EN 12413:2007+A1:2011

(Main)Safety requirements for bonded abrasive products

Safety requirements for bonded abrasive products

This standard is applicable to rotating bonded abrasive products. It specifies requirements and/or measures for the removal or reduction of hazards resulting from the design and application of the abrasive products.

This standard also contains procedures and tests for verification of compliance with the requirements as well as safety information for use, which is to be made available to the user by the manufacturer.

The hazards taken into consideration are listed in Clause 4 of this standard.

This standard does not apply to superabrasives and coated abrasive products.

Sicherheitsanforderungen für Schleifkörper aus gebundenem Schleifmittel

Diese Norm gilt für rotierende Schleifkörper aus gebundenem Schleifmittel. Sie legt Anforderungen und/oder Maßnahmen zur Beseitigung oder Verringerung von Gefährdungen fest, die von der Gestaltung und Anwendung der Schleifwerkzeuge herrühren.

Diese Norm umfasst auch Verfahren und Prüfungen zur Feststellung der Übereinstimmung mit den Anforderungen sowie Benutzerinformationen, die der Hersteller dem Anwender zur Verfügung zu stellen hat.

Die berücksichtigten Gefährdungen sind in Abschnitt 4 dieser Norm aufgeführt.

Diese Norm gilt nicht für Schleifkörper mit Diamant oder Bornitrid als Schleifmittel und nicht für Schleifmittel auf Unterlagen.

Exigences de sécurité pour les produits abrasifs agglomérés

La présente norme s'applique aux produits abrasifs agglomérés rotatifs. Elle spécifie les exigences et/ou mesures pour la suppression ou la réduction des risques résultant de la conception et de l'application des produits abrasifs.

La présente norme contient également les modes opératoires et les essais permettant de vérifier la conformité avec les exigences ainsi que les informations de sécurité pour l'utilisation que le fabricant doit fournir à l’utilisateur.

Les phénomènes dangereux à prendre en considération sont listés à l'Article 4 de la présente norme.

La présente norme ne s'applique pas aux superabrasifs, ni aux produits abrasifs appliqués.

Varnostne zahteve za vezana brusilna sredstva

Ta standard velja za rotirajoča se vezana brusilna sredstva. Določa zahteve in/ali ukrepe za odpravo ali zmanjševanje nevarnosti, ki so posledica načrtovanja in uporabe abrazivnih proizvodov.

Ta standard vsebuje tudi postopke in preskuse za preverjanje skladnosti z zahtevami in varnostnimi informacijami o uporabi, ki jih mora proizvajalec priskrbeti uporabniku.

Nevarnosti, ki so upoštevane, so navedene v klavzuli 4 tega standarda.

Ta standard ne velja za superabrazive in prevlečene abrazivne proizvode.

General Information

- Status

- Withdrawn

- Publication Date

- 08-Mar-2011

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 143 - Machine tools - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-Oct-2019

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 15-Jan-2011

- Effective Date

- 30-Oct-2019

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 12413:2007+A1:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety requirements for bonded abrasive products". This standard covers: This standard is applicable to rotating bonded abrasive products. It specifies requirements and/or measures for the removal or reduction of hazards resulting from the design and application of the abrasive products. This standard also contains procedures and tests for verification of compliance with the requirements as well as safety information for use, which is to be made available to the user by the manufacturer. The hazards taken into consideration are listed in Clause 4 of this standard. This standard does not apply to superabrasives and coated abrasive products.

This standard is applicable to rotating bonded abrasive products. It specifies requirements and/or measures for the removal or reduction of hazards resulting from the design and application of the abrasive products. This standard also contains procedures and tests for verification of compliance with the requirements as well as safety information for use, which is to be made available to the user by the manufacturer. The hazards taken into consideration are listed in Clause 4 of this standard. This standard does not apply to superabrasives and coated abrasive products.

EN 12413:2007+A1:2011 is classified under the following ICS (International Classification for Standards) categories: 25.100.70 - Abrasives. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12413:2007+A1:2011 has the following relationships with other standards: It is inter standard links to EN 12413:2007, EN 12413:2007/FprA1, EN 12413:2019, EN 1462:2004, EN ISO 6103:2014, EN ISO 22975-3:2014, EN ISO 21207:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12413:2007+A1:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnostne zahteve za vezana brusilna sredstvaSicherheitsanforderungen für Schleifkörper aus gebundenem SchleifmittelExigences de sécurité pour les produits abrasifs agglomérésSafety requirements for bonded abrasive products25.100.70BrusivaAbrasivesICS:Ta slovenski standard je istoveten z:EN 12413:2007+A1:2011SIST EN 12413:2007+A1:2011en,fr,de01-maj-2011SIST EN 12413:2007+A1:2011SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12413:2007+A1

March 2011 ICS 25.100.70 Supersedes EN 12413:2007English Version

Safety requirements for bonded abrasive products

Exigences de sécurité pour les produits abrasifs agglomérés

Sicherheitsanforderungen für Schleifkörper aus gebundenem Schleifmittel This European Standard was approved by CEN on 10 May 2007 and includes Amendment 1 approved by CEN on 17 January 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12413:2007+A1:2011: ESIST EN 12413:2007+A1:2011

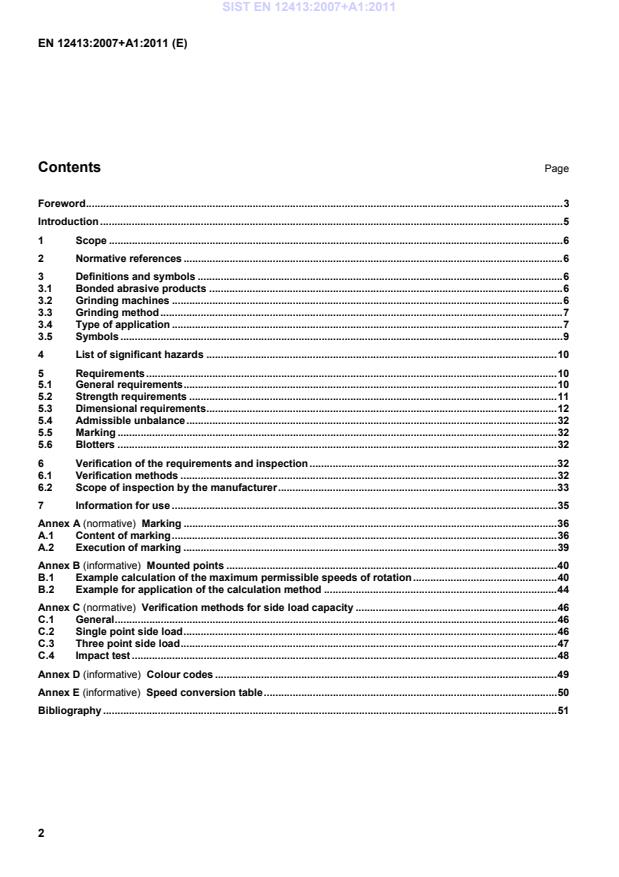

Marking . 36A.1Content of marking . 36A.2Execution of marking . 39Annex B (informative)

Mounted points . 40B.1Example calculation of the maximum permissible speeds of rotation . 40B.2Example for application of the calculation method . 44Annex C (normative)

Verification methods for side load capacity . 46C.1General . 46C.2Single point side load . 46C.3Three point side load . 47C.4Impact test . 48Annex D (informative)

Colour codes . 49Annex E (informative)

Speed conversion table . 50Bibliography . 51 SIST EN 12413:2007+A1:2011

1 Scope This standard is applicable to rotating bonded abrasive products. It specifies requirements and/or measures for the removal or reduction of hazards resulting from the design and application of the abrasive products. This standard also contains procedures and tests for verification of compliance with the requirements as well as safety information for use, which is to be made available to the user by the manufacturer. The hazards taken into consideration are listed in Clause 4 of this standard. This standard does not apply to superabrasives and coated abrasive products. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN ISO 6103, Bonded abrasive products — Permissible unbalances of grinding wheels as delivered — Static testing (ISO 6103:2005) ISO 525, Bonded abrasive products — General requirements ISO 13942, Bonded abrasive products — Limit deviations and run-out tolerances 3 Definitions and symbols 3.1 Bonded abrasive products Products consisting of abrasives e.g. aluminium oxide, silicon carbide held together by a bond. Bonded abrasive products within the meaning of this standard are all products as defined, see for example by ISO 525. 3.2 Grinding machines 3.2.1 Stationary machines Machines that are fixed in position during operation, see for example EN 13218. Included are fixed swing-frame machines and mobile machines clamped firmly in position during use. 3.2.2 Mobile machines Machines that are not fixed in position during operation. They are manually guided (but not supported) by hand during use, e.g. floor grinding machines, flexibly suspended swing-frame grinding machines. 3.2.3 Hand-held machines Machines, including those with flexible drives that are held in the hand during the grinding process, see for example EN 792-7, EN 792-9, EN 60745-2-3 and EN ISO 19432. SIST EN 12413:2007+A1:2011

sprprvvf= — fbr Burst speed factor

Minimum bursting speed divided by maximum operating speed:

sbrbrvvfmin= — vbr Bursting speed Peripheral speed at which the abrasive product breaks due to centrifugal force m/s vbr min Minimum bursting speed Peripheral speed, which the abrasive product shall at least reach without bursting due to centrifugal force m/s Sbr Safety factor against bursting due to centrifugal force Bursting speed divided by maximum operating speed, all squared:

2=sbrbrvvS — Sab Safety factor of spindle deflection for mounted points Deflection speed divided by maximum permissible speed of rotation:

maxnnSabab= — A Impact resistance Resistance of a rotating abrasive product to lateral impact Nm FS1 Single point side load Resistance of a rotating abrasive product to lateral single point load N FS3 Three point side load Resistance of a rotating abrasive product to lateral three point load N SIST EN 12413:2007+A1:2011

4 List of significant hazards Table 3 — List of significant hazards Hazard designation Hazardous situation (Examples) Relevant clauses in this standard Ejection of parts 1. Wheel breakage caused by

— improper design 5.1, 5.2, 5.3 and Annex C — manufacturing defects 5.1 — wrong selection 5.5, 7 and Annex A — improper handling and storage 7 — improper use (mounting and grinding process) 5.6, 7 and Annex A 2. Grinding debris 7 Vibration Hand arm vibration on hand-held machines caused by

— manufacturing defects 5.3 and 5.4 — improper use 7 — incorrect mounting 7

5 Requirements 5.1 General requirements 5.1.1 General Abrasive products shall be designed and manufactured in such a way that they resist the forces and loads that are to be expected when used as intended. They shall not present visible faults and shall comply with the requirements listed in the following clauses. 5.1.2 Maximum operating speeds Abrasive products shall be manufactured for maximum operating speeds according to the following range: < 16 — 16 — 20 — 25 — 32 — 35 — 40 — 45 — 50 — 63 — 80 — 100 — 125 in m/s The only exception to this is where the application requirements dictate an intermediate speed. The manufacturer can select any of these speeds up to the maximum values shown in Table 6. For a conversion table for speeds of rotation and maximum operating speeds as a function of the outside diameter D of the abrasive products, see Annex E. SIST EN 12413:2007+A1:2011

Burst speed factor fbr

Stationary machines High pressure grinding wheels ≤ 80 3,5 1,87 Cutting-off wheels ≤ 80 3,5a 1,87 ≤ 100 2,0 1,41 All other types all 3,0 1,73 Stationary machines totally enclosed High pressure grinding wheels ≤ 100 3,0 1,73 All other types all 1,75 1,32 Mobile

machines Grinding and cutting-off wheels ≤ 100 3,5 1,87 Hand-held machines Grinding wheels D > 125 mm ≤ 50 3,0 1,73 50 < vs ≤ 80 3,5 1,87 Cutting-off wheels D > 125 mm ≤ 100 3,5 1,87 All types D ≤ 125 mm ≤ 80 3,0 1,73 > 80 3,5 1,87 a Only manually guided cutting-off.

5.2.2 Safety factors for mounted wheels and points Mounted wheels and points shall have a safety factor against bursting due to centrifugal forces of Sbr = 3 at their maximum operating speed. The spindle shall have a safety factor against deflection of Sab = 1,3. For further requirements, see Annex B. SIST EN 12413:2007+A1:2011

product Maximum operating speed Outside

diameter Side load capacity Single point side load test Three point side load test Impact test Single point side load Three point side load Impact resistance

vs D FS1 FS3 A

m/s mm N N Nm Depressed-centre grinding wheels (type 27a, type 28a and type 29b) ≤ 80

≥ 115 290 — —

150 290 — 4,5

180 290 — 5,4

230 290 — 6,9 Straight and depressed-centre cutting-off wheels (type 41 and type 42)a ≤ 80

≥ 115

40 — —

50 — 1,2

50 — 1,5

50 — 2,0

300 125 150 5,4 350/356 125 150 5,4 400/406 125 150 5,4 80 < vs ≤ 100

300 125 150 5,4 350/356 125 150 5,4 400/406 125 150 5,4 a According to ISO 525. b With back-up pad as intended for the type of application.

5.3 Dimensional requirements 5.3.1 Dimensional limitations and maximum operating speeds Bonded abrasive products shall comply with the dimensional limitations and maximum operating speeds as specified in Table 6.

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondbV B BFR RFE MG PL V B BF R RF PL Type 1 Straight grinding wheel Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D 40506350—40 25*) 50 H ≤ 0,67 D

63—

16**)H ≤ 0,50 D

80—

Mechanically guided grinding totally enclosed

— ————— — — H ≤ 0,50 D 125100100100— — Mechanically guided high pressure grinding H ≤ 0,50 D — 80———— — — — — — — — — — Mechanically guided high pressure grinding totally enclosed — ————— — — H ≤ 0,33 D — 100— — — — Stationary and mobile grinding machines Manually guided grinding H ≤ 0,67 D 355063505040 25*) 50 H ≤ 0,50 D —

63—

63—

16**)H ≤ 0,33 D — —

80—

80— D × T × Hb Hand-held grinding machines Hand-held grinding H ≤ 0,25 D — 50805080— — 50 H ≤ 0,25 D —

63—

63— —

*) D ≤ 1 000 mm **) D > 1 000 mm a Definitions see 3.2 and 3.3. b Types of bond and designation examples see ISO 525. (continued)

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 2 Cemented or clamped cylinder wheel Stationary grinding machines Mechanicallyguided grinding W < 0,17 D 3240———— 25 40 W < 0,17 D 63 63 — — — 50

Key 1 Plate Manually guided grinding 3240———— — 40 — 50 — — — 50 D × T × W b a Definitions see 3.2 and 3.3. b Types of bond and designation examples see ISO 525. (continued)

machinea Type of

applicationaMaximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensionallimitations Types of bondb V B BFRRFE MG PL V B BF R RF PL Type 3 Wheel tapered on one side Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D 4050—50—— — 50 H ≤ 0,67 D

63—

63—

63H ≤ 0,50 D

80—

80— —

Mechanically guided grinding totally enclosed — ————— — — H ≤ 0,50 D 125100— 100— — D/J × T × H b Type 4 Wheel tapered on both sides Hand-held grinding machines Hand-held grinding D ≤ 200 — 5080——— — — — — — — — — —

D × T × H b a Definitions see 3.2 and 3.3. b Types of bond and designation examples see ISO 525. (continued)

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 5 Wheel recessed on one side Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — 50 H ≤ 0,67 D E ≥ 0,50 T

6363 63

H ≤ 0,50 D E ≥ 0,50 T

8080 — Mechanically guided grinding totally enclosed — ————— — — H ≤ 0,50 D E ≥ 0,50 T 100100— 100— — Stationary and mobile grinding machines Manually guided grinding 3550—50—— — 50 H ≤ 0,50 D E ≥ 0,50 T — — 63 — 63 — H ≤ 0,33 D E ≥ 0,50 T — — 80 — 80 — Hand-held grinding machines Hand-held grinding H ≤ 0,25 D E ≥ 0,75 T — 50805080— — 50 H ≤ 0,25 D E ≥ 0,75 T —

63—

63— — D × T × H-P × F b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued)

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 6 Straight cup wheel Stationary grinding machines Mechanically guided grinding E ≥ 0,20 T 3240—40—— — 40 E ≥ 0,20 T

63—

63— —

Manually guided grinding 3240—40—— — 40 —

50— — — — Hand-held grinding machines Hand-held grinding D ≤ 180 T ≤ 70 E ≥ 0,25 T — 50———— — — — — — — — — — D × T × H-W × E b Type 7 Wheel recessed on both sides Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — 50 H ≤ 0,67 D E ≥ 0,50 T

63—

63— 63

H ≤ 0,50 D E ≥ 0,50 T

80—

80— — Mechanically guided grinding totally enclosed — ————— — — 100100— 100— — D × T × H-P × F/G b a Definitions see 3.2 and 3.3. b Types of bond and designation examples see ISO 525. (continued)

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 9 Double cup wheel Stationary grinding machines Mechanically guided grinding E ≥ 0,2 T 3240—40—— — 40 E ≥ 0,2 T 50 50 — 50 — —

D × T × H-W × E b Type 11 Taper cup wheel Stationary grinding machines Mechanically guided grinding E ≥ 0,2 T 3240—40—— — 40 E ≥ 0,2 T 50 50 — 50 — —

Mechanically guided grinding totally enclosed — — ————— — — E ≥ 0,2 T 63 80 — 63 — 50 Manually guided grinding E ≥ 0,2 T 3240—40—— — 40 — — — — — — — D/J × T × H-W × E b Hand-held grinding machines Hand-held grinding E ≥ 0,25 T — 50———— — 40 — — — — — — — a Definitions see 3.2 and 3.3. b Types of bond and designation examples see ISO 525. (continued) SIST EN 12413:2007+A1:2011

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 12 Dish wheel Stationary grinding machines Mechanically guided grinding E ≥ 0,5 T 3240—40—— — 40 E ≥ 0,5 T 50 50 — 50 — —

Mechanically guided grinding totally enclosed — — ————— — — E ≥ 0,5 T 63 80 — 63 — 50 Manually guided grinding

(tool sharpening) E ≥ 0,5 T 3240—40—— — — — — — — — — — D/J × T × H b Type 13 Saucer wheel Mechanically guided grinding E ≥ 0,5 T 3240—40—— — 40 E ≥ 0,5 T 50 50 — 50 — —

Mechanically guided grinding totally enclosed — — ————— — — E ≥ 0,5 T 63 80 — 63 — 50 Manually guided grinding

(tool sharpening) E ≥ 0,5 T 3240—40—— — — — — — — — — — D/J × T/U × H-K b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued)

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Cones and plugs Examples: Type 16 Hand-held grinding machines Hand-held grinding D ≤

80 T ≤ 100 4050———— — — D ≤

80 T ≤ 100 50 — — — — — Type 17 Type 18 Type 18R

Type 19 D × T-H × L b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued) SIST EN 12413:2007+A1:2011

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operatingspeeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 20 Wheel relieved on one side Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — 50 H ≤ 0,67 D E ≥ 0,50 T

63—

63— 63

H ≤ 0,50 D E ≥ 0,50 T

80—

80—

Mechanically guided grinding totally enclosed H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — — H ≤ 0,50 D E ≥ 0,50 T 100100— 100— — D/K × T/N × H b Type 21 Wheel relieved on both sides Mechanically guided grinding H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — 50 H ≤ 0,67 D E ≥ 0,50 T

63—

63— 63

H ≤ 0,50 D E ≥ 0,50 T

80—

80— — Mechanically guided grinding totally enclosed H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — — H ≤ 0,50 D E ≥ 0,50 T 100100— 100— — D/K × T/N × H b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued) SIST EN 12413:2007+A1:2011

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 22 Wheel relieved on one side and recessed on the other side Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — 50 H ≤ 0,67 D E ≥ 0,50 T

63—

63— 63

H ≤ 0,50 D E ≥ 0,50 T

80—

80— — Mechanically guided grinding totally enclosed H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — — H ≤ 0,50 D E ≥ 0,50 T 100100— 100— — D/K × T/N × H-P × F b Type 23 Wheel relieved and recessed on one side Mechanically guided grinding H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — 50 H ≤ 0,67 D E ≥ 0,50 T

63—

63— 63

H ≤ 0,50 D E ≥ 0,50 T

80—

80— — Mechanically guided grinding totally enclosed H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — — H ≤ 0,50 D E ≥ 0,50 T 100100— 100— — D × T/N × H-P × F b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued) SIST EN 12413:2007+A1:2011

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 24 Wheel relieved and recessed on one side and recessed on the other Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — 50 H ≤ 0,67 D E ≥ 0,50 T

63—

63— 63

H ≤ 0,50 D E ≥ 0,50 T

80—

80— — Mechanically guided grinding totally enclosed H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — — H ≤ 0,50 D E ≥ 0,50 T 100100— 100— — D × T/N × H-P × F/G b Type 25 Wheel relieved and recessed on one side and relieved on the other side Mechanically guided grinding H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — 50 H ≤ 0,67 D E ≥ 0,50 T

63—

63— 63

H ≤ 0,50 D E ≥ 0,50 T

80—

80— — Mechanically guided grinding totally enclosed H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — — H ≤ 0,50 D E ≥ 0,50 T 100100— 100— — D/K × T/N × H-P × F b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 52. (continued) SIST EN 12413:2007+A1:2011

Table 6 (continued) Shape, designation, dimensional letters Type of

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 26 Wheel relieved and recessed on both sides Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — 50 H ≤ 0,67 D E ≥ 0,50 T

63—

63— 63

H ≤ 0,50 D E ≥ 0,50 T

80—

80— — Mechanically guided grinding totally enclosed H ≤ 0,67 D E ≥ 0,50 T 4050—50—— — — H ≤ 0,50 D E ≥ 0,50 T 100100— 100— — D × T/N × H-P × F/Gb Type 27 Depressed centre grinding wheel Hand-held grinding machines Hand-held grinding D ≤ 230 H ≤ 22,23 U ≤ 10 — —80——— — — — — — — — — —

D × U × H b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued) SIST EN 12413:2007+A1:2011

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 28 Depressed-centre grinding wheel cone shaped Hand-held grinding machines Hand-held grinding D ≤ 230 H ≤ 22,23 U ≤ 10 — —80——— — — — — — — — — —

D × U × H b Type 29 Depressed-centre semi-flexible wheel D ≤ 230 H ≤ 22,23 — —80——— — — — — — — — — —

D × U × H b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued) SIST EN 12413:2007+A1:2011

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 31 Segments Examples: Stationary grinding machines Mechanically guided grinding Maximum length out of clamping

head Lf ≤ 1,5 C 3240———40 25 — Maximum length out of clamping

head

Lf ≤ 1,5 C 63 63 — — — — Manually guided grinding 3240———40 25 — — — — — — — — B × C × L b Type 35 Cemented or clamped, disc wheel Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D 3250———— 25 40 H ≤ 0,67 D 63 63 — — — 50

Key 1 Plate Manually guided grinding 3250———— — 40 — — — — — — — D × T × H b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued) SIST EN 12413:2007+A1:2011

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 36 Disc wheel with inserted nuts Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D 3250———— 25 40 H ≤ 0,67 D 63 63 — — — 50

Key 1 Plate Manually guided grinding 3250———— — 40 — — — — — — — D × T × H b Type 37 Cylinder wheel with inserted nuts Mechanically guided grinding W ≤ 0,17 D 3250———— — 40 W ≤ 0,17 D 63 63 — — — 50

Key 1 Plate Manually guided grinding 3250———— — 40 — — — — — — — D × T × W b a Definitions see 3.2 and 3.3; b Types of bond and designation examples, see ISO 525; (continued) SIST EN 12413:2007+A1:2011

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 38 Hubbed wheel Stationary grinding machines Mechanically guided grinding H ≤ 0,67 D U ≥ 0,025 D 4050—50—— — 50 H ≤ 0,67 D U ≥ 0,005 D

63—

63— —

H ≤ 0,5 D U ≥ 0,005 D

80—

80— — Mechanically guided grinding totally enclosed 4050—50—— — — H ≤ 0,5 D U ≥ 0,005 D 125100— 100— — D/J × T/U × H b Type 39 Double hubbed wheel Mechanically guided grinding H ≤ 0,67 D U ≥ 0,025 D 4050—50—— — 50 H ≤ 0,67 D U ≥ 0,005 D

63—

63— —

H ≤ 0,5 D U ≥ 0,005 D

80—

80— — Mechanically guided grinding totally enclosed 4050—50—— — — H ≤ 0,5 D U ≥ 0,005 D 125100— 100— — D/J × T/U × H b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued)

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 41 Flat cutting-off wheel Stationary cutting-off machines Mechanically guided grinding T ≤ 0,02 D H ≤ 0,33 D — 80100638063 — — T ≤ 0,02 D H ≤ 0,33 D — — —

80100—

Manually guided grinding T ≤ 0,02 D H ≤ 0,33 D — 80100638063 — — — — — — — — — Mechanically guided grinding totally enclosed T ≤ 0,02 D H ≤ 0,33 D — —100——— — — T ≤ 0,02 D H ≤ 0,33 D — 100125100125— Mobile cutting-off machines Manually guided cutting-off T ≤ 0,02 D H ≤ 0,25 D — —100——— — — — — — — — — — Hand-held cutting-off machines Hand-held cutting-off D ≤ 230 T < 4,0 H ≤ 22,23 — —

80——— — — D ≤ 125 — — 125— — — D = 300 to 406 T ≤ 0,015 D H ≤ 0,25 D — —

80——— — — D = 300 to 406 T ≤ 0,015 D H ≤ 0,25 D — — 100— — — D × T × H b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued)

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 42 Depressed centre cutting-off wheel Stationary cutting-off machines Mechanically guided grinding U ≤ 0,02 D H ≤ 0,33 D — —100—80— — — U ≤ 0,02 D H ≤ 0,33 D — — — — 100—

Manually guided grinding U ≤ 0,02 D H ≤ 0,33 D — —100—80— — — — — — — — — — Mechanically guided grinding totally enclosed U ≤ 0,02 D H ≤ 0,33 D — —100—80— — — U ≤ 0,02 D H ≤ 0,33 D — — 125— 125— Mobile cutting-off machines Manually guided cutting-off U ≤ 0,02 D H ≤ 0,25 D — —

80—80— — — — — — — — — — Hand-held cutting-off machines Hand-held cutting-off D ≤ 230 U < 4,0 H ≤ 22,23 — —

80——— — — — — — — — — — D × U × H b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. (continued)

machinea Type of

applicationa Maximum operating speeds and dimensional limitationsStandard operating speeds Special operating speedsm/s m/s Dimensionallimitations Types of bondb Dimensional limitations Types of bondb V B BFR RFE MG PL V B BF R RF PL Type 52 Mounted pointsc Examples: Stationary grinding machines Mechanically guided grinding (internal grinding) D ≤ 80 T ≤ 80 4050—50—— — 50 D ≤ 80 T ≤ 80 63 63 — 63 — —

Hand-held grinding machines Hand-held grinding D ≤ 80 T ≤ 80 5050—50—— — 50 D ≤ 80 T ≤ 80 — 63 — — — — D × T × Sd b a Definitions see 3.2 and 3.3. b Types of bond and designation examples, see ISO 525. c For maximum permissible speeds according to shape, dimensions and overhang length, see Annex C.

vs m/s Test and minimum percentage of manufacturing batch to be testeda Designation Type Bond Dimensions mm Safety speed test Bursting speed test Visualinspec-tion Straight cutting-off wheels not reinforced 41 B, R, E D < 150 all — — 100 % 150 ≤ D ≤ 406 all 5 % or 0,1 %b 100 % D > 406 5 % — 100 % Straight and depressed-centre cutting–off wheels, reinforced 41, 42 BF, RF D < 150 all — — 100 % 150 ≤ D ≤ 406 all — 0,1 % 100 % D > 406 5 % or 0,1 %b 100 % Straight and depressed-centre grinding wheels reinforced, coolie-hat wheels, flexible wheels1, 4, 5, 27, 28, 29 BF, RF D < 150 all — — 100 % 150 ≤ D ≤ 406 all — 0,1 % 100 % D > 406 5 % or 0,1 %b 100 % Straight grindin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...