ASTM C1565-03

(Test Method)Standard Test Method for Determination of Pack-Set Index of Portland Cement

Standard Test Method for Determination of Pack-Set Index of Portland Cement

SCOPE

1.1 This test method covers the determination of the pack-set index, which provides an indication of the mechanical force needed to overcome the consolidation of portland cement.

1.2 The pack-set index number provides a numerical value useful for manufacturers who desire to measure and control the effect that vibration-induced consolidation has upon the manufactured cement.

1.3 The values stated in SI units are to be regarded as the standard. Values stated in Inch-Pound units are for informational purposes only and are enclosed in parentheses. Values stated in SI units shall be obtained by measurement in SI units or by appropriate conversion, using the rules of Conversion and rounding given in Standard IEEE/ASTM SI 10, of measurements made in other units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (WARNING—Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and ittuse upon prolonged exposure).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1565 – 03

Standard Test Method for

Determination of Pack-Set Index of Portland Cement

This standard is issued under the fixed designation C 1565; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 maximum voltage, n—as pertaining to this method

only, the energy in volts applied to consolidate the sample,

1.1 This test method covers the determination of the pack-

which results in the maximum pack-set index for a particular

set index, which provides an indication of the mechanical force

cement and the apparatus used for the measurement.

needed to overcome the consolidation of portland cement.

3.1.2 pack set, n—a condition of hydraulic cement, exhib-

1.2 The pack-set index number provides a numerical value

ited in varying degrees, following silo storage or transport in

useful for manufacturers who desire to measure and control the

bulk railcars or trucks, that causes the cement to resist flowing

effect that vibration-induced consolidation has upon the manu-

until considerable mechanical effort has been applied.

factured cement.

3.1.3 pack-set index, n—the numerical indication of the

1.3 The values stated in SI units are to be regarded as the

degree of pack set a particular cement exhibits when subjected

standard. Values stated in Inch-Pound units are for informa-

to the procedures of this test method.

tional purposes only and are enclosed in parentheses. Values

stated in SI units shall be obtained by measurement in SI units

4. Summary of Test Method

or by appropriate conversion, using the rules of Conversion

4.1 Portland cement is placed into a flask and then consoli-

and rounding given in Standard IEEE/ASTM SI 10, of mea-

dated on a vibrating table by a vibration force controlled by

surements made in other units.

time and energy (volts). The consolidated bed is measured for

1.4 This standard does not purport to address all of the

relative strength by turning the flask to a horizontal position

safety concerns, if any, associated with its use. It is the

and rotating in 180° increments until the bed collapses from the

responsibility of the user of this standard to establish appro-

bottom of the flask. The number of half turns is a relative

priate safety and health practices and determine the applica-

indication of the force required to overcome the consolidation

bility of regulatory limitations prior to use. (WARNING—

and is designated the pack-set index, or P.S.I.

Fresh hydraulic-cementitious mixtures are caustic and may

cause chemical burns to skin and tissue upon prolonged

5. Significance and Use

exposure.)

5.1 This method is intended to help manufacturers deter-

mine the relative pack-set tendency of their cement(s). The test

2. Referenced Documents

establishes a pack-set index which, when properly correlated

2.1 ASTM Standards:

3 with field performance, is useful in predicting or preventing

C 150 Specification for Portland Cement

field unloading difficulties.

C 1005 Specification for Reference Masses and Devices for

5.2 The test is an aid to routine control during cement

Determining Mass and Volume for Use in the Physical

3 production and is not suitable for specification purposes.

Testing of Hydraulic Cements

5.3 In general, field performance of cement flowability is

IEEE/ASTM SI 10 International System of Units (SI) The

4 satisfactory when the pack-set index as determined on freshly

Modernized Metric System

ground cement averages 0 to 15 and is unsatisfactory when the

3. Terminology index exceeds 25. Any prediction of field performance of

cement flowability measuring 16 to 25 is tenable. These are

3.1 Definitions of Terms Specific to This Standard:

general ranges and the field performance of individual cements

may not necessarily fall within these ranges. Additional con-

This test method is under the jurisdiction of ASTM Committee C01 on Cement

ditions, after the cement has left the control of the manufac-

and is the direct responsibility of Subcommittee C01.20 on Additions.

turing facility, can affect the apparent pack set index as well.

Current edition approved July 10, 2003. Published October 2003.

Section on Safety, Manual of Cement Testing, Annual Book of ASTM

5.4 Any attempt to apply the critical range of pack-set index

Standards, Vol 04.01.

numbers based on freshly ground cement to job cement without

Annual Book of ASTM Standards, Vol 04.01.

special treatment of the sample would be problematic. The test

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1565–03

is a “GO-NO GO” type of test and should not be used for be determined, with a sensitivity of no less than 0.1 g and a

specification purposes. readability of 0.1 g or less.

5.5 The pack-set index of field cement can be evaluated in

NOTE 4—There are enough differences between Erlenmeyer flasks of

terms of the pack-set index ranges of that cement as determined

the same rated capacity to cause significant difference in the pack-set

when freshly-ground. This comparison can aid the manufac-

index. It is recommended that several flasks which deliver similar pack-set

turer in producing cement that offers the best field performance index numbers for the same cement be kept as spares.

for pack-set properties.

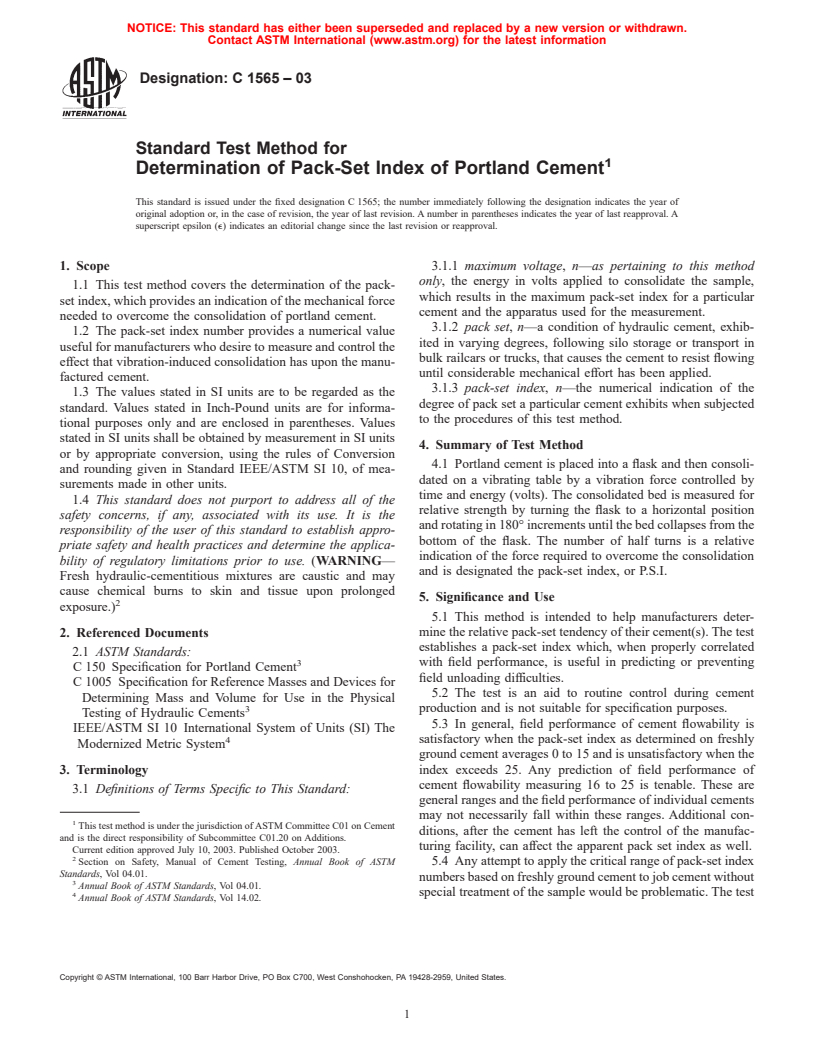

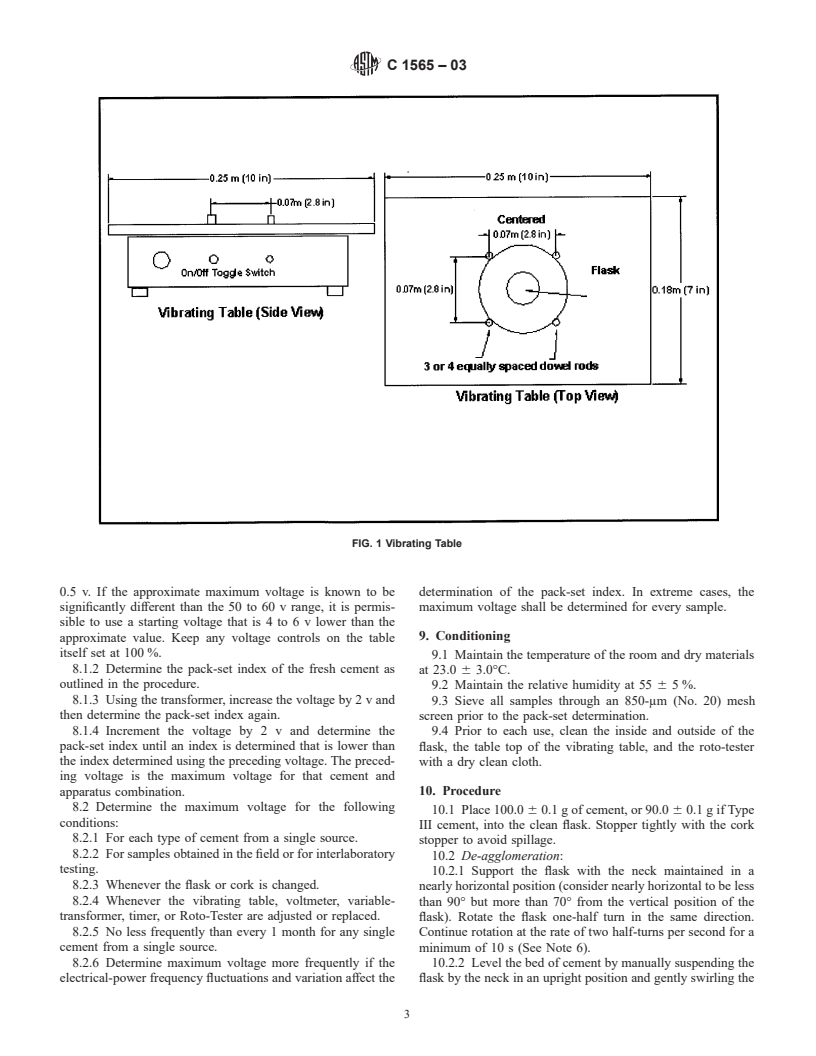

7.3 Vibrating Table, (see Fig. 1), capable of generating

5.6 Silo storage of cement may result in a greater amount of

electromagnetic vibrations at the rate of 3600 vbm at 50 VAC,

consolidation than this method is designed to induce, and the

60 cycle, having a wooden top with dowel pins installed

resulting forces required to overcome that consolidation are not

equidistant from each other on the circumference of the circle

measured by this test method.

with a radius equal to the largest radius of the flask plus 1 mm

5.7 Pack set is not to be confused with “warehouse set”

plus the dowel pin radius (to restrain the flask movement on the

which results from surface hydration of the cement from 5

table). A device that is capable of stopping any lateral

adsorbed moisture.

movement of the flask during vibration is required (See Note

5). The air gap setting between the armatures of the vibrating

6. Interferences

table is critical to the generation of the proper vibrational

6.1 Results obtained from the pack-set test are dependent on

amplitude and must be adjusted according to the manufactur-

sample exposure (See Note 1). er’s instructions. Manufacturer’s recommendations and pre-

cautions for proper operation must be followed to assure the

NOTE 1—Fresh cement has a greater pack-set tendency. Cement stored

accurate determination of the pack set index.

in silos for only a day or two will test similar to fresh cement. Cement

stored in full silos, where aeration is negligible, may develop lower

NOTE 5—Three or four dowel pins of 6 to 10 mm diameter and 25 to 30

pack-set indices upon further aging, Even samples in sealed containers

mm long will be sufficient to restrain the flask. Interconnecting rubber

may vary.

bands or rubber cam-locks can be used to restrain the flask to prevent

lateral movement of the flask during vibration.

6.2 Pack-set index determination can be affected by sample

temperature (See Note 2).

7.4 Roto-Tester, (see Fig. 2), a device on which the Erlen-

meyer flask can be mounted in a horizontal position against a

NOTE 2—Cement with a temperature noticeably hotter than room

vertical, flat, rotating plate that contains frictional hold-down

temperature may produce a different pack-set index number than that same

cams to prevent the flask from falling, and capable of smoothly

cement cooled to room temperature. Cooling of hot cement samples must

be accomplished with minimum aeration to avoid moisture and CO

rotating the flask and table while in that horizontal position, in

adsorption.

180° increments at the rate of approximately 40 one-half

rotations per minute with a short partial second pause between

6.3 The testing room humidity can significantly influence

half-rotations. The device shall be equipped with a counter

the determined pack-set index.

capable of recording the number of one-half rotations of the

6.4 Keep the apparatus level during the testing procedure.

table.

6.5 The vibration energy transferred to the sample is af-

7.5 Voltmeter, capable of measuring and displaying the

fected by the support given the apparatus (See Note 3). The

voltage delivered to the vibrating table to the nearest 0.5 VAC.

determination of pack-set index for unknown samples shall be

7.6 Variable-voltage Tra

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.