SIST EN 15095:2008+A1:2009

(Main)Power-operated mobile racking and shelving, carousels and storage lifts - Safety requirements

Power-operated mobile racking and shelving, carousels and storage lifts - Safety requirements

This European Standard provides terms and definitions on concepts and parameters used for EN 1005-21), prEN 1005-3, EN 1005-41) and EN 1005-51).

Basic concepts and general ergonomic principles for the design of machinery are dealt with in EN 292-1, EN 292-2 and EN 614-1.

This document is not applicable to specify the machinery which is manufactured before the date of publication of this document by CEN.

Kraftbetriebene verschiebbare Paletten- und Fachbodenregale, Umlaufregale und Lagerlifte - Sicherheitsanforderungen

1.1 Diese Europäische Norm behandelt die Sicherheitsanforderungen an die folgenden Arten von kraftbetriebenen Lagereinrichtungen:

Umlaufregale;

Lagerlifte;

verfahrbare Fachboden-, Paletten- und Kragarmregale

mit dem Ziel, die in Abschnitt 4 aufgeführten Gefährdungen zu eliminieren oder zu minimieren. Diese Gefährdungen können während der Montage, der Inbetriebnahme, des Betriebes, der Instandhaltung, der Prüfung und der Demontage der Einrichtung entstehen.

1.2 Wesentlich ist, dass die Sicherheitsanforderungen und/oder Maßnahmen dieser Norm auf Lagereinrich-tungen angewendet werden, die in geschlossenen Räumen betrieben werden. Beim Einsatz unter erschwerten Bedingungen kommt es darauf an, dass zusätzliche Gefährdungsanalysen und Sicherheits¬maßnahmen berücksichtigt werden, z. B. Bedingungen bei Betrieb im Freien, Kühlhausanwendungen, hohe Temperaturen, korrosive Umgebungen, starke magnetische Felder, Gefahr einer explosionsfähigen Atmosphäre, radioaktive Bedingungen, Lagergüter, die auf Grund ihrer Beschaffenheit gefährliche Situationen hervorrufen könnten (z. B. feuerflüssiges Metall, Säuren/Laugen, zerbrechliche Güter oder Sprengstoffe), Auswirkungen von Erdbeben und auch Kontakt mit Lebensmitteln.

1.3 Beispiele von kraftbetriebenen Lagereinrichtungen, für die diese Norm gilt, sind im Anhang A dargestellt.

1.4 Für Gebäude und Gebäudeteile gilt diese Norm nur insoweit, als eine Bewertung hinsichtlich Gefährdungen und Risiken im Zusammenhang mit Schnittstellen zu den Lagereinrichtungen erfolgt.

1.5 Vom Anwendungsbereich dieser Norm sind Lagereinrichtungen ausgenommen, deren einzige Kraft-quelle die unmittelbar angewandte menschliche Arbeitskraft oder die Schwerkraft ist.

1.6 Kraftbetriebene Lagereinrichtungen oder Teile davon fallen nicht unter die Vorschriften für Aufzüge. [....]

Élévateurs de stockage, carrousels et rayonnages à palette et à tablette, mobiles et motorisés - Prescriptions de sécurité

1.1 La présente Norme européenne traite des prescriptions techniques pour les types suivants d’équipements de

stockage à commande mécanique :

— carrousels de stockage ;

— élévateurs de stockage ;

— rayonnage mobile, rayonnage à palettes et rayonnage en porte-à-faux ;

dans le but de réduire à un minimum les phénomènes dangereux décrits dans l’Article 4. Ces phénomènes

dangereux peuvent survenir pendant l’installation, la mise en route, le fonctionnement, la maintenance, les essais et

le démontage de l’équipement.

1.2 Il est essentiel que les prescriptions et/ou mesures de sécurité prises dans la présente norme s’appliquent aux

équipements de stockage qui fonctionnent en intérieur. Dans des conditions difficiles, il est essentiel qu’une analyse

des risques supplémentaire et des mesures additionnelles de sécurité soit prises en compte, par exemple : conditions

extérieures, applications à basse température, hautes températures, environnement corrosif, champs magnétiques

forts, risque d’atmosphère explosive, conditions radioactives, marchandises de stockage qui par nature sont

susceptibles de créer des situations dangereuses (par exemple : métal fondu, acides/alcalis, marchandises fragiles

ou explosifs), effets sismiques et également contact avec la nourriture.

1.3 Des exemples d’équipements de stockage motorisés auxquels la présente norme s’applique sont illustrés

dans l’Annexe A.

Pomični regali, pomični paletni regali, vrtljive naprave in skladiščna dvigala z lastnim pogonom - Varnostne zahteve

General Information

- Status

- Published

- Publication Date

- 11-Jan-2009

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 08-Jan-2009

- Due Date

- 15-Mar-2009

- Completion Date

- 12-Jan-2009

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 01-Sep-2010

- Effective Date

- 18-Jan-2023

Overview

EN 15095:2007+A1:2008 is a CEN (European Committee for Standardization) type C European Standard that specifies safety requirements for power-operated storage equipment including mobile racking and shelving, carousels and storage lifts. It defines terms and concepts, identifies significant hazards, and sets out protective measures, verification procedures and information for the user. The standard applies primarily to indoor, power-operated storage systems used for handling and storing goods (not passenger lifts), and it includes Amendment A1 (2008).

Key Topics

- Scope and definitions: Clear terminology for carousels, storage lifts, mobile shelving, pallet/cantilever racking and related components.

- Hazard identification: Lists significant hazards including mechanical, electrical, ergonomic, power-supply failures, safety-system failures and electromagnetic influences.

- Safety requirements & protective measures: Design and engineering principles to eliminate or reduce risks during installation, operation, maintenance, testing and dismantling.

- Verification and testing: Conformity checks in design/manufacture, on-site installation checks before power-up, and commissioning tests.

- User information: Requirements for instruction handbooks, marking and maintenance information to support safe use.

- Annexes & technical guidance: Illustrative examples (types of equipment), rail tolerances, rack-and-pinion guidance, chains for carousels, and relationship to EU Machinery Directives.

Practical applications

EN 15095 is used to ensure safe design, manufacture, installation and operation of automated storage equipment in warehouses, distribution centres, manufacturing plants and archival storage. Typical practical uses:

- Guiding manufacturers and system integrators in risk reduction for power-operated mobile racking, shelving and carousels.

- Informing safety engineers and designers how to address mechanical and electrical hazards and ergonomic design principles.

- Framing installation and commissioning checklists for installers and facility managers to verify rail tolerances, protective devices and emergency stop functions.

- Supporting compliance and procurement teams when specifying safety features and user documentation for storage lifts and automated shelving.

Who should use this standard

- Manufacturers and OEMs of automated storage systems

- System integrators and installers

- Safety engineers, compliance officers and risk assessors

- Maintenance teams and facility managers

- Procurement specialists specifying storage equipment

Related Standards

EN 15095 references and complements several standards for machinery safety and control systems, including EN ISO 12100 (basic safety concepts), EN 60204-1 (electrical equipment of machines), EN ISO 13849-1 (safety-related control systems) and EN 61496 (electro-sensitive protective equipment). It also links to EU Machinery Directives via informative annexes.

Keywords: EN 15095, power-operated mobile racking, mobile shelving, carousels, storage lifts, safety requirements, CEN, machinery safety, warehouse equipment.

Frequently Asked Questions

SIST EN 15095:2008+A1:2009 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Power-operated mobile racking and shelving, carousels and storage lifts - Safety requirements". This standard covers: This European Standard provides terms and definitions on concepts and parameters used for EN 1005-21), prEN 1005-3, EN 1005-41) and EN 1005-51). Basic concepts and general ergonomic principles for the design of machinery are dealt with in EN 292-1, EN 292-2 and EN 614-1. This document is not applicable to specify the machinery which is manufactured before the date of publication of this document by CEN.

This European Standard provides terms and definitions on concepts and parameters used for EN 1005-21), prEN 1005-3, EN 1005-41) and EN 1005-51). Basic concepts and general ergonomic principles for the design of machinery are dealt with in EN 292-1, EN 292-2 and EN 614-1. This document is not applicable to specify the machinery which is manufactured before the date of publication of this document by CEN.

SIST EN 15095:2008+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 53.080 - Storage equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15095:2008+A1:2009 has the following relationships with other standards: It is inter standard links to SIST EN 15095:2008, SIST EN 15095:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15095:2008+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 15095:2008+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kraftbetriebene verschiebbare Paletten- und Fachbodenregale, Umlaufregale und Lagerlifte - SicherheitsanforderungenÉlévateurs de stockage, carrousels et rayonnages à palette et à tablette, mobiles et motorisés - Prescriptions de sécuritéPower-operated mobile racking and shelving, carousels and storage lifts - Safety requirements53.080Storage equipmentICS:Ta slovenski standard je istoveten z:EN 15095:2007+A1:2008SIST EN 15095:2008+A1:2009en,fr01-marec-2009SIST EN 15095:2008+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15095:2007+A1

December 2008 ICS 53.080 Supersedes EN 15095:2007 English Version

Power-operated mobile racking and shelving, carousels and storage lifts - Safety requirements

Élévateurs de stockage, carrousels et rayonnages à palette et à tablette, mobiles et motorisés - Prescriptions de sécurité

Kraftbetriebene verschiebbare Paletten- und Fachbodenregale, Umlaufregale und Lagerlifte - Sicherheitsanforderungen This European Standard was approved by CEN on 23 September 2007 and includes Amendment 1 approved by CEN on 9 November 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15095:2007+A1:2008: ESIST EN 15095:2008+A1:2009

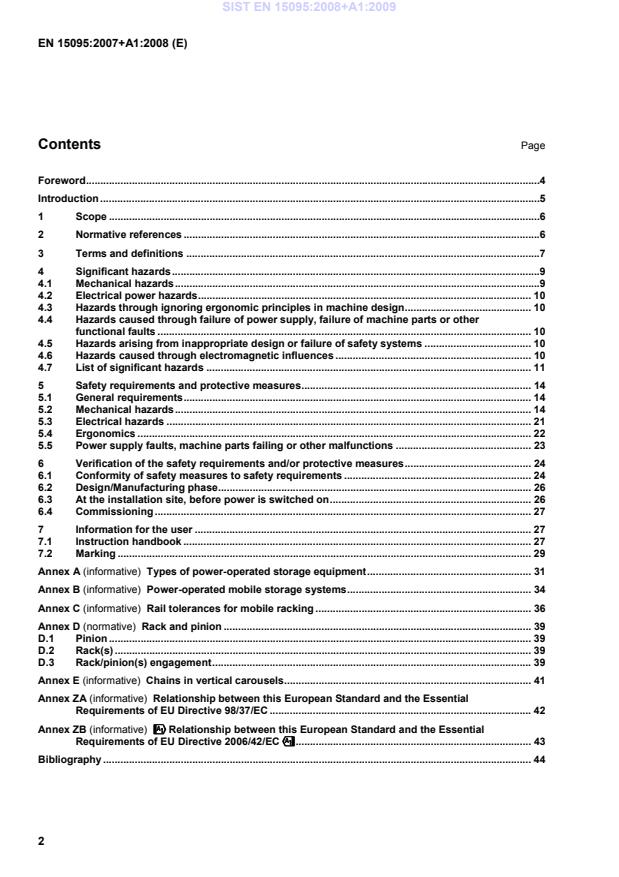

Types of power-operated storage equipment . 31 Annex B (informative)

Power-operated mobile storage systems . 34 Annex C (informative)

Rail tolerances for mobile racking . 36 Annex D (normative)

Rack and pinion . 39 D.1 Pinion . 39 D.2 Rack(s) . 39 D.3 Rack/pinion(s) engagement . 39 Annex E (informative)

Chains in vertical carousels . 41 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 42 Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 43 Bibliography . 44

Tables Table 1 — List of significant hazards . 12 Table 2 . 25

When this standard was prepared it was assumed that: only trained staff would operate, repair or maintain the machine; components without special requirements are 1) sized in accordance with good engineering practice and methods of calculation including all types of failure; 2) correctly constructed mechanically and electrically; 3) made of materials of adequate loading capacity and of suitable quality; 4) made of materials that are fit for that purpose. components are kept in a good repair and operating condition so that the required characteristics can be maintained in spite of wear and tear; sizing of load bearing parts ensures safe operation of the machine in a loading range from 0 % to 100 % of the nominal capacity and during testing conditions if applicable; details of particular conditions of use and the installation site are agreed between user and manufacturer; working area is adequately illuminated; installation site permits safe operation of the machine. SIST EN 15095:2008+A1:2009

1.3 Examples of power-operated storage equipment to which this standard applies are shown in Annex A. 1.4 With regard to buildings and parts of buildings, this standard applies only insofar that an assessment regarding hazards and risks in connection with interfaces to the storage equipment is carried out. 1.5 Storage equipment whose only power source is directly used human labour or gravity are excluded from the scope of application of this standard. 1.6 Power-operated storage equipment or parts of them do not fall under the regulations for passenger lifts. They are intended to handle and store goods. They are not intended to transport passengers under normal use (except for maintenance) and therefore not considered to be lifts (elevators).

1.7 This standard does not take hazards into account, which arise from noisy environments or environments subject to electromagnetic interference outside the range quoted in EN 61000-6-2. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. !deleted text" EN 349:1993, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body !deleted text" EN 1760-1, Safety of machinery — Pressure sensitive protective devices — Part 1: General principles for the design and testing of pressure sensitive mats and pressure sensitive floors EN 1760-2, Safety of machinery — Pressure sensitive protective devices — Part 2: General principles for the design and testing of pressure sensitive edges and pressure sensitive bars EN 12369-1, Wood-based panels — Characteristic values for structural design — Part 1: OSB, particleboards and fibreboards SIST EN 15095:2008+A1:2009

3.5 cable barriers current carrying access barrier 3.6 access opening opening in cladding or covers for the purposes of loading and unloading 3.7 compartment load intended permissible uniformly distributed load of a horizontal load carrying surface between two upright frames 3.8 bay load sum or compartment loads between two upright frames (including base supported compartment load) 3.9 accidental stop stopping of racking equipment running against an obstacle 3.10 normal stop stopping of a mobile rack under controlled manner 3.11 emergency stop stopping of the machine as a result of the operation of an emergency device 3.12 authorised person person instructed to operate the machine and/or to carry out specified maintenance or other work which may have safety implications SIST EN 15095:2008+A1:2009

!!!!3.15"""" global aisle-free system to stop and inhibit the movement of racks unless the aisle has been observed and confirmed to be clear of obstructions and all personnel 4 Significant hazards NOTE Under this section the significant hazards are listed: 4.1 Mechanical hazards 4.1.1 Crushing and shearing hazards These hazards can occur, when parts move towards, relative to, or past one another, or towards, relative to or past fixed parts whereby people or parts of their body can be crushed or severed. 4.1.2 Entanglement hazards These hazards can occur, when projecting sharp edges, teeth, wedges, screws, lubricating nipples, shafts, ends of shafts or similar items move in such way that people, parts of their body or their clothing can be caught and carried along. 4.1.3 Drawing-in hazards These hazards can occur, when parts move in such way that a narrow throat is formed in which people or parts of their body or their clothing can be pulled in.

4.1.4 Hazards from impact/collision These hazards can occur, when parts move relative to people in such way that they themselves or parts of their body can be injured through being impacted or run into. 4.1.5 Hazards arising from objects falling out and/or dropping These hazards can occur through objects falling out of and/or dropping from the storage equipment, parts of the storage equipment or the stored goods.

4.1.6 Hazards arising from potential failure of structure These hazards might be caused, for example, by failure of supporting parts or fastenings.

Hazard Danger point Requirements section 1 Mechanical hazards 1.1 Crushing hazards General Dangerous movements Contactless protective devices Operating opening Access openings Remedying malfunctions Edges Operating aisles Safety devices 5.1 5.2.1.2, 5.2.3.55.2.1.9 5.2.2.1 5.2.2.1 5.2.3.1, 5.2.3.25.2.4.3 5.2.4.6 5.2.4.7 1.2 Shearing hazards General Dangerous movements Openings Operating opening Access openings Remedying faults Building clearances 5.1 5.2.1.5 5.2.2.1, 5.2.3.15.2.2.1 5.2.3.1.1 5.2.3.4, 7.1.4 5.2.4.2,

Annex B 1.5 Hazards arising through drawing-in or entanglement General Dangerous movements Uneven loading Remedying faults Floor clearances Building clearances 5.1 5.2.1.9, 5.2.3.15.2.2.2.3 5.2.3.4 5.4.2 5.2.4.2, Annex B 1.6 Hazards arising from impact Hand drive Dangerous movements Uneven loading Remedying faults Drawers Operating aisles 5.2.1.10 5.2.1.9 5.2.2.2.3 5.2.3.5 5.2.4.5 5.2.4.6, 5.2.4.71.10 Hazards arising through parts of machinery of storage goods falling out or dropping down Installation Transporting persons Components, drawers Carousels 5.2.1.2 5.2.3.5 5.2.4.5 5.2.2.2.3

Hazard Danger point Requirements section 1.11 Loss of stability (of machinery or machine parts) General Installation Stability Breakage 5.2.1 5.2.1.2 5.2.1.3 5.2.1.4 1.12 Hazards arising from slipping, stumbling and falling over in connection with machinery (because of mechanical construction) Transporting persons Floor Chassis covering 5.2.3.5 5.4.2 5.2.4.4 2 Electrical hazards 2.1 Electrical contact (direct or indirect) Isolating devices Environment Wiring method 5.3.1.2 5.3.1.3 5.3.1.4 2.3 Thermal radiation or occurrences such as splashing of melted parts, chemical reactions with short circuits, overloading etc. Isolating devices Environment Wiring method 5.3.1.2 5.3.1.3 5.3.1.4 8 Hazards arising through neglect of ergonomic principles in machine design (incompatibility with human characteristics and ability) e. g. through 8.1 Unhealthy postures or excessive physical strain Pick-up and deposit areas Control elements Control stations 5.4.1 5.4.3 5.4.4 8.2 Insufficient consideration of human anatomy with respect to hands/arms and feet/legs Design of floor Operating elements 5.4.2 5.4.3 8.4 Failure to provide suitable local lighting Transporting persons Design of floor 5.2.3.5 5.4.2 8.6 Incorrect human behaviour In-aisle protection,

Information for the user 5.2.4.7.2), 7.1.5, 7.1.1 10 Hazards arising through faults in the power supply, breaking off of machine parts and other malfunction such as 10.1 Faults in the power supply (to the drive and/or the control system) General 5.5.1 10.2 Accidental ejection of machine parts Suspension chains 5.2.1.5 10.3 Malfunction, fault in the control system (unexpected start, unexpected rotation) Suspension chains Control systems 5.2.1.5 5.5.2 10.5 Rotation, unexpected loss of stability of machine Suspension chain 5.2.1.5 11 Hazards arising through (intermittent) failure and/or incorrect location of protection measures/protection devices, e. g. 11.1 All types of isolating protective devices Transporting persons Emergency and stop devices Emergency shutdown devices 5.2.3.5 5.5.2.1 5.5.2.3 SIST EN 15095:2008+A1:2009

Hazard Danger point Requirements section 11.2 All types of safety (protective) equipment Emergency and stop devices Emergency shutdown devices 5.5.2.1 5.5.2.3 11.3 Starting and braking equipment Uneven loading 5.2.2.2.3 11.5 All types of information and warning systems Operating instructions Minimum marking 7.1 7.2 11.6 Isolating the power supply General 5.5.1 11.9 Equipment and accessories required for setting and/or repairs Remedying faults 5.2.3.4

5 Safety requirements and protective measures 5.1 General requirements Storage equipment shall conform to the safety requirements and/or protective measures of this section and also to the requirements of EN ISO 12100-1 and EN ISO 12100-2 concerning relevant but not significant hazards, which are not dealt with in this standard. Storage equipment and their accessories shall be suitable for operation in the intended condition of use in the working environment for which they have been designed.

Care shall be taken to review the safety aspects of the interfaces with other storage products such as mobile and static racking or pedestrian access areas. 5.2 Mechanical hazards 5.2.1 Design and Installation 5.2.1.1 General Storage equipment shall be designed and installed in such a way that it is able to support the load of the storage goods safely when used in a correct manner.

The stability and load carrying capacity shall be sufficient for the operating loads and be established through calculations of the carrying capacity of the load bearing elements or via static load tests.

The intersection between single components shall be co-ordinated (e. g.: connecting forces, -moments and -stiffness's, as well as electrical, pneumatic and hydraulic connections). 5.2.1.2 Installation Storage equipment and their accessories shall be constructed so that they can be safely installed. If necessary anchorage points for safety harnesses shall be provided. Storage equipment shall be aligned vertically to the tolerances specified by the designer and as laid down in the installation instructions.

The maximum deviation from the vertical shall not exceed 1/350 of the height. SIST EN 15095:2008+A1:2009

only top most storage level is loaded, single sided; all storage levels are loaded, single sided, with the exception of the level directly supported by the base of the mobile equipment. Pattern loading to check the tipping stability in case of vertical carousels:

only top most storage level is loaded. For other products stability shall be checked in the worst possible loading condition. 5.2.1.4 Safeguarding against failure of racking The basis of design for steel bases and rack structures will be in accordance with EN 1993-1-1 and EN 1993-1-3 as far as it applies to these structures. Inertia forces due to accidental stop (stopping distance max. 15 mm) have to be considered with a load factor: 1,1. 5.2.1.5 Safeguarding against failure of suspension and drive elements of carousels and storage lifts The storage equipment manufacturer shall have a certificate on chains/ropes/belts (or other) showing the minimum design breaking load of chains/ropes/belts (or other) and refer to that certificate for each purchase. To minimise calculation and validation effort (e. g. wear, and tear, contamination, shock loading during the lifetime of the equipment) it is permitted to use the following simplified methods: a) Vertical carousels The suspension chains shall be designed in accordance with ISO 10823 to withstand, without breaking, 7 times the maximum static force or 5 times the maximum dynamic force occurring during fully loaded operation. For the calculation of the maximum break load is the sum of the load fixed on maximum length of vertical chain segments located over each other mandatory (see Annex E). b) Horizontal carousels No specific condition is required if failure of the drive elements results in a fail-safe condition, otherwise a) applies. c) Storage lifts The suspension chains, ropes, belts and other suspension elements shall be designed to withstand, without breaking, 7 times the maximum static force or 5 times the maximum dynamic load force occurring during fully SIST EN 15095:2008+A1:2009

Storage lifts with a working load limit of 1 000 kg or more shall be provided with an overload protection. 5.2.1.6 Actions (Loads and forces) When verifying the level of safety with regard to stability and failure, the following possible combination of actions shall be considered: sum of self-weights; sum of specified imposed loads (e. g. design values for shelf loads and weight of load units); placement loads, as a consequence of the method of manual or mechanical operating the storage equipment; inertia forces due to normal stop and emergency stop. The initial non-verticality imperfection may not be regarded as a loading, but shall be treated as an initial property of the structure. Nevertheless it is allowed to take the non-verticality into account as an equivalent horizontal load at each storage level. This imperfection shall be taken into account in the longitudinal as well as in the transversal direction, but not simultaneously. 5.2.1.7 Locks against falling out and/or down Components of storage equipment shall be designed or secured in such a way that they cannot fall out or down (e. g. clipped or hooked-in components, drawers).

5.2.1.8 Deflection The following deflection limits shall be considered for the maximum permissible imposed load, if no specific requirements have to be fulfilled: steel: span/200; timber or wood-based: span/150. but taking into account the influence of the load duration according to EN 12369-1. )1()(defkdeflectiontermshortdeflectionFinal+×= where

defk = load duration factor depending on material type and load duration classification 5.2.1.9 Safeguarding hazardous locations Dangerous locations (e. g. crushing, drawing-in, shearing locations) on storage equipment shall be guarded, where safety distances according to !EN ISO 13857" respectively the minimum distances to avoid crushing according to EN 349 are not maintained. If guards are used, they shall be fixed in a reliable manner and of adequate mechanical strength. It shall only be possible to remove them with a tool or they shall be interlocked with the drive.

5.2.1.12 Tripbars

Tripbars shall work over the full length. Limit switches which are operated by the tripbars shall be of a positive operated type and interlocked with the drive so that when they are operated the dangerous movement is safely stopped. Automatic re-starting shall be prevented.

NOTE See EN 1760-2 and EN 50047 for design shapes of position switches. 5.2.2 Carousels 5.2.2.1 Openings 5.2.2.1.1 General To safeguard the operating personnel against dangerous movement of load bearing devices of carousels the following protective measures are necessary. 5.2.2.1.2 Opening for picking

Dangerous areas and shearing points shall be protected e. g. by trip bars, contactless safety devices. 5.2.2.1.3 Carousels with more than one access opening Carousels with more than one access opening shall be fitted with electrically interlocked doors or monitoring elements so that only one access opening can be used at a time. Monitoring elements can be motion sensors, switching mats, light barriers or similar devices.

The monitoring and interlocking elements shall be in compliance with EN ISO 13849-1 as defined after the risk analysis for the whole machine. 5.2.2.1.4 Cladding Covers on Carousels which have to be opened by the operator when dealing with operating faults shall be electrically interlocked with the drive. SIST EN 15095:2008+A1:2009

5.2.2.2.2 Protection against uncontrolled forward and backward motion through uneven loading Generally vertical carousels shall be designed so that unintentional forward and backward movement is prevented effectively, when the highest degree of uneven loading distribution occurs (load difference between front and rear loading planes). For storage units of more than 3 tonnes load capacity devices are permitted which indicate optically or acoustically when the uneven loading distribution has reached the permissible limit and which prevent starting up or interrupt the moving operation in the critical direction when the limit has been exceeded. The correct sequence of loading and unloading shall be described in the operating manual.

For carousels with storage goods of almost the same shape and a complete view into the unit (e. g. carpet display units), it is sufficient to design the drive for the highest permitted degree of uneven loading distribution and to provide definite instructions in the operating manual.

5.2.2.2.3 Protection against items falling off Carousels shall be provided with safety measures against items falling off. Panelling, covering and protection devices shall be adequately dimensioned and secured. Protective measures shall not generate new dangerous locations.

5.2.3 Storage lifts 5.2.3.1 Openings 5.2.3.1.1 Openings for picking Areas where there is a possibility of entanglement or shearing shall be protected either by interlocked doors or light curtains at the outer rim of the picking opening or by means of light curtains at another position together with mechanical design which prevents the occurrence. EXAMPLE The danger of entanglement between a load bearing device and picking opening is avoided, if the picking opening is designed smooth and when the distance between load bearing equipment and picking opening is either less than 5 mm or more than 50 mm. A warning label has to be mounted durable and easy visible at the opening with clear declarations of the risks. It shall be ensured that a load carrier e. g. storage container which is being dealt with at an access opening cannot be called up from a different access opening. 5.2.3.1.2 Opening for maintenance Access openings for maintenance if provided shall be guarded in accordance with EN 953. They shall only be opened with a special tool or shall be interlocked with the electrical drive. 5.2.3.2 Protection against items falling off Storage lifts shall be provided with safety measures against falling items. Panelling, covering and protection devices shall be adequately secured. Protective measures shall not generate new dangerous locations.

50 mm high on all sides; survival space of 1,5 m height shall be provided; means shall be provided to anchor the person being transported against a fall. This shall be ensured by anchoring points on the platform; control equipment on the platform shall have priority over all other control equipment. 5.2.4 Mobile shelving, pallet racking and cantilever racking 5.2.4.1 Floor clearances In order to avoid injury to feet, the distance between the bottom edges of mobile storage equipment (also of safety devices) and the floor shall not exceed 15 mm for: handloaded mobile shelving equipment; SIST EN 15095:2008+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...