ASTM F1312-19(2023)

(Specification)Standard Specification for Brick, Insulating, High Temperature, Fire Clay

Standard Specification for Brick, Insulating, High Temperature, Fire Clay

ABSTRACT

This specification covers thermal insulating bricks made from fire clay that are used as backup insulation for refractory furnace linings of boiler furnaces. The bricks shall be composed of heat-resistant materials that have been burned or fired to produce the desired density, strength, and structure. Representative bricks shall be tested, and shall conform accordingly to specified values of bulk density, modulus of rupture, and reheat change.

SCOPE

1.1 This specification covers two types of thermal insulating brick for industrial or marine boiler furnaces. Type I is a special, 2500 °F (1371 °C) maximum service temperature, insulating firebrick that is used as backup insulation for refractory furnace linings.2 Type II is a standard insulating brick that, in general, is used where there may be direct contact with combustion gases, such as forge and stress relieving furnaces.3

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1312 − 19 (Reapproved 2023) An American National Standard

Standard Specification for

Brick, Insulating, High Temperature, Fire Clay

This standard is issued under the fixed designation F1312; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope C134 Test Methods for Size, Dimensional Measurements,

and Bulk Density of Refractory Brick and Insulating

1.1 This specification covers two types of thermal insulating

Firebrick

brick for industrial or marine boiler furnaces. Type I is a

C155 Classification of Insulating Firebrick

special, 2500 °F (1371 °C) maximum service temperature,

C210 Test Method for Reheat Change of Insulating Firebrick

insulating firebrick that is used as backup insulation for

2 D1974/D1974M Practice for Methods of Closing, Sealing,

refractory furnace linings. Type II is a standard insulating

and Reinforcing Fiberboard Boxes

brick that, in general, is used where there may be direct contact

D3953 Specification for Strapping, Flat Steel and Seals

with combustion gases, such as forge and stress relieving

3 D4727/D4727M Specification for Corrugated and Solid Fi-

furnaces.

berboard Sheet Stock (Container Grade) and Cut Shapes

1.2 The values stated in inch-pound units are to be regarded

D5118/D5118M Practice for Fabrication of Fiberboard Ship-

as standard. The values given in parentheses are mathematical

ping Boxes

conversions to SI units that are provided for information only

D6251/D6251M Specification for Wood-Cleated Panelboard

and are not considered standard.

Shipping Boxes

1.3 This standard does not purport to address all of the

D6880/D6880M Specification for Wood Boxes

safety concerns, if any, associated with its use. It is the

2.2 Military Specification:

responsibility of the user of this standard to establish appro-

MIL-L-10547 Liners, Case, and Sheet, Overwrap; Vapor-

priate safety, health, and environmental practices and deter- proof or Waterproof, Flexible

mine the applicability of regulatory limitations prior to use.

2.3 Military Standards:

1.4 This international standard was developed in accor-

MIL-STD-129 Marking for Shipment and Storage

dance with internationally recognized principles on standard-

MIL-STD-147 Palletized Unit Load 40 Inch by 48 Inch

ization established in the Decision on Principles for the

4-Way (Partial) Pallet Skids, Runners, or Pallet Type Base

Development of International Standards, Guides and Recom-

MIL-STD-2073-1 Standard Practice for Military Packaging

mendations issued by the World Trade Organization Technical

2.4 ASQ Document:

Barriers to Trade (TBT) Committee.

ANSI/ASQ Z1.4 Sampling Procedures and Tables for In-

spection by Attributes

2. Referenced Documents

3. Classification

2.1 ASTM Standards:

C133 Test Methods for Cold Crushing Strength and Modu-

3.1 Refractory insulating brick shall be of the following

lus of Rupture of Refractories

types, as specified (see Section 6): Type I — 2500 °F

(1371 °C), Type II — 2800 °F (1538 °C). Type II brick is part

of Group No. 28 of Classification C155.

This specification is under the jurisdiction of ASTM Committee F25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.07 on

4. Ordering Information

General Requirements.

Current edition approved May 1, 2023. Published June 2023. Originally 4.1 Orders for material under this specification shall include

approved in 1990. Last previous edition approved in 2019 as F1312 – 19. DOI:

the following information as necessary to describe the material

10.1520/F1312-19R23.

adequately:

Type I is a replacement for MIL-B-16008C, Brick, Insulating, High

4.1.1 ASTM designation and year of issue,

Temperature, Fire Clay

Type II is a replacement for MIL-B-16305B Class B, Brick, Refractory,

Insulating.

4 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Standards volume information, refer to the standard’s Document Summary page on Available from American Society for Quality (ASQ), 600 N. Plankinton Ave.,

the ASTM website. Milwaukee, WI 53203, http://www.asq.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1312 − 19 (2023)

4.1.2 Type insulating firebrick required, 9. Sampling

4.1.3 Dimensions required (see 7.1), and

9.1 For purposes of sampling, an inspection lot for exami-

4.1.4 Optional requirements, if any (see Supplementary

nation and tests shall consist of all material of the same size

Requirements S1, S2, and S3).

and shape offered for delivery at one time.

9.2 The sample unit for the tests of Section 10 shall be one

5. Materials and Manufacture

brick.

5.1 Bricks shall be composed of heat-resistant materials

9.3 The sample size (the number of sample units) for the

which have been burned or fired to produce the desired density,

tests of Section 10 shall be as specified in Table 2.

strength, low heat conductivity, and structure.

10. Test Methods

6. Physical and Mechanical Properties

10.1 Testing of the End Item—The end item shall be tested

6.1 The average bulk density shall not exceed 45.0 lb/ft

for the applicable characteristics as shown in Table 2 from each

(720 kg/m ) for Type I brick. The bulk density shall be a

lot presented for examination for each size and shape of brick.

3 3

maximum of 60 lb/ft (993.1 kg/m ) for Type II brick (see

10.2 Dimensions and Bulk Density—Dimensions and bulk

10.2).

density shall be determined in accordance with the test method

6.2 The modulus of rupture shall average not less than 100

specified in Test Methods C134.

psi (700 kPa) for Type I brick. The modulus of rupture shall

10.3 Modulus of Rupture—The modulus of rupture shall be

average not less than 175 psi (1206.6 kPa) and not more than

determined in accordance with the test method specified in Test

two of the ten bricks tested shall show less than 150 psi

Methods C133.

(1034.6 kPa) for Type II brick (see 10.3).

10.4 Reheat Change—The reheat change shall be deter-

6.3 Bricks shall show an average linear reheat change of not

mined in accordance with Test Method C210, except that the

more than 1 % when heated at 2450 °F (1343 °C) for Type I

Type I test specimens shall be maintained at a temperature of

bricks. Bricks shall show an average linear reheat change of

2450 °F (1343 °C) for 24 hours. Type II test specimens shall be

not more than 2 % when heated at 2750 °F (1510 °C) for Type

maintained at a temperature of 2750 °F (1510 °C) for 24 hours.

II brick (see 10.4).

11. Inspection

7. Dimensions and Permissible Variations

11.1 Unless otherwise specified in the contract or purchase

7.1 Insulating brick shall be furnished in the dimensions

order, the supplier is responsible for the performance of all

specified (see 4.1.3). Standard size brick shall be 9 in. by

inspection requirements specified herein. Except as otherwise

1 1

4 ⁄2 in. by 2 ⁄2 in. (229 mm by 114 mm by 64 mm), 9 in. by

specified, the supplier may use his own or any other facilities

4 ⁄2 in. by 2 in. (229 mm by 114 mm by 51 mm), or 9 in. by

suitable for the performance of the inspection requirements

1 1

4 ⁄2 in. by 1 ⁄4 in. (229 mm by 114 mm by 32 mm), as specified.

specified herein, unless disapproved by the purchaser. The

7.2 Dimension Tolerances—Length, width, and thickness purchaser reserves the right to perform any of the inspections

set forth in the specification where such inspections are deemed

dimensions of brick shall have the tolerances as specified in

Table 1 (see 10.2). necessary to ensure that supplies and services conform to

prescribed requirements.

8. Workmanship, Finish, and Appearance

12. Product Marking

8.1 Bricks shall be of homogeneous structure, and shall be

12.1 Bricks shall be marked with the manufacturer’s brand

free from cracks, laminations, segregations, void defects, or

name and Type I or II in accordance with this specification by

soft centers. All corners and edges shall be sufficiently strong

indelible stamping or stenciling.

to prevent excessive crumbling or chipping when handled or

shipped.

13. Packaging

13.1 Bricks shall be packed in containers which will ensure

acceptance by common carrier and safe delivery to destination

TABLE 1 Dimension Tolerances

at the lowest applicable rate. Containers shall comply with

Dimension-inches (millimetres) Tolerances-inch (millimetres)

commercial carrier regulations.

9 (229 mm) ± ⁄32 in. (3 mm)

1 1

2 (51 mm) to 4 ⁄2 (114 mm) inclusive ± ⁄16 in. (2 mm)

14. Keywords

1 1

1 ⁄4 (32 mm) ± ⁄32 in. (1 mm)

14.1 brick; insulating brick; fire clay

F1312 − 19 (2023)

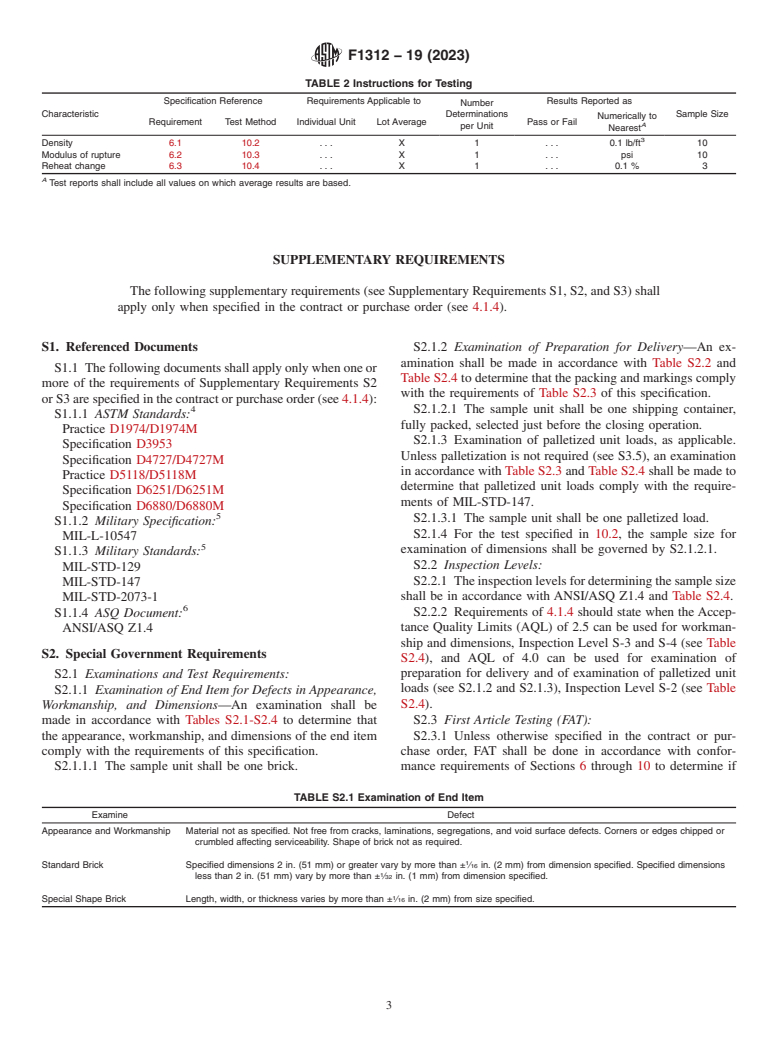

TABLE 2 Instructions for Testing

Specification Reference Requirements Applicable to Results Reported as

Number

Characteristic Determinations Sample Size

Numerically to

Requirement Test Method Individual Unit Lot Average Pass or Fail

A

per Unit

Nearest

Density 6.1 10.2 . . . X 1 . . . 0.1 lb/ft 10

Modulus of rupture 6.2 10.3 . . . X 1 . . . psi 10

Reheat change 6.3 10.4 . . . X 1 . . . 0.1 % 3

A

Test reports shall include all values on which average results are based.

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements (see Supplementary Requirements S1, S2, and S3) shall

apply only when specified in the contract or purchase order (see 4.1.4).

S1. Referenced Documents S2.1.2 Examination of Preparation for Delivery—An ex-

amination shall be made in accordance with Table S2.2 and

S1.1 The following documents shall apply only when one or

Table S2.4 to determine that the packing and markings comply

more of the requirements of Supplementary Requirements S2

with the requirements of Table S2.3 of this specification.

or S3 are specified in the contract or purchase order (see 4.1.4):

S2.1.2.1 The sample unit shall be one shipping container,

S1.1.1 ASTM Standards:

fully packed, selected just before the closing operation.

Practice D1974/D1974M

S2.1.3 Examination of palletized unit loads, as applicable.

Specification D3953

Unless palletization is not required (see S3.5), an examination

Specification D4727/D4727M

in accordance with Table S2.3 and Table S2.4 shall be made to

Practice D5118/D5118M

determine that palletized u

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.