ASTM E930-18

(Test Method)Standard Test Methods for Estimating the Largest Grain Observed in a Metallographic Section (ALA Grain Size)

Standard Test Methods for Estimating the Largest Grain Observed in a Metallographic Section (ALA Grain Size)

SIGNIFICANCE AND USE

4.1 The presence of large grains has been correlated with anomalous mechanical behavior in, for example, crack initiation, crack propagation, and fatigue. Thus there is engineering justification for reporting the ALA grain size.

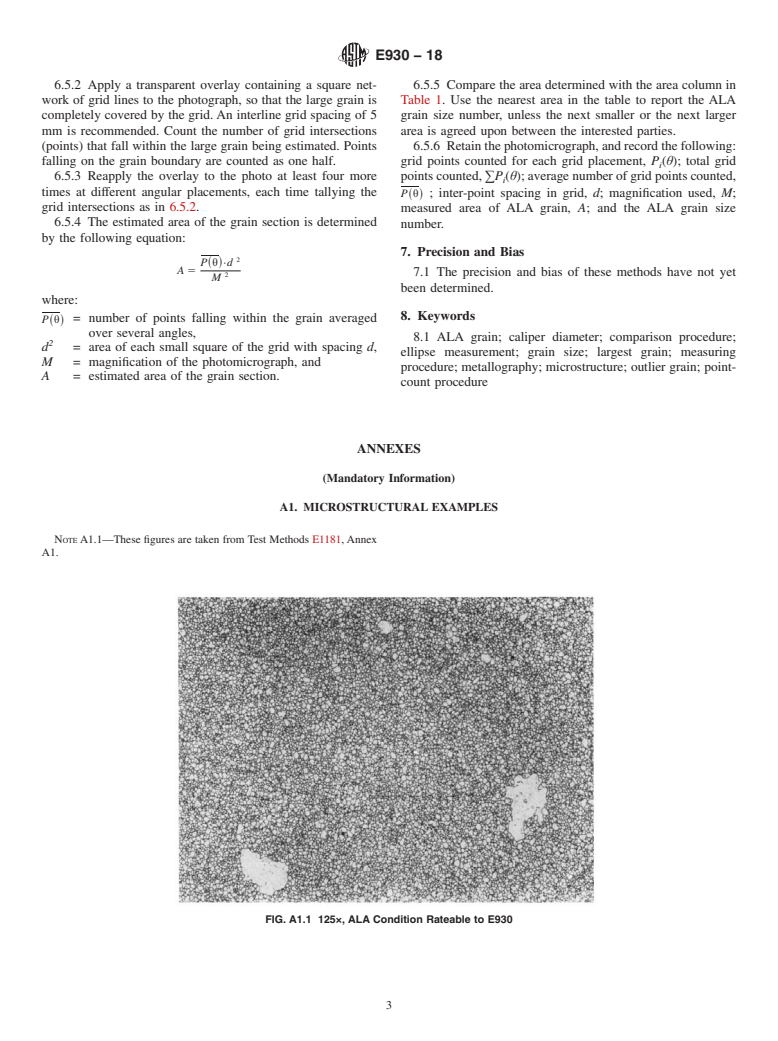

4.2 These methods shall only be used with the presence of outlier coarse grains, 3 or more ASTM grain size numbers larger than the rest of the microstructure and comprising 5 % or less of the specimen area. A typical example is shown in Annex A1 as Fig. A1.1.

4.3 These methods shall not be used for the determination of average grain size, which is treated in Test Methods E112. Examples of microstructures that do not qualify for ALA treatment are shown in Annex A1 as Fig. A1.2, Fig. A1.3, and Fig. A1.4.

4.4 These methods may be applied in the characterization of duplex grain sizes, as instructed in the procedures for Test Methods E1181.

SCOPE

1.1 These test methods describe simple manual procedures for measuring the size of the largest grain cross-section observed on a metallographically prepared plane section.

1.2 These test methods shall only be valid for microstructures containing outlier coarse grains, where their population is too sparse for grain size determination by Test Methods E112.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E930 − 18

Standard Test Methods for

Estimating the Largest Grain Observed in a Metallographic

1

Section (ALA Grain Size)

This standard is issued under the fixed designation E930; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

Commercial material specifications sometimes include, in size limits for grain structures, the need

for identification of the largest grain observed in a sample, often expressed asALA(as large as) grain

size. The methods presented here are for use when the number of large grains is too few for

measurement by Test Methods E112. It shall be understood that larger (but unobserved) grains may

exist in the local volume sampled.

1. Scope E112 Test Methods for Determining Average Grain Size

E407 Practice for Microetching Metals and Alloys

1.1 These test methods describe simple manual procedures

E1181 Test Methods for Characterizing Duplex Grain Sizes

for measuring the size of the largest grain cross-section

observed on a metallographically prepared plane section. 2.2 ASTM Adjuncts:

ALAGrain SizeVisualAid for Comparison Procedure (One

1.2 These test methods shall only be valid for microstruc-

3

Opaque Print and One Transparency)

tures containing outlier coarse grains, where their population is

too sparse for grain size determination by Test Methods E112.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 For definitions of terms used in these test methods, see

responsibility of the user of this standard to establish appro-

Terminology E7.

priate safety, health, and environmental practices and deter-

3.2 Definitions:

mine the applicability of regulatory limitations prior to use.

3.2.1 ALA grain, n—the largest grain observed in a random

1.4 This international standard was developed in accor-

scatterofindividualcoarsegrainscomprising5 %orlessofthe

dance with internationally recognized principles on standard-

specimen area, where the apparent grain size of the coarse

ization established in the Decision on Principles for the

grain(s) differs by 3 or more ASTM grain size numbers from

Development of International Standards, Guides and Recom-

the balance of the microstructure.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 3.2.2 outlier grain, n—a grain substantially different in size

from the predominant grain size in a microstructure; for

2. Referenced Documents

example, an ALA grain.

2

2.1 ASTM Standards:

4. Significance and Use

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

4.1 The presence of large grains has been correlated with

anomalous mechanical behavior in, for example, crack

initiation, crack propagation, and fatigue. Thus there is engi-

1

This test method is under the jurisdiction of ASTM Committee E04 on

neering justification for reporting the ALA grain size.

Metallographyand is the direct responsibility of Subcommittee E04.08 on Grain

Size.

4.2 These methods shall only be used with the presence of

Current edition approved Dec. 1, 2018. Published February 2019. Originally

outlier coarse grains, 3 or more ASTM grain size numbers

approvedin1983.Lastpreviouseditionapprovedin2015asE930 – 99(2015).DOI:

10.1520/E0930-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJE0930.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E930 − 18

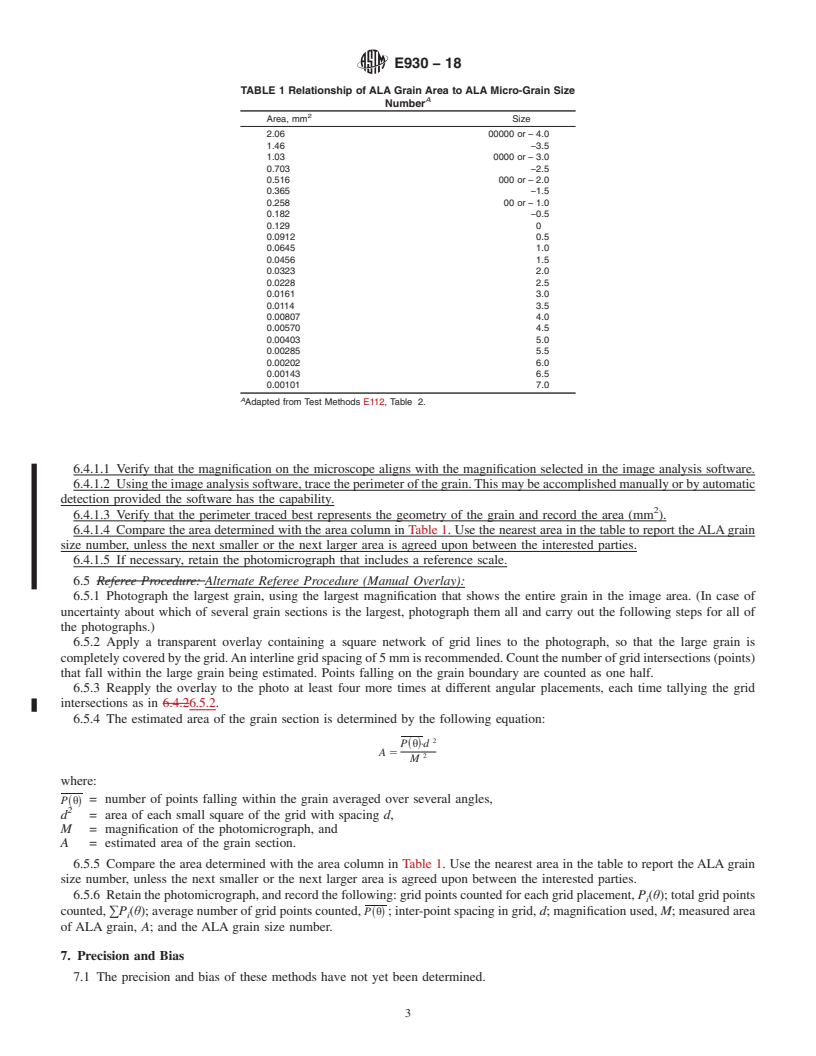

TABLE 1 Relationship of ALA Grain Area to ALA Micro-Grain Size

largerthantherestofthemicrostructureandcomprising5 %or

A

Number

lessofthespecimenarea.AtypicalexampleisshowninAnnex

2

Area, mm Size

A1 as Fig. A1.1.

2.06 00000 or − 4.0

4.3 Thesemethodsshallnotbeusedforthedeterminationof

1.46 −3.5

1.03 0000 or − 3.0

average grain size, which is treated in Test Methods E112.

0.703 −2.5

Examples of microstructures that do not qualify for ALA

0.516 000 or − 2.0

treatment are shown in Annex A1 as Fig. A1.2, Fig. A1.3, and

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E930 − 99 (Reapproved 2015) E930 − 18

Standard Test Methods for

Estimating the Largest Grain Observed in a Metallographic

1

Section (ALA Grain Size)

This standard is issued under the fixed designation E930; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

INTRODUCTION

Commercial material specifications sometimes include, in size limits for grain structures, the need

for identification of the largest grain observed in a sample, often expressed as ALA (as large as) grain

size. The methods presented here are for use when the number of large grains is too few for

measurement by Test Methods E112. It shall be understood that larger (but unobserved) grains may

exist in the local volume sampled.

1. Scope

1.1 These test methods describe simple manual procedures for measuring the size of the largest grain cross-section observed

on a metallographically prepared plane section.

1.2 These test methods shall only be valid for microstructures containing outlier coarse grains, where their population is too

sparse for grain size determination by Test Methods E112.

1.3 This standard does not purport to address all of the safety problems,concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and

determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

E112 Test Methods for Determining Average Grain Size

E407 Practice for Microetching Metals and Alloys

E1181 Test Methods for Characterizing Duplex Grain Sizes

2.2 ASTM Adjuncts:

3

ALA Grain Size Visual Aid for Comparison Procedure (One Opaque Print and One Transparency)

3. Terminology

3.1 Definitions:

3.1.1 All For definitions of terms used in these test methods are either defined in methods, see Terminology E7, or are discussed

in 3.2.

3.2 Definitions of Terms Specific to This Standard:Definitions:

1

This test method is under the jurisdiction of ASTM Committee E04 on Metallographyand is the direct responsibility of Subcommittee E04.08 on Grain Size.

Current edition approved Oct. 1, 2015Dec. 1, 2018. Published November 2015February 2019. Originally approved in 1983. Last previous edition approved in 20072015

as E930 – 99(2007).(2015). DOI: 10.1520/E0930-99R15.10.1520/E0930-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from ASTM International Headquarters. Order Adjunct No. ADJE0930.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E930 − 18

3.2.1 ALA grain, n—the largest grain observed in a random scatter of individual coarse grains comprising 5 % or less of the

specimen area, where the apparent grain size of thesethe coarse grainsgrain(s) differs by 3 or more ASTM grain size numbers from

the balance of the microstructure.

3.2.2 outlier grain, n—a grain substantially different in size from the predominant grain size in a microstructure; for example,

an ALA grain.

4. Significance and Use

4.1 The presence of large grains has been correlated with anomalous mechanical behavior in, for example, crack initiation, crack

propagation, and fatigue. Thus there is engineering justification for reporting the ALA grain size.

4.2 These methods shall only be used with the presence of outlier coarse grains, 3 or more ASTM grain size numbers larger

than the rest of the microstructure and comprising 5 % or less of the specimen area. A typical example is shown in Annex A1 as

Fig. A1.1.

4.3 These methods sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.