (EMC) as required by the EMC Directive 89/336/EEC of 03-05-89. This European Standard does not apply to: - hand held motor-operated electric tools or any adaptation permitting their use in a different mode, i.e. bench mounting; NOTE 1 Hand-held motor operated electric tools are covered by the requirements of EN 60745-1:2006 together with EN 60745-2-20:2003. - transportable machines set up on a bench or a table similar to a bench, which are intended to carry out work in a stationary position, capable of being lifted by one person by hand. NOTE 2 Transportable electrically driven machines are covered by the requirements of EN 61029-1:2000 together with EN 61029-2-5:2002. This European Standard does not cover the hazards arising from machining processes (e.g. milling and sawing) of related to associated machines e.g. canters and circular saws. This European Standard is primarily directed at machines which are manufactured after the date of issue of this standard.

This document specifies all significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to stationary and displaceable band sawing machines with either manual or automatic loading and/or unloading, hereinafter referred to as "machines" designed to cut solid wood, chipboard, fibreboard, plywood and also these materials where they are covered with plastic laminate or edgings. This European Standard does not cover the hazards related to Electromagnetic Compatibility (EMC) as required by the EMC Directive 89/336/EEC of 03-05-89. This European Standard does not apply to: - hand held motor-operated electric tools or any adaptation permitting their use in a different mode, i.e. bench mounting; NOTE 1 Hand-held motor operated electric tools are covered by the requirements of EN 60745-1:2006 together with EN 60745-2-20:2003. - transportable machines set up on a bench or a table similar to a bench, which are intended to carry out work in a stationary position, capable of being lifted by one person by hand. NOTE 2 Transportable electrically driven machines are covered by the requirements of EN 61029-1:2000 together with EN 61029-2-5:2002. This European Standard does not cover the hazards arising from machining processes (e.g. milling and sawing) of related to associated machines e.g. canters and circular saws. This European Standard is primarily directed at machines which are manufactured after the date of issue of this standard.

EN 1807:1999+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 79.120.10 - Woodworking machines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1807:1999+A1:2009 has the following relationships with other standards: It is inter standard links to EN 1807:1999/prA1, EN 1807:1999, EN 1807-2:2013, EN 1807-1:2013, CLC/TS 61496-2:2006, EN 60825-1:2007, EN 60947-4-1:2001, HD 21.1 S4:2002, HD 22.1 S4:2002, EN 60529:1991, EN 61029-2-5:2002, EN 61029-1:2000, EN 60947-5-1:2004, EN 894-1:1997, EN 1005-4:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1807:1999+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1807:1999+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit von Holzbearbeitungsmaschinen - BandsägemaschinenSécurité des machines pour le travail du bois - Machines à scier à rubanSafety of woodworking machines - Band sawing machines79.120.10Lesnoobdelovalni strojiWoodworking machines25.080.60Strojne žageSawing machinesICS:Ta slovenski standard je istoveten z:EN 1807:1999+A1:2009SIST EN 1807:2000+A1:2009en01-november-2009SIST EN 1807:2000+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1807:1999+A1

September 2009 ICS 79.120.10 Supersedes EN 1807:1999English Version

Safety of woodworking machines - Band sawing machines

Sécurité des machines pour le travail du bois - Machines à scier à ruban

Sicherheit von Holzbearbeitungsmaschinen - Bandsägemaschinen This European Standard was approved by CEN on 6 May 1999 and includes Amendment 1 approved by CEN on 30 July 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1807:1999+A1:2009: ESIST EN 1807:2000+A1:2009

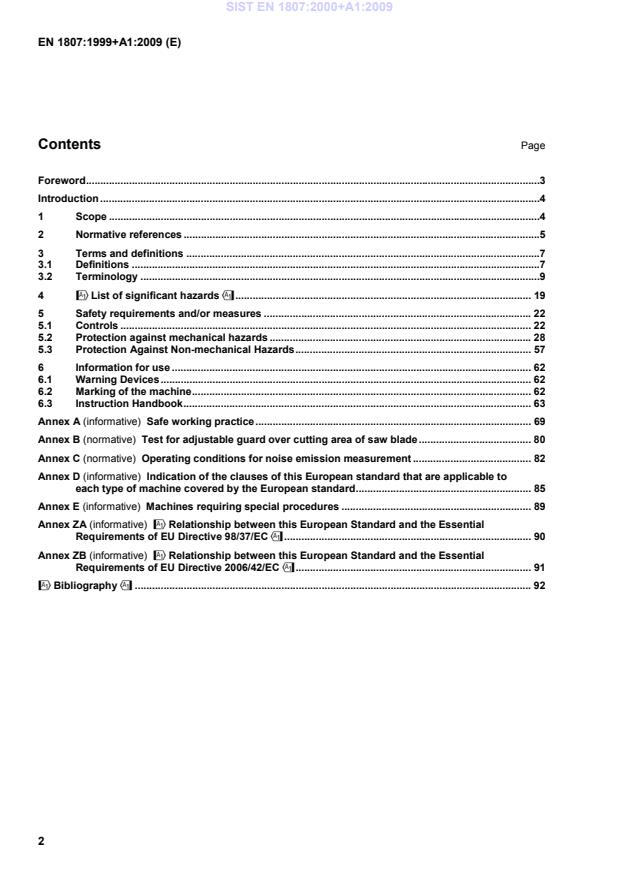

Safe working practice . 69Annex B (normative)

Test for adjustable guard over cutting area of saw blade . 80Annex C (normative)

Operating conditions for noise emission measurement . 82Annex D (informative)

Indication of the clauses of this European standard that are applicable to each type of machine covered by the European standard . 85Annex E (informative)

Machines requiring special procedures . 89Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC" . 90Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 91!Bibliography" . 92 SIST EN 1807:2000+A1:2009

!EN ISO 12100-1:2003" for a description of A, B and C standards). According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

This European Standard is a type "C" standard as defined in !EN ISO 12100-1:2003". The extent to which hazards are covered is indicated in the scope of this European Standard. The requirements of this standard concern designers, manufacturers, suppliers and importers of band sawing machines, re-sawing machines and log sawing machines. This European Standard also includes information to be provided by the manufacturer to the user. 1 Scope !This document specifies all significant hazards, hazardous situations and events as listed in Clause 4 which are relevant to stationary and displaceable band sawing machines with either manual or automatic loading and/or unloading, hereinafter referred to as “machines” designed to cut solid wood, chipboard, fibreboard, plywood and also these materials where they are covered with plastic laminate or edgings." !deleted text" !deleted text" This European Standard does not cover the hazards related to Electromagnetic Compatibility (EMC) as required by the EMC Directive 89/336/EEC of 03-05-89. This European Standard does not apply to: !hand held motor-operated electric tools or any adaptation permitting their use in a different mode, i.e. bench mounting;" !NOTE 1 Hand-held motor operated electric tools are covered by the requirements of

EN 60745-1:2006 together with EN 60745-2-20:2003." !transportable machines set up on a bench or a table similar to a bench, which are intended to carry out work in a stationary position, capable of being lifted by one person by hand." !NOTE 2 Transportable electrically driven machines are covered by the requirements of EN 61029-1:2000 together with EN 61029-2-5:2002." This European Standard does not cover the hazards arising from machining processes (e.g. milling and sawing) of related to associated machines e.g. canters and circular saws. This European Standard is primarily directed at machines which are manufactured after the date of issue of this standard. SIST EN 1807:2000+A1:2009

!(IEC 60947-4-1:2000)" !EN 60947-5-1:2004", Specification for low voltage switchgear and control gear — Part 5: Control circuits, devices and switching elements — Section 1: Electromechanical control circuit devices

!(IEC 60947-5-1:2003)" !EN 61029:2000", Safety of transportable motor operated electric tools — Part 1: General requirements !(IEC 61029-1:1990, modified)" !EN 61029-2-5:2002, Safety of transportable motor-operated electric tools — Part 2: Particular requirements for band saws (IEC 61029-2-5:1993+A1:2001, modified)" !CLC/TS 61496-2:2006", Safety of machinery — Electro-sensitive protective equipment — !Part 2: Particular requirements for equipment using active opto-electronic protective devices (AOPDs)

(IEC 61496-2:2006)" EN ISO 3743-1:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Engineering methods for small, moveable sources in reverberant fields — Part 1: Comparison method for hard walled test rooms (ISO 3743-1:1994) EN ISO 3743-2:1996, Acoustics — Determination of sound power levels of noise sources using sound pressure — Engineering methods for small, moveable sources in reverberant fields — Part 2: Methods for special reverberant test rooms (ISO 3743-2:1996) EN ISO 3744:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Engineering method in an essentially free field over a reflecting plane (ISO 3744:1995) !EN ISO 3745:2003, Acoustics — Determination of sound power levels of noise sources using sound pressure — Precision methods for anechoic and semi-anechoic rooms (ISO 3745:2003)" EN ISO 3746:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting plane (ISO 3746:1995) EN ISO 9614-1:1995, Acoustics — Determination of sound power levels of noise sources using sound intensity — Part 1: Measurement at discrete points (ISO 9614-1:1993) !EN ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996)" EN ISO 11202:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at the workstation and at other specified positions — Survey method in situ (ISO 11202:1995) EN ISO 11204:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at the workstation and at other specified positions — Method requiring environmental corrections (ISO 11204:1995) !EN ISO 11688-1:1998, Acoustics — Recommended practice for the design of low-noise machinery and equipment — Part 1: Planning (ISO/TR 11688-1:1995)" !EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) SIST EN 1807:2000+A1:2009

Hand feed includes the use of a hand operated carriage on which the workpiece is placed manually or clamped and the use of a demountable power feed unit 3.1.12 demountable power feed unit a feed mechanism which is mounted on a hand fed machine so that it can be moved from its working position without the use of a spanner or similar additional device 3.1.13 integrated feed a feed mechanism for the workpiece or tool which is integrated with the machine and where the workpiece or machine element with incorporated tool are held and controlled mechanically during the machining operation 3.1.14 run-up time the elapsed time from the actuation of the start control device until the driven band wheel reaches the intended speed 3.1.15 run-down time the elapsed time from the actuation of the stop control device until driven band wheel standstill 3.1.16 manual loading of power fed machines where the workpiece is presented by the operator directly to the machine integrated feed, e.g. rotating feed rollers, travelling table or reciprocating carriage;

i.e. for which there is no intermediate loading device to receive and transfer the workpiece from the operator to the integrated feed 3.1.17 manual unloading of power fed machines where the workpiece is removed by the operator directly from the machine outfeed; i.e. for which there is no intermediate unloading device to receive and transfer the workpiece from the machine outfeed to the operator SIST EN 1807:2000+A1:2009

the area where the saw blade is not involved in the cutting process 3.1.20 !displaceable machine" a machine which is located on the floor, stationary during use and equipped with a device, normally wheels, which allows it to be moved between locations 3.1.21 stationary machine a machine designed to be located on or fixed to the floor or other parts of the structure of the premises and to be stationary during use 3.1.22 !information from the supplier" statements, sales literature, leaflets or other documents, where the manufacturer (or supplier) declares either the characteristics or the compliance of the material or product to a relevant standard 3.2 Terminology The names of the main parts of the machines are shown in figures and Tables 1 to 6.

Figure 1 a) — Guards closed SIST EN 1807:2000+A1:2009

Figure 1b) — Guards open Figure 1 — Hand fed table band saw Table 1 — Terminology for table band saw

1 Table 2 Adjustable fence 3 Bandsaw blade 4 Top band wheel 5 Bottom band wheel 6 Start and stop controls 7 Band wheel guard 8 Adjustable guard for saw blade !deleted text"

Figure 2 — Band re-saw SIST EN 1807:2000+A1:2009

1 Feed roller 2 Workpiece support (table) 3 Infeed table roller 4 Outfeed table roller 5 Fence 6 Handwheel for adjustment of feed rollers 7 Band wheel guard 8 Adjustable guard for saw blade !9 Start and stop controls"

Figure 3 — Travelling table log saw SIST EN 1807:2000+A1:2009

1 Travelling table 2 Dogging 3 Fence 4 Saw blade 5 Band wheel guards 6 Adjustable guard for saw blade 7 Below travelling table height by not more than 100 mm

Figure 4 — Reciprocating carriage log saw SIST EN 1807:2000+A1:2009

Table 4 — Terminology for reciprocating carriage log saw

1 Reciprocating log carriage 2 Band wheel guard 3 Saw guides 4. Saw blade 5 Adjustable guard for saw blade 6 Dust extraction outlet 7 Pit

Figure 5 — Conveyor fed log saw Table 5 — Terminology for conveyor fed log saw

1 Conveyor 2 Saw blades 3 Spiked idle roller 4 Band wheel guards

Figure 6 — Moving head rig log saw Table 6 — Terminology for moving head rig log saw

1 Moving head rig 2 Saw blade 3 Band wheel guard

Figure 7 — Hand fed table band saw with three band wheels

Figure 8 — Hand fed table band saw (tilting saw unit)

Figure 9 — Twin opposed band re-saws

Figure 10 —Twin band re-saws in tandem 4 !List of significant hazards" !This clause contains all significant hazards, hazardous situations and events (see EN 1050:1996) as far as they are dealt with in this document, identified by risk assessment as significant for the machines as defined in the scope and which require action to eliminate or reduce the risk. This document deals with these significant hazards by defining safety requirements and/or measures or by reference to relevant standards. These hazards are listed in Table 1 in accordance with Annex A of EN 1050:1996.

No Hazards, hazardous situations and hazardous events EN ISO 12100 Relevant sub-clause of this document

Part 1: 2003 Part 2: 2003

1 Mechanical hazards related to: - machine parts or work-pieces:

a) shape; 4.2 4.2.1, 4.2.2, 5 5.2.2, 5.2.3.1, 5.2.6, 5.2.7.1.2, 5.2.7.2, 5.2.7.3, 5.2.8

b) relative location; 5.1.2, 5.1.4, 5.2.3.1, 5.2.3.2, 5.2.7.1.2, 5.2.7.4, 5.2.8, 5.2.9

c) mass and stability (potential energy of elements which may move under the effect of gravity); 5.2.5

d) mass and velocity (kinetic energy of elements in controlled or uncontrolled motion); 5.2.1, 5.2.7.1.2, 5.2.7.3

e) mechanical strength. 5.2.2.1, 5.2.6.2

- accumulation of energy inside the machinery:

f) elastic elements (springs), or 4.2 4.10, 5.5.4 5.2.6

g) liquids and gases under pressure; 4.2 4.10, 5.5.4 5.3.7, 5.3.8 1.1 Crushing hazard 4.2.1

5.2.9 1.2 Shearing hazard 5.2.8, 5.2.9 1.3 Cutting or severing hazard 5.2.7 1.4 Entanglement hazard 5.2.7, 5.2.8 1.5 Drawing-in or trapping hazard 5.2.7, 5.2.8, 5.2.9 1.6 Impact hazard 5.2.7 1.7 Stabbing or puncture hazard 5.2.2 1.9 High pressure fluid injection or ejection hazard 5.3.7, 5.3.8 SIST EN 1807:2000+A1:2009

5.3.12 7 Hazards generated by materials and substances (and their constituent elements) processed or used by the machinery 7.1 Hazards from contact with or inhalation of harmful fluids and dusts 4.8 4.3b, 4.4

5.3.3 7.2 Fire hazard 4.8 4.4

5.3.1 8 Hazards generated by neglecting ergonomic principles in machinery design related to: 8.1 Unhealthy postures or excessive effort 4.9 4.7, 4.8.2, 4.11.12, 5.5.5, 5.5.6 5.1.2 8.2 Hand-arm or foot-leg anatomy 4.9 4.8.3

5.1.2 8.4 Local lighting

4.8.6 6.3 8.6 Human error, human behaviour

4.8, 4.11.8, 4.11.10, 5.5.2, 6 6.3 8.7 Design, location or identification of manual controls

4.8.7, 4.11.8 5.1.2 8.8 Design or location of visual display units

4.8.8, 6.2 5.1.2 10 Unexpected start up, unexpected overrun/overspeed (or any similar malfunction) from: 10.1 Failure/disorder of the control system

4.11, 5.5.4

5.1.1 10.2 Restoration of energy supply after an interruption

4.11.4

5.1.1, 5.1.9 10.3 External influences on electrical equipment

4.11.11 5.1.1 10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities, see 8.6) 4.9 4.8, 4.11.8, 4.11.10, 5.5.2, 6 5.1.1, 5.3.5, 6.3 11 Impossibility of stopping the machine in the best possible conditions

4.11.1, 4.11.3, 5.5.2

5.1.2, 5.1.4, 5.2 13 Failure of the power supply

4.11.1, 4.11.4 5.1.9 SIST EN 1807:2000+A1:2009

4.11, 5.5.4 5.1.1 15 Errors of fitting 4.9

4.7, 6.5

5.1.8 16 Break-up during operation 4.2.2 4.3 5.2.2 17 Falling or ejected objects or fluids 4.2.2 4.3, 4.10 5.2.2, 5.2.3, 5.2.9

18 Loss of stability / overturning of machinery 4.2.2 5.2.6

5.2.1 " 5 Safety requirements and/or measures For guidance in connection with risk reduction by design, see !4.1 of EN ISO 12100-2:2003" and in addition: 5.1 Controls 5.1.1 Safety and reliability of control systems !For the purposes of this standard a safety related control system is one from and including the initial manual control or position detector or sensor up to and including the power control element of the final machine actuator, e.g. motor or brake." The safety related control systems of this machine are those for: starting the drive motor for the driven band wheel (see 5.1.3); starting the integrated feed (see 5.1.3 and 5.1.3.1); normal stopping (see 5.1.4.1 and 5.1.4.2); emergency stopping (if required) (see 5.1.5); stopping powered feed rollers (see 5.1.2.1 and 5.1.5); interlocking (see 5.2.7.1.1, 5.2.7.2.1, 5.2.7.3.1, 5.2.7.3.2, 5.2.7.4 and 5.2.8); interlocking with guard locking (see 5.2.7.1.1, 5.2.7.2.1, 5.2.7.3.1 and 5.2.8); mode selection (if required) (see 5.1.6); opening/closing the adjustable saw blade guard during movement of the reciprocating carriage, moving head rig, conveyor feed or travelling table (see 5.2.7.3.2.1); trip devices (where fitted) (see 5.2.7.2.5); activation of the compensation device (see 5.2.3.1); initiation of the braking system (see 5.2.4); brake release (see 5.1.6); pressure sensitive devices (where fitted) (see 5.2.7.2.4); SIST EN 1807:2000+A1:2009

The circuits shall be 'hardwired'.

If electronic components are used in safety related control systems Category 1 is fulfilled if they are in accordance with 9.4.2.2 or 9.4.2.3 of !EN 60204-1:2006"; c) mechanical components if they comply with !4.5 of EN ISO 12100-2:2003"; d) mechanically actuated position detectors for guards if they are actuated in the positive mode and their arrangement/fastening and their cam design/mounting are in accordance with 5.2 and 5.3 of EN 1088:1995; e) interlocking devices with guard locking if they are in accordance with conditional unlocking in Table 1 of EN 1088:1995; f) hydraulic and pneumatic components and systems if they are in accordance with EN 982:1996 and EN 983:1996 respectively; g) opto-electronic devices, if they comply with type 2 of !CLC/TS 61496-2" and if they are tested together with the associated control circuits at least at each starting of the machine. Verification: By checking the relevant drawings and/or circuit diagrams and inspection of the machine. !deleted text". !NOTE For components characteristics the information from the component supplier can be useful." 5.1.2 Position of controls 5.1.2.1 Log band saws Controls required for the normal processing operation of log band saws shall either: a) be positioned at least 1,2 m from the cutting area as shown in figure 11; or b) be separated from the cutting area by a deterring/impeding device which creates a reach distance of 1,2 m to the saw blade. SIST EN 1807:2000+A1:2009

Verification: By checking the relevant drawings and/or circuit diagrams, measurement, visual inspection and functional testing of the machine.

1 1 200 mm to sawline Figure 11 — Log saws - Danger area around the blade 5.1.2.2 Table band saws On table band saws electrical controls including the emergency stop control (if fitted) shall be positioned: a) on the infeed side; b) between 600 mm and 1 400 mm from floor level; SIST EN 1807:2000+A1:2009

1 Control positin in shaded area 2 Ground level Figure 12 — Table band saws and re-saws - Position of controls SIST EN 1807:2000+A1:2009

An emergency stop control shall be positioned at any infeed and outfeed position and on any fixed or moveable control panel. Verification: By checking the relevant drawings and/or circuit diagrams, measurement, visual inspection and functional testing of the machine. 5.1.3 Starting See 9.2.5.2 of !EN 60204-1:2006". For the purposes of this standard ".all of the safeguards in place and functional." is achieved by the interlocking arrangements described in 5.2.7.1.1 and "operation" means rotation of the driven band wheel and powered movement of the integrated feed.

The exceptions described in 9.2.5.2 of !EN 60204-1:2006" are not relevant. The drive motor for the driven band wheel shall only become operable after any interlocked guards are in place and functional. Movement of integrated feed or demountable power feed as applicable, shall only become operable after the drive motor for the driven band wheel has been started. Verification: By checking the relevant drawings and/or circuit diagrams, inspection and relevant functional testing of the machine.

5.1.3.1 Log band saws At log band saws under manual control, the controls for integrated feed movement shall be of the 'hold-to-run' type unless the machine is located within an interlocked perimeter fence. At log band saws under manual control the controls which operate the log turning devices shall be of the hold-to-run type unless the log turning device is enclosed in an interlocked perimeter fence. Verification: By checking the relevant drawings and/or circuit diagrams, inspection and relevant functional testing of the machine. 5.1.3.2 Table band saws For table band saws fitted with a demountable power feed by a manufacturer, a separate start control shall be provided at the demountable power feed. Verification: By checking the relevant drawings and/or circuit diagrams, inspection and relevant functional testing of the machine.

5.1.4 Normal stopping 5.1.4.1 All machines A stop control shall be fitted and located at the main control position, except where an emergency stop control which performs the same function is fitted.

The control, when operated, shall disconnect power from all the machine actuators and actuate the brake (if provided). The normal stop control system shall be either: SIST EN 1807:2000+A1:2009

5.1.5 Emergency stop See !EN ISO 13850:2008". An emergency stop control shall be fitted on all machines, except table band saws which do not have an electrical connection for a demountable power feed. If the machine is fitted with a mechanical brake, the emergency stop control system shall be a Category 0 stop in accordance with 9.2.2 of !EN 60204-1:2006". In all other cases, the emergency stop control system shall be a Category 1 stop in accordance with !EN 60204-1:2006". Dangerous movements caused by gravity, pressure etc. shall be avoided, e.g. by automatic mechanical blocking or clamping devices. Where a Category 1 stop is fitted, the stopping sequence shall be as in 5.1.4. Verification: By checking the relevant drawings and/or circuit diagrams, measurement, inspection and relevant functional testing of the machine. 5.1.6 Tracking mode On machines where the band wheels are < 1,2 m in diameter and where the brake is held on while power is off and the wheels are rotated by hand for tracking, provision shall be made for releasing the brake for tracking.

It shall not be possible to release the brake until the band wheels are stationary. On machines where the band wheels are ≥ 1,2 m in diameter, where unbraked run-down is required during tracking, a mode selector shall be provided.

The conditions in 5.2.4.3 shall be met in full. SIST EN 1807:2000+A1:2009

Where speed changing is provided the operator shall be able to determine running speed before starting the machine. Verification: By checking relevant drawings, inspection and relevant functional testing of the machine. 5.1.8 Control duplication The requirements of !EN ISO 12100-2:2003" shall apply.

Where duplicate controls are provided for operation of the integrated feed and/or the driven band wheel drive motor, the control circuit shall only allow one control to be effective at a given time. Verification: By checking relevant drawings and/or circuit diagrams, inspection and relevant functional testing of the machine. 5.1.9 Failure of the power supply On electrically driven machines an automatic restart in the case of a supply interruption after the restoration of the voltage shall be prevented in accordance with the requirements of 7.5 paragraphs 1 and 3 of !EN 60204-1:2006". On machines with pneumatic clamping of the workpiece, provision shall be made to maintain the pneumatic pressure in the event of a failure in the pneumatic power supply, e.g. by the use of a non-return valve. Verification: By checking the relevant drawings and/or circuit diagrams, inspection, functional testing of the machine and confirmation from the manufacturer. 5.1.10 Failure of control circuits See 5.1.1 5.2 Protection against mechanical hazards 5.2.1 Stability Machines and ancillary equipment shall be provided with a facility, e.g. holes, for fixing them to the floor or other structure. !Displaceable machines" shall also be fitted with a brake for the wheels if fitted. The band wheels shall be individually balanced in accordance with G.6.3 of !ISO 1940-1:2003". NOTE The requirements for a stability test for "!displaceable machines"" with wheels, both when being moved from location to location and when in use, will be considered at the first revision of the standard. Verification: By checking relevant drawings, inspection and functional testing of the machine and by checking the balance of each driven band wheel or confirmation from the manufacturer of the degree of balance. SIST EN 1807:2000+A1:2009

Minimum material thickness mm. ≤ 315 1,00 2,50 2,00 5,00 316 - 999 1,50 3,00 3,00 5,00 ≥ 1000 2,00 3,50 3,00 5,00

Verification: By checking the relevant drawings, measurement !and" inspection of the machine !deleted text". !NOTE For the ultimate tensile strength a confirmation from the manufacturer of the material can be useful." 5.2.2.2 Cleaning and lubrication 5.2.2.2.1 Cleaning Machines with tensioned saw blades shall be fitted with devices which ensure that the saw blade and band wheels are cleaned, e.g. brushes or scrapers (see figures 13 and 14). Where the cleaning devices are manually adjusted this shall be without the aid of a tool. Verification: By checking relevant drawings, visual inspection and functional testing of the machine.

Figure 13 — Blade and wheel cleaning SIST EN 1807:2000+A1:2009

1 Drip feed lubricator 2 Blade wiper 3 Saw cleaning device in open position 4 Close when cleaning Figure 14 — Blade lubrication SIST EN 1807:2000+A1:2009

Where the machine is designed to be tracked under power with all guards closed, provision shall be made for establishing the position of the saw blade, e.g. by means of marks on the machine table or by sighting slots in the band wheel guard. The position and size of openings shall conform to Tables 2 and 5 of

!EN ISO 13857:2008". See also 6.2. Verification: By checking relevant drawings and/or circuit diagrams, inspection, measurement and functional testing of saw strain indicator.

Figure 15 — Blade straining 1 Tilting pulley 2 Bandsaw blade

Figure 16 — Blade tracking 5.2.3.2 Saw blade guides Machines shall be equipped with saw blade guides, which shall conform to the requirements set out in

Table 9. SIST EN 1807:2000+A1:2009

Machine design Permitted saw blade guide types

Required saw blade guide Adjustable saw blade guides

Roller Cheek Pressureposition

Vertical saw blade -

band wheel diameter ≤ 315 mm

X

X

(at least) above workpiece

Upper Vertical

saw blade - band wheel

Non-tensioned

X

X

Above and below

Upper diameter > 315 mm Tensioned

X

X workpiece

Horizontal

Non-tensioned

X

X

Both sides of Closest to non-driven saw blade Tensioned

X X workpiece band wheels Where cheek guides are fitted, one set shall be adjustable, in accordance with Table 9, so that it can be moved towards the workpiece or work support level and be secured in that position (see figure 17). On machines without tensioned saw blades, a rear guide (thrust wheel) shall be fitted above the workpiece to maintain the saw blade in position when sawing (see figure 18). Verification: By checking relevant drawings, inspection and functional testing of the machine.

Figure 17a) — Pressure guides

Figure 17b)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...