ASTM A990-00e1

(Specification)Standard Specification for Castings, Iron-Nickel-Chromium and Nickel Alloys, Specially Controlled for Pressure Retaining Parts for Corrosive Service

Standard Specification for Castings, Iron-Nickel-Chromium and Nickel Alloys, Specially Controlled for Pressure Retaining Parts for Corrosive Service

SCOPE

1.1 This specification covers iron-nickel-chromium and nickel alloy castings specially processed with restricted melt practices, weldability testing and nondestructive examination (NDE) requirements.

1.2 A number of grade of iron-nickel-chromium and nickel alloy castings are included in this specification. Since these grades possess varying degrees of suitability for service in corrosive environments, it is the responsibility of the purchaser to determine which grade shall be furnished. Selection will depend on design and service conditions, mechanical properties, and corrosion-resistant characteristics.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in parentheses. The value stated in each system are not exact equivalents; therefore, each system must be used independently of the other. combining values from the two systems may result in nonconformance with this specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: A 990 – 00

Standard Specification for

Castings, Iron-Nickel-Chromium and Nickel Alloys, Specially

Controlled for Pressure Retaining Parts for Corrosive

1

Service

This standard is issued under the fixed designation A 990; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Section 2 was revised editorially in January 2002.

2

1. Scope fication of Procedures and Personnel

A 494/A 494M Specification for Castings, Nickel and

1.1 This specification covers iron-nickel-chromium and

2

Nickel Alloy

nickel alloy castings specially processed with restricted melt

A 703/A 703M Specification for Steel Castings, General

practices, weldability testing and nondestructive examination

2

Requirements, for Pressure-Containing Parts

(NDE) requirements.

A 743/A 743M Specification for Castings, Iron-Chromium,

1.2 A number of grades of iron-nickel-chromium and nickel

Iron-Chromium-Nickel, Corrosion Resistant, for General

alloy castings are included in this specification. Since these

2

Application

grades possess varying degrees of suitability for service in

A 744/A 744M Specification for Castings, Iron-

corrosive environments, it is the responsibility of the purchaser

Chromium-Nickel, Corrosion-Resistant, for Severe Ser-

to determine which grade shall be furnished. Selection will

2

vice

depend on design and service conditions, mechanical proper-

A 802/A 802M Practice for Steel Castings, Surface Accep-

ties, and corrosion-resistant characteristics.

2

tance Standards, Visual Examination

1.3 The values stated in either inch-pound units or SI units

A 903/A 903M Specification for Steel Castings, Surface

are to be regarded separately as the standard. Within the text,

Acceptance Standards, Magnetic Particle and Liquid Pen-

the SI units are shown in parentheses. The values stated in each

2

etrant Inspection

system are not exact equivalents; therefore, each system must

A 941 Terminology Relating to Steel, Stainless Steel, Re-

be used independently of the other. Combining values from the

3

lated Alloys, and Ferroalloys

two systems may result in nonconformance with this specifi-

4

E 94 Guide for Radiographic Testing

cation.

4

E 165 Test Method for Liquid Penetrant Examination

1.4 This standard does not purport to address all of the

1

E 186 Reference Radiographs for Heavy-Walled (2 to 4 ⁄2-

safety concerns, if any, associated with its use. It is the

4

in. (51 to 114-mm)) Steel Castings

responsibility of the user of this standard to establish appro-

E 272 Reference Radiographs for High-Strength Copper-

priate safety and health practices and determine the applica-

4

Base and Nickel-Copper Alloy Castings

bility of regulatory limitations prior to use.

1

E 280 Reference Radiographs for Heavy-Walled (4 ⁄2 to

4

2. Referenced Documents 12-in. (114 to 305-mm)) Steel Castings

E 446 Reference Radiographs for Steel Castings Up to 2 in.

2.1 ASTM Standards:

4

(51 mm) in Thickness

A 351/A 351M Specification for Castings, Austenitic,

5

2.2 AWS Standards:

Austenitic-Ferritic (Duplex), for Pressure-Containing

2

AWS A5.4, Specification for Stainless Steel Electrodes for

Parts

Shielded Metal Arc Welding

A 370 Test Methods and Definitions for Mechanical Testing

2

AWS A5.9, Specification for Bare Stainless Steel Welding

of Steel Products

Electrodes and Rods

A 488/A 488M Practice for Steel Castings, Welding, Quali-

AWS A5.11, Specification for Nickel and Nickel Alloy

Electrodes for Shielded Metal Arc Welding

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

3

A01.18 on Castings. Annual Book of ASTM Standards, Vol 01.01.

4

Current edition approved September 10, 2000. Published October 2000. Origi- Annual Book of ASTM Standards, Vol 03.03.

5

nally published as A 990–98. Last previous edition A 990–98. Available from the American Welding Society, 2501 NW, 7th Street, Miami, FL

2

Annual Book of ASTM Standards, Vol 01.02. 33125.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

A990–00

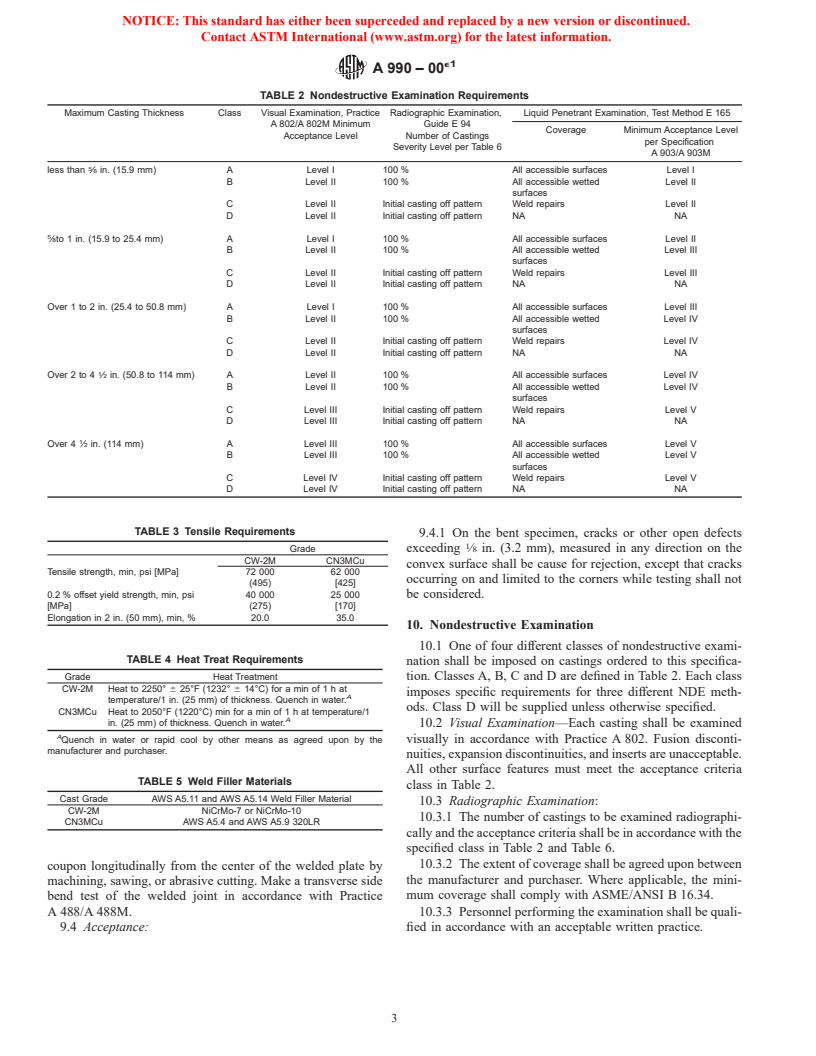

AWS A5.14, Specification for Nickel and Nickel Alloy Bare 5.1.4 Nondestructive inspection class required (Table 2).

Welding Electrodes and Rods Class D will be supplied unless otherwise specified.

6

2.3 ASME/ANSI Standard: 5.1.5 Wetted surfaces (Table 2).

ASME/ANSI B16.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.