ASTM D4045-15

(Test Method)Standard Test Method for Sulfur in Petroleum Products by Hydrogenolysis and Rateometric Colorimetry

Standard Test Method for Sulfur in Petroleum Products by Hydrogenolysis and Rateometric Colorimetry

SIGNIFICANCE AND USE

4.1 In many petroleum refining processes, low levels of sulfur in feed stocks may poison expensive catalysts. This test method can be used to monitor the amount of sulfur in such petroleum fractions.

4.2 This test method may also be used as a quality-control tool for sulfur determination in finished products.

SCOPE

1.1 This test method covers the determination of sulfur in petroleum products in the range from 0.02 mg/kg to 10.00 mg/kg.

1.2 This test method may be extended to higher concentration by dilution.

1.3 This test method is applicable to liquids whose boiling points are between 30 °C and 371 °C (86 °F and 700 °F). Materials that can be analyzed include naphtha, kerosine, alcohol, steam condensate, various distillates, jet fuel, benzene, and toluene.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4.1 Certain specifications for the recorder (see 5.5) are excepted.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4045 − 15

Standard Test Method for

Sulfur in Petroleum Products by Hydrogenolysis and

1

Rateometric Colorimetry

This standard is issued under the fixed designation D4045; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* and hydrogen are pyrolyzed at a temperature of 1300 °C, or

above, to convert sulfur compounds to hydrogen sulfide (H S).

2

1.1 This test method covers the determination of sulfur in

Readout is by the rateometric detection of the colorimetric

petroleum products in the range from 0.02 mg⁄kg to

reactionofH Swithleadacetate.Condensablecomponentsare

2

10.00 mg⁄kg.

converted to gaseous products, such as methane, during hy-

1.2 This test method may be extended to higher concentra-

drogenolysis.

tion by dilution.

4. Significance and Use

1.3 This test method is applicable to liquids whose boiling

points are between 30 °C and 371 °C (86 °F and 700 °F).

4.1 In many petroleum refining processes, low levels of

Materials that can be analyzed include naphtha, kerosine,

sulfur in feed stocks may poison expensive catalysts. This test

alcohol,steamcondensate,variousdistillates,jetfuel,benzene,

method can be used to monitor the amount of sulfur in such

and toluene.

petroleum fractions.

1.4 The values stated in SI units are to be regarded as

4.2 This test method may also be used as a quality-control

standard. The values given in parentheses are for information

tool for sulfur determination in finished products.

only.

3,4

5. Apparatus

1.4.1 Certain specifications for the recorder (see 5.5) are

excepted.

5.1 Pyrolysis Furnace—A furnace that can provide an

adjustable temperature from 900 °C to 1400 °C in a 5 mm

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the inside diameter or larger tube is required to pyrolyze the

sample. The furnace entry temperature shall allow insertion of

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- the hypodermic tip to a depth at which the temperature is

bility of regulatory limitations prior to use. 550 °C to provide sample vaporization at the injection syringe

tip. This temperature shall be above the boiling point of the

2. Referenced Documents

sample and of the sulfur compounds in the sample (see Fig. 1).

2

2.1 ASTM Standards: The pyrolyzer tube may be of quartz; however, the lifetime is

D1193 Specification for Reagent Water limited above 1250 °C. Ceramic may be used at any tempera-

D6299 Practice for Applying Statistical Quality Assurance ture.

and Control Charting Techniques to Evaluate Analytical

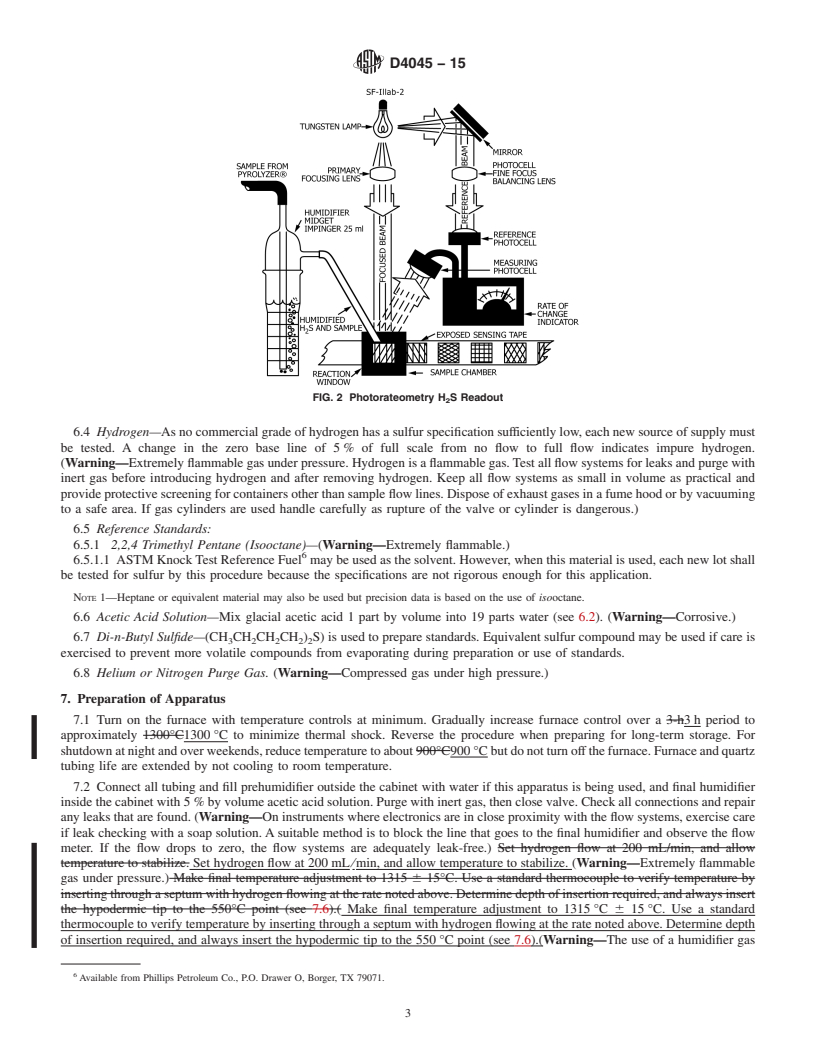

5.2 Rateometric H S Readout—Hydrogenolysis products

2

Measurement System Performance

contain H S in proportion to sulfur in the sample. The HSis

2 2

measuredbymeasuringrateofchangeofreflectancecausedby

3. Summary of Test Method

darkening when lead sulfide is formed. Rateometric

3.1 The sample is injected at a constant rate into a flowing

electronics, adapted to provide a first derivative output, allows

hydrogen stream in a hydrogenolysis apparatus. The sample

sufficient sensitivity to measure below 0.1 mg/L (see Fig. 2).

1

This test method is under the jurisdiction of ASTM Committee D02 on

3

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of The apparatus described in 5.1 – 5.4 inclusive is similar in specification to the

Subcommittee D02.03 on Elemental Analysis. equipment available from Analytical Systems Keco, 9215 Solon Rd., Suite A4,

Current edition approved April 1, 2015. Published April 2015. Originally Houston, TX 77064. For further information see Drushel, H. V., “Trace Sulfur

approved in 1987. Last previous edition approved in 2010 as D4045 – 04 (2010). Determination Petroleum Fractions,” Analytical Chemistry, Vol 50, 1978, p. 76.

4

DOI: 10.1520/D4045-15. The sole source of supply of the apparatus known to the committee at this time

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or isAnalyticalSystemsKeco.Ifyouareawareofalternativesuppliers,pleaseprovide

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM this information to ASTM International Headquarters. Your comments will receive

1

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

the ASTM website. you may attend.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4045 − 04 (Reapproved 2010) D4045 − 15

Standard Test Method for

Sulfur in Petroleum Products by Hydrogenolysis and

1

Rateometric Colorimetry

This standard is issued under the fixed designation D4045; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the determination of sulfur in petroleum products in the range from 0.020.02 mg ⁄kg to 10.00

10.00 mg mg/kg.⁄kg.

1.2 This test method may be extended to higher concentration by dilution.

1.3 This test method is applicable to liquids whose boiling points are between 3030 °C and 371°C (86371 °C (86 °F and

700°F).700 °F). Materials that can be analyzed include naphtha, kerosine, alcohol, steam condensate, various distillates, jet fuel,

benzene, and toluene.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4.1 Certain specifications for the recorder (see 5.5) are excepted.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

3. Summary of Test Method

3.1 The sample is injected at a constant rate into a flowing hydrogen stream in a hydrogenolysis apparatus. The sample and

hydrogen are pyrolyzed at a temperature of 1300°C,1300 °C, or above, to convert sulfur compounds to hydrogen sulfide (H S).

2

Readout is by the rateometric detection of the colorimetric reaction of H S with lead acetate. Condensable components are

2

converted to gaseous products, such as methane, during hydrogenolysis.

4. Significance and Use

4.1 In many petroleum refining processes, low levels of sulfur in feed stocks may poison expensive catalysts. This test method

can be used to monitor the amount of sulfur in such petroleum fractions.

4.2 This test method may also be used as a quality-control tool for sulfur determination in finished products.

3,4

5. Apparatus

5.1 Pyrolysis Furnace—A furnace that can provide an adjustable temperature from 900900 °C to 1400°C1400 °C in a

5-mm51 mm inside diameter or larger tube is required to pyrolyze the sample. The furnace entry temperature shall allow insertion

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved May 1, 2010April 1, 2015. Published May 2010April 2015. Originally approved in 1987. Last previous edition approved in 20042010 as

D4045D4045 – 04 (2010).– 04. DOI: 10.1520/D4045-04R10.10.1520/D4045-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The apparatus described in 5.1 – 5.4 inclusive is similar in specification to the equipment available from Houston Atlas, Inc., 22001 North Park Dr., Kingswood, TX

77339-3804.Analytical Systems Keco, 9215 Solon Rd., Suite A4, Houston, TX 77064. For further information see Drushel, H. V., “Trace Sulfur Determination Petroleum

Fractions,” Analytical Chemistry, Vol 50, 1978, p. 76.

4

The sole source of supply of the apparatus known to the committee at this time is Houston Atlas, Inc.Analytical Systems Keco. If you are aware of alternative suppliers,

1

please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee,

which you may attend.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4045 − 15

of the hypodermic tip to a depth at which the temperature is 550°C550 °C to provide sample vaporization

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.