ASTM D8276-19(2024)

(Test Method)Standard Test Method for Hydrocarbon Types in Middle Distillates, including Biodiesel Blends by Gas Chromatography/Mass Spectrometry

Standard Test Method for Hydrocarbon Types in Middle Distillates, including Biodiesel Blends by Gas Chromatography/Mass Spectrometry

SIGNIFICANCE AND USE

5.1 A knowledge of the hydrocarbon composition of the middle distillates, including the biodiesel blends is useful in following the effect of changes in process variables, diagnosing the source of plant upsets, and in evaluating the effect of changes in composition on product performance properties. The total aromatics content and polycyclic aromatics content are also important to evaluate the quality of diesel fuels/biodiesel blends. It requires an appropriate analytical method to make such determinations for diesel fuel/biodiesel blends production process and quality control.

5.2 This test method provides a comprehensive analytical strategy for the determination of the total aromatics contents, polycyclic aromatics contents and the detail hydrocarbon composition of diesel fuel/biodiesel blends to ensure compliance with certain specifications or regulations.

5.3 Test Method D2425 is applicable to the determination of the detailed hydrocarbon composition in middle distillates, however, the pre-separation procedure of elution chromatography is time-consuming and not eco-friendly. By combining with the separation procedures described in Test Method D8144, the dual column GC-MS system proposed in this method can determine the total aromatic hydrocarbon contents, polycyclic aromatic hydrocarbon contents and detailed hydrocarbon composition of diesel fuel/biodiesel blends simultaneously. The content of FAME in biodiesel blends can also be determined by GC. It is demonstrated to be time-saving and eco-friendly for the quality control of diesel fuel and biodiesel blends.

SCOPE

1.1 This test method covers an analytical scheme using the gas chromatography/mass spectrometry (GC-MS) to determine the hydrocarbon types present in middle distillates 170 °C to 365 °C boiling range, 5 % to 95 % by volume as determined by Test Method D86, including biodiesel blends with up to 20 % by volume of fatty acid methyl ester (FAME). The detailed hydrocarbon composition, total aromatic hydrocarbon and polycyclic aromatic hydrocarbon contents can be determined. The hydrocarbon types include: paraffins, noncondensed cycloparaffins, condensed dicycloparaffins, condensed tricycloparaffins, alkylbenzenes, indans or tetralins, or both, CnH2n-10 (indenes, etc.), naphthalenes, CnH2n-14 (acenaphthenes, etc.), CnH2n-16 (acenaphthylenes, etc.), and tricyclic aromatics. The content of FAME in biodiesel blends can also be determined by GC.

1.2 The values stated in acceptable SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8276 − 19 (Reapproved 2024)

Standard Test Method for

Hydrocarbon Types in Middle Distillates, including Biodiesel

Blends by Gas Chromatography/Mass Spectrometry

This standard is issued under the fixed designation D8276; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers an analytical scheme using the

D86 Test Method for Distillation of Petroleum Products and

gas chromatography/mass spectrometry (GC-MS) to determine

Liquid Fuels at Atmospheric Pressure

the hydrocarbon types present in middle distillates 170 °C to

D2425 Test Method for Hydrocarbon Types in Middle Dis-

365 °C boiling range, 5 % to 95 % by volume as determined by

tillates by Mass Spectrometry

Test Method D86, including biodiesel blends with up to 20 %

D4057 Practice for Manual Sampling of Petroleum and

by volume of fatty acid methyl ester (FAME). The detailed

Petroleum Products

hydrocarbon composition, total aromatic hydrocarbon and

D4177 Practice for Automatic Sampling of Petroleum and

polycyclic aromatic hydrocarbon contents can be determined.

Petroleum Products

The hydrocarbon types include: paraffins, noncondensed

D6299 Practice for Applying Statistical Quality Assurance

cycloparaffins, condensed dicycloparaffins, condensed

and Control Charting Techniques to Evaluate Analytical

tricycloparaffins, alkylbenzenes, indans or tetralins, or both,

Measurement System Performance

C H (indenes, etc.), naphthalenes, C H

n 2n-10 n 2n-14

D6300 Practice for Determination of Precision and Bias

(acenaphthenes, etc.), C H (acenaphthylenes, etc.), and

n 2n-16

Data for Use in Test Methods for Petroleum Products,

tricyclic aromatics. The content of FAME in biodiesel blends

Liquid Fuels, and Lubricants

can also be determined by GC.

D8144 Test Method for Separation and Determination of

Aromatics, Nonaromatics, and FAME Fractions in Middle

1.2 The values stated in acceptable SI units are to be

Distillates by Solid-Phase Extraction and Gas Chromatog-

regarded as the standard. No other units of measurement are

raphy

included in this standard.

1.3 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

3.1 Definitions of Terms Specific to This Standard:

responsibility of the user of this standard to establish appro-

3.1.1 The detailed definitions of the summation of charac-

priate safety, health, and environmental practices and deter-

teristic mass fragments can be found in Test Method D2425.

mine the applicability of regulatory limitations prior to use.

3.1.2 dual column GC-MS system, n—a gas

1.4 This international standard was developed in accor- chromatography/mass spectrometry system equipped with a

dance with internationally recognized principles on standard- hydrogen flame ionization detector (FID). Samples introduced

ization established in the Decision on Principles for the by the sample introduction system are split into two capillary

Development of International Standards, Guides and Recom- columns in parallel, in which one column connected to the FID

and the other one connected to the mass spectrometer.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.1.3 polycyclic aromatic hydrocarbons, n—sum of the

concentrations of naphthalenes, C H (acenaphthenes, etc.),

n 2n-14

C H (acenaphthylenes, etc.) and tricyclic aromatics.

n 2n-16

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.04.0M on Mass Spectrometry. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 15, 2024. Published April 2024. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2019. Last previous edition approved in 2019 as D8276 – 19. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D8276-19R24. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D8276 − 19 (2024)

3.1.4 total aromatic hydrocarbons, n—sum of the concen- 5.3 Test Method D2425 is applicable to the determination of

trations of alkylbenzenes, indans, tetralins, C H (indenes, the detailed hydrocarbon composition in middle distillates,

n 2n-10

etc.) and polycyclic aromatics. however, the pre-separation procedure of elution chromatog-

raphy is time-consuming and not eco-friendly. By combining

4. Summary of Test Method

with the separation procedures described in Test Method

D8144, the dual column GC-MS system proposed in this

4.1 Samples are separated into saturate, aromatic, and/or

method can determine the total aromatic hydrocarbon contents,

FAME fractions by Test Method D8144. Aliquots of internal

polycyclic aromatic hydrocarbon contents and detailed hydro-

standards are added to these fractions and all of these fractions

carbon composition of diesel fuel/biodiesel blends simultane-

are analyzed by the dual column GC-MS system. The contents

ously. The content of FAME in biodiesel blends can also be

of the saturates, aromatic, and/or FAME fractions are calcu-

determined by GC. It is demonstrated to be time-saving and

lated based on the FID peak areas according to Test Method

eco-friendly for the quality control of diesel fuel and biodiesel

D8144 and the detailed hydrocarbon composition analysis can

blends.

be determined by the summation of characteristic mass frag-

ments in the saturate and aromatic fractions. Calculations are

6. Apparatus

performed as the procedures described in Test Method D2425

and the concentration of hydrocarbon types in each fraction are

6.1 Dual Column GC-MS System—The dual column

mathematically combined according to their mass percents.

GC-MS system shall be equipped with sample introduction

The contents of total aromatics and polycyclic aromatics can be

system, capillary column, column temperature programmer,

calculated by summing up the concentrations of corresponding

FID, mass spectrometer, and data acquisition system. Samples

hydrocarbon types. The content of FAME in biodiesel blends

are introduced into the dual column GC-MS system and split

can be determined by GC-FID. Results are expressed in mass

into two capillary columns in parallel, then analyzed by the

percent.

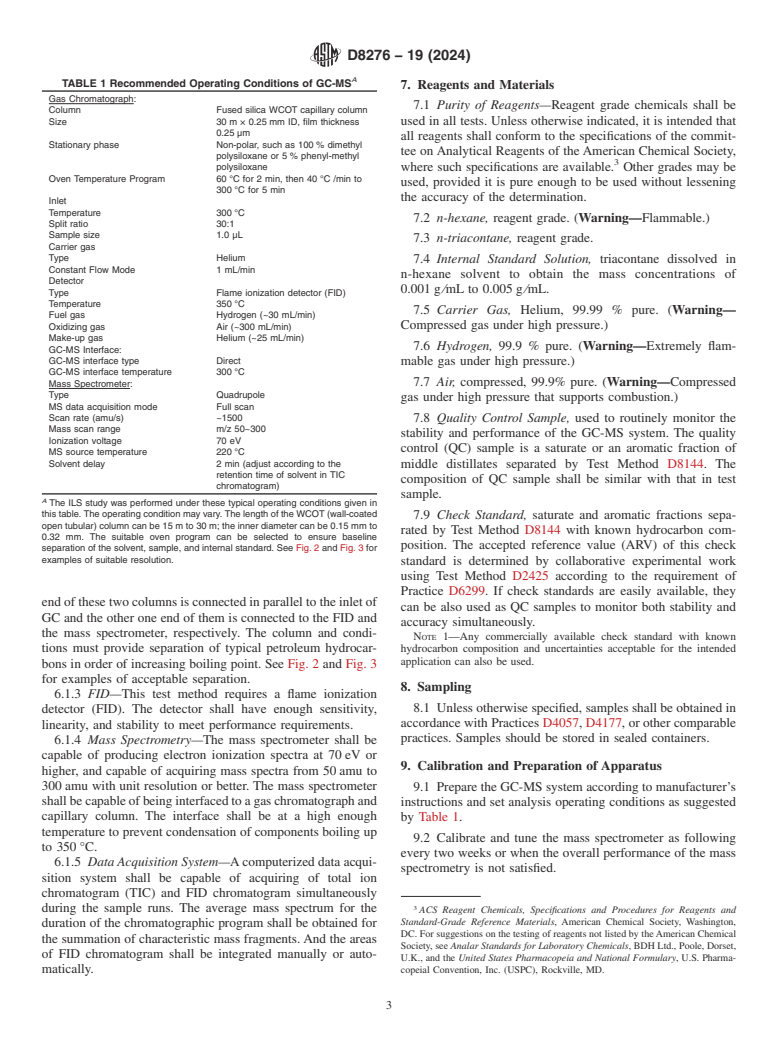

FID and mass spectrometer, respectively. The schematic rep-

resentation of dual column GC-MS system is shown in Fig. 1.

5. Significance and Use

Recommended GC-MS operating conditions are given in Table

5.1 A knowledge of the hydrocarbon composition of the

1. The GC-MS system and operating conditions shall ensure

middle distillates, including the biodiesel blends is useful in

baseline separation of the solvent, sample and internal standard

following the effect of changes in process variables, diagnosing

as shown in Fig. 2 and Fig. 3. Any other GC-MS system and

the source of plant upsets, and in evaluating the effect of

operating conditions capable of yielding equivalent results may

changes in composition on product performance properties.

be used.

The total aromatics content and polycyclic aromatics content

6.1.1 Sample Introduction System—Manual or recom-

are also important to evaluate the quality of diesel fuels/

mended automated liquid syringe injection into a splitting inlet

biodiesel blends. It requires an appropriate analytical method

may be employed. An inlet adaptor and two-hole ferrule are

to make such determinations for diesel fuel/biodiesel blends

required for connecting two capillary columns in parallel to the

production process and quality control.

inlet of GC. The sample amount reaching the column (combi-

5.2 This test method provides a comprehensive analytical nation of injection volume and split ratio) should meet the

requirement of separation efficiency of column and linear

strategy for the determination of the total aromatics contents,

response calibration range.

polycyclic aromatics contents and the detail hydrocarbon

composition of diesel fuel/biodiesel blends to ensure compli- 6.1.2 Capillary Column—Two identical non-polar silica

ance with certain specifications or regulations. capillary columns are recommended in this test method. One

FIG. 1 Schematic Representation of Dual Column GC-MS System

D8276 − 19 (2024)

A

TABLE 1 Recommended Operating Conditions of GC-MS

7. Reagents and Materials

Gas Chromatograph:

7.1 Purity of Reagents—Reagent grade chemicals shall be

Column Fused silica WCOT capillary column

Size 30 m × 0.25 mm ID, film thickness used in all tests. Unless otherwise indicated, it is intended that

0.25 μm

all reagents shall conform to the specifications of the commit-

Stationary phase Non-polar, such as 100 % dimethyl

tee on Analytical Reagents of the American Chemical Society,

polysiloxane or 5 % phenyl-methyl

polysiloxane

where such specifications are available. Other grades may be

Oven Temperature Program 60 °C for 2 min, then 40 °C /min to

used, provided it is pure enough to be used without lessening

300 °C for 5 min

the accuracy of the determination.

Inlet

Temperature 300 °C

7.2 n-hexane, reagent grade. (Warning—Flammable.)

Split ratio 30:1

Sample size 1.0 μL

7.3 n-triacontane, reagent grade.

Carrier gas

Type Helium

7.4 Internal Standard Solution, triacontane dissolved in

Constant Flow Mode 1 mL/min

n-hexane solvent to obtain the mass concentrations of

Detector

0.001 g ⁄mL to 0.005 g ⁄mL.

Type Flame ionization detector (FID)

Temperature 350 °C

7.5 Carrier Gas, Helium, 99.99 % pure. (Warning—

Fuel gas Hydrogen (~30 mL/min)

Oxidizing gas Air (~300 mL/min) Compressed gas under high pressure.)

Make-up gas Helium (~25 mL/min)

7.6 Hydrogen, 99.9 % pure. (Warning—Extremely flam-

GC-MS Interface:

GC-MS interface type Direct

mable gas under high pressure.)

GC-MS interface temperature 300 °C

7.7 Air, compressed, 99.9% pure. (Warning—Compressed

Mass Spectrometer:

Type Quadrupole

gas under high pressure that supports combustion.)

MS data acquisition mode Full scan

Scan rate (amu/s) ~1500 7.8 Quality Control Sample, used to routinely monitor the

Mass scan range m/z 50~300

stability and performance of the GC-MS system. The quality

Ionization voltage 70 eV

control (QC) sample is a saturate or an aromatic fraction of

MS source temperature 220 °C

Solvent delay 2 min (adjust according to the

middle distillates separated by Test Method D8144. The

retention time of solvent in TIC

composition of QC sample shall be similar with that in test

chromatogram)

sample.

A

The ILS study was performed under these typical operating conditions given in

this table. The operating condition may vary. The length of the WCOT (wall-coated

7.9 Check Standard, saturate and aromatic fractions sepa-

open tubular) column can be 15 m to 30 m; the inner diameter can be 0.15 mm to

rated by Test Method D8144 with known hydrocarbon com-

0.32 mm. The suitable oven program can be selected to ensure baseline

position. The accepted reference value (ARV) of this check

separation of the solvent, sample, and internal standard. See Fig. 2 and Fig. 3 for

examples of suitable resolution.

standard is determined by collaborative experimental work

using Test Method D2425 according to the requirement of

Practice D6299. If check standards are easily available, they

end of these two columns is connected in parallel to the inlet of

can be also used as QC samples to monitor both stability and

GC and the other one end of them is connected to the FID and

accuracy simultaneously.

the mass spectrometer, respectively. The column and condi-

NOTE 1—Any commercially available check standard with known

tions must provide separation of typical petroleum hydrocar- hydrocarbon composition and uncertainties acceptable for the intended

application can also be used.

bons in order of increasing boiling point. See Fig. 2 and Fig. 3

for examples of acceptable separation.

8. Sampling

6.1.3 FID—This test method requires a flame ionization

8.1 Unless otherwise specified, samples shall be obtained in

detector (FID). The detector shall have enough sensitivity,

accordance with Practices D4057, D4177, or other comparable

linearity, and stability to meet performance requirements.

practices. Samples should be stored in sealed containers.

6.1.4 Mass Spectrometry—The mass spectrometer shall be

capable of producing electron ionization spectra at 70 eV or

9. Calibration and Preparation of Apparatus

higher, and capable of acquiring mass spectra from 50 amu to

300 amu with unit resolution or better. The mass spectrometer 9.1 Prepare the GC-MS system according to manufacturer’s

shall be capable of being interfaced to a gas chromatograph and

instructions and set analysis operating conditions as suggested

capillary column. The interface shall be at a high enough

by Table 1.

temperature to prevent condensation of components boiling up

9.2 Calibrate and tune the mass spectrometer as following

to 350 °C.

every two weeks or when the overall performance of the mass

6.1.5 Data Acquisition System—A computerized data acqui-

spectrometry is not satisfied.

sition system shall be capable of acquiring of total ion

chromatogram (TIC) and FID chromatogram simultaneously

during the sample runs. The average mass spectrum for the

ACS Reagent Chemicals, Specifications and Procedures for Reagents and

Standard-Grade Reference Materials, American Chemical Society, Washington,

duration of the chromatographic program shall be obtained for

DC. For suggestions on the testing of reagents not listed by the American Chemical

the summation of characteristic mass fragments. And the areas

Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

of FID chromatogram shall be integrated manually or auto-

U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

matically. copeial Convention, Inc. (USPC), Rockville, MD.

D8276 − 19 (2024)

FIG. 2 Total Ion Chromatograms (TIC) and Flame Ionization Detector (FID) Chromatograms of Saturate and Aromatic Fractions in Diesel

Fuel

9.2.1 Mass calibration for the mass spectrometer is per- MNL7. The QC sample precision should be periodically

formed using perfluorotributylamine (PFTBA) w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.