ASTM D5118/D5118M-95

(Practice)Standard Practice for Fabrication of Fiberboard Shipping Boxes

Standard Practice for Fabrication of Fiberboard Shipping Boxes

SCOPE

1.1 This practice covers the fabrication of new fiberboard boxes, liners and sleeves.

1.2 This practice points out the factors and components that must be controlled in the manufacture of corrugated and solid fiberboard boxes, liners and sleeves.

1.3 This practice does not cover the adequacy of fiberboard containers under all conditions of exposure to atmosphere, handling, shipping and storage.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5118/D 5118M – 95

Standard Practice for

Fabrication of Fiberboard Shipping Boxes

This standard is issued under the fixed designation D 5118/D 5118M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope PPP-B-638 Packing of Boxes, Caps, Liners, and Sleeves

FED-STD-123 Marking for Shipment (Civil Agencies)

1.1 This practice covers the fabrication of new fiberboard

MIL-STD-129 Marking for Shipment and Storage

boxes, liners and sleeves.

2.3 Code of Federal Regulations:

1.2 This practice points out the factors and components that

Title 49

must be controlled in the manufacture of corrugated and solid

2.4 Other Publications:

fiberboard boxes, liners and sleeves.

National Motor Freight Classification

1.3 This practice does not cover the adequacy of fiberboard

Uniform Freight Classification

containers under all conditions of exposure to atmosphere,

Federal Food, Drug and Cosmetic Act

handling, shipping and storage.

1.4 The values stated in either inch-pound units or SI units

3. Terminology

are to be regarded separately as standard. Within the text, the

3.1 Definitions of terms relating to packaging are found in

SI units are shown in brackets. The values stated in each

Terminology D 996.

system are not exact equivalents; therefore, each system must

be used independently of the other. Combining values from the

4. Significance and Use

two systems may result in non-conformance with the standard.

4.1 Corrugated and solid fiberboard boxes, sleeves and

1.5 This standard does not purport to address all of the

liners are used to unitize products into packages of size and

safety concerns, if any, associated with its use. It is the

shape suitable for manual or mechanical handling and to

responsibility of the user of this standard to establish appro-

protect the contents against environmental, handling, shipping,

priate safety and health practices and determine the applica-

and storage conditions.

bility of regulatory limitations prior to use.

4.2 This practice covers some of the basic constructions and

styles of commercially available fiberboard packaging used to

2. Referenced Documents

unitize and protect contents.

2.1 ASTM Standards:

4.3 Use of Other Specifications—Nothing in this practice

D 685 Practice for Conditioning Paper and Paper Products

shall be construed to prohibit the use of boxes of special design

for Testing

or of fiberboard packages identified by package number in the

D 996 Terminology of Packaging and Distribution Environ-

current Uniform Freight Classification and National Motor

ments

Freight Classification when in the experience and judgement of

D 3950 Specification for Strapping, Nonmetallic (and Join-

2 the purchaser, the nature of the articles or material to be

ing Methods)

2 shipped justifies such boxes or packages. Some commodities

D 3951 Practice for Commercial Packaging

2 may require less protection while other commodities may

D 3953 Specification for Strapping, Flat Steel and Seals

require better boxes than are specified herein. Containers for

D 4727 Specification for Corrugated and Solid Fiberboard

2 explosives and dangerous articles must also comply with

Sheet Stock (Container Grade) and Cut Shapes

3 regulations for the Transport of Hazardous Materials (CFR

2.2 Federal Specifications:

Title 49).

MMM-A-250 Adhesives, Water-Resistant (For Closure of

Fiberboard Boxes)

This practice is under the jurisdiction of ASTM Committee D-10 on Packaging

and is the direct responsibility of Subcommittee D10.27 on Paper and Paperboard

Products. Available from National Motor Freight Classification, Inc., 2200 Mill Road,

Current edition approved Nov. 10, 1995. Published March 1996. Originally Alexandria, VA 22314.

published as D 5118/D 5118M – 90. Last previous edition D 5118/D 5118M – 90. Available from National Railroad Freight Committee, Suite 1120, 222 River-

Annual Book of ASTM Standards, Vol 15.09. side Plaza, Chicago, IL 60606.

3 6

Available from Standardization Documents, Order Desk, Bldg. 4, Section D, Available from the Superintendent of Documents, US Government Printing

700 Robbins Ave., Philadelphia, PA 19111-5094, attn: NPODS. Office, Washington, DC 20402.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5118/D 5118M

5. Styles

5.1 Fiberboard boxes covered by this practice may be of the

following styles:

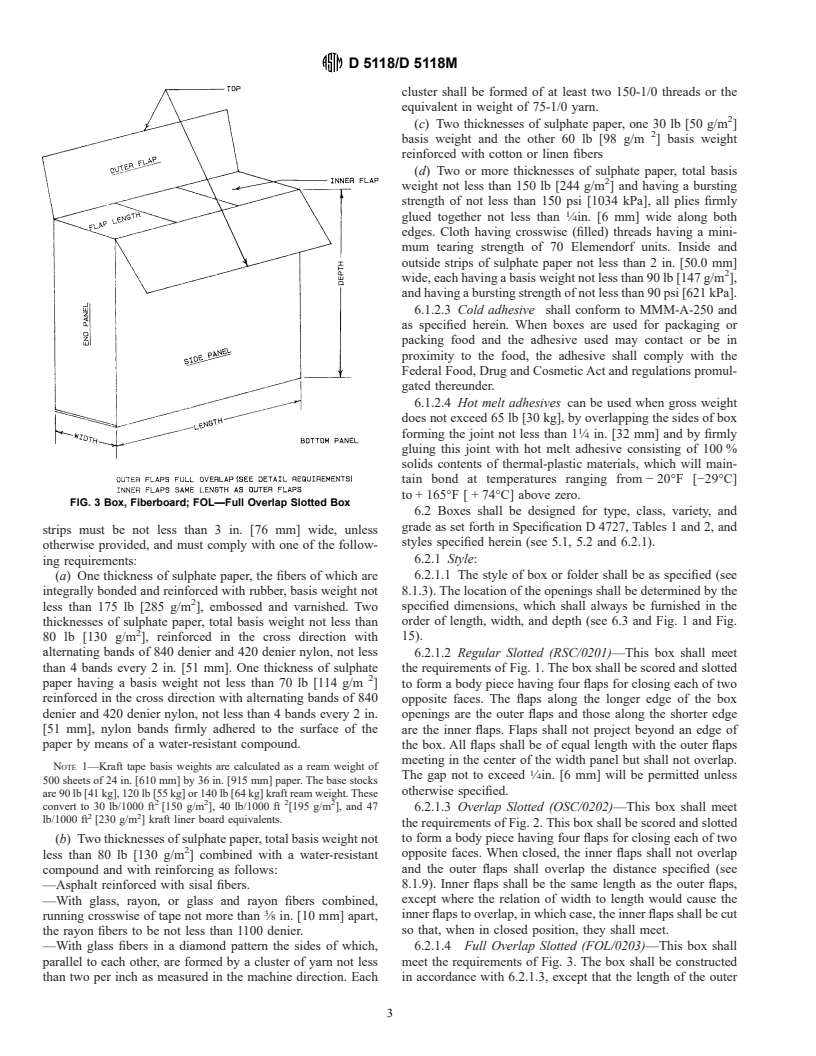

5.1.1 RSC/0201 —Regular slotted box (Fig. 1).

5.1.2 OSC/0202 —Overlap slotted box (Fig. 2).

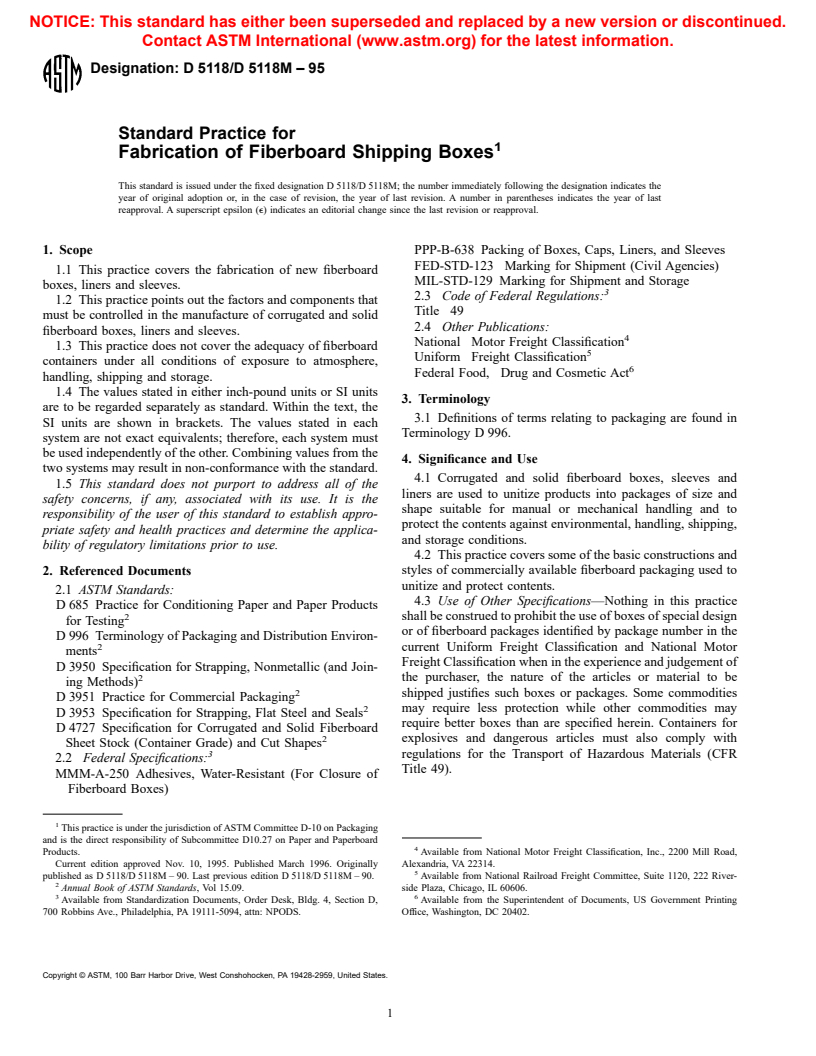

5.1.3 FOL/0203 —Full overlap slotted box (Fig. 3).

5.1.4 SFF/0206 —Special full flap slotted box (Fig. 4).

5.1.5 CSSC/0204 —Center special slotted box (Fig. 5).

5.1.6 CSOSC/0205 —Center special overlap slotted box

(Fig. 5).

5.1.7 HSCC/0312 —Half slotted box with cover (Fig. 6).

5.1.8 DBLCC/0310 —Double cover box (Fig. 7).

5.1.9 IC/0325 —Interlocking double cover box (Fig. 8).

5.1.10 FTC/0301 —Full telescope box (Fig. 9).

5.1.11 FTHS/0320 —Full telescope half slotted box (Fig.

10).

5.1.12 OPF/0401 —One piece folder (Fig. 11).

5.1.13 FPF/0410 —Five panel folder (Fig. 12).

5.1.14 TS—Triple slide box (type CF only) (Fig. 13).

5.1.15 TSC—Tongue and slot closure box (Fig. 14).

5.2 Other styles may also be applicable (see 8.1.3).

6. Requirements

6.1 Materials:

Available from European Federation of Manufacturers of Corrugated Board

FIG. 2 Box, Fiberboard; OSC—Overlap Slotted Box

(FEFCO), 37 Rue d’Amsterdam, 75008, Paris, France. Also known as the

International Box Code System, that is, in RSC/0201, RSC stands for regular slotted

6.1.1 Fiberboard shall conform to type, class, variety, and

container and 0201 is the international box code number for the RSC.

grade of Specification D 4727 unless otherwise specified. Flute

structure shall be as specified in Specification D 4727 (see

8.1.2).

6.1.2 Manufacturer’s joints shall be secured by one of the

following materials: (The joint is that seam of a box where the

ends of the box blank are joined.)

6.1.2.1 Metal fasteners shall be commercially preformed

staples or staples formed from commercial steel stitching wire.

All metal fasteners shall have commercially applied coating of

zinc or copper wash.

6.1.2.2 Manufacturer’s joint tapes shall be of the following

constructions:

(1) For boxes not exceeding 65 lb [30 kg] gross weight

sealing strips must not be less than 2 in. [51 mm] wide, and

must comply with one of the following requirements:

(a) Two thicknesses of sulphate paper, total basis weight not

less than 80 lb [130 g/m ] combined with a water-resistant

compound and reinforced with not less than double strand

nylon fiber not less than 210 denier forming a pattern with

strands not more than ⁄2 in. [13 mm] apart.

(b) Cloth having crosswise (filler) threads having a mini-

mum tearing strength of 40 Elemendorf units. Inside and

outside strips of sulphate paper not less than 2 in. [51 mm]

wide; outside strip having a basis weight of not less than 60 lb

[100 g/m ] having a bursting strength of not less than 60 psi

[414 kPa]; inside strip having a basis weight not less than 40 lb

[65 g/m ], and a bursting strength of not less than 40 psi [275

kPa].

FIG. 1 Box, Fiberboard; RSC—Regular Slotted Box (2) For boxes exceeding 65 lb [30 kg] gross weight, sealing

D 5118/D 5118M

cluster shall be formed of at least two 150-1/0 threads or the

equivalent in weight of 75-1/0 yarn.

(c) Two thicknesses of sulphate paper, one 30 lb [50 g/m ]

basis weight and the other 60 lb [98 g/m ] basis weight

reinforced with cotton or linen fibers

(d) Two or more thicknesses of sulphate paper, total basis

weight not less than 150 lb [244 g/m ] and having a bursting

strength of not less than 150 psi [1034 kPa], all plies firmly

glued together not less than ⁄4in. [6 mm] wide along both

edges. Cloth having crosswise (filled) threads having a mini-

mum tearing strength of 70 Elemendorf units. Inside and

outside strips of sulphate paper not less than 2 in. [50.0 mm]

wide, each having a basis weight not less than 90 lb [147 g/m ],

and having a bursting strength of not less than 90 psi [621 kPa].

6.1.2.3 Cold adhesive shall conform to MMM-A-250 and

as specified herein. When boxes are used for packaging or

packing food and the adhesive used may contact or be in

proximity to the food, the adhesive shall comply with the

Federal Food, Drug and Cosmetic Act and regulations promul-

gated thereunder.

6.1.2.4 Hot melt adhesives can be used when gross weight

does not exceed 65 lb [30 kg], by overlapping the sides of box

forming the joint not less than 1 ⁄4 in. [32 mm] and by firmly

gluing this joint with hot melt adhesive consisting of 100 %

solids contents of thermal-plastic materials, which will main-

tain bond at temperatures ranging from − 20°F [−29°C]

to + 165°F [ + 74°C] above zero.

FIG. 3 Box, Fiberboard; FOL—Full Overlap Slotted Box

6.2 Boxes shall be designed for type, class, variety, and

grade as set forth in Specification D 4727, Tables 1 and 2, and

strips must be not less than 3 in. [76 mm] wide, unless

styles specified herein (see 5.1, 5.2 and 6.2.1).

otherwise provided, and must comply with one of the follow-

6.2.1 Style:

ing requirements:

(a) One thickness of sulphate paper, the fibers of which are 6.2.1.1 The style of box or folder shall be as specified (see

8.1.3). The location of the openings shall be determined by the

integrally bonded and reinforced with rubber, basis weight not

less than 175 lb [285 g/m ], embossed and varnished. Two specified dimensions, which shall always be furnished in the

order of length, width, and depth (see 6.3 and Fig. 1 and Fig.

thicknesses of sulphate paper, total basis weight not less than

80 lb [130 g/m ], reinforced in the cross direction with 15).

alternating bands of 840 denier and 420 denier nylon, not less 6.2.1.2 Regular Slotted (RSC/0201)—This box shall meet

than 4 bands every 2 in. [51 mm]. One thickness of sulphate

the requirements of Fig. 1. The box shall be scored and slotted

paper having a basis weight not less than 70 lb [114 g/m ] to form a body piece having four flaps for closing each of two

reinforced in the cross direction with alternating bands of 840

opposite faces. The flaps along the longer edge of the box

denier and 420 denier nylon, not less than 4 bands every 2 in. openings are the outer flaps and those along the shorter edge

[51 mm], nylon bands firmly adhered to the surface of the

are the inner flaps. Flaps shall not project beyond an edge of

paper by means of a water-resistant compound. the box. All flaps shall be of equal length with the outer flaps

meeting in the center of the width panel but shall not overlap.

NOTE 1—Kraft tape basis weights are calculated as a ream weight of

The gap not to exceed ⁄4in. [6 mm] will be permitted unless

500 sheets of 24 in. [610 mm] by 36 in. [915 mm] paper. The base stocks

otherwise specified.

are 90 lb [41 kg], 120 lb [55 kg] or 140 lb [64 kg] kraft ream weight. These

2 2 2 2

convert to 30 lb/1000 ft [150 g/m ], 40 lb/1000 ft [195 g/m ], and 47

6.2.1.3 Overlap Slotted (OSC/0202)—This box shall meet

2 2

lb/1000 ft [230 g/m ] kraft liner board equivalents.

the requirements of Fig. 2. This box shall be scored and slotted

to form a body piece having four flaps for closing each of two

(b) Two thicknesses of sulphate paper, total basis weight not

opposite faces. When closed, the inner flaps shall not overlap

less than 80 lb [130 g/m ] combined with a water-resistant

and the outer flaps shall overlap the distance specified (see

compound and with reinforcing as follows:

8.1.9). Inner flaps shall be the same length as the outer flaps,

—Asphalt reinforced with sisal fibers.

except where the relation of width to length would cause the

—With glass, rayon, or glass and rayon fibers combined,

inner flaps to overlap, in which case, the inner flaps shall be cut

running crosswise of tape not more than ⁄8 in. [10 mm] apart,

so that, when in closed position, they shall meet.

the rayon fibers to be not less than 1100 denier.

—With glass fibers in a diamond pattern the sides of which, 6.2.1.4 Full Overlap Slotted (FOL/0203)—This box shall

parallel to each other, are formed by a cluster of yarn not less meet the requirements of Fig. 3. The box shall be constructed

than two per inch as measured in the machine direction. Each in accordance with 6.2.1.3, except that the length of the outer

D 5118/D 5118M

FIG. 4 Box, Fiberboard; SFF—Special Full Flap Slotted Box

FIG. 6 Box, Fiberboard; HSCC—Half Slotted Box with Cover

shall meet the requirements of Fig. 4. This box shall be

constructed in accordance with 6.2.1.3, except that the length

FIG. 5 Box, Fiberboard; CSSC—Center Special Slotted Box and

of the inner flaps in the closed position shall be such that they

CSOSC—Center Special Overlap Slotted Box

meet in the center of the box but do not overlap. A gap not to

exceed ⁄4 in. [6 mm] will be permitted.

flaps shall be the full width of the box and shall not extend 6.2.1.6 Center Special Slotted (CSSC/0204)— This box

beyond the edge of the box (see 6.6). shall meet the requirements of Fig. 5. The box shall be

6.2.1.5 Special Full Flap Slotted (SFF/0206)—This box constructed in accordance with 6.2.1.2, except that the length

D 5118/D 5118M

FIG. 7 Box, Fiberboard; DBLCC—Double Cover

FIG. 9 Box, Fiberboard; FTC—Full Telescope

FIG. 8 Box, Fiberboard; IC—Interlocking Double Cover

of the inner and outer flaps shall be such that they meet in the

center of the box but do not overlap. A gap not to exceed ⁄4 in.

FIG. 10 Box, Fiberboard; FTHS—Two Piece Full Telescope Half

[6 mm] will be permitted.

Slotted Box

6.2.1.7 Center Special Overlap Slotted (CSOCS/0205)—

(See Fig. 5.) This box shall be as specified herein. When to form a tube having four flaps, of equal length on the bottom.

closed, the inner flaps shall meet in the middle of the face with

The outer flaps shall meet when closed with a gap not to exceed

1 1

a gap not to exceed ⁄4 in. [6.4 mm] when in the closed position. ⁄4 in. [6.4 mm]. Unless otherwise specified, the cover shall be

Outer flaps shall be the same length as the inner flaps and may a Type I (see Fig. 16) stitch locked cover. When specified (see

overlap (no flap cutting is required). Dimension of the box 8.1.10), the cover shall be Type II (see Fig. 16). Unless

shall be such that the outer flaps do not extend beyond the otherwise specified, (see 8.1.11 and 8.1.12) the cover depth

configuration of the box. shall be 3 in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.