ASTM E2608-20

(Practice)Standard Practice for Equipment Control Matrix (ECM)

Standard Practice for Equipment Control Matrix (ECM)

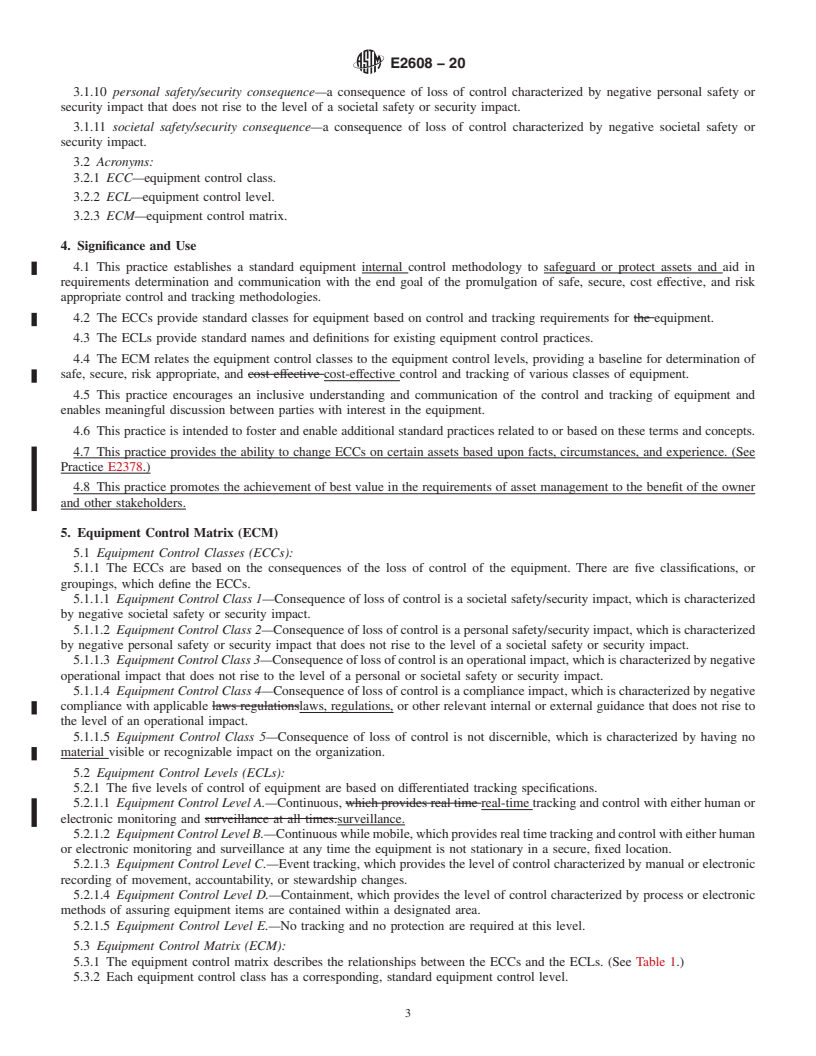

SIGNIFICANCE AND USE

4.1 This practice establishes a standard equipment internal control methodology to safeguard or protect assets and aid in requirements determination and communication with the end goal of the promulgation of safe, secure, cost effective, and risk appropriate control and tracking methodologies.

4.2 The ECCs provide standard classes for equipment based on control and tracking requirements for equipment.

4.3 The ECLs provide standard names and definitions for existing equipment control practices.

4.4 The ECM relates the equipment control classes to the equipment control levels, providing a baseline for determination of safe, secure, risk appropriate, and cost-effective control and tracking of various classes of equipment.

4.5 This practice encourages an inclusive understanding and communication of the control and tracking of equipment and enables meaningful discussion between parties with interest in the equipment.

4.6 This practice is intended to foster and enable additional standard practices related to or based on these terms and concepts.

4.7 This practice provides the ability to change ECCs on certain assets based upon facts, circumstances, and experience. (See Practice E2378.)

4.8 This practice promotes the achievement of best value in the requirements of asset management to the benefit of the owner and other stakeholders.

SCOPE

1.1 This practice describes equipment control classes (ECCs), equipment control levels (ECLs), and their relationships.

1.2 This practice is intended to be applicable and appropriate for all equipment-holding entities.

1.3 This practice covers property categorized as equipment. Equipment as defined in Terminology E2135 is non-expendable, tangible moveable property needed for the performance of a task or useful in effecting an obligation.

1.4 This practice can be applied to an individual item of equipment, to groupings of equipment, or to all or a subset of an entity's equipment.

1.5 In accordance with the provisions of Practice E2279, this practice enhances internal controls, and clarifies and enables effective and efficient control and tracking of equipment.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2608 − 20

Standard Practice for

1

Equipment Control Matrix (ECM)

This standard is issued under the fixed designation E2608; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E2279 Practice for Establishing the Guiding Principles of

Property Asset Management

1.1 This practice describes equipment control classes

E2378 Practice for the Recognition of Impaired or Retired

(ECCs), equipment control levels (ECLs), and their relation-

Property Assets

ships.

E2452 Practice for Equipment Management Process Matu-

1.2 This practice is intended to be applicable and appropri-

rity (EMPM) Model

ate for all equipment-holding entities.

E2495 Practice for Prioritizing Asset Resources in

1.3 This practice covers property categorized as equipment. Acquisition, Utilization, and Disposition

Equipment as defined in Terminology E2135 is non-

expendable, tangible moveable property needed for the perfor-

3. Terminology

mance of a task or useful in effecting an obligation.

3.1 Definitions—For definitions relating to property and

1.4 This practice can be applied to an individual item of

asset management, refer to Terminology E2135.

equipment, to groupings of equipment, or to all or a subset of

3.1.1 compliance impact—a consequence of loss of control

an entity’s equipment.

characterized by negative compliance with applicable laws,

regulations, or other relevant internal or external requirements

1.5 In accordance with the provisions of Practice E2279,

that does not rise to the level of an operational impact.

this practice enhances internal controls, and clarifies and

enables effective and efficient control and tracking of equip-

3.1.2 containment—the level of control characterized by

ment.

process or electronic methods of assuring equipment items are

1.6 This standard does not purport to address all of the

contained within a designated area.

safety concerns, if any, associated with its use. It is the

3.1.3 continuous control—real time tracking and control

responsibility of the user of this standard to establish appro-

with either human or electronic monitoring and surveillance.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.1.4 continuous control while mobile—real time tracking

1.7 This international standard was developed in accor-

and control with either human or electronic monitoring and

dance with internationally recognized principles on standard- surveillance at any time the equipment is not stationary in a

ization established in the Decision on Principles for the

secure, fixed location.

Development of International Standards, Guides and Recom-

3.1.5 equipment control classes (ECCs)—five classifications

mendations issued by the World Trade Organization Technical

or groupings of equipment based on the consequences of the

Barriers to Trade (TBT) Committee.

loss of control of the equipment.

2. Referenced Documents

3.1.6 equipment control levels (ECLs)—five levels of con-

2

2.1 ASTM Standards: trol of equipment based on differentiated tracking specifica-

tions.

E2135 Terminology for Property and Asset Management

3.1.7 equipment control matrix (ECM)—the relationships

1

This practice is under the jurisdiction of ASTM Committee E53 on Asset

between the ECCs and the ECLs.

Management and is the direct responsibility of Subcommittee E53.01 on Process

Management.

3.1.8 event tracking—the level of control characterized by

Current edition approved July 1, 2020. Published August 2020. Originally

manual or electronic recording of movement, accountability, or

approved in 2008. Last previous edition approved in 2014 as E2608–08 (2014).

stewardship changes.

DOI: 10.1520/E2608-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.9 operational impact—a consequence of loss of control

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

characterized by negative operational impact that does not rise

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. to the level of a personal or societal safety or security impact.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2608 − 20

3.1.10 personal safety/security consequence—a conse- negative operational impact that does not rise to the le

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2608 − 08 (Reapproved 2014) E2608 − 20

Standard Practice for

1

Equipment Control Matrix (ECM)

This standard is issued under the fixed designation E2608; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes equipment control classes (ECCs), equipment control levels (ECLs), and their relationships.

1.2 This practice is intended to be applicable and appropriate for all equipment-holding entities.

1.3 This practice covers property categorized as equipment. Equipment as defined in Terminology E2135 is non-expendable,

tangible moveable property needed for the performance of a task or useful in effecting an obligation.

1.4 This practice can be applied to an individual item of equipment, to groupings of equipment, or to all or a subset of an entity’s

equipment.

1.5 In accordance with the provisions of Practice E2279, this practice enhances internal controls, and clarifies and enables

effective and efficient control and tracking of equipment.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E2135 Terminology for Property and Asset Management

E2279 Practice for Establishing the Guiding Principles of Property Asset Management

E2378 Practice for the Recognition of Impaired or Retired Property Assets

E2452 Practice for Equipment Management Process Maturity (EMPM) Model

E2495 Practice for Prioritizing Asset Resources in Acquisition, Utilization, and Disposition

3. Terminology

3.1 Definitions—For definitions relating to property and asset management, refer to Terminology E2135.

3.1.1 compliance impact—a consequence of loss of control characterized by negative compliance with applicable laws,

regulations, or other relevant internal or external guidancerequirements that does not rise to the level of an operational impact.

3.1.2 containment—the level of control characterized by process or electronic methods of assuring equipment items are

contained within a designated area.

3.1.3 continuous control—real time tracking and control with either human or electronic monitoring and surveillance at all

times.surveillance.

3.1.4 continuous control while mobile—real time tracking and control with either human or electronic monitoring and

surveillance at any time the equipment is not stationary in a secure, fixed location.

3.1.5 equipment control classes (ECCs)—five classifications or groupings of equipment based on the consequences of the loss

of control of the equipment.

1

This practice is under the jurisdiction of ASTM Committee E53 on Asset Management and is the direct responsibility of Subcommittee E53.01 on Process Management.

Current edition approved June 1, 2014July 1, 2020. Published June 2014August 2020. Originally approved in 2008. Last previous edition approved in 20082014 as

E2608–08. –08 (2014). DOI: 10.1520/E2608-08R14.10.1520/E2608-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2608 − 20

3.1.6 equipment control levels (ECLs)—five levels of control of equipment based on differentiated tracking specifications.

3.1.7 equipment control matrix (ECM)—the relationships between the ECCs and the ECLs.

3.1.8 event tracking—the level of control characterized by manual or electronic recording of movement, accountability, or

stewardship changes.

3.1.9 operational impact—a consequence of loss of control characterized by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.