ASTM D189-24

(Test Method)Standard Test Method for Conradson Carbon Residue of Petroleum Products

Standard Test Method for Conradson Carbon Residue of Petroleum Products

SIGNIFICANCE AND USE

5.1 The carbon residue value of burner fuel serves as a rough approximation of the tendency of the fuel to form deposits in vaporizing pot-type and sleeve-type burners. Similarly, provided alkyl nitrates are absent (or if present, provided the test is performed on the base fuel without additive) the carbon residue of diesel fuel correlates approximately with combustion chamber deposits.

5.2 The carbon residue value of motor oil, while at one time regarded as indicative of the amount of carbonaceous deposits a motor oil would form in the combustion chamber of an engine, is now considered to be of doubtful significance due to the presence of additives in many oils. For example, an ash-forming detergent additive may increase the carbon residue value of an oil yet will generally reduce its tendency to form deposits.

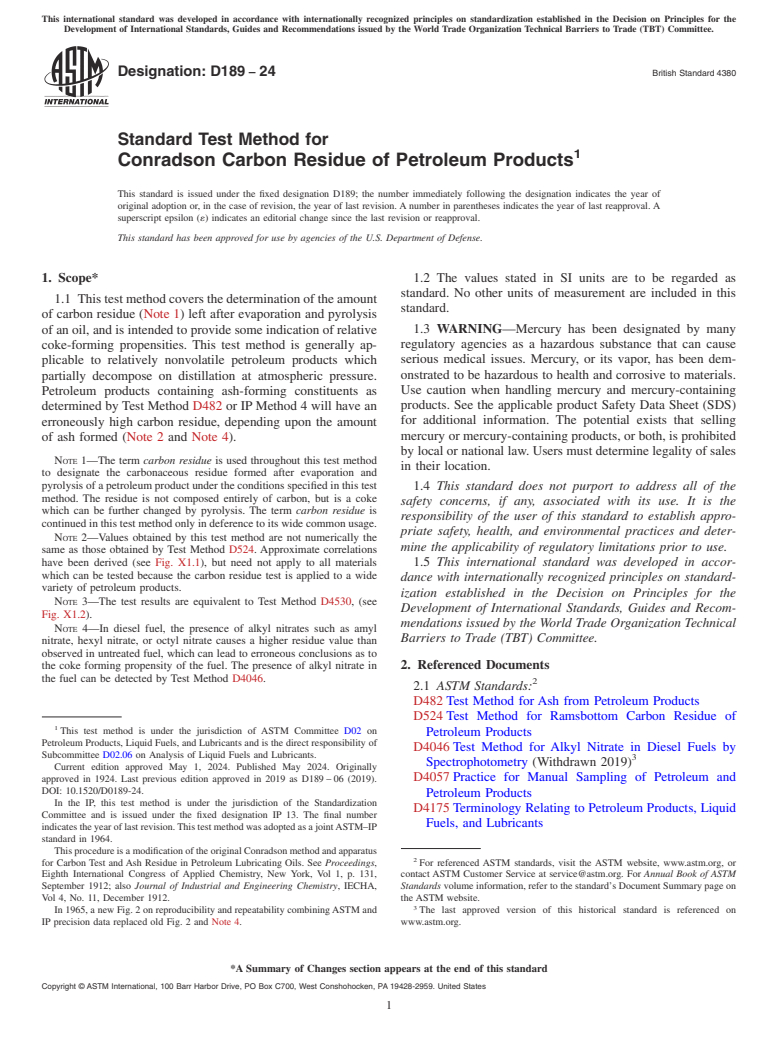

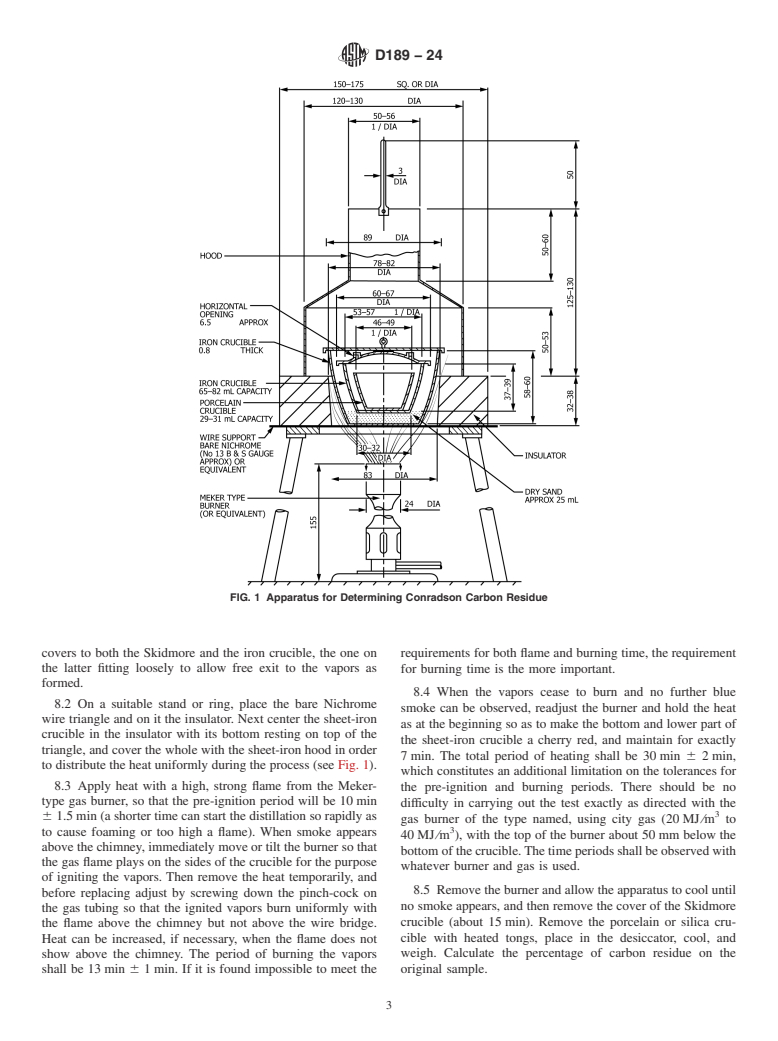

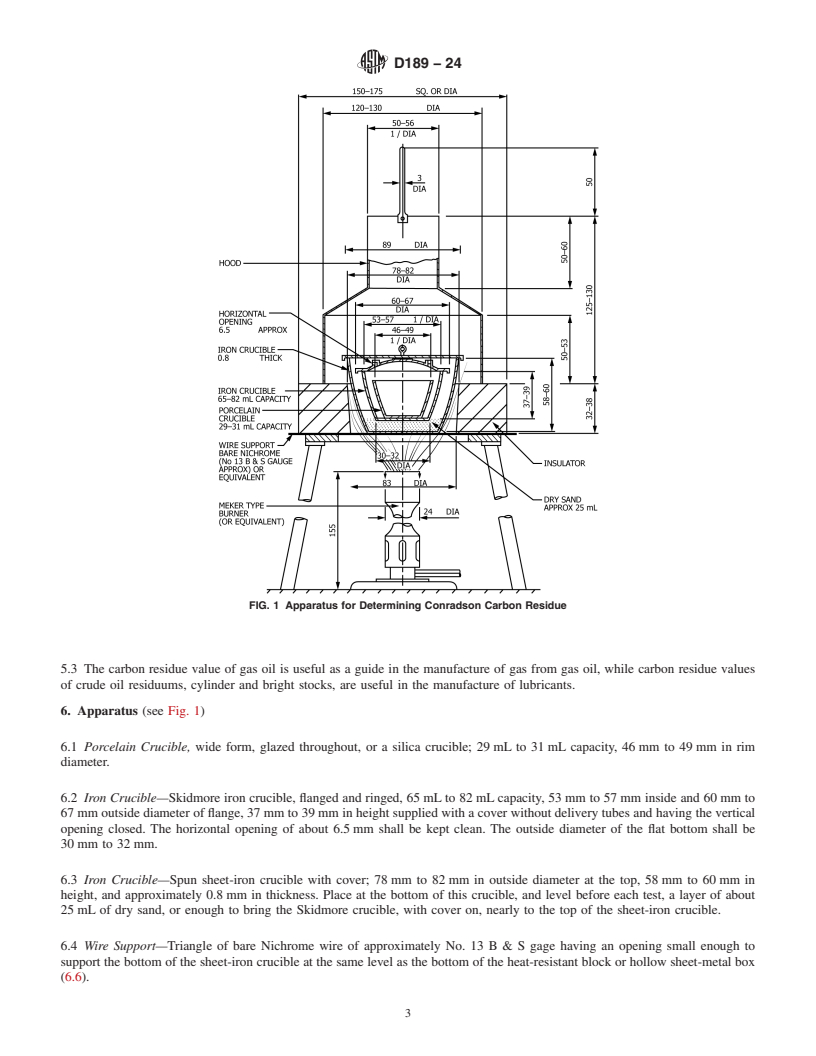

5.3 The carbon residue value of gas oil is useful as a guide in the manufacture of gas from gas oil, while carbon residue values of crude oil residuums, cylinder and bright stocks, are useful in the manufacture of lubricants.

SCOPE

1.1 This test method covers the determination of the amount of carbon residue (Note 1) left after evaporation and pyrolysis of an oil, and is intended to provide some indication of relative coke-forming propensities. This test method is generally applicable to relatively nonvolatile petroleum products which partially decompose on distillation at atmospheric pressure. Petroleum products containing ash-forming constituents as determined by Test Method D482 or IP Method 4 will have an erroneously high carbon residue, depending upon the amount of ash formed (Note 2 and Note 4).

Note 1: The term carbon residue is used throughout this test method to designate the carbonaceous residue formed after evaporation and pyrolysis of a petroleum product under the conditions specified in this test method. The residue is not composed entirely of carbon, but is a coke which can be further changed by pyrolysis. The term carbon residue is continued in this test method only in deference to its wide common usage.

Note 2: Values obtained by this test method are not numerically the same as those obtained by Test Method D524. Approximate correlations have been derived (see Fig. X1.1), but need not apply to all materials which can be tested because the carbon residue test is applied to a wide variety of petroleum products.

Note 3: The test results are equivalent to Test Method D4530, (see Fig. X1.2).

Note 4: In diesel fuel, the presence of alkyl nitrates such as amyl nitrate, hexyl nitrate, or octyl nitrate causes a higher residue value than observed in untreated fuel, which can lead to erroneous conclusions as to the coke forming propensity of the fuel. The presence of alkyl nitrate in the fuel can be detected by Test Method D4046.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 WARNING—Mercury has been designated by many regulatory agencies as a hazardous substance that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Use caution when handling mercury and mercury-containing products. See the applicable product Safety Data Sheet (SDS) for additional information. The potential exists that selling mercury or mercury-containing products, or both, is prohibited by local or national law. Users must determine legality of sales in their location.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Prin...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D189 − 24 British Standard 4380

Standard Test Method for

1

Conradson Carbon Residue of Petroleum Products

This standard is issued under the fixed designation D189; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 This test method covers the determination of the amount

standard.

of carbon residue (Note 1) left after evaporation and pyrolysis

1.3 WARNING—Mercury has been designated by many

of an oil, and is intended to provide some indication of relative

regulatory agencies as a hazardous substance that can cause

coke-forming propensities. This test method is generally ap-

serious medical issues. Mercury, or its vapor, has been dem-

plicable to relatively nonvolatile petroleum products which

onstrated to be hazardous to health and corrosive to materials.

partially decompose on distillation at atmospheric pressure.

Use caution when handling mercury and mercury-containing

Petroleum products containing ash-forming constituents as

products. See the applicable product Safety Data Sheet (SDS)

determined by Test Method D482 or IP Method 4 will have an

for additional information. The potential exists that selling

erroneously high carbon residue, depending upon the amount

mercury or mercury-containing products, or both, is prohibited

of ash formed (Note 2 and Note 4).

by local or national law. Users must determine legality of sales

NOTE 1—The term carbon residue is used throughout this test method

in their location.

to designate the carbonaceous residue formed after evaporation and

pyrolysis of a petroleum product under the conditions specified in this test 1.4 This standard does not purport to address all of the

method. The residue is not composed entirely of carbon, but is a coke

safety concerns, if any, associated with its use. It is the

which can be further changed by pyrolysis. The term carbon residue is

responsibility of the user of this standard to establish appro-

continued in this test method only in deference to its wide common usage.

priate safety, health, and environmental practices and deter-

NOTE 2—Values obtained by this test method are not numerically the

mine the applicability of regulatory limitations prior to use.

same as those obtained by Test Method D524. Approximate correlations

have been derived (see Fig. X1.1), but need not apply to all materials 1.5 This international standard was developed in accor-

which can be tested because the carbon residue test is applied to a wide

dance with internationally recognized principles on standard-

variety of petroleum products.

ization established in the Decision on Principles for the

NOTE 3—The test results are equivalent to Test Method D4530, (see

Development of International Standards, Guides and Recom-

Fig. X1.2).

mendations issued by the World Trade Organization Technical

NOTE 4—In diesel fuel, the presence of alkyl nitrates such as amyl

Barriers to Trade (TBT) Committee.

nitrate, hexyl nitrate, or octyl nitrate causes a higher residue value than

observed in untreated fuel, which can lead to erroneous conclusions as to

the coke forming propensity of the fuel. The presence of alkyl nitrate in 2. Referenced Documents

the fuel can be detected by Test Method D4046.

2

2.1 ASTM Standards:

D482 Test Method for Ash from Petroleum Products

D524 Test Method for Ramsbottom Carbon Residue of

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

D4046 Test Method for Alkyl Nitrate in Diesel Fuels by

Subcommittee D02.06 on Analysis of Liquid Fuels and Lubricants.

3

Spectrophotometry (Withdrawn 2019)

Current edition approved May 1, 2024. Published May 2024. Originally

approved in 1924. Last previous edition approved in 2019 as D189 – 06 (2019). D4057 Practice for Manual Sampling of Petroleum and

DOI: 10.1520/D0189-24.

Petroleum Products

In the IP, this test method is under the jurisdiction of the Standardization

D4175 Terminology Relating to Petroleum Products, Liquid

Committee and is issued under the fixed designation IP 13. The final number

Fuels, and Lubricants

indicates the year of last revision. This test method was adopted as a joint ASTM–IP

standard in 1964.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D189 − 06 (Reapproved 2019) D189 − 24 British Standard 4380

Standard Test Method for

1

Conradson Carbon Residue of Petroleum Products

This standard is issued under the fixed designation D189; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 This test method covers the determination of the amount of carbon residue (Note 1) left after evaporation and pyrolysis of an

oil, and is intended to provide some indication of relative coke-forming propensities. This test method is generally applicable to

relatively nonvolatile petroleum products which partially decompose on distillation at atmospheric pressure. Petroleum products

containing ash-forming constituents as determined by Test Method D482 or IP Method 4 will have an erroneously high carbon

residue, depending upon the amount of ash formed (Note 2 and Note 4).

NOTE 1—The term carbon residue is used throughout this test method to designate the carbonaceous residue formed after evaporation and pyrolysis of

a petroleum product under the conditions specified in this test method. The residue is not composed entirely of carbon, but is a coke which can be further

changed by pyrolysis. The term carbon residue is continued in this test method only in deference to its wide common usage.

NOTE 2—Values obtained by this test method are not numerically the same as those obtained by Test Method D524. Approximate correlations have been

derived (see Fig. X1.1), but need not apply to all materials which can be tested because the carbon residue test is applied to a wide variety of petroleum

products.

NOTE 3—The test results are equivalent to Test Method D4530, (see Fig. X1.2).

NOTE 4—In diesel fuel, the presence of alkyl nitrates such as amyl nitrate, hexyl nitrate, or octyl nitrate causes a higher residue value than observed in

untreated fuel, which can lead to erroneous conclusions as to the coke forming propensity of the fuel. The presence of alkyl nitrate in the fuel can be

detected by Test Method D4046.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 WARNING—Mercury has been designated by many regulatory agencies as a hazardous materialsubstance that can cause

central nervous system, kidney and liver damage. serious medical issues. Mercury, or its vapor, may has been demonstrated to be

hazardous to health and corrosive to materials. Caution should be taken Use caution when handling mercury and mercury

containing mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.06 on Analysis of Liquid Fuels and Lubricants.

Current edition approved Dec. 1, 2019May 1, 2024. Published December 2019May 2024. Originally approved in 1924. Last previous edition approved in 20142019 as

D189 – 06 (2014).(2019). DOI: 10.1520/D0189-06R19.10.1520/D0189-24.

In the IP, this test method is under the jurisdiction of the Standardization Committee and is issued under the fixed designation IP 13. The final number indicates the year

of last revision. This test method was adopted as a joint ASTM–IP standard in 1964.

This procedure is a modification of the original Conradson method and apparatus for Carbon Test and Ash Residue in Petroleum Lubricating Oils. See Proceedings, Eighth

International Congress of Applied Chemistry, New York, Vol 1, p. 131, September 1912; also Journal of Industrial and Engineering Chemistry, IECHA, Vol 4, No. 11,

December 1912.

In 1965, a new Fig. 2 on reproducibility and repeatability combining ASTM and IP precision data replaced old Fig. 2 and Note 4.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D189 − 24

website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware (SDS) for additional informa-

tion. The potential exists that selling mercury and/or merc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.