ASTM E2691-09

(Practice)Standard Practice for Job Productivity Measurement

Standard Practice for Job Productivity Measurement

SIGNIFICANCE AND USE

JPM produces two measurements: construction production rate and productivity.

JPM measures the overall production rate by comparing CPIP to the time elapsed in the construction schedule.

JPM measures overall job productivity through a comparison of labor usage to a reference point.

JPM issues early warning signals for construction.

JPM identifies productivity deviations in the form of any gains or losses in productivity, and anomalies indicating a special cause, from the productivity reference point.

JPM measures the productivity changes to individual building elements (according to the UNIFORMAT II format for organizing building data, in Classification E1557) with the same methodology used for overall job productivity measurement.

JPM measures ongoing changes in labor usage.

JPM measures productivity wherever the labor is used in construction by:

Any contractor or construction manager directly or indirectly responsible for the productivity of the labor and its usage.

Any contractor or construction manager conducting self performance on any portion of the construction job.

Any contractor or construction manager supervising labor performance on any portion of a construction job.

SCOPE

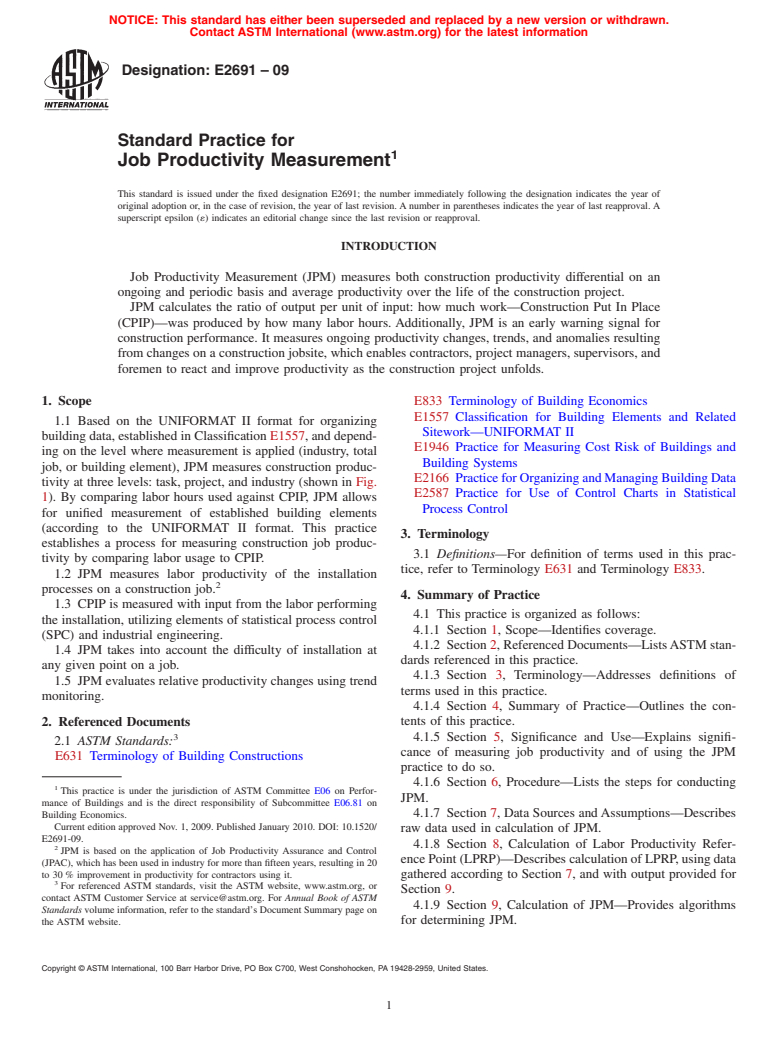

1.1 Based on the UNIFORMAT II format for organizing building data, established in Classification E1557, and depending on the level where measurement is applied (industry, total job, or building element), JPM measures construction productivity at three levels: task, project, and industry (shown in Fig. 1). By comparing labor hours used against CPIP, JPM allows for unified measurement of established building elements (according to the UNIFORMAT II format. This practice establishes a process for measuring construction job productivity by comparing labor usage to CPIP.

1.2 JPM measures labor productivity of the installation processes on a construction job.

1.3 CPIP is measured with input from the labor performing the installation, utilizing elements of statistical process control (SPC) and industrial engineering.

1.4 JPM takes into account the difficulty of installation at any given point on a job.

1.5 JPM evaluates relative productivity changes using trend monitoring.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2691 – 09

Standard Practice for

Job Productivity Measurement

This standard is issued under the fixed designation E2691; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Job Productivity Measurement (JPM) measures both construction productivity differential on an

ongoing and periodic basis and average productivity over the life of the construction project.

JPM calculates the ratio of output per unit of input: how much work—Construction Put In Place

(CPIP)—was produced by how many labor hours. Additionally, JPM is an early warning signal for

construction performance. It measures ongoing productivity changes, trends, and anomalies resulting

from changes on a construction jobsite, which enables contractors, project managers, supervisors, and

foremen to react and improve productivity as the construction project unfolds.

1. Scope E833 Terminology of Building Economics

E1557 Classification for Building Elements and Related

1.1 Based on the UNIFORMAT II format for organizing

Sitework—UNIFORMAT II

building data, established in Classification E1557, and depend-

E1946 Practice for Measuring Cost Risk of Buildings and

ing on the level where measurement is applied (industry, total

Building Systems

job, or building element), JPM measures construction produc-

E2166 PracticeforOrganizingandManagingBuildingData

tivity at three levels: task, project, and industry (shown in Fig.

E2587 Practice for Use of Control Charts in Statistical

1). By comparing labor hours used against CPIP, JPM allows

Process Control

for unified measurement of established building elements

(according to the UNIFORMAT II format. This practice

3. Terminology

establishes a process for measuring construction job produc-

3.1 Definitions—For definition of terms used in this prac-

tivity by comparing labor usage to CPIP.

tice, refer to Terminology E631 and Terminology E833.

1.2 JPM measures labor productivity of the installation

processes on a construction job.

4. Summary of Practice

1.3 CPIP is measured with input from the labor performing

4.1 This practice is organized as follows:

the installation, utilizing elements of statistical process control

4.1.1 Section 1, Scope—Identifies coverage.

(SPC) and industrial engineering.

4.1.2 Section 2, Referenced Documents—ListsASTM stan-

1.4 JPM takes into account the difficulty of installation at

dards referenced in this practice.

any given point on a job.

4.1.3 Section 3, Terminology—Addresses definitions of

1.5 JPM evaluates relative productivity changes using trend

terms used in this practice.

monitoring.

4.1.4 Section 4, Summary of Practice—Outlines the con-

tents of this practice.

2. Referenced Documents

4.1.5 Section 5, Significance and Use—Explains signifi-

2.1 ASTM Standards:

cance of measuring job productivity and of using the JPM

E631 Terminology of Building Constructions

practice to do so.

4.1.6 Section 6, Procedure—Lists the steps for conducting

This practice is under the jurisdiction of ASTM Committee E06 on Perfor-

JPM.

mance of Buildings and is the direct responsibility of Subcommittee E06.81 on

Building Economics. 4.1.7 Section 7, Data Sources andAssumptions—Describes

Current edition approved Nov. 1, 2009. Published January 2010. DOI: 10.1520/

raw data used in calculation of JPM.

E2691-09.

4.1.8 Section 8, Calculation of Labor Productivity Refer-

JPM is based on the application of Job Productivity Assurance and Control

ence Point (LPRP)—Describes calculation of LPRP, using data

(JPAC), which has been used in industry for more than fifteen years, resulting in 20

to 30 % improvement in productivity for contractors using it.

gathered according to Section 7, and with output provided for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Section 9.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1.9 Section 9, Calculation of JPM—Provides algorithms

Standards volume information, refer to the standard’s Document Summary page on

for determining JPM.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2691 – 09

FIG. 1 Measurement of Productivity at the Industry, Project, and Task Level

4.1.10 Section 10, Report—Describes various types of re- 5.2.1 JPM identifies productivity deviations in the form of

porting output for JPM. any gains or losses in productivity, and anomalies indicating a

4.1.11 Section 11, Applications—Describes where and how

special cause, from the productivity reference point.

JPM information can be used.

5.2.2 JPM measures the productivity changes to individual

4.1.12 Section 12, Keywords—Lists related words and

building elements (according to the UNIFORMAT II format

phrases.

for organizing building data, in Classification E1557) with the

same methodology used for overall job productivity measure-

5. Significance and Use

ment.

5.1 JPM produces two measurements: construction produc-

5.2.3 JPM measures ongoing changes in labor usage.

tion rate and productivity.

5.3 JPMmeasuresproductivitywhereverthelaborisusedin

5.1.1 JPM measures the overall production rate by compar-

construction by:

ing CPIP to the time elapsed in the construction schedule.

5.3.1 Any contractor or construction manager directly or

5.1.2 JPM measures overall job productivity through a

comparison of labor usage to a reference point. indirectly responsible for the productivity of the labor and its

5.2 JPM issues early warning signals for construction. usage.

E2691 – 09

5.3.2 Any contractor or construction manager conducting Seven to twelve cost codes are effective for most applications.

self performance on any portion of the construction job. Reference the descriptions listed as individual elements in

5.3.3 Any contractor or construction manager supervising Section 3 of UNIFORMAT II for creating cost codes.

labor performance on any portion of a construction job. 7.3.3 Depending on the application level of JPM, tasks are

defined by either UNIFORMAT II, or when applied at the

6. Procedure

project level, are generated and described individually as a

subset of each cost code.

6.1 Establish a baseline labor hour budget (BLHB) for the

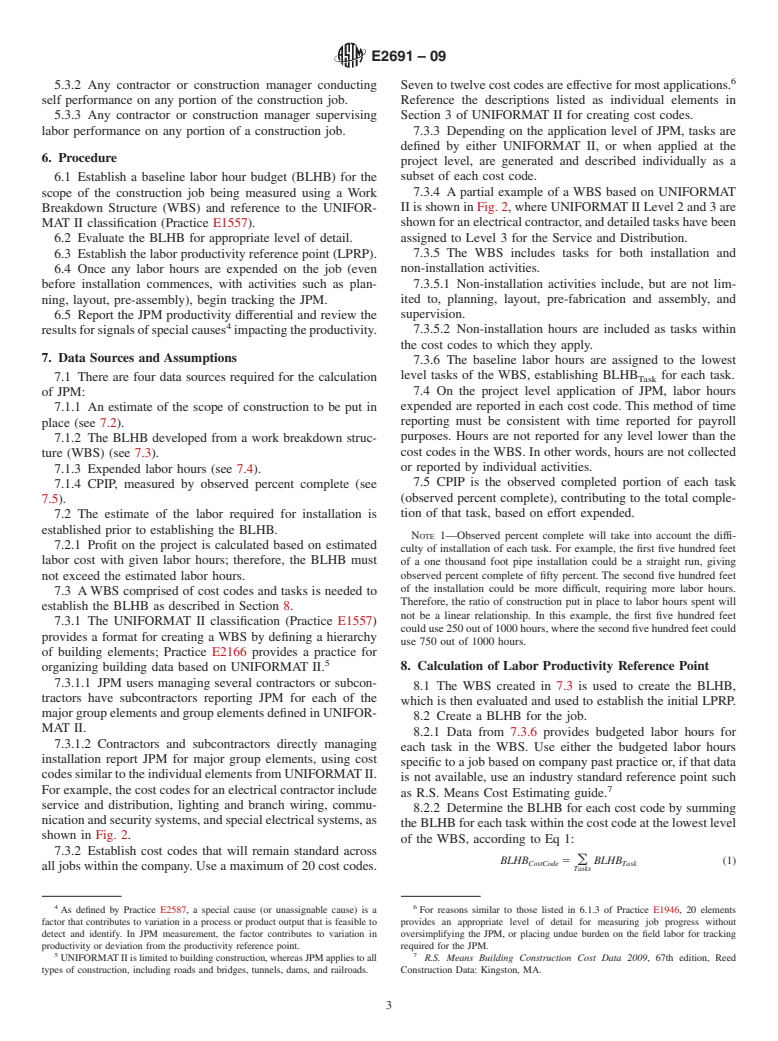

scope of the construction job being measured using a Work 7.3.4 A partial example of a WBS based on UNIFORMAT

II is shown in Fig. 2, where UNIFORMATII Level 2 and 3 are

Breakdown Structure (WBS) and reference to the UNIFOR-

MAT II classification (Practice E1557). shown for an electrical contractor, and detailed tasks have been

assigned to Level 3 for the Service and Distribution.

6.2 Evaluate the BLHB for appropriate level of detail.

6.3 Establish the labor productivity reference point (LPRP). 7.3.5 The WBS includes tasks for both installation and

non-installation activities.

6.4 Once any labor hours are expended on the job (even

before installation commences, with activities such as plan- 7.3.5.1 Non-installation activities include, but are not lim-

ited to, planning, layout, pre-fabrication and assembly, and

ning, layout, pre-assembly), begin tracking the JPM.

supervision.

6.5 Report the JPM productivity differential and review the

7.3.5.2 Non-installation hours are included as tasks within

resultsforsignalsofspecialcauses impactingtheproductivity.

the cost codes to which they apply.

7. Data Sources and Assumptions

7.3.6 The baseline labor hours are assigned to the lowest

level tasks of the WBS, establishing BLHB for each task.

7.1 There are four data sources required for the calculation

Task

7.4 On the project level application of JPM, labor hours

of JPM:

expended are reported in each cost code. This method of time

7.1.1 An estimate of the scope of construction to be put in

reporting must be consistent with time reported for payroll

place (see 7.2).

purposes. Hours are not reported for any level lower than the

7.1.2 The BLHB developed from a work breakdown struc-

cost codes in the WBS. In other words, hours are not collected

ture (WBS) (see 7.3).

or reported by individual activities.

7.1.3 Expended labor hours (see 7.4).

7.5 CPIP is the observed completed portion of each task

7.1.4 CPIP, measured by observed percent complete (see

(observed percent complete), contributing to the total comple-

7.5).

tion of that task, based on effort expended.

7.2 The estimate of the labor required for installation is

established prior to establishing the BLHB.

NOTE 1—Observed percent complete will take into account the diffi-

7.2.1 Profit on the project is calculated based on estimated

culty of installation of each task. For example, the first five hundred feet

labor cost with given labor hours; therefore, the BLHB must

of a one thousand foot pipe installation could be a straight run, giving

observed percent complete of fifty percent. The second five hundred feet

not exceed the estimated labor hours.

of the installation could be more difficult, requiring more labor hours.

7.3 AWBS comprised of cost codes and tasks is needed to

Therefore, the ratio of construction put in place to labor hours spent will

establish the BLHB as described in Section 8.

not be a linear relationship. In this example, the first five hundred feet

7.3.1 The UNIFORMAT II classification (Practice E1557)

coulduse250outof1000hours,wherethesecondfivehundredfeetcould

provides a format for creating a WBS by defining a hierarchy

use 750 out of 1000 hours.

of building elements; Practice E2166 provides a practice for

8. Calculation of Labor Productivity Reference Point

organizing building data based on UNIFORMAT II.

7.3.1.1 JPM users managing several contractors or subcon-

8.1 The WBS created in 7.3 is used to create the BLHB,

tractors have subcontractors reporting JPM for each of the

which is then evaluated and used to establish the initial LPRP.

majorgroupelementsandgroupelementsdefinedinUNIFOR-

8.2 Create a BLHB for the job.

MAT II.

8.2.1 Data from 7.3.6 provides budgeted labor hours for

7.3.1.2 Contractors and subcontractors directly managing

each task in the WBS. Use either the budgeted labor hours

installation report JPM for major group elements, using cost

specific to a job based on company past practice or, if that data

codessimilartotheindividualelementsfromUNIFORMATII.

is not available, use an industry standard reference point such

For example, the cost codes for an electrical contractor include

as R.S. Means Cost Estimating guide.

service and distribution, lighting and branch wiring, commu-

8.2.2 Determine the BLHB for each cost code by summing

nicationandsecuritysystems,andspecialelectricalsystems,as

the BLHB for each task within the cost code at the lowest level

shown in Fig. 2.

of the WBS, according to Eq 1:

7.3.2 Establish cost codes that will remain standard across

BLHB 5 BLHB (1)

(

CostCode Task

all jobs within the company. Use a maximum of 20 cost codes.

Tasks

4 6

As defined by Practice E2587, a special cause (or unassignable cause) is a For reasons similar to those listed in 6.1.3 of Practice E1946, 20 elements

factor that contributes to variation in a process or product output that is feasible to provides an appropriate level of detail for measuring job progress without

detect and identify. In JPM measurement, the factor contributes to variation in oversimplifying the JPM, or placing undue burden on the field labor for tracking

productivity or deviation from the productivity reference point. required for the JPM.

5 7

UNIFORMATII is limited to building construction, whereas JPM applies to all R.S. Means Building Construction Cost Data 2009, 67th edition, Reed

types of construction, including roads and bridges, tunnels, dams, and railroads. Construction Data: Kingston, MA.

E2691 – 09

FIG. 2 One Section of the UNIFORMAT II Classification of Building Elements (Practice E1557), Shown as a Format for Creating a WBS

E2691 – 09

FIG. 3 Partial WBS for Electrical Subcontractor, Based on UNIFORMAT II

8.2.3 Determine the BLHB for the total job by summing the 8.4 Account for change orders.

hours budgeted in each cost code, as shown in Eq 2. 8.4.1 The budgeted labor hours associated with change

orders are added or subtracted from the BLHB, and are

BLHB 5 BLHB (2)

Job ( CostCode

CostCodes

includedinthecalculationofthebaselineproductivityfromthe

point at which they are recognized by the labor performing

8.2.4 The summed cost code hours comprise the total direct

installation.

labor budget for the job. An illustration of a conversion from

8.4.2 Note reasons for change orders as part of the JPM.

the WBS into a BLHB is shown in Table 1.

8.3 Evaluate the BLHB.

9. Calculation of JPM

8.3.1 Calculate the contribution of each BLHB to its

Task

9.1 Evaluate the JPM periodically by collecting CPIP and

associated cost code, and to the overall job (Eq 3 and 4).

expended labor hours, and comparing them to the LPRP.

BLHB

Task

9.1.1 Report the CPIP, measured by observed percent com-

BLHB Task Weight per Cost Code 5 (3)

BLHB

CostCode

plete on each task, as shown in Table 3, column 6.

BLHB

Task

9.1.1.1 Calculate observed percent complete per cost code,

BLHB Task Weight per Job 5 (4)

BLHB

Job

by summing the weighted percent complete per task item for

8.3.2 Common practice has shown that a task representing

the cost code (Eq 7).

more than 2.5 % of the total job will be difficult to visualize for

Observed%Complete 5 (7)

CostCode

reporting observed percent complete. If any BLHB is

Task

Observed%Complete · BLHBTaskWeightperCostCode!

~

( Task

greater than 2.5 % of BLHB , divide the task into more

TasksforCostCode

Job

detailed tasks.

NOTE 3—For Eq 7, Observed%Complete is expressed as a percentage

8.3.3 Continue to divide tasks as necessary and reallocate

and can take any value between 0 and 100.

hours until each BLHB is less than 2.5 % of the BLHB .

Task Job

9.1.2 Report the hours expended by the labor on each cost

Examples of BLHB task weightings are shown in Table 2,

code, as shown in Table 4, column 7.

columns 4 and 5.

9.1.3 Calculate current productivity per cost code as the

8.3.4 Calculate the LPRP for each cost code as the BLHB

labor hours expended per observed percent of CPIP for each

required for one percent of CPIP (Eq 5).

cost code, based on the labor hours expended and the observed

BLHB

CostCode

percent complete per cost code (Eq 8).

LPRP 5 (5)

CostCode

LaborHoursExpended

CostCode

CurrentProductivity 5 (8)

8.3.5 Calculate the LPRP for the total job by summing the

CostCode

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.