ASTM E3110/E3110M-22

(Test Method)Standard Test Method for Collection of Ballistic Limit Data for Ballistic-resistant Torso Body Armor and Shoot Packs

Standard Test Method for Collection of Ballistic Limit Data for Ballistic-resistant Torso Body Armor and Shoot Packs

SIGNIFICANCE AND USE

5.1 U.S. Department of Defense and U.S. Department of Justice standards require ballistic limit determination for assessing the performance of ballistic-resistant body armor.

5.2 This test method may be used by private-sector and government laboratories, manufacturers, research and development organizations, and others assessing the ballistic resistance of body armor or performing research and development of new materials.

5.3 It is intended that this test method be referenced by other standards, specifications, and test methods.

SCOPE

1.1 This test method addresses the collection of ballistic limit data for ballistic-resistant torso body armor and shoot packs.

1.2 This test method is intended for testing of soft body armor, hard armor plates, and shoot packs. This test method does not apply to ballistic helmets.

1.3 This test method describes procedures for collecting data and does not specify computation or performance criteria for the ballistic limit. Instructions for computation and performance criteria are specified in other standards and specifications.

1.4 Several commonly used test item mounting procedures and ballistic limit procedures are included in this test method; certifiers, purchasers, and other users will specify the procedures to be used.

1.5 This test method does not address conditioning of test items.

1.6 It is anticipated that this test method will be referenced by certifiers, purchasers, or other users to meet their specific needs.

1.6.1 Certifier, purchasers, and other users will specify and describe the ballistic test threats to be used. Within this test method, the reference will be called the “test threats document.”

1.6.2 Certifiers, purchasers, and other users will provide specific instructions for the determination of complete penetrations or partial penetrations.

1.6.3 In this test method, “other standards and specifications” and “unless specified elsewhere” refer to documents (for example, military standards, purchase specifications) that require the use of this test method. Certifiers, purchasers, and other users are responsible for the “other standards and specifications” and for specifying any requirements that supersede those of this test method.

1.7 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.7.1 The user of this standard will identify the system of units to be used, and it is critical to ensure that any cross-referenced standards maintain consistency of units between standards.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

- Status

- Published

- Publication Date

- 30-Sep-2022

- Technical Committee

- E54 - Homeland Security Applications

- Drafting Committee

- E54.04 - Public Safety Equipment

- Current Stage

Relations

- Effective Date

- 01-Apr-2024

- Effective Date

- 01-Apr-2020

- Effective Date

- 01-Apr-2020

- Effective Date

- 01-Apr-2020

- Effective Date

- 01-Feb-2020

- Effective Date

- 01-May-2019

- Effective Date

- 01-Oct-2018

- Effective Date

- 01-Feb-2017

- Effective Date

- 01-Nov-2015

- Effective Date

- 01-Nov-2015

- Effective Date

- 01-Nov-2015

ASTM E3110/E3110M-22 - Standard Test Method for Collection of Ballistic Limit Data for Ballistic-resistant Torso Body Armor and Shoot Packs

REDLINE ASTM E3110/E3110M-22 - Standard Test Method for Collection of Ballistic Limit Data for Ballistic-resistant Torso Body Armor and Shoot Packs

Frequently Asked Questions

ASTM E3110/E3110M-22 is a standard published by ASTM International. Its full title is "Standard Test Method for Collection of Ballistic Limit Data for Ballistic-resistant Torso Body Armor and Shoot Packs". This standard covers: SIGNIFICANCE AND USE 5.1 U.S. Department of Defense and U.S. Department of Justice standards require ballistic limit determination for assessing the performance of ballistic-resistant body armor. 5.2 This test method may be used by private-sector and government laboratories, manufacturers, research and development organizations, and others assessing the ballistic resistance of body armor or performing research and development of new materials. 5.3 It is intended that this test method be referenced by other standards, specifications, and test methods. SCOPE 1.1 This test method addresses the collection of ballistic limit data for ballistic-resistant torso body armor and shoot packs. 1.2 This test method is intended for testing of soft body armor, hard armor plates, and shoot packs. This test method does not apply to ballistic helmets. 1.3 This test method describes procedures for collecting data and does not specify computation or performance criteria for the ballistic limit. Instructions for computation and performance criteria are specified in other standards and specifications. 1.4 Several commonly used test item mounting procedures and ballistic limit procedures are included in this test method; certifiers, purchasers, and other users will specify the procedures to be used. 1.5 This test method does not address conditioning of test items. 1.6 It is anticipated that this test method will be referenced by certifiers, purchasers, or other users to meet their specific needs. 1.6.1 Certifier, purchasers, and other users will specify and describe the ballistic test threats to be used. Within this test method, the reference will be called the “test threats document.” 1.6.2 Certifiers, purchasers, and other users will provide specific instructions for the determination of complete penetrations or partial penetrations. 1.6.3 In this test method, “other standards and specifications” and “unless specified elsewhere” refer to documents (for example, military standards, purchase specifications) that require the use of this test method. Certifiers, purchasers, and other users are responsible for the “other standards and specifications” and for specifying any requirements that supersede those of this test method. 1.7 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined. 1.7.1 The user of this standard will identify the system of units to be used, and it is critical to ensure that any cross-referenced standards maintain consistency of units between standards. 1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 5.1 U.S. Department of Defense and U.S. Department of Justice standards require ballistic limit determination for assessing the performance of ballistic-resistant body armor. 5.2 This test method may be used by private-sector and government laboratories, manufacturers, research and development organizations, and others assessing the ballistic resistance of body armor or performing research and development of new materials. 5.3 It is intended that this test method be referenced by other standards, specifications, and test methods. SCOPE 1.1 This test method addresses the collection of ballistic limit data for ballistic-resistant torso body armor and shoot packs. 1.2 This test method is intended for testing of soft body armor, hard armor plates, and shoot packs. This test method does not apply to ballistic helmets. 1.3 This test method describes procedures for collecting data and does not specify computation or performance criteria for the ballistic limit. Instructions for computation and performance criteria are specified in other standards and specifications. 1.4 Several commonly used test item mounting procedures and ballistic limit procedures are included in this test method; certifiers, purchasers, and other users will specify the procedures to be used. 1.5 This test method does not address conditioning of test items. 1.6 It is anticipated that this test method will be referenced by certifiers, purchasers, or other users to meet their specific needs. 1.6.1 Certifier, purchasers, and other users will specify and describe the ballistic test threats to be used. Within this test method, the reference will be called the “test threats document.” 1.6.2 Certifiers, purchasers, and other users will provide specific instructions for the determination of complete penetrations or partial penetrations. 1.6.3 In this test method, “other standards and specifications” and “unless specified elsewhere” refer to documents (for example, military standards, purchase specifications) that require the use of this test method. Certifiers, purchasers, and other users are responsible for the “other standards and specifications” and for specifying any requirements that supersede those of this test method. 1.7 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined. 1.7.1 The user of this standard will identify the system of units to be used, and it is critical to ensure that any cross-referenced standards maintain consistency of units between standards. 1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM E3110/E3110M-22 is classified under the following ICS (International Classification for Standards) categories: 13.340.01 - Protective equipment in general; 13.340.99 - Other protective equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM E3110/E3110M-22 has the following relationships with other standards: It is inter standard links to ASTM E3005-24, ASTM E3004-20, ASTM E3086-20, ASTM E3062/E3062M-20, ASTM E3005-20, ASTM E3062/E3062M-19, ASTM E3005-18, ASTM E3086-17, ASTM E3005-15, ASTM E3004-15, ASTM E3004-15e1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM E3110/E3110M-22 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3110/E3110M − 22

Standard Test Method for

Collection of Ballistic Limit Data for Ballistic-resistant Torso

Body Armor and Shoot Packs

ThisstandardisissuedunderthefixeddesignationE3110/E3110M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope specifications” and for specifying any requirements that super-

sede those of this test method.

1.1 This test method addresses the collection of ballistic

1.7 Units—The values stated in either SI units or inch-

limit data for ballistic-resistant torso body armor and shoot

pound units are to be regarded separately as standard. The

packs.

values stated in each system are not necessarily exact equiva-

1.2 This test method is intended for testing of soft body

lents; therefore, to ensure conformance with the standard, each

armor, hard armor plates, and shoot packs. This test method

system shall be used independently of the other, and values

does not apply to ballistic helmets.

from the two systems shall not be combined.

1.3 This test method describes procedures for collecting

1.7.1 The user of this standard will identify the system of

data and does not specify computation or performance criteria

units to be used, and it is critical to ensure that any cross-

for the ballistic limit. Instructions for computation and perfor-

referenced standards maintain consistency of units between

mance criteria are specified in other standards and specifica-

standards.

tions.

1.8 This standard does not purport to address all of the

1.4 Several commonly used test item mounting procedures safety concerns, if any, associated with its use. It is the

and ballistic limit procedures are included in this test method; responsibility of the user of this standard to establish appro-

certifiers, purchasers, and other users will specify the proce- priate safety, health, and environmental practices and deter-

dures to be used. mine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accor-

1.5 This test method does not address conditioning of test

dance with internationally recognized principles on standard-

items.

ization established in the Decision on Principles for the

1.6 It is anticipated that this test method will be referenced

Development of International Standards, Guides and Recom-

by certifiers, purchasers, or other users to meet their specific

mendations issued by the World Trade Organization Technical

needs.

Barriers to Trade (TBT) Committee.

1.6.1 Certifier, purchasers, and other users will specify and

2. Referenced Documents

describe the ballistic test threats to be used. Within this test

method, the reference will be called the “test threats docu-

2.1 ASTM Standards:

ment.”

B209/B209M Specification for Aluminum and Aluminum-

1.6.2 Certifiers, purchasers, and other users will provide

Alloy Sheet and Plate

specific instructions for the determination of complete penetra-

E3004 Specification for Preparation and Verification of Clay

tions or partial penetrations.

BlocksUsedinBallistic-ResistanceTestingofTorsoBody

1.6.3 In this test method, “other standards and specifica-

Armor

tions” and “unless specified elsewhere” refer to documents (for

E3005 Terminology for Body Armor

example, military standards, purchase specifications) that re-

E3062/E3062M Specification for Indoor Ballistic Test

quire the use of this test method. Certifiers, purchasers, and

Ranges for Small Arms and Fragmentation Testing of

other users are responsible for the “other standards and

Ballistic-resistant Items

E3086 Practice for CreatingAppliques for Use in Testing of

Nonplanar Soft Body Armor Designed for Females

This test method is under the jurisdiction of ASTM Committee E54 on

Homeland Security Applications and is the direct responsibility of Subcommittee

E54.04 on Public Safety Equipment. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2022. Published November 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2018. Last previous edition approved in 2020 as E3110/E3110M – 20. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E3110_E3110M-22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E3110/E3110M − 22

2.2 U.S. Army Research Laboratory: 6. Test Equipment and Apparatus

ARL-TN-437 LangMod Users Manual

6.1 Test threats shall be specified in a separate test threats

2.3 Department of Defense Standards:

document.

MIL-STD-662F V Ballistic Test for Armor

6.2 The ballistic test range shall meet the requirements of

2.4 Department of Justice Standards:

Specification E3062/E3062M.

NIJ Standard–0101.06 Ballistic Resistance of Personal Body

6.2.1 The method of measuring yaw may be with a yaw

Armor

card, flash radiography, high speed video, or photography and

2.5 ISO Standards:

shall be capable of determining, at the point of measurement,

ISO/IEC 17025 General Requirements for the Competence

whether the angle of yaw was greater or less than 5°.

of Testing and Calibration Laboratories

6.3 When clay blocks are required to be used as backing

assemblies behind test items, they shall meet the requirements

3. Terminology

of Specification E3004.

3.1 For terms not defined in this test method, the following

6.4 Fortestproceduresrequiringthetestitemtobemounted

definitions of Terminology E3005 apply: angle of incidence,

in a frame, the frame shall consist of two layers of metal

applique, backing assembly, backing material, backing fixture,

between which the test item is secured.

ballistic limit, body armor, complete penetration, fair hit, gate,

6.4.1 The frame shall be of sufficient size to allow restraint

hard armor, obliquity, partial penetration, plates, shoot pack,

of the test item during ballistic impact. The frame, supports,

shot-to-edge distance, shot-to-shot distance, soft body armor,

clamps, and mounting fixtures shall be capable of securely

stop, strike face, test item, test series, unfair hit, V,V ,

x 50

retaining the test item and withstanding shock resulting from

warmer round, yaw, and zone of mixed results (ZMR).

ballistic impact by the test projectiles.

6.4.2 Additional frame details, such as frame size and

4. Summary of Test Method

clamping force, are provided in other standards and specifica-

4.1 This test method specifies multiple methods for ballistic

tions.

limit testing, which are designed to estimate the penetration

6.5 When required by some test procedures, a witness panel

resistance of soft body armor, hard armor, or shoot packs.

shall be used to determine whether a complete penetration has

4.2 The test method also specifies multiple methods for

occurred.

mounting test items.Atest item is either mounted on a backing

6.5.1 Thewitnesspanelshallbeatleast305 mmby305mm

assembly with clay backing material or mounted in a frame

[12 in. by 12 in.].

with a separate witness panel.

NOTE 1—The witness panel may be larger to allow for impact by all

4.3 Projectiles are fired at the test item starting at a specified

fragments resulting from projectile penetration.

velocity, with subsequent projectiles incrementally increasing

6.5.2 For opaque test items, the witness panel shall be a

or decreasing in velocity based on each shot outcome (com-

0.50 mm 6 0.08 mm [0.020 in. 6 0.003 in.] thick sheet of

plete penetration or partial penetration). This information is 7

2024-T3, 2024-T4, or 5052 aluminum alloy.

subsequently used to calculate the ballistic limit.

7. Hazards

5. Significance and Use

7.1 The ballistic tests described in this test method have

5.1 U.S. Department of Defense and U.S. Department of

inherent hazards.Adequate safeguards for personnel and prop-

Justice standards require ballistic limit determination for as-

erty shall be employed when conducting these tests.

sessing the performance of ballistic-resistant body armor.

8. Sampling and Test Items

5.2 This test method may be used by private-sector and

government laboratories, manufacturers, research and develop-

8.1 Thetestitemsshallbeindividualsoftarmorpanels,hard

ment organizations, and others assessing the ballistic resistance

armor plates, or shoot packs.

of body armor or performing research and development of new

8.2 Test item details, including quantity, size, and

materials.

conditioning, shall be specified in other standards and specifi-

5.3 Itisintendedthatthistestmethodbereferencedbyother

cations.

standards, specifications, and test methods.

NOTE 2—It is recommended that spare test items be provided.

9. Test Requirements

Available from U.S. Army Research Laboratory, 2800 Powder Mill Rd.,

9.1 Unless otherwise specified, each ballistic impact shall

Adelphi, MD 20783-1138, https://www.arl.army.mil.

Available from U.S. Government Printing Office, Superintendent of

meet the requirements listed below to be considered a fair hit.

Documents, 732 N. Capitol St., NW, Washington, DC 20401-0001, http://

9.1.1 The test threat shall impact the test item at an angle

www.access.gpo.gov.

5 ≤5° from the intended angle.

AvailablefromNationalInstituteofJustice(NIJ),8107thSt.,NW,Washington,

DC 20531, http://nij.gov.

Available from International Organization for Standardization (ISO), ISO

Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Specifications for these alloys may be found in Specification B209/B209M or

Geneva, Switzerland, http://www.iso.org. equivalent international specifications.

E3110/E3110M − 22

9.1.2 The test threat shall have yaw verified using a yaw 10.2 The test item shall be held in contact with the clay

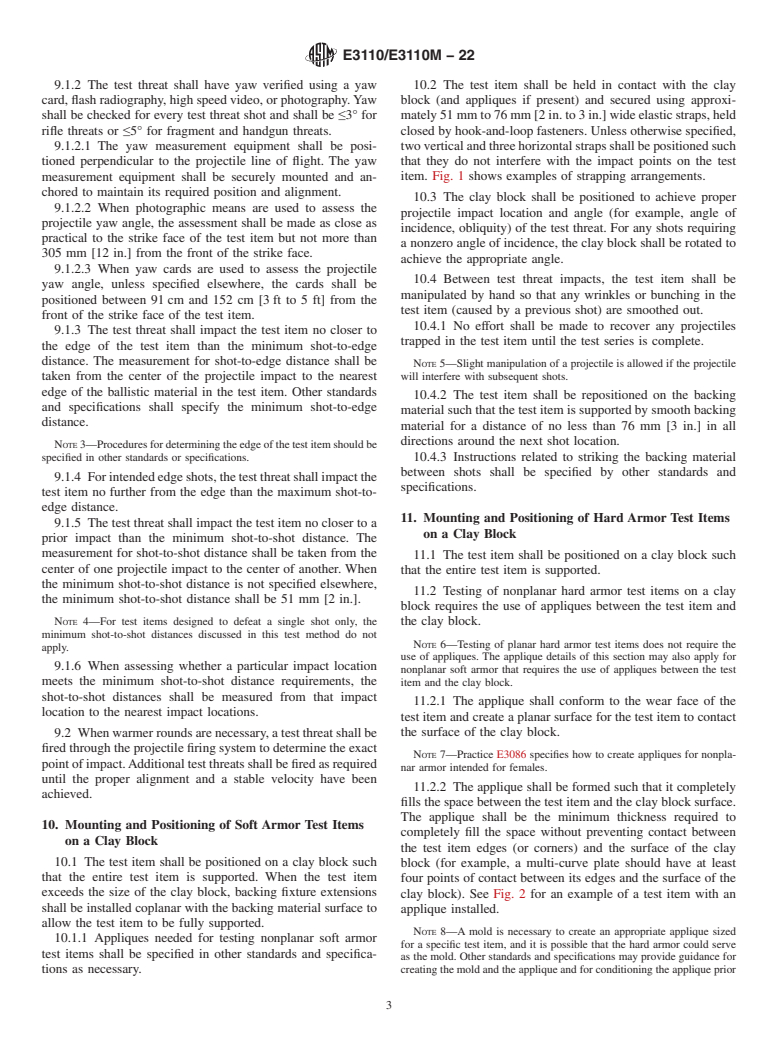

card, flash radiography, high speed video, or photography.Yaw block (and appliques if present) and secured using approxi-

shall be checked for every test threat shot and shall be≤3° for mately51 mmto76mm[2 in.to3in.]wideelasticstraps,held

rifle threats or ≤5° for fragment and handgun threats. closed by hook-and-loop fasteners. Unless otherwise specified,

9.1.2.1 The yaw measurement equipment shall be posi- twoverticalandthreehorizontalstrapsshallbepositionedsuch

tioned perpendicular to the projectile line of flight. The yaw that they do not interfere with the impact points on the test

measurement equipment shall be securely mounted and an- item. Fig. 1 shows examples of strapping arrangements.

chored to maintain its required position and alignment.

10.3 The clay block shall be positioned to achieve proper

9.1.2.2 When photographic means are used to assess the

projectile impact location and angle (for example, angle of

projectile yaw angle, the assessment shall be made as close as

incidence, obliquity) of the test threat. For any shots requiring

practical to the strike face of the test item but not more than

a nonzero angle of incidence, the clay block shall be rotated to

305 mm [12 in.] from the front of the strike face.

achieve the appropriate angle.

9.1.2.3 When yaw cards are used to assess the projectile

10.4 Between test threat impacts, the test item shall be

yaw angle, unless specified elsewhere, the cards shall be

manipulated by hand so that any wrinkles or bunching in the

positioned between 91 cm and 152 cm [3 ft to 5 ft] from the

test item (caused by a previous shot) are smoothed out.

front of the strike face of the test item.

10.4.1 No effort shall be made to recover any projectiles

9.1.3 The test threat shall impact the test item no closer to

trapped in the test item until the test series is complete.

the edge of the test item than the minimum shot-to-edge

distance. The measurement for shot-to-edge distance shall be

NOTE 5—Slight manipulation of a projectile is allowed if the projectile

taken from the center of the projectile impact to the nearest will interfere with subsequent shots.

edge of the ballistic material in the test item. Other standards

10.4.2 The test item shall be repositioned on the backing

and specifications shall specify the minimum shot-to-edge

material such that the test item is supported by smooth backing

distance.

material for a distance of no less than 76 mm [3 in.] in all

directions around the next shot location.

NOTE 3—Procedures for determining the edge of the test item should be

10.4.3 Instructions related to striking the backing material

specified in other standards or specifications.

between shots shall be specified by other standards and

9.1.4 Forintendededgeshots,thetestthreatshallimpactthe

specifications.

test item no further from the edge than the maximum shot-to-

edge distance.

11. Mounting and Positioning of Hard Armor Test Items

9.1.5 The test threat shall impact the test item no closer to a

on a Clay Block

prior impact than the minimum shot-to-shot distance. The

measurement for shot-to-shot distance shall be taken from the

11.1 The test item shall be positioned on a clay block such

center of one projectile impact to the center of another. When

that the entire test item is supported.

the minimum shot-to-shot distance is not specified elsewhere,

11.2 Testing of nonplanar hard armor test items on a clay

the minimum shot-to-shot distance shall be 51 mm [2 in.].

block requires the use of appliques between the test item and

NOTE 4—For test items designed to defeat a single shot only, the the clay block.

minimum shot-to-shot distances discussed in this test method do not

NOTE 6—Testing of planar hard armor test items does not require the

apply.

use of appliques. The applique details of this section may also apply for

9.1.6 When assessing whether a particular impact location

nonplanar soft armor that requires the use of appliques between the test

meets the minimum shot-to-shot distance requirements, the item and the clay block.

shot-to-shot distances shall be measured from that impact

11.2.1 The applique shall conform to the wear face of the

location to the nearest impact locations.

test item and create a planar surface for the test item to contact

the surface of the clay block.

9.2 Whenwarmerroundsarenecessary,atestthreatshallbe

fired through the projectile firing system to determine the exact

NOTE 7—Practice E3086 specifies how to create appliques for nonpla-

pointofimpact.Additionaltestthreatsshallbefiredasrequired

nar armor intended for females.

until the proper alignment and a stable velocity have been

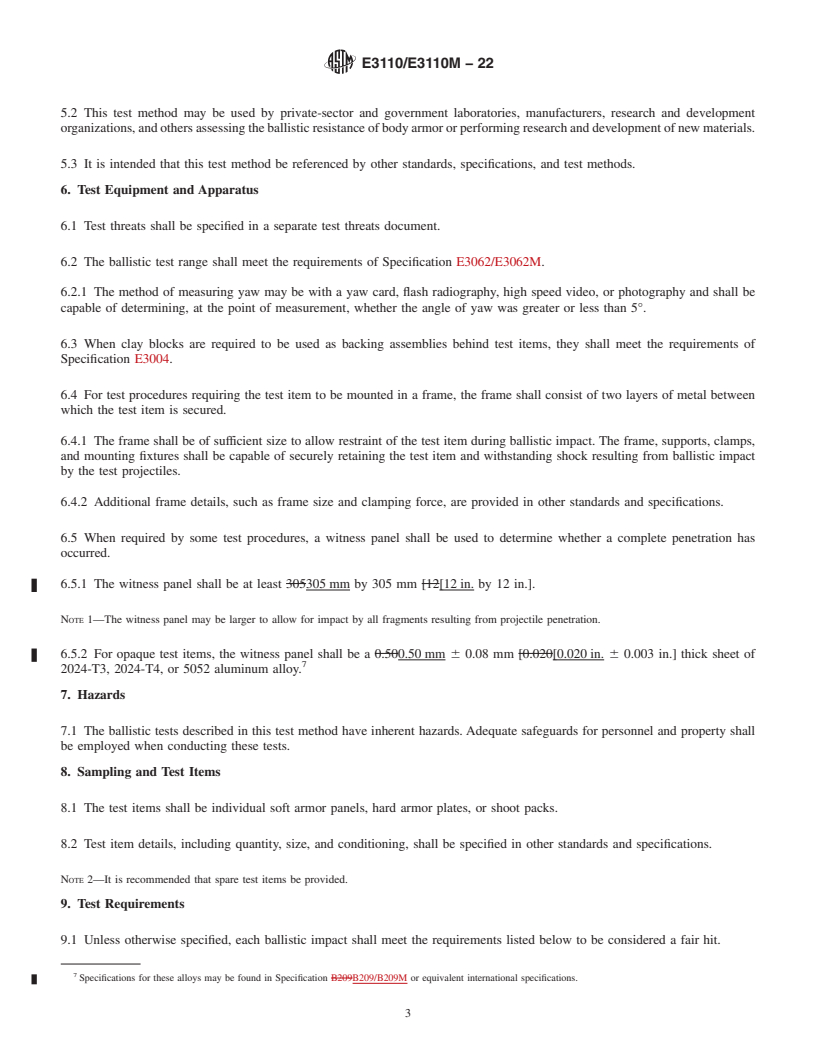

11.2.2 The applique shall be formed such that it completely

achieved.

fills the space between the test item and the clay block surface.

The applique shall be the minimum thickness required to

10. Mounting and Positioning of Soft Armor Test Items

completely fill the space without preventing contact between

on a Clay Block

the test item edges (or corners) and the surface of the clay

10.1 The test item shall be positioned on a clay block such

block (for example, a multi-curve plate should have at least

that the entire test item is supported. When the test item

four points of contact between its edges and the surface of the

exceeds the size of the clay block, backing fixture extensions

clay block). See Fig. 2 for an example of a test item with an

shall be installed coplanar with the backing material surface to

applique installed.

allow the test item to be fully supported.

NOTE 8—A mold is necessary to create an appropriate applique sized

10.1.1 Appliques needed for testing nonplanar soft armor

for a specific test item, and it is possible that the hard armor could serve

test items shall be specified in other standards and specifica-

as the mold. Other standards and specifications may provide guidance for

tions as necessary. creating the mold and the applique and for conditioning the applique prior

E3110/E3110M − 22

FIG. 1 Examples of Strapping Arrangements

FIG. 2 Example of Test Item with Applique Installed

to use. Some testing requires that the hard armor be tested with soft armor

11.2.3.1 When necessary to further secure the applique to

or a shoot pack (that is, in conjunction with armor). In those cases, the

the clay block, hand form conditioned clay into a long, thin

hard armor shall be placed appropriately in contact with the soft armor or

strip. Place the strip around portions of the perimeter of the

a shoot pack (placed on the front or inserted).

applique at the interface with the clay block, and press the clay

11.2.3 The applique shall be placed in intimate contact with

strip into the interface to ensure that the applique remains

the clay block prior to testing, and a modicum of force shall be

adhered to the clay block during testing.

applied to hold the applique in position.

E3110/E3110M − 22

11.2.3.2 Care is required to ensure that the shape of the 13.2.2 The test procedure shall result in an equal number of

applique is not significantly changed during affixing it to the the highest partial penetration velocities and the lowest com-

clay block. plete penetration velocities, which occur within a specified

velocity range.

11.3 The test item shall be positioned on a clay block (with

13.2.2.1 Therequirednumberofhighestpartialpenetrations

or without an applique installed, as appropriate) such that the

and lowest complete penetrations shall be specified by other

entire test item is supported, as shown in Fig. 2.

standards and specifications, and typical numbers and the

11.4 The test item shall be held in contact with the clay

maximum allowable velocity range are listed in Table 1.

block and secured using approximately 51 mm to 76 mm [2 in.

13.2.2.2 The number of test items to be provided for the

to 3 in.] wide elastic straps, held closed by hook-and-loop

above shots shall be specified by other standards and specifi-

fasteners. Vertical and horizontal straps shall be positioned

cations.

suchthattheydonotinterferewiththeimpactpointsonthetest

13.2.3 Unlessspecifiedelsewhere,thestartingvelocityshall

item.

be 23 m⁄s to 30 m⁄s [75 ft⁄s to 100 ft⁄s] above the minimum

required V as specified in other standards and specifications.

11.5 The clay block shall be positioned to achieve proper

13.2.4 The intended angle of incidence for all shots shall be

projectile impact location and angle of incidence of the test

specified in other standards and specifications.

threat. For any shots requiring a nonzero angle of incidence,

13.2.5 Firingshallbedoneusingarandompatternofimpact

the clay block shall be rotated to achieve the appropriate angle.

sites, unless specified otherwise in other standards and speci-

11.6 Between test threat impacts, any soft armor backing

fications.

shall be manipulated by hand so that any wrinkles or bunching

13.2.6 For every shot, verify that the shot was a fair hit (per

in the test item (caused by a previous shot) are smoothed out.

Section 9 of this test method), taking the following steps:

Noeffortshallbemadetorecoveranyprojectilestrappedinthe

13.2.6.1 Thevelocityshallbecheckedtodeterminewhether

test item until the test series is complete.

it was within the specified range.

13.2.6.2 The difference between the velocity readings from

NOTE 9—Slight manipulation of a projectile is permitted if the

each independent instrument shall be compared as specified in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E3110/E3110M − 20 E3110/E3110M − 22

Standard Test Method for

Collection of Ballistic Limit Data for Ballistic-resistant Torso

Body Armor and Shoot Packs

This standard is issued under the fixed designation E3110/E3110M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method addresses the collection of ballistic limit data for ballistic-resistant torso body armor and shoot packs.

1.2 This test method is intended for testing of soft body armor, hard armor plates, and shoot packs. This test method does not apply

to ballistic helmets.

1.3 This test method describes procedures for collecting data and does not specify computation or performance criteria for the

ballistic limit. Instructions for computation and performance criteria are specified in other standards and specifications.

1.4 Several commonly used test item mounting procedures and ballistic limit procedures are included in this test method; certifiers,

purchasers, and other users will specify the procedures to be used.

1.5 This test method does not address conditioning of test items.

1.6 It is anticipated that this test method will be referenced by certifiers, purchasers, or other users to meet their specific needs.

1.6.1 Certifier, purchasers, and other users will specify and describe the ballistic test threats to be used. Within this test method,

the reference will be called the “test threats document.”

1.6.2 Certifiers, purchasers, and other users will provide specific instructions for the determination of complete penetrations or

partial penetrations.

1.6.3 In this test method, “other standards and specifications” and “unless specified elsewhere” refer to documents (for example,

military standards, purchase specifications) that require the use of this test method. Certifiers, purchasers, and other users are

responsible for the “other standards and specifications” and for specifying any requirements that supersede those of this test

method.

1.7 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in

each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other, and values from the two systems shall not be combined.

This test method is under the jurisdiction of ASTM Committee E54 on Homeland Security Applications and is the direct responsibility of Subcommittee E54.04 on

Personal ProtectivePublic Safety Equipment (PPE).

Current edition approved April 1, 2020Oct. 1, 2022. Published April 2020November 2022. Originally approved in 2018. Last previous edition approved in 20192020 as

E3110/E3110M – 19.E3110/E3110M – 20. DOI: 10.1520/E3110_E3110M-20.10.1520/E3110_E3110M-22.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E3110/E3110M − 22

1.7.1 The user of this standard will identify the system of units to be used, and it is critical to ensure that any cross-referenced

standards maintain consistency of units between standards.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

B209B209/B209M Specification for Aluminum and Aluminum-Alloy Sheet and Plate (Metric) B0209_B0209M

E3004 Specification for Preparation and Verification of Clay Blocks Used in Ballistic-Resistance Testing of Torso Body Armor

E3005 Terminology for Body Armor

E3062/E3062M Specification for Indoor Ballistic Test Ranges for Small Arms and Fragmentation Testing of Ballistic-resistant

Items

E3086 Practice for Creating Appliques for Use in Testing of Nonplanar Soft Body Armor Designed for Females

2.2 U.S. Army Research Laboratory:

ARL-TN-437 LangMod Users Manual

2.3 Department of Defense Standards:

MIL-STD-662F V Ballistic Test for Armor

2.4 Department of Justice Standards:

NIJ Standard–0101.06 Ballistic Resistance of Personal Body Armor

2.5 ISO Standards:

ISO/IEC 17025 General Requirements for the Competence of Testing and Calibration Laboratories

3. Terminology

3.1 For terms not defined in this test method, the following definitions of Terminology E3005 apply: angle of incidence, applique,

backing assembly, backing material, backing fixture, ballistic limit, body armor, complete penetration, fair hit, gate, hard armor,

obliquity, partial penetration, plates, shoot pack, shot-to-edge distance, shot-to-shot distance, soft body armor, stop, strike face,

test item, test series, unfair hit, V , V , warmer round, yaw, and zone of mixed results (ZMR).

x 50

4. Summary of Test Method

4.1 This test method specifies multiple methods for ballistic limit testing, which are designed to estimate the penetration resistance

of soft body armor, hard armor, or shoot packs.

4.2 The test method also specifies multiple methods for mounting test items. A test item is either mounted on a backing assembly

with clay backing material or mounted in a frame with a separate witness panel.

4.3 Projectiles are fired at the test item starting at a specified velocity, with subsequent projectiles incrementally increasing or

decreasing in velocity based on each shot outcome (complete penetration or partial penetration). This information is subsequently

used to calculate the ballistic limit.

5. Significance and Use

5.1 U.S. Department of Defense and U.S. Department of Justice standards require ballistic limit determination for assessing the

performance of ballistic-resistant body armor.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from U.S. Army Research Laboratory, 2800 Powder Mill Rd., Adelphi, MD 20783-1138, https://www.arl.army.mil.

Available from U.S. Government Printing Office, Superintendent of Documents, 732 N. Capitol St., NW, Washington, DC 20401-0001, http://www.access.gpo.gov.

Available from National Institute of Justice (NIJ), 810 7th St., NW, Washington, DC 20531, http://nij.gov.

Available from International Organization for Standardization (ISO), ISO Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Geneva,

Switzerland, http://www.iso.org.

E3110/E3110M − 22

5.2 This test method may be used by private-sector and government laboratories, manufacturers, research and development

organizations, and others assessing the ballistic resistance of body armor or performing research and development of new materials.

5.3 It is intended that this test method be referenced by other standards, specifications, and test methods.

6. Test Equipment and Apparatus

6.1 Test threats shall be specified in a separate test threats document.

6.2 The ballistic test range shall meet the requirements of Specification E3062/E3062M.

6.2.1 The method of measuring yaw may be with a yaw card, flash radiography, high speed video, or photography and shall be

capable of determining, at the point of measurement, whether the angle of yaw was greater or less than 5°.

6.3 When clay blocks are required to be used as backing assemblies behind test items, they shall meet the requirements of

Specification E3004.

6.4 For test procedures requiring the test item to be mounted in a frame, the frame shall consist of two layers of metal between

which the test item is secured.

6.4.1 The frame shall be of sufficient size to allow restraint of the test item during ballistic impact. The frame, supports, clamps,

and mounting fixtures shall be capable of securely retaining the test item and withstanding shock resulting from ballistic impact

by the test projectiles.

6.4.2 Additional frame details, such as frame size and clamping force, are provided in other standards and specifications.

6.5 When required by some test procedures, a witness panel shall be used to determine whether a complete penetration has

occurred.

6.5.1 The witness panel shall be at least 305305 mm by 305 mm [12[12 in. by 12 in.].

NOTE 1—The witness panel may be larger to allow for impact by all fragments resulting from projectile penetration.

6.5.2 For opaque test items, the witness panel shall be a 0.500.50 mm 6 0.08 mm [0.020[0.020 in. 6 0.003 in.] thick sheet of

2024-T3, 2024-T4, or 5052 aluminum alloy.

7. Hazards

7.1 The ballistic tests described in this test method have inherent hazards. Adequate safeguards for personnel and property shall

be employed when conducting these tests.

8. Sampling and Test Items

8.1 The test items shall be individual soft armor panels, hard armor plates, or shoot packs.

8.2 Test item details, including quantity, size, and conditioning, shall be specified in other standards and specifications.

NOTE 2—It is recommended that spare test items be provided.

9. Test Requirements

9.1 Unless otherwise specified, each ballistic impact shall meet the requirements listed below to be considered a fair hit.

Specifications for these alloys may be found in Specification B209B209/B209M or equivalent international specifications.

E3110/E3110M − 22

9.1.1 The test threat shall impact the test item at an angle ≤5° from the intended angle.

9.1.2 The test threat shall have yaw verified to be using a yaw card, flash radiography, high speed video, or photography. Yaw shall

be checked for every test threat shot and shall be ≤3° for rifle threats or ≤5° for fragment and handgun threats. Yaw shall be checked

for every test threat shot.

9.1.2.1 The yaw measurement equipment shall be positioned perpendicular to the projectile line of flight. The yaw measurement

equipment shall be securely mounted and anchored to maintain its required position and alignment.

9.1.2.2 When photographic means are used to assess the projectile yaw angle, the assessment shall be made as close as practical

to the strike face of the test item but not more than 305 mm [12 in.] from the front of the strike face.

9.1.2.3 When yaw cards are used to assess the projectile yaw angle, unless specified elsewhere, the cards shall be positioned

between 51 and 305 mm [2 and 12 in.]91 cm and 152 cm [3 ft to 5 ft] from the front of the strike face of the test item.

9.1.3 The test threat shall impact the test item no closer to the edge of the test item than the minimum shot-to-edge distance. The

measurement for shot-to-edge distance shall be taken from the center of the projectile impact to the nearest edge of the ballistic

material in the test item. Other standards and specifications shall specify the minimum shot-to-edge distance.

NOTE 3—Procedures for determining the edge of the test item should be specified in other standards or specifications.

9.1.4 For intended edge shots, the test threat shall impact the test item no further from the edge than the maximum shot-to-edge

distance.

9.1.5 The test threat shall impact the test item no closer to a prior impact than the minimum shot-to-shot distance. The

measurement for shot-to-shot distance shall be taken from the center of one projectile impact to the center of another. When the

minimum shot-to-shot distance is not specified elsewhere, the minimum shot-to-shot distance shall be 51 mm [2 in.].

NOTE 4—For test items designed to defeat a single shot only, the minimum shot-to-shot distances discussed in this test method do not apply.

9.1.6 When assessing whether a particular impact location meets the minimum shot-to-shot distance requirements, the shot-to-shot

distances shall be measured from that impact location to the nearest impact locations.

9.2 When warmer rounds are necessary, a test threat shall be fired through the projectile firing system to determine the exact point

of impact. Additional test threats shall be fired as required until the proper alignment and a stable velocity have been achieved.

10. Mounting and Positioning of Soft Armor Test Items on a Clay Block

10.1 The test item shall be positioned on a clay block such that the entire test item is supported. When the test item exceeds the

size of the clay block, backing fixture extensions shall be installed coplanar with the backing material surface to allow the test item

to be fully supported.

10.1.1 Appliques needed for testing nonplanar soft armor test items shall be specified in other standards and specifications as

necessary.

10.2 The test item shall be held in contact with the clay block (and appliques if present) and secured using approximately 5151 mm

to 76 mm [2[2 in. to 3 in.] wide elastic straps, held closed by hook-and-loop fasteners. Unless otherwise specified, two vertical

and three horizontal straps shall be positioned such that they do not interfere with the impact points on the test item. Fig. 1 shows

examples of strapping arrangements.

10.3 The clay block shall be positioned to achieve proper projectile impact location and angle (for example, angle of incidence,

obliquity) of the test threat. For any shots requiring a nonzero angle of incidence, the clay block shall be rotated to achieve the

appropriate angle.

E3110/E3110M − 22

FIG. 1 Examples of Strapping Arrangements

10.4 Between test threat impacts, the test item shall be manipulated by hand so that any wrinkles or bunching in the test item

(caused by a previous shot) are smoothed out.

10.4.1 No effort shall be made to recover any projectiles trapped in the test item until the test series is complete.

NOTE 5—Slight manipulation of a projectile is allowed if the projectile will interfere with subsequent shots.

10.4.2 The test item shall be repositioned on the backing material such that the test item is supported by smooth backing material

for a distance of no less than 76 mm [3 in.] in all directions around the next shot location.

10.4.3 Instructions related to striking the backing material between shots shall be specified by other standards and specifications.

11. Mounting and Positioning of Hard Armor Test Items on a Clay Block

11.1 The test item shall be positioned on a clay block such that the entire test item is supported.

11.2 Testing of nonplanar hard armor test items on a clay block requires the use of appliques between the test item and the clay

block.

NOTE 6—Testing of planar hard armor test items does not require the use of appliques. The applique details of this section may also apply for nonplanar

soft armor that requires the use of appliques between the test item and the clay block.

E3110/E3110M − 22

11.2.1 The applique shall conform to the wear face of the test item and create a planar surface for the test item to contact the

surface of the clay block.

NOTE 7—Practice E3086 specifies how to create appliques for nonplanar armor intended for females.

11.2.2 The applique shall be formed such that it completely fills the space between the test item and the clay block surface. The

applique shall be the minimum thickness required to completely fill the space without preventing contact between the test item

edges (or corners) and the surface of the clay block (for example, a multi-curve plate should have at least four points of contact

between its edges and the surface of the clay block). See Fig. 2 for an example of a test item with an applique installed.

NOTE 8—A mold is necessary to create an appropriate applique sized for a specific test item, and it is possible that the hard armor could serve as the mold.

Other standards and specifications may provide guidance for creating the mold and the applique and for conditioning the applique prior to use. Some

testing requires that the hard armor be tested with soft armor or a shoot pack (that is, in conjunction with armor). In those cases, the hard armor shall

be placed appropriately in contact with the soft armor or a shoot pack (placed on the front or inserted).

11.2.3 The applique shall be placed in intimate contact with the clay block prior to testing, and a modicum of force shall be applied

to hold the applique in position.

11.2.3.1 When necessary to further secure the applique to the clay block, hand form conditioned clay into a long, thin strip. Place

the strip around portions of the perimeter of the applique at the interface with the clay block, and press the clay strip into the

interface to ensure that the applique remains adhered to the clay block during testing.

11.2.3.2 Care is required to ensure that the shape of the applique is not significantly changed during affixing it to the clay block.

11.3 The test item shall be positioned on a clay block (with or without an applique installed, as appropriate) such that the entire

test item is supported, as shown in Fig. 2.

11.4 The test item shall be held in contact with the clay block and secured using approximately 5151 mm to 76 mm [2[2 in. to

3 in.] wide elastic straps, held closed by hook-and-loop fasteners. Vertical and horizontal straps shall be positioned such that they

do not interfere with the impact points on the test item.

11.5 The clay block shall be positioned to achieve proper projectile impact location and angle of incidence of the test threat. For

any shots requiring a nonzero angle of incidence, the clay block shall be rotated to achieve the appropriate angle.

11.6 Between test threat impacts, any soft armor backing shall be manipulated by hand so that any wrinkles or bunching in the

test item (caused by a previous shot) are smoothed out. No effort shall be made to recover any projectiles trapped in the test item

until the test series is complete.

NOTE 9—Slight manipulation of a projectile is permitted if the projectile will interfere with subsequent shots.

FIG. 2 Example of Test Item with Applique Installed

E3110/E3110M − 22

12. Mounting of Test Items in a Frame

12.1 The test item shall be sandwiched in a frame and restrained with mechanical or pneumatic clamping devices either at the

center of each side of the frame or at each corner of the frame.

12.2 The witness panel shall be positioned behind and parallel to the test item. The witness panel distance to the test item shall

be specified in other standards and specifications. If no specification is listed, securely mount the witness panel 150150 mm 6 25

mm [6.0[6.0 in. 6 1.0 in.] behind the area of impact.

12.3 Between test threat impacts on soft armor, the test item shall be removed from the frame and manipulated by hand so that

any wrinkles or bunching in the test item (caused by a previous shot) are smoothed out. No effort shall be made to recover any

projectiles trapped in the test item until the test series is complete unless the projectile or fragment interferes with the clamping

mechanism in such a way that would result in unequal pressure applied to all sides of the test item.

NOTE 10—Slight manipulation of a projectile is allowed if the projectile will interfere with subsequent shots.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...