SIST EN 1398:2010

Dock levellers - Safety requirements

Dock levellers - Safety requirements

1.1 This European Standard specifies the safety requirements for design, construction, installation, maintenance and testing of dock levellers and for safety components on dock levellers.

With the exception of:

a) dock levellers for marine and aircraft applications;

b) lifting tables;

c) vehicle mounted tail lifts.

NOTE 1 Requirements for lifting tables are laid down in EN 1570.

NOTE 2 Requirements for vehicle mounted tail lifts are laid down in EN 1756-1.

1.2 This European Standard is applicable to dock levellers which are used by persons and/or manual or power driven transport equipment (e. g. forklift trucks) as traffic paths between goods vehicles, both road vehicles and rail wagons, and parts of buildings such as loading docks. This standard does not deal with other bridging devices not shown in Figure 1.

Ladebrücken - Sicherheitsanforderungen

1.1 Diese Europäische Norm beschreibt Sicherheitsanforderungen für Auslegung, Bau, Installation,

Wartung und Prüfung von Ladebrücken und für Sicherheitsbauteile an Ladebrücken.

Mit Ausnahme von:

a) Ladebrücken für Wasser- und Luftfahrzeuge;

b) Hubtische;

c) Hubladebühnen (Ladebordwände).

ANMERKUNG 1 Anforderungen für Hubtische sind in EN 1570 festgelegt.

ANMERKUNG 2 Anforderungen für Hubladebühnen sind in EN 1756-1 festgelegt.

1.2 Diese Europäische Norm gilt für Ladebrücken, die durch Personen und/oder handbetätigte oder

kraftbetätigte Transportmittel (z. B. Gabelstapler) genutzt werden als Verkehrswege zwischen

Warentransportfahrzeugen, sowohl als Straßen- wie auch als Eisenbahnfahrzeuge und Teilen von Gebäuden,

wie Laderampen. Andere überbrückende Einrichtungen als in Bild 1 dargestellt, sind in dieser Norm nicht

behandelt.

a) Ladeblech

handbetätigte, ortsbewegliche Ladebrücke

b) handbetätigte oder kraftbetriebene

Ladebrücke, an der Rampenkante befestigt

c) handbetätigte Ladebrücke, in eine

Laderampe eingebaut, Klapplippe

d) kraftbetriebene Ladebrücke in eine Laderampe

eingebaut, Vorschub- oder Klapplippe

Bild 1 — Typen von Ladebrücken

ANMERKUNG Nur Ladebrücken, die mit einem Antriebssystem ausgerüstet sind und nicht direkt manuell betrieben

werden, sind Maschinen im Sinne der Maschinenrichtlinie.

1.3 Diese Europäische Norm beschreibt Anforderungen zum Schutz von Personen und Gegenständen

gegen Unfälle und Gesundheitsprobleme und Beschädigung bei der Nutzung und im Betrieb von Ladebrücken.

Zu schützende Personen sind:

a) Bedienungspersonen und Nutzer;

b) Wartungs- und Überwachungspersonen;

c) Personen in der Nähe der Ladebrücken.

d) Zu schützende Gegenstände sind:

e) Waren auf Ladebrücken;

f) Transportmittel auf Ladebrücken.

Rampes ajustables - Prescriptions de sécurité

1.1 La présente Norme européenne spécifie les prescriptions de sécurité pour la conception, la

construction, l'installation, l'entretien et les essais des rampes ajustables, ainsi que pour les composants de

sécurité des rampes ajustables.

A l’exception :

a) des rampes ajustables pour les applications navales et aéronautiques ;

b) des tables élévatrices ;

c) des hayons élévateurs montés sur véhicules.

NOTE 1 Les prescriptions relatives aux tables élévatrices sont traitées dans l’EN 1570.

NOTE 2 Les prescriptions relatives aux hayons élévateurs montés sur véhicules sont traitées dans l’EN 1756-1.

1.2 La présente Norme européenne s’applique aux rampes ajustables qui sont utilisées par des personnes

et/ou du matériel de transport mû manuellement ou motorisé (par exemple, un chariot élévateur à fourche),

comme voie de passage entre des véhicules transportant des marchandises, des véhicules sur route et des

wagons sur rails, et des parties de bâtiments, telles que des quais de chargement. La présente norme ne

traite pas des autres dispositifs de montage en pont qui ne sont pas représentés à la Figure 1.

Nagibne premostitvene ploščadi - Varnostne zahteve

Ta evropski standard opredeljuje varnostne zahteve za načrtovanje, konstrukcijo, namestitev, vzdrževanje in preskušanje nagibnih premostitvenih ploščadi ter za varnostne sestavne dele na nagibnih premostitvenih ploščadih, z izjemo: a) nagibnih premostitvenih ploščadi za gradnjo ladij in čolnov ter letal, b) dvižnih miz, c) dvižnih ploščadi, nameščenih na vozila. Ta evropski standard se uporablja za nagibne premostitvene ploščadi, ki jih uporabljajo osebe, in/ali ročno ali motorno transportno opremo (npr. viličarji) kot transportne poti med težkimi tovornimi vozili, tako cestnimi vozili kot železniškimi vagoni in deli zgradb, kot so doki za nakladanje. Ta standard ne obravnava drugih premostitvenih naprav, ki niso prikazane na Sliki 1. Ta evropski standard opredeljuje zahteve z namenom zaščite oseb in stvari pred nesrečami in zdravstvenimi težavami ter škodo med uporabo in delovanjem nagibnih premostitvenih ploščadi. Osebe, ki jih je treba zaščititi, so: a) upravljavci in uporabniki, b) vzdrževalno in nadzorno osebje, c) osebe v bližini nagibne premostitvene ploščadi. Stvari, ki jih je treba zaščititi, so: d) blago na nagibnih premostitvenih ploščadih; e) transportna oprema na nagibnih premostitvenih ploščadih. Velike nevarnosti nagibnih premostitvenih ploščadi so navedene v Klavzuli 4. Te nevarnosti so bile ugotovljene z oceno tveganja v skladu z EN ISO 12100-2 ter zahtevajo delovanje za preprečitev nevarnosti ali zmanjšanje tveganja, ki ga zajema Klavzula 5. Varnostne zahteve so osnovane na predpostavki, da nagibne premostitvene ploščadi redno vzdržuje usposobljeno osebje v skladu z navodili proizvajalca ter da je bila oseba, ki jo upravlja, poučena o uporabi nagibne premostitvene ploščadi. Ta evropski standard se ne uporablja za nagibne premostitvene ploščadi, ki so bile proizvedene pred datumom, ko je bil objavljen kot EN. Ta evropski standard obravnava vse velike nevarnosti, nevarne situacije in primere v zvezi z nagibnimi premostitvenimi ploščadmi, kadar se uporabljajo v skladu z namembnostjo in pod pogoji, kot jih je predvidel proizvajalec (glej Klavzulo 4).

General Information

- Status

- Published

- Publication Date

- 01-Feb-2010

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 20-Jan-2010

- Due Date

- 27-Mar-2010

- Completion Date

- 02-Feb-2010

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 01-Sep-2010

- Effective Date

- 01-Mar-2010

Overview

EN 1398:2009 - Dock levellers: Safety requirements is the CEN (European) standard that specifies safety requirements for the design, construction, installation, maintenance and testing of dock levellers (dock levelers). It applies to fixed and installed dock levellers and manually or power-operated devices used to bridge the gap between vehicles (road or rail) and building loading docks. The standard focuses on protecting operators, maintenance staff and nearby persons, as well as goods and transport equipment, during normal use and foreseeable misuse.

Key facts:

- Issued by CEN (approved 14 February 2009), superseding EN 1398:1997.

- Applies to bridge plates, hinged or telescopic-lip levellers used as traffic paths for people and powered/manual transport equipment.

- Excludes levellers for marine and aircraft applications, lifting tables and vehicle-mounted tail lifts.

Key topics and technical requirements

EN 1398:2009 addresses the full lifecycle safety of dock levellers and contains requirements and verification methods. Major technical areas include:

- Structural design and calculations - levellers must withstand all operating/static loads; design loads and verification methods are defined (Clause 5.1).

- Significant hazards and risk reduction - crushing, shearing, impact, high-pressure fluid ejection, electrical contact, noise, slips/trips and stability are identified and linked to protective measures (Clauses 4–5).

- Safety components and controls - requirements for emergency stop devices, automatic safety devices to prevent uncontrolled lowering, control systems and measures against unexpected start-up (Clauses 5.2–5.4).

- Manual vs power-operated levellers - additional specific requirements for both manually operated and powered systems (Clauses 5.3, 5.4).

- Verification, testing and maintenance - tests, stability checks and instructions for use, maintenance and inspection are mandated to ensure ongoing safety (Clauses 6–7 and Annex A).

- Marking and documentation - mandatory information for safe use, maintenance and inspection is defined (Clause 7).

Applications and who uses this standard

EN 1398 is essential for:

- Manufacturers and designers of dock levellers to ensure compliant product design and safe construction.

- Installers and contractors fitting loading docks and levellers in warehouses, distribution centres and rail/road terminals.

- Safety managers, inspectors and maintenance personnel who perform routine inspections, testing and maintenance to meet regulatory and operational safety obligations.

- Procurement and facilities teams specifying compliant loading equipment for logistics operations.

Practical benefits: reduces accident risk during loading/unloading, ensures mechanical and control safety, supports compliance with EU machinery directives and harmonised safety practice.

Related standards

Relevant standards referenced or related:

- EN ISO 12100 (machine safety / risk assessment)

- EN ISO 13849-1 (safety-related control systems)

- EN 1570 (lifting tables)

- EN 1756-1 (vehicle-mounted tail lifts)

- EN 60204-1 (electrical equipment of machines)

- EN 349, EN 982, EN 983 (safety of machinery components)

Keywords: EN 1398:2009, dock levellers, dock levelers, safety requirements, loading dock safety, bridge plate, emergency stop, automatic safety device, CEN.

Frequently Asked Questions

SIST EN 1398:2010 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Dock levellers - Safety requirements". This standard covers: 1.1 This European Standard specifies the safety requirements for design, construction, installation, maintenance and testing of dock levellers and for safety components on dock levellers. With the exception of: a) dock levellers for marine and aircraft applications; b) lifting tables; c) vehicle mounted tail lifts. NOTE 1 Requirements for lifting tables are laid down in EN 1570. NOTE 2 Requirements for vehicle mounted tail lifts are laid down in EN 1756-1. 1.2 This European Standard is applicable to dock levellers which are used by persons and/or manual or power driven transport equipment (e. g. forklift trucks) as traffic paths between goods vehicles, both road vehicles and rail wagons, and parts of buildings such as loading docks. This standard does not deal with other bridging devices not shown in Figure 1.

1.1 This European Standard specifies the safety requirements for design, construction, installation, maintenance and testing of dock levellers and for safety components on dock levellers. With the exception of: a) dock levellers for marine and aircraft applications; b) lifting tables; c) vehicle mounted tail lifts. NOTE 1 Requirements for lifting tables are laid down in EN 1570. NOTE 2 Requirements for vehicle mounted tail lifts are laid down in EN 1756-1. 1.2 This European Standard is applicable to dock levellers which are used by persons and/or manual or power driven transport equipment (e. g. forklift trucks) as traffic paths between goods vehicles, both road vehicles and rail wagons, and parts of buildings such as loading docks. This standard does not deal with other bridging devices not shown in Figure 1.

SIST EN 1398:2010 is classified under the following ICS (International Classification for Standards) categories: 53.080 - Storage equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1398:2010 has the following relationships with other standards: It is inter standard links to SIST EN 1398:1999/AC:2001, SIST EN 1398:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1398:2010 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC, EUR-PUB; Standardization Mandates: M/396, M/BC/CEN/91/1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1398:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Ladebrücken - SicherheitsanforderungenRampes ajustables - Prescriptions de sécuritéDock levellers - Safety requirements53.080Storage equipmentICS:Ta slovenski standard je istoveten z:EN 1398:2009SIST EN 1398:2010en,fr,de01-marec-2010SIST EN 1398:2010SLOVENSKI

STANDARDSIST EN 1398:1999/AC:2001SIST EN 1398:19991DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1398March 2009ICS 53.080Supersedes EN 1398:1997

English VersionDock levellers - Safety requirementsRampes ajustables - Prescriptions de sécuritéLadebrücken - SicherheitsanforderungenThis European Standard was approved by CEN on 14 February 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1398:2009: ESIST EN 1398:2010

Examples of suitable tests . 28 A.1 General . 28 A.2 Stability test . 28 A.3 Function test of the automatic safety device . 30 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 31 Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 32 Bibliography . 33

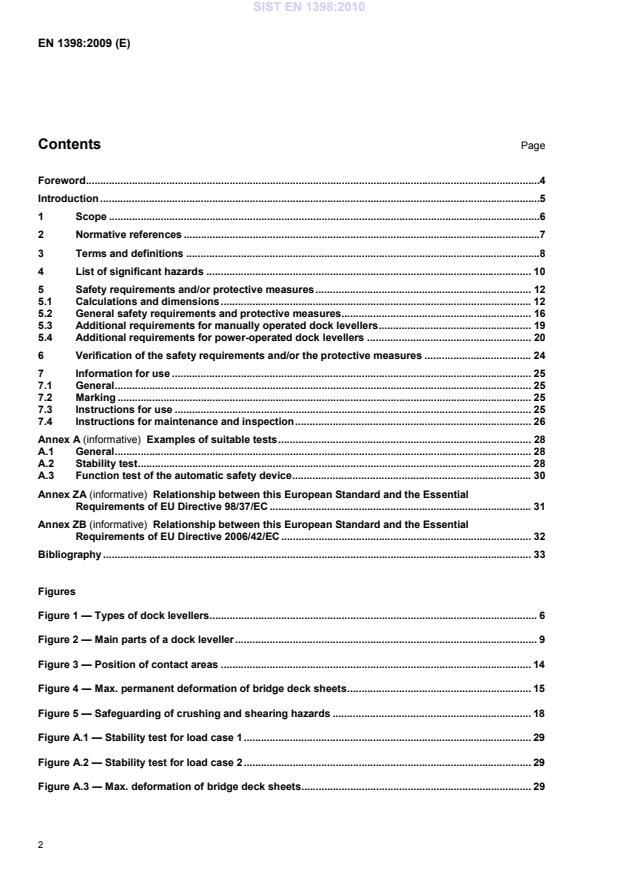

Figures Figure 1 — Types of dock levellers . 6 Figure 2 — Main parts of a dock leveller . 9 Figure 3 — Position of contact areas . 14 Figure 4

Max. permanent deformation of bridge deck sheets . 15 Figure 5 — Safeguarding of crushing and shearing hazards . 18 Figure A.1 — Stability test for load case 1 . 29 Figure A.2 — Stability test for load case 2 . 29 Figure A.3

Max. deformation of bridge deck sheets . 29 SIST EN 1398:2010

a) Bridge plate (dock plate) manually operated, mobile b)Manuallyor power operated dockleveller, fixed at the dock edge

c) Manually operated dock leveller, installed in a pit, hinged lip d)Power operated dock leveller, installed in a pit, telescopic or hinged lip Figure 1 — Types of dock levellers NOTE Only dock levellers fitted with a drive system other than directly applied human effort are machines in the sense of the Machinery Directive. 1.3 This European Standard specifies requirements in order to protect persons and objects against accidents and health problems and damage during use and operation of dock levellers. SIST EN 1398:2010

Key 1 Bridge deck 2 Bearer 3 Hinged lip Figure 2 — Main parts of a dock leveller 3.5 bearer supporting part of a dock leveller in the form of a beam, fixed at the under side of the bridge deck (see Figure 2) 3.6 support device part of a dock leveller, e. g. in the form of a block, bar or bolt which supports the dock leveller in the horizontal stored position 3.7 hinged lip part of a dock leveller hinged to the bridge deck and resting on the vehicle in the operational position (see Figure 2) 3.8 telescopic lip part of a dock leveller which can be telescopically extended towards the vehicle and which rests on the vehicle in the operational position 3.9 loading loading or unloading a vehicle using a dock leveller 3.10 free floating condition mode in which the dock leveller supported on the vehicle may follow automatically the vertical movements of the vehicle during the loading process 3.11 stored position position to which the dock leveller is put, or to which it returns, when loading has finished SIST EN 1398:2010

Table 1 — Significant hazards and safety requirements

Significant hazards Safety requirements; Relevant clauses in this standard 1.1 Crushing hazard 5.2.9, 5.2.10, 5.4.2.1, 5.4.2.2, 5.4.2.4, 5.4.2.5, 5.4.2.7, 5.4.2.8 1.2 Shearing hazard 5.2.9, 5.2.10, 5.4.2.1, 5.4.2.2, 5.4.2.4, 5.4.2.5, 5.4.2.7, 5.4.2.8 1.6 Impact hazard 5.2.11 1.9 High pressure fluid ejection hazard 5.4.4.1, 5.4.4.2, 5.4.4.3, 5.4.4.4, 5.4.4.5 2.1 Contact of persons with live part (direct contact) 5.4.2.6, 5.4.3 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) 5.4.3, 5.4.2.6 4 Hazards generated by noise 5.2.6 8 Hazards generated by neglecting ergonomic principles in machine design 8.1 Unhealthy postures or excessive effort 5.3.3, 5.3.4 8.2 Inadequate consideration of hand-arm or foot-leg anatomy 5.3.3, 5.3.4 8.5 Mental overload and underload, stress not applicable 8.6 Human error, human behaviour 5.4.2.5, 7.4.2 8.7 Inadequate design, location or identification of manual controls 5.4.2.2, 5.4.2.3, 5.4.2.5 8.8 Inadequate design or location of visual display units 5.4.2.5 10 Unexpected start-up

10.1 Failure, malfunction of control system 5.4.2.5, 5.4.2.7, 7.3.2 10.2 Restoration of energy supply after an interruption 5.4.2.9, 7.3.2 10.4 Other external influence gravity, wind etc. 5.1.2.2, 5.2.5

11 Impossible to stop the machine in the best position 5.2.2, 5.4.1 14 Failure of the power supply 5.4.2.7, 5.4.2.8, 5.4.2.9 18 Loss of stability 5.1 19 Slip, trip and fall hazard 5.2.2, 5.2.3, 5.2.4, 5.2.5, 5.2.6, 5.2.7, 5.2.8, 5.2.11, 5.3.2, 5.4.1 SIST EN 1398:2010

5 Safety requirements and/or protective measures 5.1 Calculations and dimensions 5.1.1 General Dock levellers shall be designed to withstand all loads and forces under all operating and static conditions according to the scope. Dock levellers have an adequate strength if when the loads and forces given in 5.1.2 are used in the calculation methods given in 5.1.3 the necessary design criteria/safety factors of 5.1.5 are achieved. 5.1.2 Structural design 5.1.2.1 General Dock levellers wider than 1,25 m shall, in principle, be designed to withstand the passage of forklift and similar industrial trucks. At widths up to 1,25 m, such dock levellers may be designed to withstand loads resulting from pedestrian traffic and pedestrian operated industrial trucks only. 5.1.2.2 Loads and forces 5.1.2.2.1 General When calculating dock levellers all relevant loads and forces subdivided into primary and supplementary loads and forces shall be taken into account. Primary loads and forces are as follows: a) dead loads; b) rated load plus dynamic effects. Supplementary loads and forces are considered to be: c) wind forces; d) braking and starting loads; e) inertia forces; f) impact loads. Applicable forces and loads at different load combinations are shown in Table 2. SIST EN 1398:2010

Primary loads Safety against yield stress (factor for combined loads) * Safety against yield stress (factor for not combined loads) * Supplementary loads Applicable factors and loads at different load combinations Dead loads (factor) Rated load (dynamic factor) Inertia forces, factor Out of service wind load (kN/m2) Impact loads (at 1 m) Braking and starting loads (factor) ** Clause 5.1.2.2.2 5.1.2.2.3 5.1.5.2 5.1.5.2 5.1.2.2.6 5.1.2.2.4 5.1.2.2.7 5.1.2.2.5Normal operation, leveller in use, or not in use 1 1,4 1,33 1,5 – – – 0,3 Cross traffic operation, leveller in stored position 1 1,4 1,33 1,5 – – – 0,3 Leveller in stored position, no rated load, wind load can occur 1 – 1,33 1,5 – 1 1 0 Exceptional situation, emergency stop 1 1 1 1 1,4 – – 0 *

** Safety factor against the yield stress is 1,33 when primary and supplementary loads are combined, or 1,5 when not combined loads Braking and starting loads are acting in traffic direction

5.1.2.2.2 Dead loads The masses of all permanently fixed and movable components shall be taken as dead loads. 5.1.2.2.3 Rated load including dynamic effects In addition to the rated load dynamic effects shall be considered. SIST EN 1398:2010

a) point load for b ≤ 1,25 m; b) axle load on one axle for b > 1,25 m. Point loads shall be taken as acting over a square contact area. Axle loads shall be taken acting over two rectangular contact areas at 1 m lateral distance. These areas shall only apply if the actual conditions do not call for more severe loading. The size of the footprint [mm2] is derived from the wheel load [N] divided by 2 [N/mm2]. The ratio of the rectangular print is W:L = 3:2. The position of the contact areas is shown in Figure 3.

Key 1 Centre to centre

L Length of the contact area 2 Direction of the traffic

W Width of the contact area Figure 3 — Position of contact areas 5.1.2.2.4

Wind forces Dock levellers exposed to the environment shall be designed to withstand a wind pressure of w = 1,0 kN/m2 in both directions, directly on to the front of the deck and also directly on to the back of the deck. This is particularly valid for dock levellers which are stowed in the vertical position when not in use. 5.1.2.2.5 Braking and starting loads The braking and starting loads for transport equipment operations shall be deemed to be effective at the level of the bridge deck. They shall be calculated at 30 % of the rated load. 5.1.2.2.6 Inertia forces The effects of inertia shall be taken into account for shock-inducing speed changes of movable components, in particular when a dock leveller travels at operational speed to the final end position in either direction or when the automatic safety device (see 5.4.1) is operated. 5.1.2.2.7 Impact loads For vertically stowed and latched dock levellers, a directly applied horizontal load of 1 kN/m of width evenly distributed on a line shall be deemed to be effective at a location 1 m above the top of the hinge line of the dock leveller and at right angles to the bridge deck. For dock levellers shorter than 1 m this horizontal load shall be applied to the top edge of the raised dock leveller. Vehicle impact loads need not be considered. NOTE The defined horizontal load has to be considered, to prevent the dock leveller plate from being knocked over by persons or mechanical handling equipment.

Key a Width of deck plate supporting sections Figure 4

Maximum permanent deformation of bridge deck sheets Distortion of bridge decks occurring under operating conditions, e. g. by a fork lift truck offset to one side shall be considered. 5.1.4 Design Test As an alternative to calculations, components may be subjected to testing to demonstrate their satisfactory design. The rated load multiplied by the dynamic factor (see 5.1.2.2.3) and the valid safety factor (see 5.1.5.2) SIST EN 1398:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...