ASTM A990-00

(Specification)Standard Specification for Castings, Iron-Nickel-Chromium and Nickel Alloys, Specially Controlled for Pressure Retaining Parts for Corrosion Service

Standard Specification for Castings, Iron-Nickel-Chromium and Nickel Alloys, Specially Controlled for Pressure Retaining Parts for Corrosion Service

SCOPE

1.1 This specification covers iron-nickel-chromium and nickel alloy castings specially processed with restricted melt practices, weldability testing and nondestructive examination (NDE) requirements.

1.2 A number of grade of iron-nickel-chromium and nickel alloy castings are included in this specification. Since these grades possess varying degrees of suitability for service in corrosive environments, it is the responsibility of the purchaser to determine which grade shall be furnished. Selection will depend on design and service conditions, mechanical properties, and corrosion-resistant characteristics.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in parentheses. The value stated in each system are not exact equivalents; therefore, each system must be used independently of the other. combining values from the two systems may result in nonconformance with this specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 990 – 00 An American National Standard

Standard Specification for

Castings, Iron-Nickel-Chromium and Nickel Alloys, Specially

Controlled for Pressure Retaining Parts for Corrosive

Service

This standard is issued under the fixed designation A 990; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A 494/A 494M Specification for Castings, Nickel and

Nickel Alloy

1.1 This specification covers iron-nickel-chromium and

A 703/A 703M Specification for Steel Castings, General

nickel alloy castings specially processed with restricted melt

Requirements, for Pressure-Containing Parts

practices, weldability testing and nondestructive examination

A 743/A 743M Specification for Castings, Iron-Chromium,

(NDE) requirements.

Iron-Chromium-Nickel, Corrosion Resistant, for General

1.2 A number of grades of iron-nickel-chromium and nickel

Application

alloy castings are included in this specification. Since these

A 744/A 744M Specification for Castings, Iron-

grades possess varying degrees of suitability for service in

Chromium-Nickel, Corrosion-Resistant, for Severe Ser-

corrosive environments, it is the responsibility of the purchaser

vice

to determine which grade shall be furnished. Selection will

A 802/A 802M Practice for Steel Castings, Surface Accep-

depend on design and service conditions, mechanical proper-

tance Standards, Visual Examination

ties, and corrosion-resistant characteristics.

A 903/A 903M Specification for Steel Castings, Surface

1.3 The values stated in either inch-pound units or SI units

Acceptance Standards, Magnetic Particle and Liquid Pen-

are to be regarded separately as the standard. Within the text,

etrant Inspection

the SI units are shown in parentheses. The values stated in each

A 919 Terminology Relating to Heat Treatment of Metals

system are not exact equivalents; therefore, each system must

E 94 Guide for Radiographic Testing

be used independently of the other. Combining values from the

E 165 Test Method for Liquid Penetrant Examination

two systems may result in nonconformance with this specifi-

E 186 Reference Radiographs for Heavy-Walled (2 to 4 ⁄2-

cation.

in. (51 to 114-mm)) Steel Castings

1.4 This standard does not purport to address all of the

E 272 Reference Radiographs for High-Strength Copper-

safety concerns, if any, associated with its use. It is the

Base and Nickel-Copper Alloy Castings

responsibility of the user of this standard to establish appro-

E 280 Reference Radiographs for Heavy-Walled (4 ⁄2 to

priate safety and health practices and determine the applica-

12-in. (114 to 305-mm)) Steel Castings

bility of regulatory limitations prior to use.

E 446 Reference Radiographs for Steel Castings Up to 2 in.

2. Referenced Documents

(51 mm) in Thickness

2.2 AWS Standards:

2.1 ASTM Standards:

AWS A5.4, Specification for Stainless Steel Electrodes for

A 351/A 351M Specification for Castings, Austenitic,

Shielded Metal Arc Welding

Austenitic-Ferritic (Duplex), for Pressure-Containing

AWS A5.9, Specification for Bare Stainless Steel Welding

Parts

Electrodes and Rods

A 370 Test Methods and Definitions for Mechanical Testing

AWS A5.11, Specification for Nickel and Nickel Alloy

of Steel Products

Electrodes for Shielded Metal Arc Welding

A 488/A 488M Practice for Steel Castings, Welding, Quali-

AWS A5.14, Specification for Nickel and Nickel Alloy Bare

fication of Procedures and Personnel

Welding Electrodes and Rods

2.3 ASME/ANSI Standard:

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 03.03.

A01.18 on Castings. Available from the American Welding Society, 2501 NW, 7th Street, Miami, FL

Current edition approved September 10, 2000. Published October 2000. Origi- 33125.

nally published as A 990–98. Last previous edition A 990–98. Available from the American Society of Mechanical Engineers, United Engi-

Annual Book of ASTM Standards, Vol 01.02. neering Center, 345 East 47th Street, New York, NY 10017.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 990

ASME/ANSI B16.34, Valves-Flanged, Threaded, and 6. Process and Manufacture

Welding End

6.1 Alloys shall be made by one of the two following

processes:

3. Terminology

6.1.1 Electric arc or induction furnace melting followed by

3.1 Definitions— The definitions in Test Methods and Defi-

AOD or VOD refining, or

nitions A 370 and Terminology A 919 are applicable to this

6.1.2 Electric induction furnace melting of refined ingot.

specification.

6.1.2.1 Additions of up to 5 % are permitted for composi-

3.2 Definitions of Terms Specific to This Standard:

tional adjustments and deoxidation.

3.2.1 accessible surface, n—surface that can be welded on

6.1.2.2 Revert shall not be used.

without cutting access holes in the casting.

7. Chemical Composition

3.2.2 revert, n—gates, risers, and castings. Also includes

scrapped machinery and fabricated items, chips and turnings.

7.1 These alloys shall conform to the chemical composition

3.2.3 refined ingot, n—metal processed by argon-oxygen-

requirements prescribed in Table 1. An analysis of every heat

decarburization (AOD) or vacuum-oxygen-decarburization

is required.

(VOD) and cast to a size and shape suitable for remelting.

8. Tensile Properties

4. General Conditions for Delivery

8.1 One tension test shall be made from each heat. Test

results shall conform to the tensile requirements specified in

4.1 Material furnished to this specification shall conform to

Table 3. The bar shall be solution heat treated per the

the requirements of Specification A 703/A 703M, including

requirements of Table 4 in production furnaces to the same

any supplementary requirements that are indicated in the

procedure as the castings it represents. If the casting grade does

purchase order. Failure to comply with the general require-

not require heat treatment, the bar used for the test specimen

ments of Specification A 703/A 703M constitutes nonconfor-

shall not be heat treated.

mance with this specification. In case of conflict between the

requirements of this specification an Specification A 703/

9. Weldability Qualification

A 703M, this specification shall prevail.

9.1 Each heat shall be qualified by weldability testing.

5. Ordering Information 9.2 Sampling:

9.2.1 The weldability test plate shall be cast in accordance

5.1 It is the responsibility of the purchaser to specify all

with Fig. 1.

requirements that are necessary for material ordered to this

9.2.2 For heats produced under 6.1.1, at least one weldabil-

specification. Such requirements may include, but are not

ity test plate shall be cast from each heat.

limited to, the following:

9.2.3 For heats produced under 6.1.2, at least one weldabil-

5.1.1 Quantity.

ity test plate shall be cast from the first heat in an uninterrupted

5.1.2 Grade designation (Table 1).

series of heats, made in the same furnace from the same heat of

refined ingot using the same melting procedure, and shall

TABLE 1 Chemical Requirements

qualify all of the subsequent heats in that series made in the

Element, %

same shift.

(max, except where Grade

9.3 Procedure:

range is given)

9.3.1 The test plates required under 9.2 shall be processed

CW-2M CN3MCu

and tested as follows:

C 0.020 0.030

9.3.1.1 Prior to welding, the test plate shall be solution heat

Mn 1.00 1.50

Si 0.80 1.00

treated according to the requirements of Table 4 in production

P 0.030 0.030

furnaces to the same procedure as the castings it represents.

S 0.015 0.015

9.3.1.2 All forms of cold working, mechanical deformation,

Mo 15.0-17.5 2.0-3.0

Fe 2.00 balance

hammering or peening, in excess of that required for normal

Ni balance 27.5-30.5

cleaning is prohibited.

Cr 15.0-17.5 19.0-22.0

9.3.1.3 Fill the groove in the plate with weld deposit

Cu . . . 3.0-3.5

W 1.00 . . .

according to the procedure used in Section 11 and the filler

material grade specified in Table 5.

9.3.1.4 For the purposes of the weldability test only, post

5.1.3 Description of the casting by pattern number or

weld heat treatment of the test plate is prohibited even if part

drawing. Dimensional tolerances should be included on the of the procedure. Remove one ⁄8-in. (10-mm) min thick bend

casting drawing. coupon longitudinally from the center of the welded plate by

5.1.4 Nondestructive inspection class required (Table 2). machining, sawing, or abrasive cutting. Make a transverse side

Class D will be supplied unless otherwise specified. bend test of the welded joint in accordance with Practice

5.1.5 Wetted surfaces (Table 2). A 488/A 488M.

5.2 The purchaser shall specify any supplementary require- 9.4 Acceptance:

ments desired, including standards of acceptance, required to 9.4.1 On the bent specimen, cracks or other open defects

describe adequately the desired material. exceeding ⁄8 in. (3.2 mm), measured in any direction on the

A 990

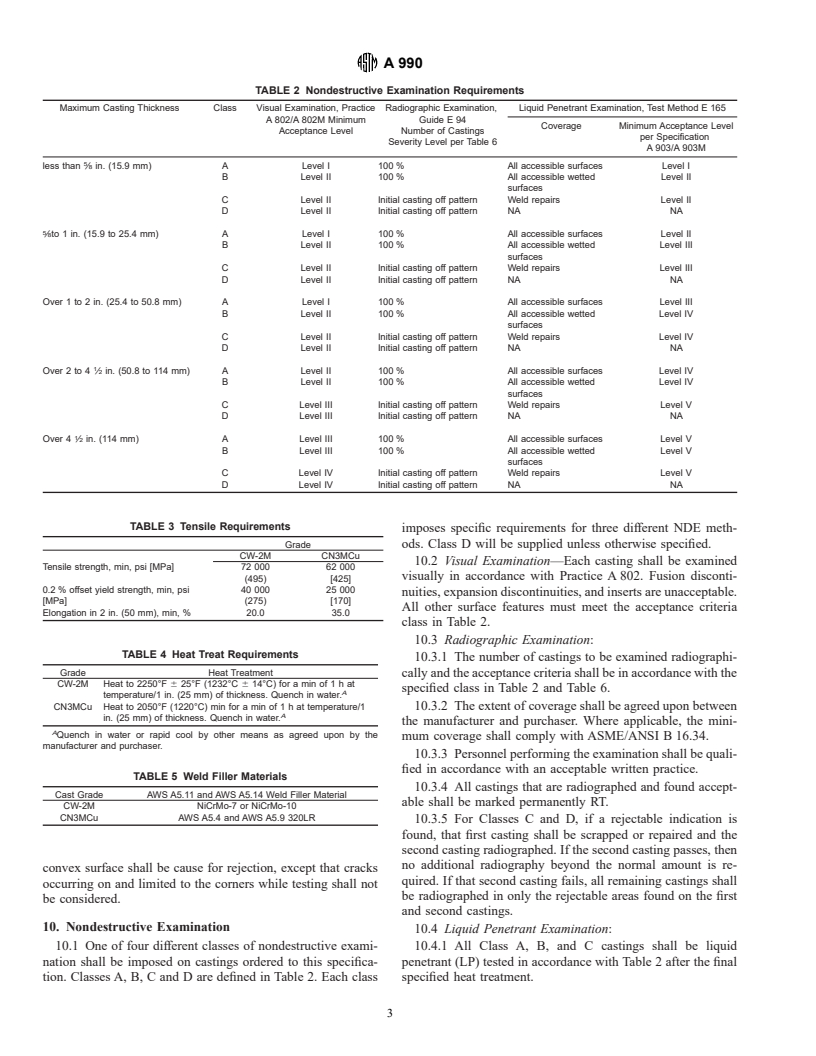

TABLE 2 Nondestructive Examination Requirements

Maximum Casting Thickness Class Visual Examination, Practice Radiographic Examination, Liquid Penetrant Examination, Test Method E 165

A 802/A 802M Minimum Guide E 94

Coverage Minimum Acceptance Level

Acceptance Level Number of Castings

per Specification

Severity Level per Table 6

A 903/A 903M

less than ⁄8 in. (15.9 mm) A Level I 100 % All accessible surfaces Level I

B Level II 100 % All accessible wetted Level II

surfaces

C Level II Initial casting off pattern Weld repairs Level II

D Level II Initial casting off pattern NA NA

⁄8to 1 in. (15.9 to 25.4 mm) A Level I 100 % All accessible surfaces Level II

B Level II 100 % All accessible wetted Level III

surfaces

C Level II Initial casting off pattern Weld repairs Level III

D Level II Initial casting off pattern NA NA

Over 1 to 2 in. (25.4 to 50.8 mm) A Level I 100 % All accessible surfaces Level III

B Level II 100 % All accessible wetted Level IV

surfaces

C Level II Initial casting off pattern Weld repairs Level IV

D Level II Initial casting off pattern NA NA

Over2to4 ⁄2 in. (50.8 to 114 mm) A Level II 100 % All accessible surfaces Level IV

B Level II 100 % All accessible wetted Level IV

surfaces

C Level III Initial casting off pattern Weld repairs Level V

D Level III Initial casting off pattern NA

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.