ASTM D7212-13(2018)

(Test Method)Standard Test Method for Low Sulfur in Automotive Fuels by Energy-Dispersive X-ray Fluorescence Spectrometry Using a Low-Background Proportional Counter

Standard Test Method for Low Sulfur in Automotive Fuels by Energy-Dispersive X-ray Fluorescence Spectrometry Using a Low-Background Proportional Counter

SIGNIFICANCE AND USE

5.1 This test method determines total sulfur in automotive fuels with a typical analysis time around 10 min per sample.

5.2 The quality of automotive fuel is related to the amount of sulfur present. Knowledge of sulfur level is necessary for processing purposes.

5.3 Sulfur level in automotive fuels affects performance characteristics and air quality. Federal, state, and local agencies regulate the level of sulfur in fuel delivered at the pump.

5.4 This test method can be referenced in specification documents to determine if the material meets the desired sulfur content.

5.5 If this test method is applied to petroleum matrices with significantly different composition to those used in the interlaboratory precision study, then the caution and recommendations in Section 6 should be observed when interpreting the results.

SCOPE

1.1 This test method specifies an energy-dispersive X-ray fluorescence (EDXRF) method for the determination of the total sulfur content of automotive fuels with a concentration range from 7 mg/kg to 50 mg/kg.

1.1.1 The pooled limit of quantitation of this test method as obtained by statistical analysis of interlaboratory test results is 7 mg/kg sulfur.

1.2 The values stated in SI units are to be regarded as the standard. The preferred concentration units are mg/kg sulfur.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7212 − 13 (Reapproved 2018)

Standard Test Method for

Low Sulfur in Automotive Fuels by Energy-Dispersive X-ray

Fluorescence Spectrometry Using a Low-Background

Proportional Counter

This standard is issued under the fixed designation D7212; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6299 Practice for Applying Statistical Quality Assurance

and Control Charting Techniques to Evaluate Analytical

1.1 This test method specifies an energy-dispersive X-ray

Measurement System Performance

fluorescence (EDXRF) method for the determination of the

D6300 Practice for Determination of Precision and Bias

total sulfur content of automotive fuels with a concentration

Data for Use in Test Methods for Petroleum Products and

range from 7 mg/kg to 50 mg/kg.

Lubricants

1.1.1 The pooled limit of quantitation of this test method as

D6792 Practice for Quality Management Systems in Petro-

obtained by statistical analysis of interlaboratory test results is

leum Products, Liquid Fuels, and Lubricants Testing

7 mg⁄kg sulfur.

Laboratories

1.2 The values stated in SI units are to be regarded as the

D7343 Practice for Optimization, Sample Handling,

standard. The preferred concentration units are mg/kg sulfur.

Calibration, and Validation of X-ray Fluorescence Spec-

1.3 This standard does not purport to address all of the

trometry Methods for Elemental Analysis of Petroleum

safety concerns, if any, associated with its use. It is the

Products and Lubricants

responsibility of the user of this standard to establish appro-

E29 Practice for Using Significant Digits in Test Data to

priate safety, health, and environmental practices and deter-

Determine Conformance with Specifications

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

3. Terminology

dance with internationally recognized principles on standard-

3.1 Definitions of Terms Specific to This Standard:

ization established in the Decision on Principles for the

3.1.1 low background proportional counter, n—an X-ray

Development of International Standards, Guides and Recom-

proportional counter that can suppress the noise generated

mendations issued by the World Trade Organization Technical

when incident X rays are absorbed near the wall with resulting

Barriers to Trade (TBT) Committee.

incomplete charge collection.

2. Referenced Documents 3.1.1.1 Discussion—An electrode shield close to the wall

detects incomplete charge collection and associated electronic

2.1 ASTM Standards:

detection circuitry rejects those events. In comparison to

D4045 Test Method for Sulfur in Petroleum Products by

conventional proportional counters, this gives lower spectral

Hydrogenolysis and Rateometric Colorimetry

background and a lower limit of detection.

D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

4. Summary of Test Method

D4177 Practice for Automatic Sampling of Petroleum and

Petroleum Products

4.1 The sample is placed in the beam emitted from an X-ray

source with titanium target and primary filtration so that

excitation is by essentially monochromatic radiation of

This test method is under the jurisdiction of ASTM Committee D02 on

4.51 keV and virtually no background at 2.3 keV. A low

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

background proportional counter measures the intensity of the

Subcommittee D02.03 on Elemental Analysis.

fluorescent sulfur K series intensity and argon K series inten-

Current edition approved July 1, 2018. Published August 2018. Originally

sity (from residual air) and the accumulated counts are com-

approved in 2006. Last previous edition approved in 2013 as D7212 – 13. DOI:

10.1520/D7212-13R18.

pared with counts from previously prepared calibration stan-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

dards to obtain the sulfur concentration in mg/kg. If chlorine is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

expected to be present in some samples then other regions of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the spectrum must be measured to provide compensation for

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7212 − 13 (2018)

spectral overlap. One group of calibration standards is required 7.1.2 Low Background Proportional Counter (see 3.1.1),

to span the concentration range from 0 mg⁄kg to 150 mg⁄kg with sensitivity at 2.3 keV.

sulfur. 7.1.3 Multi-channel Analyzer, with a channel width of 10eV

NOTE 1—Operation of analyzers using X-ray tubes is to be conducted

or less, covering the energy range from 0 keV to 10 keV.

in accordance with the manufacturer’s safety instructions and federal,

7.1.4 Signal Conditioning and Data Handling Electronics,

state, and local regulations governing the use of ionizing radiation.

that include the functions of X-ray intensity counting, a

4.2 Practice D7343 should be consulted regarding standard

minimum of four energy regions (to correct for background X

operating protocols in XRF analysis.

rays and spectral overlap), spectral overlap corrections, and

conversions of sulfur X-ray intensity into sulfur concentration.

5. Significance and Use

7.1.5 Display or Printer, that reads out in mg/kg sulfur.

7.1.6 Removable Sample Cell, providing a sample depth of

5.1 This test method determines total sulfur in automotive

at least 4 mm and equipped with a replaceable X-ray transpar-

fuels with a typical analysis time around 10 min per sample.

ent plastic film window.

5.2 The quality of automotive fuel is related to the amount

7.1.7 Helium Purged Optical Path, to maximize sensitivity

of sulfur present. Knowledge of sulfur level is necessary for

and minimize spectral overlap from argon in air. The helium

processing purposes.

shall be at least 99.9 % purity.

5.3 Sulfur level in automotive fuels affects performance

8. Reagents and Materials

characteristicsandairquality.Federal,state,andlocalagencies

regulate the level of sulfur in fuel delivered at the pump.

8.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

5.4 This test method can be referenced in specification

all reagents conform to the specifications of the Committee on

documents to determine if the material meets the desired sulfur

Analytical Reagents of the American Chemical Society where

content.

such specifications are available. Other grades may be used,

5.5 If this test method is applied to petroleum matrices with

provided it is first ascertained that the reagent is of sufficiently

significantly different composition to those used in the inter-

high purity to permit its use without lessening the accuracy of

laboratory precision study, then the caution and recommenda-

the determination.

tions in Section 6 should be observed when interpreting the

8.2 Di-n Butyl Sulfide (DBS), a high purity standard with

results.

certified analysis for sulfur content. Use the certified sulfur

content when calculating the exact concentrations of the

6. Interferences

calibration standards. (Warning—Di-n-butyl sulfide is flam-

6.1 Spectral interferences result when some sample compo-

mable and toxic).

nent element or elements emit X rays that the detector cannot

8.3 MineralOil,White(MOW),withsulfurcontentlessthan

resolvefromsulfurX-rayemission.Overlappingpeaklinesare

0.2 mg⁄kgascertifiedbyasuitableanalyticalmethod,likeTest

theresultofthis.Thisoverlappingeffectmaybebyleadalkyls,

Method D4045.

silicon, phosphorus, calcium, potassium, and halides if their

aggregate concentration is more than 10 mg⁄kg. The most 8.4 X-ray Transparent Film, any film that resists attack by

likely interference is chlorine that has been found in biodiesel the sample, is free of sulfur and other interfering elements (see

derived from recycled waste vegetable oil. 6.1), and is sufficiently X-ray transparent may be used.

6.2 The presence of oxygenates or water may alter the

NOTE 2—Polycarbonate with thickness of 5 or 6 µm most closely

matches these requirements and eight of nine participants in the interlabo-

sensitivity for sulfur.

ratorystudy usedoneofthesefilms,whiletheotherlaboratoryused3 µm

6.3 Follow the manufacturer’s operating guide to compen-

polyester.

sate for the interferences.

8.4.1 Samples of high aromatic content may dissolve poly-

carbonate film and polypropylene has a tendency to absorb

7. Apparatus

some hydrocarbons and may stretch during a long measure-

7.1 Energy-dispersive X-ray Fluorescence Analyzer—Any ment time.

energy dispersive X-ray fluorescence analyzer may be used if

its design incorporates, as a minimum the following features:

The low background proportional counter is covered by a pending patent.

7.1.1 SourceofX-rayExcitation,X-raysourcewithtitanium

Interested parties are invited to submit information regarding the identification of an

target and primary filtration so that excitation is by essentially

alternative(s) to this patent-pending item toASTM International Headquarters.Your

monochromatic radiation of 4.51 keV.

comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington DC. For suggestions on testing of reagents not listed

The sole source of supply of the apparatus known to the committee at this time by the American Chemical Society, see Annual Standards for Laboratory , BDH

is the Twin-X ULS from Oxford Instruments Analytical, Halifax Road, High Ltd., Poole Dorset, U.K., and the United States Pharmacopeia and National

Wycombe, Bucks, HP12 3SE, England. If you are aware of alternative suppliers, Formulary, U.S Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

please provide this information to ASTM International Headquarters. Your com- Supporting data have been filed at ASTM International Headquarters and may

ments will receive careful consideration at a meeting of the responsible technical beobtainedbyrequestingResearchReportRR:D02-1587.ContactASTMCustomer

committee, which you may attend. Service at service@astm.org.

D7212 − 13 (2018)

NOTE3—Onelaboratoryhasshownthatpolycarbonateresistsamixture

10. Preparation of Apparatus

of 25 % by mass isooctane and 75 % by mass toluene for 80 min.

10.1 Set up the apparatus in accordance with the manufac-

8.4.2 In these cases high purity polyester is acceptable, but

turer’s instructions. Whenever possible, the instrument should

overall, polycarbonate offers the best combination of spectral

remain energized to maintain optimum stability.

purityandresistancetostretching.Othermaterialsmaybeused

10.2 When changing the helium gas cylinder or after a

for X-ray windows, provided that they do not contain any

system has been idle for a day or more ensure that the helium

elemental impurities and match the listed films for X-ray

pipes are purged of air by performing a dummy measurement.

transmission.

11. Calibration and Standardization

8.5 Sample Cells, resistant to sample attack and meet the

geometry requirements of spectrometer.

11.1 Preparation of Calibration Standards:

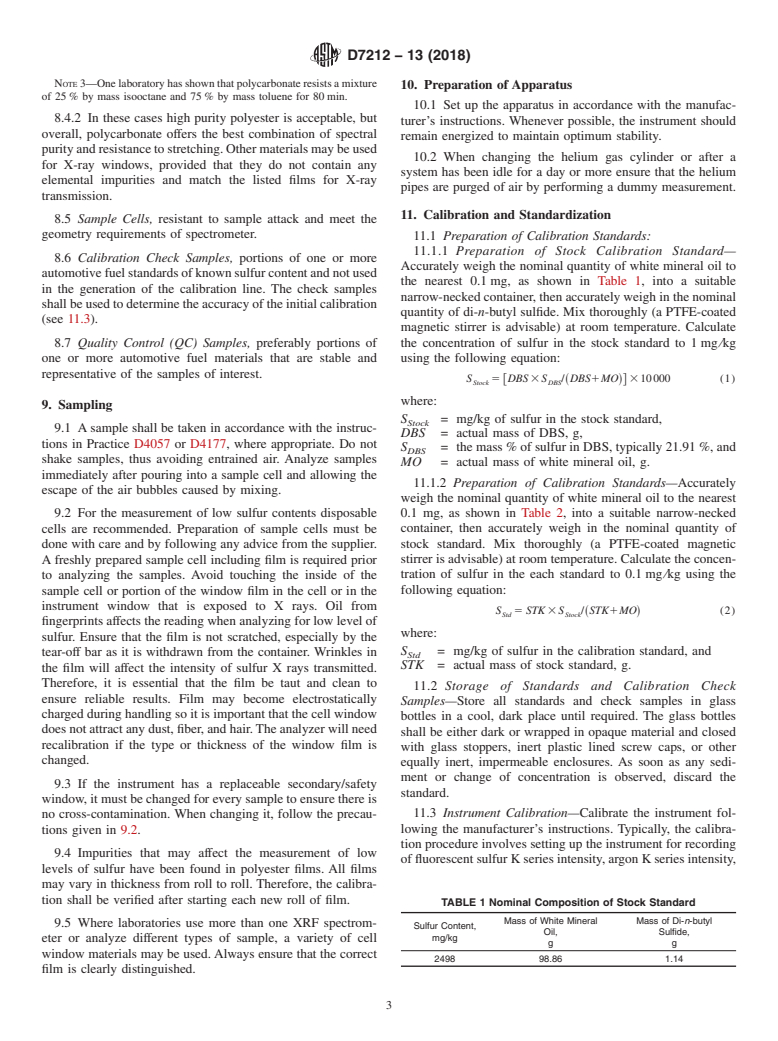

11.1.1 Preparation of Stock Calibration Standard—

8.6 Calibration Check Samples, portions of one or more

Accurately weigh the nominal quantity of white mineral oil to

automotivefuelstandardsofknownsulfurcontentandnotused

the nearest 0.1 mg, as shown in Table 1, into a suitable

in the generation of the calibration line. The check samples

narrow-necked container, then accurately weigh in the nominal

shallbeusedtodeterminetheaccuracyoftheinitialcalibration

quantity of di-n-butyl sulfide. Mix thoroughly (a PTFE-coated

(see 11.3).

magnetic stirrer is advisable) at room temperature. Calculate

8.7 Quality Control (QC) Samples, preferably portions of the concentration of sulfur in the stock standard to 1 mg⁄kg

using the following equation:

one or more automotive fuel materials that are stable and

representative of the samples of interest.

S 5 @DBS 3S /~DBS1MO!# 310000 (1)

Stock DBS

where:

9. Sampling

S = mg/kg of sulfur in the stock standard,

Stock

9.1 A sample shall be taken in accordance with the instruc-

DBS = actual mass of DBS, g,

tions in Practice D4057 or D4177, where appropriate. Do not

S = the mass % of sulfur in DBS, typically 21.91 %, and

DBS

shake samples, thus avoiding entrained air. Analyze samples

MO = actual mass of white mineral oil, g.

immediately after pouring into a sample cell and allowing the

11.1.2 Preparation of Calibration Standards—Accurately

escape of the air bubbles caused by mixing.

weigh the nominal quantity of white mineral oil to the nearest

9.2 For the measurement of low sulfur contents disposable 0.1 mg, as shown in Table 2, into a suitable narrow-necked

container, then accurately weigh in the nominal quantity of

cells are recommended. Preparation of sample cells must be

done with care and by following any advice from the supplier. stock standard. Mix thoroughly (a PTFE-coated magnetic

stirrer is advisable) at room temperature. Calculate the concen-

Afreshly prepared sample cell including film is required prior

to analyzing the samples. Avoid touching the inside of the tration of sulfur in the each standard to 0.1 mg⁄kg using the

following equation:

sample cell or portion of the window film in the cell or in the

instrument window that is exposed to X rays. Oil from

S 5 STK 3S / STK1MO (2)

~ !

Std Stock

fingerprints affects the reading when analyzing for low level of

where:

sulfur. Ensure that the film is not scratched, especially by the

S = mg/kg of sulfur in the calibration standard, and

tear-off bar as it is withdrawn from the container. Wrinkles in

Std

STK = actual mass of stock standard, g.

the film will affect the intensity of sulfur X rays transmitted.

Therefore, it is essential that the film be taut and clean to

11.2 Storage of Standards and Calibration Check

ensure reliable results. Film may become electrostatically

Samples—Store all standards and check samples in glass

charged during handling so it is important that the cell window

bottles in a cool, dark place until required. The glass bottles

doesnotattractanydust,fiber,andhair.Theanalyzerwillneed

shall be eit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.