ASTM B891/B891M-19

(Specification)Standard Specification for Seamless and Welded Titanium and Titanium Alloy Condenser and Heat Exchanger Tubes with Enhanced Surface for Improved Heat Transfer

Standard Specification for Seamless and Welded Titanium and Titanium Alloy Condenser and Heat Exchanger Tubes with Enhanced Surface for Improved Heat Transfer

ABSTRACT

This specification covers seamless and welded titanium and titanium alloy tubing on which the external or internal surface, or both, has been modified by a cold forming process to produce an integral enhanced surface for improved heat transfer. The tubes are used in surface condensers, evaporators, heat exchangers and similar heat transfer apparatus in unfinned end diameters of a specific size. Tubes shall be furnished with unenhanced ends in the annealed condition and shall be suitable for rolling-in operations. Each tube shall be subject to a nondestructive eddy current test, and either a pneumatic or hydrostatic test.

SCOPE

1.1 This specification covers seamless and welded titanium and titanium alloy tubing on which at least part of the external or internal surface has been enhanced by cold forming for improved heat transfer. The tubes are used in surface condensers, evaporators, heat exchangers, coils, and similar heat transfer apparatus in diameters up to and including 1 in. [25.4 mm]. The base tube wall thickness is typically at least 0.049 in. [1.245 mm] average, but lighter gauge may be negotiated with the manufacturer.

1.2 Tubing purchased to this specification will typically be inserted through close-fitting holes in tubesheets, baffles, or support plates spaced along the tube length such as defined in the Tubular Exchanger Manufacturer’s Association (TEMA) Standard.2 The tube ends will also be expanded, and may then be welded. Tube may also be bent to form U-tubes or be coiled or otherwise formed, although tight radii may require unenhanced length for the bends.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the order. Combining values from the two systems may result in non-conformance. Within the text, the SI units are shown in brackets. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

1.4 The following precautionary statement pertains to the test method portion only: Section 8, 9, 10 and S1 of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B891/B891M −19

Standard Specification for

Seamless and Welded Titanium and Titanium Alloy

Condenser and Heat Exchanger Tubes with Enhanced

1

Surface for Improved Heat Transfer

This standard is issued under the fixed designation B891/B891M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 This specification covers seamless and welded titanium

1.5 This international standard was developed in accor-

and titanium alloy tubing on which at least part of the external

dance with internationally recognized principles on standard-

or internal surface has been enhanced by cold forming for

ization established in the Decision on Principles for the

improved heat transfer. The tubes are used in surface

Development of International Standards, Guides and Recom-

condensers, evaporators, heat exchangers, coils, and similar

mendations issued by the World Trade Organization Technical

heat transfer apparatus in diameters up to and including 1 in.

Barriers to Trade (TBT) Committee.

[25.4 mm]. The base tube wall thickness is typically at least

0.049 in. [1.245mm] average, but lighter gauge may be

2. Referenced Documents

negotiated with the manufacturer.

3

2.1 ASTM Standards:

1.2 Tubing purchased to this specification will typically be

A1047/A1047MTestMethodforPneumaticLeakTestingof

inserted through close-fitting holes in tubesheets, baffles, or

Tubing

support plates spaced along the tube length such as defined in

B338Specification for Seamless and Welded Titanium and

the Tubular Exchanger Manufacturer’s Association (TEMA)

TitaniumAlloy Tubes for Condensers and Heat Exchang-

2

Standard. The tube ends will also be expanded, and may then

ers

bewelded.TubemayalsobebenttoformU-tubesorbecoiled

E426PracticeforElectromagnetic(EddyCurrent)Examina-

or otherwise formed, although tight radii may require unen-

tion of Seamless and Welded Tubular Products, Titanium,

hanced length for the bends.

Austenitic Stainless Steel and Similar Alloys

E1316Terminology for Nondestructive Examinations

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3. Terminology

each system may not be exact equivalents; therefore, each

system shall be used independently of the order. Combining

3.1 Definitions of Terms Specific to This Standard:

values from the two systems may result in non-conformance.

3.1.1 base tube, n—theseamlessorweldedtubeconforming

Within the text, the SI units are shown in brackets. The

to Specification B338 prior to enhancing.

inch-poundunitsshallapplyunlessthe“M”designationofthis

3.1.2 finished tube, n—the tube following enhancement and

specification is specified in the order.

any heat treatment, forming, or other processing specified.

1.4 The following precautionary statement pertains to the

3.1.3 enhanced tube or section, n—all or sections of tube

test method portion only: Section 8, 9, 10 and S1 of this

length that have been mechanically worked inside, outside, or

specification:This standard does not purport to address all of

both, to produce increased surface area for improved heat

the safety concerns, if any, associated with its use. It is the

transfer.

responsibility of the user of this standard to establish appro-

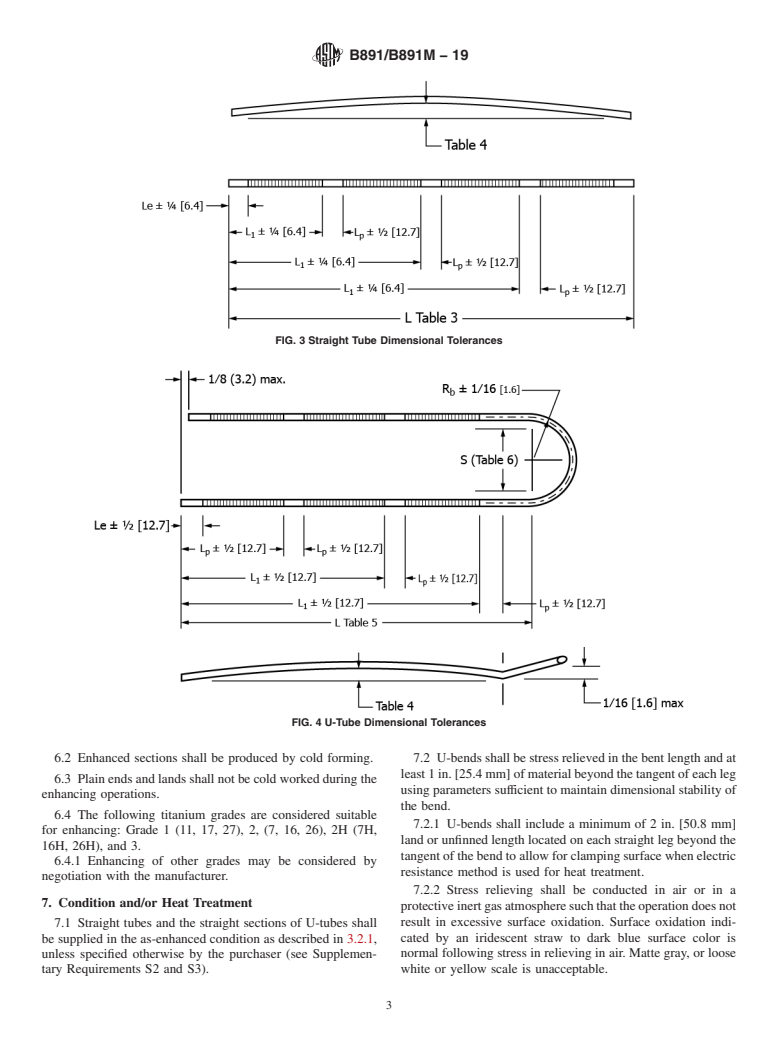

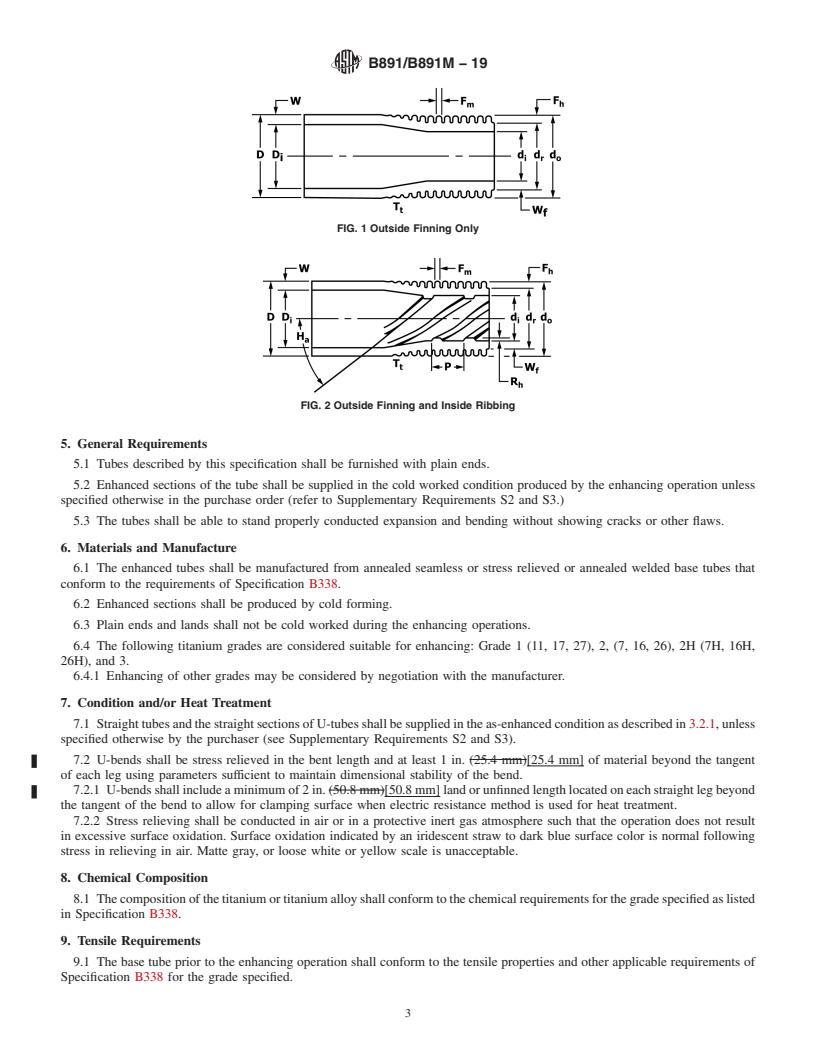

3.1.4 finned section, n—sections of tube exterior length that

have been mechanically worked to produce increased surface

area for improved heat transfer; see Table 1 for nomenclature

1

This specification is under the jurisdiction of ASTM Committee B10 on

of finning details.

Reactive and Refractory Metals and Alloys and is the direct responsibility of

Subcommittee B10.01 on Titanium.

Current edition approved April 1, 2019. Published May 2019. Originally

3

approved in 1998. Last previous edition approved in 2012 as B891–12. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/B0891_B0891M-19. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Available from Tubular Exchanger Manufacturers Association, Inc. 25 North Standards volume information, refer to the standard’s Document Summary page on

Broadway Tarrytown, NY 10591, www.tema.org. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 194

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B891 − 12 B891/B891M − 19

Standard Specification for

Seamless and Welded Titanium and Titanium Alloy

Condenser and Heat Exchanger Tubes with Enhanced

1

Surface for Improved Heat Transfer

This standard is issued under the fixed designation B891;B891/B891M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers seamless and welded titanium and titanium alloy tubing on which at least part of the external or

internal surface has been enhanced by cold forming for improved heat transfer. The tubes are used in surface condensers,

evaporators, heat exchangers, coils, and similar heat transfer apparatus in diameters up to and including 1 in. (25.4 mm).[25.4 mm].

The base tube wall thickness is typically at least 0.049 in. [1.245 mm] average, but lighter gauge may be negotiated with the

manufacturer.

1.2 Tubing purchased to this specification will typically be inserted through close-fitting holes in tubesheets, baffles, or support

2

plates spaced along the tube length such as defined in the Tubular Exchanger Manufacturer’s Association (TEMA) Standard. The

tube ends will also be expanded, and may then be welded. Tube may also be bent to form U-tubes or be coiled or otherwise formed,

although tight radii may require unenhanced length for the bends.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values given in

parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the order. Combining values

from the two systems may result in non-conformance. Within the text, the SI units are shown in brackets. The inch-pound units

shall apply unless the “M” designation of this specification is specified in the order.

1.4 The following precautionary statement pertains to the test method portion only: Section 8, 9, 10 and S1 of this

specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and

determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

A1047/A1047M Test Method for Pneumatic Leak Testing of Tubing

B338 Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers

E426 Practice for Electromagnetic (Eddy Current) Examination of Seamless and Welded Tubular Products, Titanium, Austenitic

Stainless Steel and Similar Alloys

E1316 Terminology for Nondestructive Examinations

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 base tube, n—the seamless or welded tube conforming to Specification B338 prior to enhancing.

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.01 on Titanium.

Current edition approved March 1, 2012April 1, 2019. Published March 2012May 2019. Originally approved in 1998. Last previous edition approved in 20042012 as

B891B891 – 12. – (2004). DOI: 10.1520/B0891-12.10.1520/B0891_B0891M-19.

2

Available from Tubular Exchanger Manufacturers Association, Inc. 25 North Broadway Tarrytown, NY 10591, www.tema.org.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B891/B891M − 19

3.1.2 finished tube, n—

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.