ASTM D5744-96

(Test Method)Standard Test Method for Accelerated Weathering of Solid Materials Using a Modified Humidity Cell

Standard Test Method for Accelerated Weathering of Solid Materials Using a Modified Humidity Cell

SCOPE

1.1 This test method covers a procedure that accelerates the natural weathering rate of a solid material sample so that diagnostic weathering products can be produced, collected, and quantified. Soluble weathering products are mobilized by a fixed-volume aqueous leach that is performed, collected, and analyzed weekly. When conducted in accordance with the following protocol, this laboratory test method has accelerated metal-mine waste-rock weathering rates by at least an order of magnitude greater than observed field rates (1).

1.1.1 This test method is intended for use to meet kinetic testing regulatory requirements for mining waste and ores.

1.2 This test method is a modification of an accelerated weathering test method developed originally for mining wastes (2-4). However, it may have useful application wherever gaseous oxidation coupled with aqueous leaching are important mechanisms for contaminant mobility.

1.3 This test method calls for the weekly leaching of a 1000-g solid material sample, with water of a specified purity, and the collection and chemical characterization of the resulting leachate over a minimum period of 20 weeks.

1.4 As described, this test method may not be suitable for some materials containing plastics, polymers, or refined metals. These materials may be resistant to traditional particle size reduction methods.

1.5 Additionally, this test method has not been tested for applicability to organic substances and volatile matter.

1.6 This test method is not intended to provide leachates that are identical to the actual leachate produced from a solid material in the field or to produce leachates to be used as the sole basis of engineering design.

1.7 This test method is not intended to simulate site-specific leaching conditions. It has not been demonstrated to simulate actual disposal site leaching conditions.

1.8 This test method is intended to describe the procedure for performing the accelerated weathering of solid materials to generate leachates. It does not describe all types of sampling and analytical requirements that may be associated with its application.

1.9 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5744 – 96

Standard Test Method for

Accelerated Weathering of Solid Materials Using a Modified

Humidity Cell

This standard is issued under the fixed designation D 5744; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope and analytical requirements that may be associated with its

application.

1.1 This test method covers a procedure that accelerates the

1.9 The values stated in SI units are to be regarded as the

natural weathering rate of a solid material sample so that

standard. The values given in parentheses are for information

diagnostic weathering products can be produced, collected, and

only.

quantified. Soluble weathering products are mobilized by a

1.10 This standard does not purport to address all of the

fixed-volume aqueous leach that is performed, collected, and

safety concerns, if any, associated with its use. It is the

analyzed weekly. When conducted in accordance with the

responsibility of the user of this standard to establish appro-

following protocol, this laboratory test method has accelerated

priate safety and health practices and determine the applica-

metal-mine waste-rock weathering rates by at least an order of

2 bility of regulatory limitations prior to use.

magnitude greater than observed field rates (1).

1.1.1 This test method is intended for use to meet kinetic

2. Referenced Documents

testing regulatory requirements for mining waste and ores.

2.1 ASTM Standards:

1.2 This test method is a modification of an accelerated

D 75 Practices for Sampling Aggregates

weathering test method developed originally for mining wastes

D 276 Test Methods for Identification of Fibers in Textiles

(2-4). However, it may have useful application wherever

D 420 Guide to Site Characterization for Engineering, De-

gaseous oxidation coupled with aqueous leaching are important

sign and Construction Purposes

mechanisms for contaminant mobility.

D 653 Terminology Relating to Soil, Rock, and Contained

1.3 This test method calls for the weekly leaching of a

Fluids

1000-g solid material sample, with water of a specified purity,

D 737 Test Method for Air Permeability of Textile Fabrics

and the collection and chemical characterization of the result-

D 1067 Test Methods for Acidity or Alkalinity of Water

ing leachate over a minimum period of 20 weeks.

D 1125 Test Methods for Electrical Conductivity and Re-

1.4 As described, this test method may not be suitable for

sistivity of Water

some materials containing plastics, polymers, or refined met-

D 1193 Specification for Reagent Water

als. These materials may be resistant to traditional particle size

D 1293 Test Methods for pH of Water

reduction methods.

D 1498 Practice for Oxidation-Reduction Potential of Wa-

1.5 Additionally, this test method has not been tested for

ter

applicability to organic substances and volatile matter.

D 2234 Test Methods for Collection of a Gross Sample of

1.6 This test method is not intended to provide leachates

Coal

that are identical to the actual leachate produced from a solid

D 3370 Practices for Sampling Water

material in the field or to produce leachates to be used as the

E 276 Test Method for Particle Size or Screen Analysis at

sole basis of engineering design.

No. 4 (4.75-mm) Sieve and Finer for Metal-Bearing Ores

1.7 This test method is not intended to simulate site-specific

and Related Materials

leaching conditions. It has not been demonstrated to simulate

E 877 Practice for Sampling and Sample Preparation of Iron

actual disposal site leaching conditions.

Ores and Related Materials

1.8 This test method is intended to describe the procedure

for performing the accelerated weathering of solid materials to

generate leachates. It does not describe all types of sampling

Annual Book of ASTM Standards, Vol 04.03.

Annual Book of ASTM Standards, Vol 07.01.

1 5

This test method is under the jurisdiction of ASTM Committee D-34 on Waste Annual Book of ASTM Standards, Vol 04.08.

Management and is the direct responsibility of Subcommittee D34.02 on Physical Discontinued; see 1994 Annual Book of ASTM Standards, Vol 07.01.

and Chemical Characterization. Annual Book of ASTM Standards, Vol 11.01.

Current edition approved March 10, 1996. Published May 1996. Annual Book of ASTM Standards , Vol 05.05.

2 9

The boldface numbers in parentheses refer to the list of references at the end of Annual Book of ASTM Standards, Vol 03.05.

this standard. Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 5744

3. Terminology humidity) pumped up through the sample, followed by a leach

with water on Day 7. A test duration of 20 weeks is recom-

3.1 Definitions:

mended (3, 4).

3.1.1 acid producing potential (AP), n—the potential for a

solid material sample to produce acidic effluent, based on the

5. Significance and Use

percent of sulfide contained in that sample as iron-sulfide

5.1 The purpose of this accelerated weathering procedure is

mineral (for example, pyrite or pyrrhotite) (3). The AP is

to determine the following: (1) whether a solid material will

commonly converted to the amount of calcium carbonate

produce an acidic, alkaline, or neutral effluent, (2) whether that

required to neutralize the resulting amount of acidic effluent

effluent will contain diagnostic cations (including trace metals)

produced by the oxidation of contained iron sulfide minerals; it

and anions that represent solubilized weathering products

is expressed as the equivalent tons of calcium carbonate per

formed during a specified period of time, and (3) the rate at

1000 tons of solid material (4). The AP is therefore calculated

which these diagnostic cations and anions will be released

by multiplying the percent of sulfide contained in the material

(from the solids in the effluent) under the closely controlled

by a stoichiometric factor of 31.25 (5).

conditions of the test.

3.1.2 interstitial water, n—the residual water remaining in

NOTE 1—Examples of products that can be produced from the test

the sample pore spaces at the completion of the fixed-volume

include the following: (1) weekly effluent acidity and alkalinity deter-

weekly leach.

mined by titration and (2) weekly aqueous concentrations of cations and

3.1.3 leach, n—a weekly addition of water to solid material

anions converted to their respective release rates (for example, the average

that is performed either dropwise or by flooding for a specified

release of μg sulfate ion/g of solid material sample/week, over a 20-week

time period.

period). In acid drainage studies, for example, the average weekly rates of

3.1.4 loading, n—the product of the weekly concentration

acid production (measured as μg/g/wk of sulfate released) determined

from accelerated weathering tests of mine waste samples are compared

for a constituent of interest and the weight of solution collected

with the AP present in each sample. The number of years of acidic effluent

that may be interpreted for water quality impacts.

expected to be produced under laboratory accelerated weathering condi-

3.1.5 mill tailings, n—finely ground mine waste (commonly

tions can then be estimated from this comparison. The years of accelerated

passing a 150-μm (100 mesh screen) resulting from the mill

weathering required to deplete a mine waste sample’s NP are calculated

processing of ore.

similarly by determining the average weekly calcium and magnesium

3.1.6 neutralizing potential (NP), n—the potential for a

release rates and dividing the sample’s NP by the sum of those rates (7).

solid material sample to neutralize acidic effluent produced

5.2 The principle of the accelerated weathering test method

from the oxidation of iron-sulfide minerals, based on the

is to promote more rapid oxidation of solid material constitu-

amount of carbonate present in the sample. The NP is also

ents than can be accomplished in nature and maximize the

presented in terms of tons of calcium carbonate equivalent per

loadings of weathering reaction products contained in the

1000 tons of solid material (4). It is calculated by digesting the

resulting weekly effluent. This is accomplished by controlling

solid material with an excess of standardized acid and back-

the exposure of the solid material sample to such environmen-

titrating with a standardized base to measure and convert the

tal parameters as temperature, volume, and application rate of

acid consumption to calcium carbonate equivalents (3, 6).

water and oxygen. Specifically, an excess amount of air

3.1.6.1 Discussion—The AP and NP are specifically appli-

pumped up through the sample during the dry- and wet-air

cable to the determination of AP from mining wastes com-

portions of the weekly cycle ensures that oxidation reactions

prised of iron-sulfide and carbonate minerals. These terms may

are not limited by low oxygen concentrations. Weekly leaches

be applicable to any solid material containing iron-sulfide and

with low ionic strength water ensure the removal of leachable

carbonate minerals.

oxidation products produced from the previous week’s weath-

3.1.7 run-of-mine, adj—usage in this test method refers to

ering cycle. The purpose of the three-day dry-air portion of the

ore and waste rock produced by excavation (with attendant

weekly cycle is to evaporate water that remains in the pores of

variable particle sizes) from open pit or underground mining

the sample after the weekly leach. Evaporation increases pore

operations.

water cation/anion concentrations and may also cause in-

3.1.8 waste rock, n—rock produced by excavation from

creased acidity (for example, by increasing the concentration

open pit or underground mining operations whose economic

of hydrogen ion generated from previously oxidized iron

mineral content is less than a specified economic cutoff value.

sulfide). Increased acid generation will accelerate the dissolu-

tion of additional sample constituents. Precipitation occurs as

4. Summary of Test Method

evaporation continues, and the remaining water becomes

4.1 This accelerated weathering test method is designed to over-saturated. Some of these precipitated salts are potential

increase the geological-chemical-weathering rate for selected

sources of acidity when re-solubilized (for example, melanter-

1000-g solid material samples and produce a weekly effluent ite, FeSO ·7H O; and jarosite, K Fe (OH) (SO ) ). During

4 2 2 6 12 4 4

that can be characterized for solubilized weathering products. the dry-air portion of the cycle, the oxygen diffusion rate

This test method is performed on each sample in a cylindrical through the sample may increase several orders of magnitude

cell. Multiple cells can be arranged in parallel; this configura- as compared to its diffusion rate under more saturated condi-

tion permits the simultaneous testing of different solid material tions of the leach. This increase in the diffusion rate under

samples. The test procedure calls for weekly cycles comprised near-dryness conditions helps to accelerate the abiotic oxida-

of three days of dry air (less than 10 % relative humidity) and tion of such constituents as iron sulfide. The wet (saturated)-air

three days of water-saturated air (approximately 95 % relative portion of the weekly cycle enhances the bacteria-catalyzed

D 5744

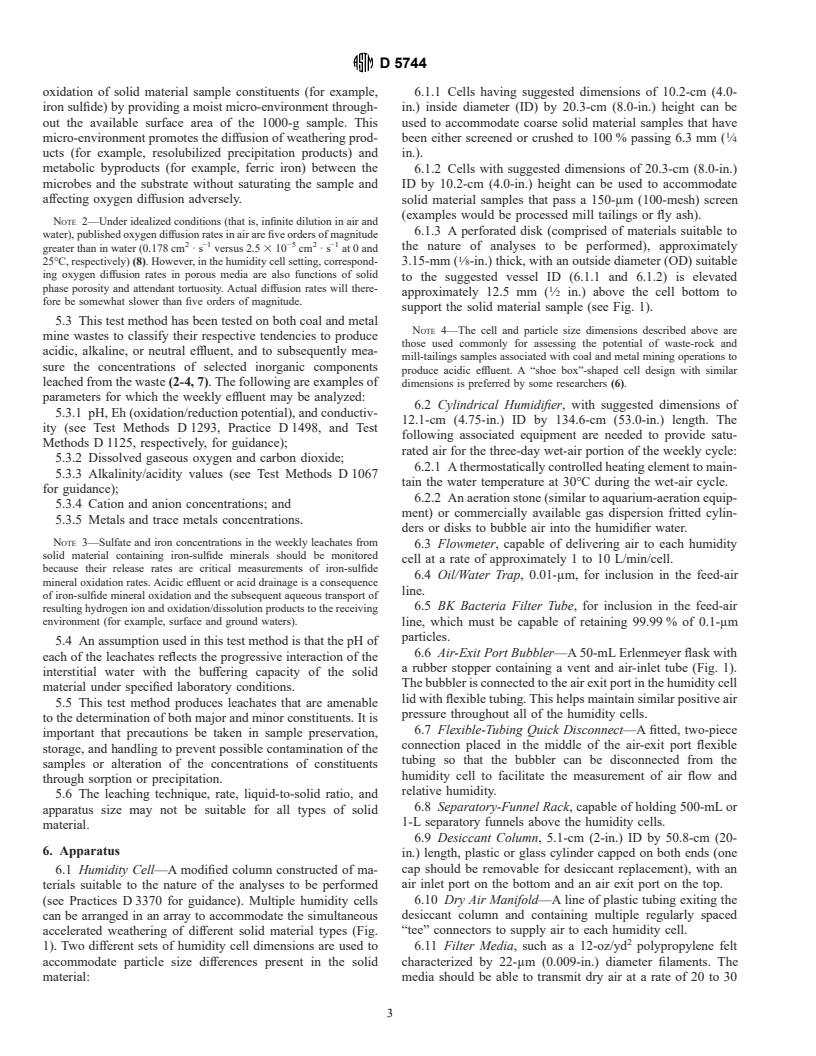

oxidation of solid material sample constituents (for example, 6.1.1 Cells having suggested dimensions of 10.2-cm (4.0-

iron sulfide) by providing a moist micro-environment through- in.) inside diameter (ID) by 20.3-cm (8.0-in.) height can be

out the available surface area of the 1000-g sample. This used to accommodate coarse solid material samples that have

micro-environment promotes the diffusion of weathering prod- been either screened or crushed to 100 % passing 6.3 mm ( ⁄4

ucts (for example, resolubilized precipitation products) and in.).

metabolic byproducts (for example, ferric iron) between the 6.1.2 Cells with suggested dimensions of 20.3-cm (8.0-in.)

microbes and the substrate without saturating the sample and

ID by 10.2-cm (4.0-in.) height can be used to accommodate

affecting oxygen diffusion adversely. solid material samples that pass a 150-μm (100-mesh) screen

(examples would be processed mill tailings or fly ash).

NOTE 2—Under idealized conditions (that is, infinite dilution in air and

6.1.3 A perforated disk (comprised of materials suitable to

water), published oxygen diffusion rates in air are five orders of magnitude

2 −1 −5 2 −1

the nature of analyses to be performed), approximately

greater than in water (0.178 cm ·s versus 2.5 3 10 cm ·s at 0 and

25°C, respectively) (8). However, in the humidity cell setting, correspond- 3.15-mm ( ⁄8-in.) thick, with an outside diameter (OD) suitable

ing oxygen diffusion rates in porous media are also functions of solid

to the suggested vessel ID (6.1.1 and 6.1.2) is elevated

phase porosity and attendant tortuosity. Actual diffusion rates will there-

approximately 12.5 mm ( ⁄2 in.) above the cell bottom to

fore be somewhat slower than five orders of magnitude.

support the solid material sample (see Fig. 1).

5.3 This test method has been tested on both coal and metal

NOTE 4—The cell and particle size dimensions described above are

mine wastes to classify their respective tendencies to produce

those used commonly for assessing the potential of waste-rock and

acidic, alkaline, or neutral effluent, and to subsequently mea-

mill-tailings samples associated with coal and metal mining operations to

sure the concentrations of selected inorganic components

produce acidic effluent. A “shoe box”-shaped cell design with similar

leached from the waste (2-4, 7). The following are examples of

dimensions is preferred by some researchers (6).

parameters for which the weekly effluent may be analyzed:

6.2 Cylindrical Humidifier, with suggested dimensions of

5.3.1 pH, Eh (oxidation/reduction potential), and conductiv-

12.1-cm (4.75-in.) ID by 134.6-cm (53.0-in.) length. The

ity (see Test Methods D 1293, Practice D 1498, and Test

following associated equipment are needed to provide satu-

Methods D 1125, respectively, for guidance);

rated air for the three-day wet-air portion of the weekly cycle:

5.3.2 Dissolved gaseous oxygen and carbon dioxide;

6.2.1 A thermostatically controlled heating element to main-

5.3.3 Alkalinity/acidity values (see Test Methods D 1067

tain the water temperature at 30°C during the wet-air cycle.

for guidance);

6.2.2 An aeration stone (similar to aquar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.