ASTM E3-95

(Practice)Standard Practice for Preparation of Metallographic Specimens

Standard Practice for Preparation of Metallographic Specimens

SCOPE

1.1 The primary objective of metallographic examinations is to reveal the constituents and structure of metals and their alloys by means of a light optical or scanning electron microscope. In special cases, the objective of the examination may require the development of less detail than in other cases but, under nearly all conditions, the proper selection and preparation of the specimen is of major importance. Because of the diversity in available equipment and the wide variety of problems encountered, the following text presents for the guidance of the metallographer only those practices which experience has shown are generally satisfactory; it cannot and does not describe the variations in technique required to solve individual specimen preparation problems.

Note 1--For a more extensive description of various metallographic techniques, refer to Samuels, L. E., Metallographic Polishing by Mechanical Methods, American Society for Metals (ASM) Metals Park, OH, 3rd Ed., 1982; Petzow, G., Metallographic Etching, ASM, 1978; and VanderVoort, G., Metallography: Principles and Practice, McGraw Hill, NY, 2nd Ed., 1999.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation:E3–95 An American National Standard

Standard Practice for

Preparation of Metallographic Specimens

This standard is issued under the fixed designation E 3; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Significance and Use

1.1 The primary objective of metallographic examinations 3.1 Microstructures have a strong influence on the proper-

is to reveal the constituents and structure of metals and their ties and successful application of metals and alloys. Determi-

alloys by means of the light microscope. In special cases, the nation and control of microstructure requires the use of

objective of the examination may require the development of metallographic examination.

less detail than in other cases but, under nearly all conditions, 3.2 Many specifications contain a requirement regarding

the proper selection and preparation of the specimen is of microstructure; hence, a major use for metallographic exami-

major importance. Because of the diversity in available equip- nation is inspection to ensure that the requirement is met. Other

ment and the wide variety of problems encountered, the major uses for metallographic examination are in failure

following text presents for the guidance of the metallographer analysis, and in research and development.

only those practices which experience has shown are generally 3.3 Proper choice of specimen location and orientation will

satisfactory; it cannot and does not describe the variations in minimize the number of specimens required and simplify their

technique required to solve individual problems. interpretation. It is easy to take too few specimens for study,

but it is seldom that too many are studied.

NOTE 1—For a more extensive description of various metallographic

techniques, refer to Samuels, L. E., Metallographic Polishing by Mechani-

4. Selection of Metallographic Specimens

cal Methods, American Society for Metals (ASM) Metals Park, OH, 3rd

4.1 The selection of test specimens for metallographic

Ed., 1982; Petzow, G., Metallographic Etching, ASM, 1978; and Vander-

Voort, G., Metallography: Principles and Practice, McGraw Hill, NY, examination is extremely important because, if their interpre-

1984.

tation is to be of value, the specimens must be representative of

the material that is being studied. The intent or purpose of the

1.2 This standard does not purport to address all of the

metallographic examination will usually dictate the location of

safety concerns, if any, associated with its use. It is the

the specimens to be studied. With respect to purpose of study,

responsibility of the user of this standard to establish appro-

metallographic examination may be divided into three classi-

priate safety and health practices and determine the applica-

fications:

bility of regulatory limitations prior to use.

4.1.1 General Studies or Routine Work—Specimens from

2. Referenced Documents

locations that are most likely to reveal the maximum variations

within the material under study should be chosen. For example,

2.1 ASTM Standards:

specimens should be taken from a casting in the zones wherein

E 7 Terminology Relating to Metallography

maximum segregation might be expected to occur as well as

E 45 Practice for Determining the Inclusion Content of

specimens from sections where segregation should be at a

Steel

minimum. In the examination of strip or wire, test specimens

E 340 Test Method for Macroetching Metals and Alloys

should be taken from each end of the coils.

E 407 Test Methods for Microetching Metals and Alloys

4.1.2 Study of Failures—Test specimens should be taken as

E 1077 Test Method for Estimating the Depth of Decarbur-

closely as possible to the fracture or to the initiation of the

ization of Steel Specimens

failure. Before taking the metallographic specimens, study of

E 1268 Practice for Assessing the Degree of Banding or

the fracture surface should be complete, or, at the very least,

Orientation of Microstructures

the fracture surface should be documented. Specimens should

E 1558 Guide to Electrolytic Polishing of Metallographic

be taken in many cases from a sound area for a comparison of

Specimens

structures and properties.

4.1.3 Research Studies—The nature of the study will dictate

This practice is under the jurisdiction of ASTM Committee E-4 on Metallog-

specimen location, orientation, etc. Sampling will usually be

raphy and is the direct responsibility of Subcommittee E04.01 on Sampling,

Specimen Preparation, and Photography. more extensive than in routine examinations.

Current edition approved Jan. 15, 1995. Published March 1995. Originally

4.2 Having established the location of the metallographic

published as E3–21T. Last previous edition E3–80 (1986).

samples to be studied, the type of section to be examined must

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E3

be decided. For a casting, a section cut perpendicular to the

surface will show the variations in structure from the outside to

the interior of the casting. In hot-worked or cold-worked

metals, both transverse and longitudinal sections should be

studied. Special investigations may at times require specimens

with surfaces prepared parallel to the original surface of the

product. In the case of wire and small rounds, a longitudinal

section through the center of the specimen proves advanta-

geous when studied in conjunction with the transverse section.

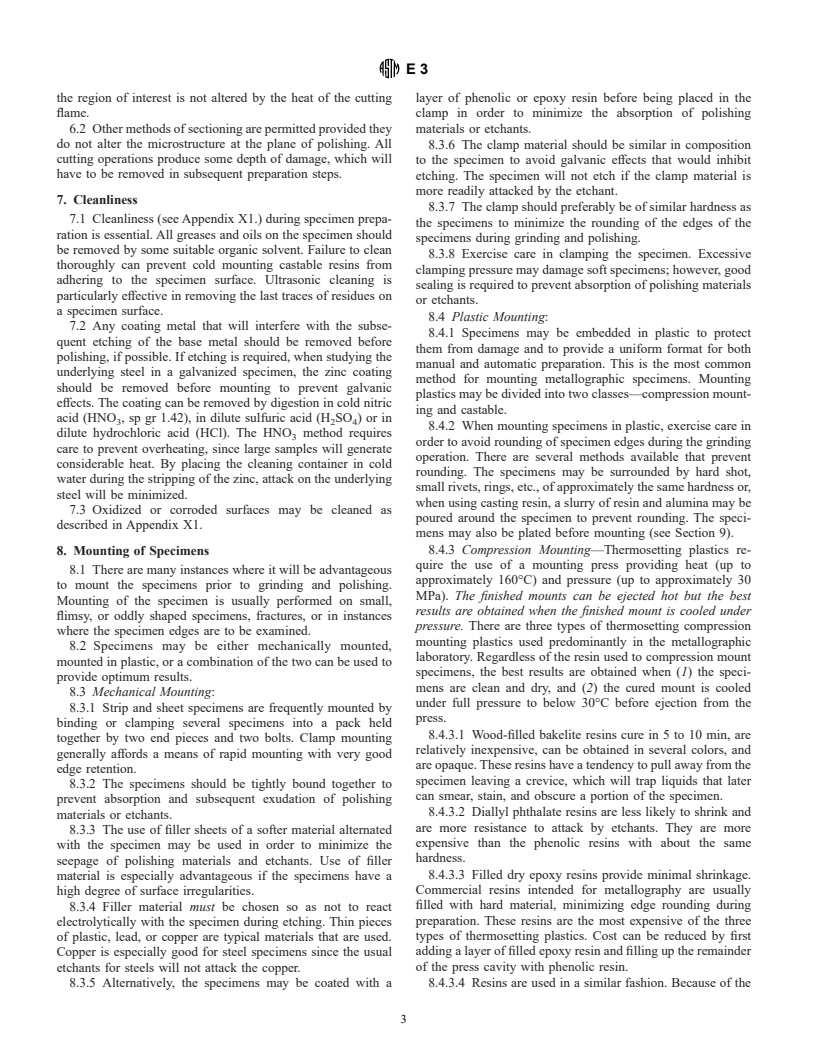

4.3 Cross sections or transverse sections taken perpendicu-

lar to the main axis of the material are more suitable for

revealing the following information:

4.3.1 Variations in structure from center to surface,

4.3.2 Distribution of nonmetallic impurities across the sec-

tion,

4.3.3 Decarburization at the surface of a ferrous material

(see Test Method E 1077), Symbol in

Suggested Designation

Diagram

4.3.4 Depth of surface imperfections,

4.3.5 Depth of corrosion,

A Rolled surface

4.3.6 Thickness of protective coatings, and

B Direction of rolling

4.3.7 Structure of protective coating.

C Rolled edge

4.4 Longitudinal sections taken parallel to the main axis of

D Longitudinal (or lengthwise) section parallel to rolled sur-

face

the material are more suitable for revealing the following

E Longitudinal section perpendicular to rolled surface

information:

F Transverse section

4.4.1 Inclusion content of steel (see Practice E 45),

G Radial longitudinal section

4.4.2 Degree of plastic deformation, as shown by grain

H Tangential longitudinal section

distortion,

FIG. 1 Method of Designating Location of Area Shown in

4.4.3 Presence or absence of banding in the structure (see

Photomicrograph.

Practice E 1268), and

4.4.4 The quality attained with any heat treatment.

body of the material, care must be exercised to minimize

4.5 The locations of surfaces examined should always be

altering the structure of the metal. Three common types of

given in reporting results and in any illustrative micrographs. A

sectioning are as follows:

suitable method of indicating surface locations is shown in Fig.

6.1.1 Sawing, whether by hand or machine with lubrication,

1.

is easy and fast, and relatively cool. It can be used on all

5. Size of Metallographic Specimens

materials with hardnesses below approximately 35 HRC. It

does produce a rough surface containing extensive plastic flow

5.1 The specimens to be polished for metallographic exami-

that must be removed in subsequent preparation.

nation are generally not more than about 12 to 25 mm (0.5 to

6.1.2 An abrasive cut-off wheel will produce a smooth

1.0 in.) square, or approximately 12 to 25 mm in diameter if the

surface often ready for fine grinding. This method of sectioning

material is round. The height of the specimen should be no

is normally faster than sawing. The choice of cut-off wheel,

greater than necessary for convenient handling during polish-

lubricant, cooling conditions, and the grade and hardness of

ing.

metal being cut will influence the quality of the cut. A poor

5.2 It is not always possible to secure specimens having the

choice of cutting conditions can easily overheat the specimen,

dimensions given in 5.1, when the material to be examined is

producing an alteration of the microstructure. As a general rule,

smaller than the ideal dimensions. For example, in the polish-

soft materials are cut with a hard bond wheel and hard

ing of wire, strip, and other small articles, it is necessary to

materials with a soft bond wheel. Aluminum oxide abrasive

mount the specimens because of their size and shape.

wheels are preferred for ferrous metals and silicon carbide

5.2.1 Larger samples may be mounted or not, as the

wheels are preferred for nonferrous alloys. Abrasive cut-off

available equipment dictates. However, the larger the speci-

wheels are essential for sectioning metals with hardnesses

men, the more difficult it is to prepare, especially by manual

above about 35 HRC. Extremely hard metallic materials and

methods.

ceramics may be more effectively cut using diamond-

5.2.2 Specimens that are too small to be handled readily

impregnated cutting wheels. Manufacturer’s instructions

during polishing should be mounted to ensure a surface

should be followed as to the choice of wheel and speeds.

satisfactory for microscopical study. There are, based on

6.1.3 Flame cutting completely alters the structure of the

technique used, three fundamental methods of mounting speci-

metal at the flame cut edge. If flame cutting is necessary to

mens (see Sections 7-9).

remove the specimen, it should be cut sufficiently large so that

6. Cutting of Metallographic Specimens

it can be recut to the proper size by some other method that will

6.1 In cutting the metallographic specimen from the main not substantially alter the structure. Exercise care to ensure that

E3

the region of interest is not altered by the heat of the cutting layer of phenolic or epoxy resin before being placed in the

flame. clamp in order to minimize the absorption of polishing

6.2 Other methods of sectioning are permitted provided they materials or etchants.

do not alter the microstructure at the plane of polishing. All

8.3.6 The clamp material should be similar in composition

cutting operations produce some depth of damage, which will

to the specimen to avoid galvanic effects that would inhibit

have to be removed in subsequent preparation steps.

etching. The specimen will not etch if the clamp material is

more readily attacked by the etchant.

7. Cleanliness

8.3.7 The clamp should preferably be of similar hardness as

7.1 Cleanliness (see Appendix X1.) during specimen prepa-

the specimens to minimize the rounding of the edges of the

ration is essential. All greases and oils on the specimen should

specimens during grinding and polishing.

be removed by some suitable organic solvent. Failure to clean

8.3.8 Exercise care in clamping the specimen. Excessive

thoroughly can prevent cold mounting castable resins from

clamping pressure may damage soft specimens; however, good

adhering to the specimen surface. Ultrasonic cleaning is

sealing is required to prevent absorption of polishing materials

particularly effective in removing the last traces of residues on

or etchants.

a specimen surface.

8.4 Plastic Mounting:

7.2 Any coating metal that will interfere with the subse-

8.4.1 Specimens may be embedded in plastic to protect

quent etching of the base metal should be removed before

them from damage and to provide a uniform format for both

polishing, if possible. If etching is required, when studying the

manual and automatic preparation. This is the most common

underlying steel in a galvanized specimen, the zinc coating

method for mounting metallographic specimens. Mounting

should be removed before mounting to prevent galvanic

plastics may be divided into two classes—compression mount-

effects. The coating can be removed by digestion in cold nitric

ing and castable.

acid (HNO , sp gr 1.42), in dilute sulfuric acid (H SO )orin

3 2 4

8.4.2 When mounting specimens in plastic, exercise care in

dilute hydrochloric acid (HCl). The HNO method requires

order to avoid rounding of specimen edges during the grinding

care to prevent overheating, since large samples will generate

operation. There are several methods available that prevent

considerable heat. By placing the cleaning container in cold

rounding. The specimens may be surrounded by hard shot,

water during the stripping of the zinc, attack on the underlying

small rivets, rings, etc., of approximately the same hardness or,

steel will be minimized.

when using casting resin, a slurry of resin and alumina may be

7.3 Oxidized or corroded surfaces may be cleaned as

poured around the specimen to prevent rounding. The speci-

described in Appendix X1.

mens may also be plated before mounting (see Section 9).

8.4.3 Compression Mounting—Thermosetting plastics re-

8. Mounting of Specimens

quire the use of a mounting press providing heat (up to

8.1 There are many instances where it will be advantageous

approximately 160°C) and pressure (up to approximately 30

to mount the specimens prior to grinding and polishing.

MPa). The finished mounts can be ejected hot but the best

Mounting of the specimen is usually performed on small,

results are obtained when the finished mount is cooled under

flimsy, or oddly shaped specimens, fractures, or in instances

pressure. There are three types of thermosetting compression

where the specimen edges are to be examined.

mounting plastics used predominantly in the metallographic

8.2 Specimens may be either mechanically mounted,

laboratory. Regardless of the resin used to compression mount

mounted in plastic, or a combination of the two can be used to

specimens, the best results are obtained when (1) the speci-

provide optimum results.

mens are clean and dry, and (2) the cured mount is cooled

8.3 Mechanical Mounting:

under full pressure to below 30°C before ejection from the

8.3.1 Strip and sheet specimens are frequently mounted by

press.

binding or clamping several specimens into a pack held

8.4.3.1 Wood-filled bakelite resins cure in 5 to 10 min, are

together by two end pieces and two bolts. Clamp mounting

relatively inexpensive, can be obtained in several colors, and

generally affords a means of rapid mounting with very good

are opaque. These resins have a tendency to pull away from the

edge retention.

s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.