SIST EN 16125:2019

(Main)LPG Equipment and Accessories - Pipework systems and supports - LPG in liquid phase and vapour pressure phase

LPG Equipment and Accessories - Pipework systems and supports - LPG in liquid phase and vapour pressure phase

This document specifies the requirements for the design, construction, testing, commissioning, operation and maintenance of LPG pipework in both the liquid phase and at full vapour pressure.

This document is applicable to LPG pipework having a maximum allowable pressure of less than or equal to 25 bar.

This document is applicable to new LPG pipework as well as to replacements of, or extensions to, existing LPG pipework.

This document is not applicable to:

- pipelines and their accessories;

- pipework for the propulsion systems of road vehicles or boats; and

- pipework on ships.

Flüssiggas-Geräte und Ausrüstungsteile - Rohrleitungssysteme und -befestigungen - Flüssigphase und ungeregelte Gasphase von Flüssiggas (LPG)

Dieses Dokument legt Anforderungen an Auslegung, Bau, Prüfung, Inbetriebnahme, Betrieb und Wartung von Rohrleitungen für Flüssiggas (en: liquefied petroleum gas, LPG) in der Flüssigphase und bei vollständigem Gasdruck fest.

Dieses Dokument gilt für Rohrleitungen für Flüssiggas mit einem maximalen Betriebsdruck bis einschließlich 25 bar.

Dieses Dokument gilt für neue Rohrleitungen für Flüssiggas sowie für den Austausch oder die Erweiterung von vorhandenen Rohrleitungen für Flüssiggas.

Dieses Dokument ist nicht anwendbar für:

- Rohrfernleitungen und deren Ausrüstungsteile;

-- Rohrleitungen für Antriebsanlagen von Straßenfahrzeugen oder Booten; und

- Rohrleitungen auf Schiffen.

Equipements pour GPL et leurs accessoires - Systèmes de canalisations et supports - Phase liquide et phase vapeur

Le présent document spécifie les prescriptions relatives à la conception, à la construction, aux essais, à la mise en service, au fonctionnement et à l'entretien des canalisations pour GPL en phase liquide et à la pleine pression de vapeur.

Le présent document est applicable aux canalisations pour GPL ayant une pression maximale admissible inférieure ou égale à 25 bar.

Le présent document est applicable aux canalisations pour GPL neuves, ainsi qu'aux pièces de remplacement ou d'extension de canalisations pour GPL existantes.

Le présent document n'est pas applicable :

— aux canalisations (telles qu'elles sont définies dans la Directive relative aux équipements sous pression 2014/68/EU) et à leurs accessoires ;

— aux systèmes de canalisations pour les systèmes de propulsion des véhicules routiers ou des embarcations ; et

— aux systèmes de canalisations des bateaux.

Oprema in pribor za utekočinjeni naftni plin (UNP) - Cevovodi in podpore - Tekoča in parna faza UNP

Ta dokument določa zahteve za načrtovanje, izgradnjo, preskušanje, začetek obratovanja, delovanje ter vzdrževanje cevovodov za utekočinjeni naftni plin (LPG) v tekoči in polni parni fazi.

Ta dokument se uporablja za cevovode za utekočinjeni naftni plin z največjim dovoljenim tlakom, manjšim ali enakim 25 barov.

Ta dokument se uporablja za nove cevovode za utekočinjeni naftni plin ter tudi za zamenjave ali razširitve obstoječih cevovodov za utekočinjeni naftni plin.

Ta dokument se ne uporablja za:

– cevovode in njihov pribor,

– cevi za pogonske sisteme cestnih vozil ali plovil ter

– cevi na ladjah.

General Information

- Status

- Published

- Public Enquiry End Date

- 06-May-2018

- Publication Date

- 06-Nov-2019

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 02-Oct-2019

- Due Date

- 07-Dec-2019

- Completion Date

- 07-Nov-2019

Relations

- Effective Date

- 01-Dec-2019

Overview

EN 16125:2019 is the CEN European standard that sets requirements for the design, construction, testing, commissioning, operation and maintenance of LPG pipework and supports operating in both the liquid phase and at full vapour pressure. It applies to new installations as well as to replacements or extensions of existing LPG pipework with a maximum allowable pressure ≤ 25 bar. The standard explicitly excludes pipelines subject to the PED (2014/68/EU), pipework for road vehicle or boat propulsion systems, and pipework on ships.

Keywords: EN 16125:2019, LPG pipework, liquid phase, vapour pressure, pipe supports, LPG piping design

Key Topics

EN 16125:2019 covers the lifecycle of LPG pipework and includes these principal technical areas:

- Design safety considerations and maximum allowable pressure limits

- Materials selection suitable for LPG in liquid and vapour phases

- Mechanical design of pipework and supports (routing, flexibility, joints)

- Corrosion protection and identification for above-ground pipework (including coatings and cathodic protection references)

- Welded pipes and fittings, welding qualifications and inspection requirements

- Inspection, documentation and testing procedures (pressure and leak tests)

- Commissioning and safe entry into service

- Maintenance and integrity management (including Pipework Integrity Management Systems – PIMS)

- Pipe sizing guidance for both liquid and gas phases (informative annexes)

Normative references in the standard point users to established test methods and complementary standards for valves, brazing, non‑destructive testing and materials.

Applications

EN 16125:2019 is intended for practical use in:

- Design and specification of LPG distribution pipework on industrial, commercial and some on‑site installations

- Construction and installation work for LPG transfer systems (liquid and vapour)

- Commissioning teams carrying out pressure and leak tests prior to operation

- Maintenance and inspection programmes to ensure ongoing safe operation

- Engineering assessments for extensions or replacements of existing LPG systems

Typical use cases include LPG storage facilities, refilling stations, industrial processing sites and local distribution systems where pressures do not exceed 25 bar.

Who should use this standard

- Mechanical and piping engineers

- LPG system designers and contractors

- Inspection and commissioning personnel

- Operations and maintenance managers

- Equipment manufacturers and suppliers of LPG fittings, valves and supports

Related standards

EN 16125 references and aligns with other standards such as:

- EN 13175 (LPG pressure vessel valves and fittings)

- EN 15001‑1 (gas installation pipework functional requirements)

- EN ISO 3183 (steel pipe specifications)

- Relevant EN/ISO welding and NDT standards (e.g., EN ISO 9606‑1, EN ISO 17637)

Using EN 16125:2019 helps ensure LPG pipework is safe, compliant and designed for long‑term integrity in both liquid and vapour service.

Frequently Asked Questions

SIST EN 16125:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "LPG Equipment and Accessories - Pipework systems and supports - LPG in liquid phase and vapour pressure phase". This standard covers: This document specifies the requirements for the design, construction, testing, commissioning, operation and maintenance of LPG pipework in both the liquid phase and at full vapour pressure. This document is applicable to LPG pipework having a maximum allowable pressure of less than or equal to 25 bar. This document is applicable to new LPG pipework as well as to replacements of, or extensions to, existing LPG pipework. This document is not applicable to: - pipelines and their accessories; - pipework for the propulsion systems of road vehicles or boats; and - pipework on ships.

This document specifies the requirements for the design, construction, testing, commissioning, operation and maintenance of LPG pipework in both the liquid phase and at full vapour pressure. This document is applicable to LPG pipework having a maximum allowable pressure of less than or equal to 25 bar. This document is applicable to new LPG pipework as well as to replacements of, or extensions to, existing LPG pipework. This document is not applicable to: - pipelines and their accessories; - pipework for the propulsion systems of road vehicles or boats; and - pipework on ships.

SIST EN 16125:2019 is classified under the following ICS (International Classification for Standards) categories: 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16125:2019 has the following relationships with other standards: It is inter standard links to SIST EN 16125:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 16125:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2019

Nadomešča:

SIST EN 16125:2016

Oprema in pribor za utekočinjeni naftni plin (UNP) - Cevovodi in podpore - Tekoča

in parna faza UNP

LPG Equipment and Accessories - Pipework systems and supports - LPG in liquid phase

and vapour pressure phase

Flüssiggas-Geräte und Ausrüstungsteile - Rohrleitungssysteme und -befestigungen -

Flüssigphase und ungeregelte Gasphase von Flüssiggas (LPG)

Equipements pour GPL et leurs accessoires - Systèmes de canalisations et supports -

Phase liquide et phase vapeur

Ta slovenski standard je istoveten z: EN 16125:2019

ICS:

75.200 Oprema za skladiščenje Petroleum products and

nafte, naftnih proizvodov in natural gas handling

zemeljskega plina equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16125

EUROPEAN STANDARD

NORME EUROPÉENNE

September 2019

EUROPÄISCHE NORM

ICS 23.040.01 Supersedes EN 16125:2015

English Version

LPG Equipment and Accessories - Pipework systems and

supports - LPG in liquid phase and vapour pressure phase

Equipements pour GPL et leurs accessoires - Systèmes Flüssiggas-Geräte und Ausrüstungsteile -

de canalisations et supports - Phase liquide et phase Rohrleitungssysteme und -befestigungen -

vapeur Flüssigphase und ungeregelte Gasphase von Flüssiggas

(LPG)

This European Standard was approved by CEN on 28 July 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16125:2019 E

worldwide for CEN national Members.

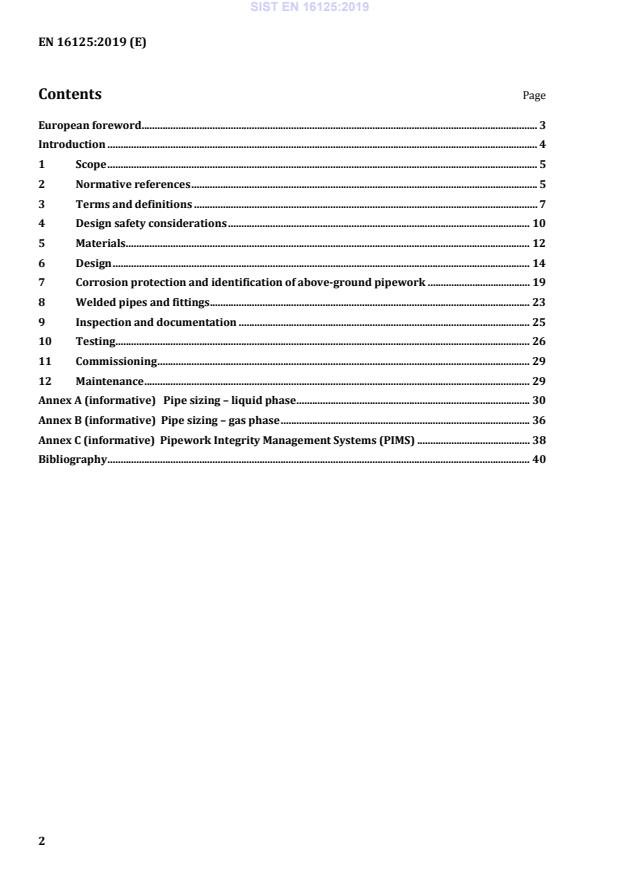

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 7

4 Design safety considerations . 10

5 Materials . 12

6 Design . 14

7 Corrosion protection and identification of above-ground pipework . 19

8 Welded pipes and fittings . 23

9 Inspection and documentation . 25

10 Testing . 26

11 Commissioning . 29

12 Maintenance . 29

Annex A (informative) Pipe sizing – liquid phase . 30

Annex B (informative) Pipe sizing – gas phase . 36

Annex C (informative) Pipework Integrity Management Systems (PIMS) . 38

Bibliography . 40

European foreword

This document (EN 16125:2019) has been prepared by Technical Committee CEN/TC 286 “LPG

Equipment and Accessories”, the secretariat of which is held by NSAI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by March 2020, and conflicting national standards shall be

withdrawn at the latest by March 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 16125:2015.

The main technical changes include:

— the removal of the environmental annex and associated clauses in favour of a reference to

CEN/TS 16765,

— the removal of Annex E (Manufacturing and type testing of composite pipes) with the intent of

developing a dedicated composite pipe manufacturing standard within CEN/TC 155. At the time of

this document going to formal vote, the proposed project within CEN/TC 155 is under consideration.

At all stages of building and operating pipework systems the use of materials and disposal of waste

material may have an effect on the environment. CEN/TS 16765 [10] sets out environmental

considerations for this document.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document calls for the use of substances and procedures that may be injurious to health and/or the

environment if adequate precautions are not taken. It refers only to technical suitability and does not

absolve the user from legal obligations at any stage.

This document is intended for users who take on the responsibility for the assembly of the pipework on

site.

Protection of the environment is a key political issue in Europe and elsewhere. Protection of the

environment is taken in a very broad sense, as in the total life cycle aspects of, e.g. a product on the

environment, including expenditure of energy and during all phases from mining of raw materials,

fabrication, packaging, distribution, use, scrapping, recycling of materials, etc.

It is recommended that manufacturers develop an environmental management policy. For guidance see

the ISO 14004 [6]. It has been assumed in the drafting of this document that the execution of its provisions

is entrusted to appropriately qualified and experienced people.

All pressures are gauge unless otherwise stated.

NOTE This document uses measurement of material properties, dimensions and pressures. All such

measurements are subject to a degree of uncertainty due to tolerances in measuring equipment, etc. It could be

beneficial to refer to the leaflet “measurement uncertainty leaflet (SP INFO 2000 27 uncertainty.pdf)”[13].

1 Scope

This document specifies the requirements for the design, construction, testing, commissioning, operation

and maintenance of LPG pipework in both the liquid phase and at full vapour pressure.

This document is applicable to LPG pipework having a maximum allowable pressure of less than or equal

to 25 bar.

This document is applicable to new LPG pipework as well as to replacements of, or extensions to, existing

LPG pipework.

This document is not applicable to:

— pipelines (as defined in 2014/68/EU, PED) and their accessories;

— pipework for the propulsion systems of road vehicles or boats; and

— pipework on ships.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 549, Rubber materials for seals and diaphragms for gas appliances and gas equipment

EN 751-2, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and

hot water – Part 2: Non-hardening jointing compounds

EN 751-3, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and

hot water – Part 3: Unsintered PTFE tapes

EN 837 (all parts), Pressure gauges

EN 1045, Brazing – Fluxes for brazing – Classification and technical delivery conditions

EN 1057, Copper and copper alloys – Seamless, round copper tubes for water and gas in sanitary and

heating applications

EN 1092-1, Flanges and their joints – Circular flanges for pipes, valves, fittings and accessories, PN

designated – Part 1: Steel flanges

EN 1254-1, Copper and copper alloys - Plumbing fittings – Part 1: Fittings with ends for capillary soldering

or capillary brazing to copper tubes

EN 1254-2, Copper and copper alloys – Plumbing fittings – Part 2: Fittings with compression ends for use

with copper tubes

EN 1254-5, Copper and copper alloys – Plumbing fittings – Part 5: Fittings with short ends for capillary

brazing to copper tubes

EN 1515-1, Flanges and their joints – Bolting – Part 1: Selection of bolting

EN 10216-1, Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 1: Non-alloy

steel tubes with specified room temperature properties

EN 10216-2, Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 2: Non-alloy

and alloy steel tubes with specified elevated temperature properties

EN 10216-3, Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 3: Alloy fine

grain steel tubes

EN 10216-4, Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 4: Non-alloy

and alloy steel tubes with specified low temperature properties

EN 10216-5, Seamless steel tubes for pressure purposes – Technical delivery conditions – Part 5: Stainless

steel tubes

EN 10217-1, Welded steel tubes for pressure purposes – Technical delivery conditions – Part 1: Non-alloy

steel tubes with specified room temperature properties

EN 10217-2, Welded steel tubes for pressure purposes – Technical delivery conditions – Part 2: Electric

welded non-alloy and alloy steel tubes with specified elevated temperature properties

EN 10217-3, Welded steel tubes for pressure purposes – Technical delivery conditions – Part 3: Alloy fine

grain steel tubes

EN 10217-4, Welded steel tubes for pressure purposes - Technical delivery conditions – Part 4: Electric

welded non-alloy steel tubes with specified low temperature properties

EN 10217-6, Welded steel tubes for pressure purposes - Technical delivery conditions – Part 6: Submerged

arc welded non-alloy steel tubes with specified low temperature properties

EN 10217-7, Welded steel tubes for pressure purposes – Technical delivery conditions – Part 7: Stainless

steel tubes

EN 10226-1, Pipe threads where pressure tight joints are made on the threads – Part 1: Taper external

threads and parallel internal threads – Dimensions, tolerances and designation

EN 10226-2, Pipe threads where pressure tight joints are made on the threads – Part 2: Taper external

threads and taper internal threads – Dimensions, tolerances and designation

EN 10253-2, Butt-welding pipe fittings – Part 2: Non alloy and ferritic alloy steels with specific inspection

requirements

EN 12068, Cathodic protection – External organic coatings for the corrosion protection of burried or

immersed steel pipelines used in conjunction with cathodic protection – Tapes and shrinkable materials

EN 12266-1, Industrial valves – Testing of metallic valves – Part 1: Pressure tests, test procedures and

acceptance criteria – Mandatory requirements

EN 12266-2, Industrial valves – Testing of metallic valves – Part 2: Tests, test procedures and acceptance

criteria – Supplementary requirements

EN 12799, Brazing – Non-destructive examination of brazed joints

EN 13175, LPG Equipment and accessories – Specification and testing for Liquefied Petroleum Gas (LPG)

pressure vessel valves and fittings

EN 14291, Foam producing solutions for leak detection on gas installations

EN 14324, Brazing – Guidance on the application of brazed joints

EN 15001-1, Gas Infrastructure – Gas installation pipework with an operating pressure greater than 0,5 bar

for industrial installations and greater than 5 bar for industrial and non-industrial installations – Part 1:

Detailed functional requirements for design, materials, construction, inspection and testing

EN ISO 3183, Petroleum and natural gas industries – Steel pipe for pipeline transportation systems

(ISO 3183)

EN ISO 3452-1, Non-destructive testing – Penetrant testing – Part 1: General principles

EN ISO 5817, Welding – Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) – Quality levels for imperfections (ISO 5817)

EN ISO 9454-2, Soft soldering fluxes – Classification and requirements – Part 2: Performance requirements

(ISO 9454-2)

EN ISO 9606-1, Qualification testing of welders – Fusion welding – Part 1: Steels (ISO 9606-1)

EN ISO 9712, Non-destructive testing – Qualification and certification of NDT personnel (ISO 9712)

EN ISO 10380, Pipework – Corrugated metal hoses and hose assemblies (ISO 10380)

EN ISO 10497, Testing of valves – Fire type-testing requirements (ISO 10497)

EN ISO 16810, Non-destructive testing – Ultrasonic testing – General principles (ISO 16810)

EN ISO 17636-1, Non-destructive testing of welds – Radiographic testing – Part 1: X- and gamma-ray

techniques with film (ISO 17636-1)

EN ISO 17637, Non-destructive testing of welds - Visual testing of fusion-welded joints (ISO 17637)

EN ISO 17638, Non-destructive testing of welds – Magnetic particle testing (ISO 17638)

EN ISO 17640, Non-destructive testing of welds - Ultrasonic testing – Techniques, testing levels, and

assessment (ISO 17640)

EN ISO 17672, Brazing – Filler metals (ISO 17672)

EN ISO 17292, Metal ball valves for petroleum, petrochemical and allied industries (ISO 17292)

ASME B31.3, Process piping

ASME B31.4, Pipeline transportation systems for liquids and slurries

ASME B16.5, Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

accessible

capable of being reached for inspection, removal or maintenance without the removal of permanent

structures

3.2

brazed joint

joint obtained by the joining of metal parts with alloys which melt at temperatures that are generally

higher than 450 °C, but less than the melting temperatures of the joined parts

3.3

commissioning

preparation for safe service

3.4

competent person

person which by combination of appropriate qualification, training, experience, and resources, is able to

make objective judgments on the subject

3.5

composite pipe

pipe manufactured from thermoplastic and/or stainless steel which is also reinforced with stainless steel

or other non-metallic materials and has an outer thermoplastic protective cover

3.6

crimped joint

joint in which gas tightness is achieved by compression with or without a seal, but cannot be readily

disassembled and reassembled

3.7

fitting

pressure containing component fitted to an LPG pressure system

3.8

dew point

temperature below which vapour at a given pressure will condense back into liquid

3.9

flexible pipe

pipe that can be bent by hand to any radius above a set minimum without any change in performance

3.10

hydrostatic relief valve

self-closing valve which automatically, without the assistance of any energy other than that of the fluid

concerned, discharges fluid at a predetermined pressure

3.11

leak test

pressure test to determine the presence of leaks at joints or within components of a piping system

[SOURCE: ISO 14692-1:2017, 3.2.68]

3.12

Liquefied Petroleum Gas

LPG

low pressure liquefied gas composed of one or more light hydrocarbons which are assigned to UN 1011,

UN 1075, UN 1965, UN 1969 or UN 1978 only and which consists mainly of propane, propene, butane,

butane isomers, butene with traces of other hydrocarbon gases

3.13

maximum allowable pressure

maximum pressure for which the equipment is designed

Note 1 to entry: All pressures are gauge pressures unless otherwise stated.

3.14

mechanical jointing

joint in which gas tightness is achieved by compression with or without a seal

Note 1 to entry: This joint can be readily disassembled and reassembled.

3.15

nominal diameter

DN

numerical designation of the size of a component, which is a convenient round number, approximately

equal to the manufacturing dimensions in millimetres (mm)

EXAMPLE DN 50.

3.16

non-return valve

valve designed to close automatically to restrict reverse flow

3.17

pipework

pressure containing enclosure used for the conveyance of LPG consisting of pipe, pipe fittings, valves and

other accessories

3.18

purging

displacing LPG with a non-flammable gas, steam or water or the reverse procedure

Note 1 to entry: Water/steam is not the preferred option for purging into service due to the difficulty of removing

water.

3.19

road tanker

rigid vehicle, semi-trailer or trailer comprising of one or more fixed pressure vessels

Note 1 to entry: Referred to as fixed tanks (tank-vehicles) and demountable tanks in the ADR.

3.20

sleeve

protective pipe through which a gas pipe passes

3.21

strength test

specific procedure intended to verify that the pipework meets the requirements for mechanical strength

3.22

threaded joint

joint in which tightness is achieved by metal to metal contact within threads with the assistance of a

sealant

3.23

void

enclosed, generally inaccessible and unventilated, space other than a service shaft

3.24

welded joint

joining of two compatible components by melting their edges and melting a suitable material into a space

between the components, or by raising the temperature of their edges to the fusion temperature and

applying pressure to join the two together

Note 1 to entry: Whilst this is most commonly applied to steel, it is also applicable to other materials such as

copper.

Note 2 to entry: Due to the application of heat, welded joints can be subject to complex stress pattern and

therefore the joints should only be made by suitably qualified personnel.

3.25

working pressure

pressure under normal operating conditions

4 Design safety considerations

4.1 General

4.1.1 The design of an LPG installation shall be done by a competent person.

4.1.2 The pipework designer shall provide information on the design and location of the pipework to

the persons responsible for the construction, installation, testing, commissioning and operation of the

pipework.

4.1.3 The pipework shall be designed, installed and constructed to allow testing and purging to be

safely carried out.

4.1.4 Pipework joints shall be kept to a minimum.

4.2 Operating conditions

Pipework used in accordance with this document shall be suitable for the following conditions:

— a minimum operating temperature of − 20 °C. In service, temperatures below this can be

encountered during short periods, for example, when filling. In some parts of Europe and certain

applications where a lower temperature than − 20 °C can be encountered, the minimum design

temperature shall be – 40 °C;

— the maximum working temperature shall be 65 °C for above ground pipework and 40 °C for

underground pipework;

— the maximum allowable pressure for pipework shall be less than or equal to 25 bar;

— pipes shall be suitable for transport and storage at − 40 °C and 65 °C.

NOTE Vacuum conditions on the pipework arising from butane at low temperature or evacuation of the

pipework can expose the pipework to a vacuum of 50 mbar absolute. The minimum pressure to which pipework is

normally exposed is 0 bar.

4.3 Protection against hazards

4.3.1 Protection against mechanical damage

Pipework shall be protected against mechanical damage. For protection of underground pipework,

see 6.6.1.5.

4.3.2 Resistance to corrosive substances and atmospheres

All pipework and fittings, including supports, shall be protected from corrosion according to the

environment and operating conditions they will be subjected to during their service life.

NOTE Stainless steel pipework and fittings can be subject to chloride induced stress cracking, e.g. coastal areas

or other areas where salt laden atmospheres can occur.

4.3.3 Protection against condensation

For vapour pressure pipework, precautions shall be taken to avoid problems occurring in the pipe and

downstream equipment due to LPG vapour condensing. Figure 1 indicates the pressure temperature

relationship for various mixtures of propane and butane.

NOTE 1 Where the stored LPG liquid temperature is higher than the temperature of the downstream pipework,

the LPG can condense to a liquid. This is known as the dew point.

NOTE 2 In Figure 1, where the LPG is exposed to a pressure above the curve, the LPG vapour will condense.

In order to prevent condensation of LPG between the pressure vessel and the first stage pressure

regulator, the pipework shall drain back to the pressure vessel. Alternatively, trace heating of the

pipework shall be considered. If this is not possible, a suitably located vapour-liquid separator (knockout

pot) may be installed in the line to allow condensation to collect and subsequently boil off without causing

problems.

Literature Reference: Buecker,D. and Wagner, W. “Reference equations of state for thermodynamic properties of

fluid phase n-Butane and Isobutane” J. Phys. Chem. Ref. Data, 35(2):929-1019, 2006

Key

X Temperature in °C

Y Pressure in bar

100 % Propane

80 % Propane 20 % Butane

50 % Propane 50 % Butane

20 % Propane 80 % Butane

100 % Butane

Figure 1 — Dew point graph

5 Materials

5.1 General

5.1.1 All materials in contact with LPG shall be physically and chemically compatible with LPG under

all operating conditions for which the pipework is designed.

5.1.2 Materials for pipework shall be selected to give adequate strength in service. Consideration shall

also be given to other modes of failure such as atmospheric corrosion, brass dezincification, stress

corrosion, impact or material failure.

Electrolytic corrosion of dissimilar metals at joints shall be prevented by the selection of compatible

materials.

Materials and components shall comply with one or more of the standards listed in Table 3, Table 4,

Table 5 and Table 6.

Materials and components can be reused where they comply with the following requirements:

— are suitable for the proposed service in light of the history of the material or component, and;

— are inspected since the previous use to reveal any defect that could impair safety, strength or

pressure tightness.

Flexible hoses shall be in accordance with EN ISO 10380 (for corrugated metal hoses) and EN 1762 (for

rubber hoses).

5.2 Accessories

5.2.1 General

Accessories shall be capable of withstanding the service conditions for which the system is designed.

5.2.2 Gaskets and ring joints

Gasket and ring joint materials shall be compatible with LPG over the range of operating conditions;

see EN 549.

5.2.3 Valves and fittings

5.2.3.1 Ball valves, globe valves, and non-return valves shall be pressure tested to the relevant

requirements of EN 12266-1 and EN 12266-2 or EN 13175, where appropriate.

5.2.2.2 All isolation valves (except those for instrumentation) shall have the means for indicating the

settings of the valve e.g. closed, open.

5.2.3.3 Shut-off valves greater than DN 25, excluding pressure vessel valves, in liquid service pipework

should preferably be ball valves in accordance with EN ISO 17292 and fire safe in accordance with

EN ISO 10497.

5.2.3.4 Except where proprietary components are being installed, all liquid connections larger than

DN 50 and vapour connections larger than shall DN 80 shall be flanged. For road tankers, connections up

to DN 80 may be threaded.

5.2.3.5 Compression fittings shall suit the material, size of the pipe and the maximum working

pressure of the system.

5.2.3.6 Bolts, screws, studs and nuts for flanges shall be correctly sized and compatible with the

material and class of the flange design, e.g. see EN 1092-1.

5.3 Lubricants, sealants and adhesives

Where used on threads and seals, lubricants, sealants, and adhesives shall be compatible with LPG and

not interfere with the operation of the valves and fittings. Sealants shall comply with EN 751-1, EN 751-2

or EN 751-3.

6 Design

6.1 General

6.1.1 For guidance on pipe sizing for liquid pipework see Annex A.

6.1.2 For guidance on pipe sizing for vapour pipework see Annex B.

6.1.3 Where stored and handled as individual grades or products (e.g. propane, butane), storage and

handling systems shall be totally segregated or physically separated using valve interlocks, etc. Where

product mixes are handled, components shall be designed for the most onerous case e.g. propane design

pressure and minimum design temperature, relief system capacity, ability to withstand vacuum

conditions, etc.

6.2 LPG pipework installation technical documentation

The designer shall ensure that technical documentation contains the following information (with parts

lists where appropriate):

a) the location and design of supports;

b) the location and design of wall and floor transits, points where pipework crosses or runs parallel

with other systems, etc.;

c) the location of pumps, compressors, meters and other equipment, stating the make, type and

connection sizes;

d) types of joints, gaskets, bolts, etc.;

e) the pipe diameters, maximum allowable pressure, design pressure, materials and types of coatings;

f) the location and sizes of valved points for testing and purging;

g) maximum flow; and

h) cathodic protection system, where fitted.

6.3 Measuring instruments

LPG installations shall incorporate such measuring instruments and test points as are necessary for their

safe operation.

6.4 Over Pressure protection

6.4.1 For sections of pipework where liquid can be trapped in between isolation valves, suitable

pressure relief protection shall be provided (e.g. by a hydrostatic relief valve discharging to a safe

location).

6.4.2 Where hydrostatic relief valves are used, they shall be set to discharge above the maximum

working pressure of the system but not greater than the maximum allowable pressure of the pipework.

6.4.3 The positioning and/or discharge point of hydrostatic relief valves shall be located so as not to

impinge on personnel, pressure vessels or equipment in the event of a release.

6.4.4 To reduce the risk of blockage, hydrostatic relief valve inlet connections shall not be installed in

the bottom quarter of horizontal pipe.

6.4.5 Hydrostatic relief valves shall have caps fitted to prevent the entry of debris and water without

affecting the operation of the valve.

6.4.6 When hydrostatic relief valves are installed in enclosed spaces, especially where personnel are

present, suitably sized discharge pipework, which will not restrict the capacity of the hydrostatic relief

valve, shall be fitted and piped to the outside, discharging at high level or, where practical, piped back to

the storage pressure vessel. A sign shall be fitted adjacent to the discharge pipework outlet. Where the

discharge is not to atmosphere, the effect of the backpressure on the outlet setting of the hydrostatic relief

valve shall be considered.

Hydrostatic relief valve piping connections shall not impose strain on the relief valve.

Where self-closing isolating devices are used for hydrostatic relief valve connections to pipework, they

shall only close when the hydrostatic relief valve is removed from the device.

6.5 Above-ground pipework

6.5.1 General

The following provisions for spacing are recommended.

6.5.2 Clearance above ground

6.5.2.1 Pipework shall not be laid directly on the ground.

6.5.2.2 Pipework shall have at least a 50 mm clearance from the finished ground level.

6.5.2.3 Pipework shall be suitably located so as not to cause a trip hazard.

6.5.2.4 Pipework shall be suitably protected from vehicular and other mechanical damage.

6.5.2.5 Pipework shall be designed to allow for easy access for inspection and maintenance.

6.5.3 Pipework separation distances from above-ground electrical services

The separation distance shall be at least 250 mm between any pipework and any above-ground:

— metal electrical conduit;

— electrical wire or cable; or

— electrical earthing electrode.

NOTE This requirement does not apply to equipotential bonding of the pipework or heat tracing of the

pipework.

6.5.4 Ventilation of concealed piping

6.5.4.1 Pipes through ducts or sleeves

Ducts or sleeves shall be ventilated at either one or both ends. Where ventilation is at one end only, it

shall be the lowest end of a non-horizontal duct or sleeve.

Ventilation openings shall terminate in a safe location.

All openings shall be the full cross-sectional area of the duct or sleeve less the cross sectional area of the

pipe.

No other pipes or cables shall run through ducts or sleeves containing LPG pipes.

6.5.4.2 Pipes through walls

All pipes that pass through walls shall be ducted or sleeved, with the duct or sleeve in compliance with

6.5.4.1.

6.5.4.3 Pipes through voids

Pipes shall not be installed directly in an unventilated void unless one of the following options is used:

— the pipes shall be sleeved continuously through the unventilated void, with the sleeve ventilated at

one or both ends into a safe place; or

— the unventilated void shall be filled with a crushed inert infill to reduce to a minimum the volume of

any gas which may accumulate. The infill material should be of a dry, chemically neutral and fire

resistant nature, e.g. crushed slate chippings or dry washed sand.

6.5.5 Pipe supports

6.5.5.1 Pipe supports shall be capable of supporting the pipework and its contents.

6.5.5.2 Pipe supports shall not interfere with the integrity of the supporting structure.

6.5.5.3 The spacing of pipe supports shall be suitable for the material type, diameter, weight and

thickness. Table 1 provides indicative spacing for pipework. Pipe support spacing's for flexible pipes shall

be obtained from the manufacturer.

6.5.5.4 Pipe supports shall be capable of maintaining the pipework in the intended position and

controlling movement of the piping system.

6.5.5.5 Pipe support material shall be compatible with the pipework material or insulated from the

pipework to prevent electrolytic corrosion.

6.5.5.6 Vibration, surge pressures and valve operating torque shall be considered in the design of

pipework and supports incorporating mechanical equipment such as pumps and valves.

Table 1 — Spacing of pipe supports for rigid pipework

Nominal diameter (DN) Support spacing

(mm) (m)

Steel pipe Copper pipe Stainless steel

8 2 1 1

10 2 1,5 1,5

15 2 1,5 1,5

18 - 1,5 1,5

20 2,5 1,5 1,5

25 2,5 2 2

32 3 2,5 2,5

40 3 2,5 2,5

50 3 3 3

65 3 3 3

80 4 4 4

100 5 4 4

125 7 4 4

150 8 4 4

200 9 4 4

6.6 Underground pipes

6.6.1 General

6.6.1.1 Whenever there are no specific provisions in national regulations, the following provisions

for spacing are recommended.

6.6.1.2 Pipes shall be located at least 1 m away from the outside of any building except at the point

of entry or where there are alternative national requirements.

6.6.1.3 Pipe routes shall be chosen to minimize the length of pipe required.

6.6.1.4 Buried metallic pipes shall have active or passive means of protection (e.g. cathodic

protection, protective coating or wrapping, etc.) or shall be inside a buried outer pipe or conduit which

terminates above ground level or in a suitable inspection pit. Provision shall be made to facilitate periodic

leak testing.

6.6.1.5 Underground pipes shall have a depth of cover of at least 600 mm or be protected in such a

way as to protect the pipe from physical damage.

6.6.1.6 To avoid undue stress, buried pipework shall be bedded on a firm compacted surface along

its entire length.

NOTE To accomplish this, it is possible to trim the trench base to ‘let in’ the fittings, collars or flanges to ensure

the whole length of pipe is evenly supported.

6.6.1.7 The bedding material should not be of the type that can be washed away by the action of

water unless the trench is lined with a suitable membrane which will allow any water to drain but not

allow the passage of the backfill material.

6.6.1.8 Bedding material and backfill shall be of a type which will not have an adverse effect on the

pipe or pipe coating. The bedding material, within 75 mm of the pipe, shall be free of stones or other

materials, which could damage the pipe or pipe coating or as required by the pipe manufacturer.

6.6.1.9 Identification warning tape shall be placed at least 150 mm above the top of the pipe.

6.6.1.10 Bedding material, backfill material and installation procedures for pipework using composite

pipes, shall comply with the pipe manufacturer's instructions.

6.6.2 Underground pipe separation distances

6.6.2.1 The separation distances horizontal and/or vertical in Table 2 shall be applied for

underground LPG pipes and underground services.

6.6.2.2 Any underground pipes crossing any other service shall cross at an angle of not less than 45°.

Table 2 — Separation distances for underground pipes

Service type Separation distance –

(mm)

a

non-ducted electrical supply cable less than 1 000 V AC 300

electrical earthing electrode 500

communications cable 300

pipework carrying oxygen 500

pipework carrying toxic or corrosive substances 1 500

pipework carrying steam or hot water above ambient 300

temperature

any other service pipework 300

a

For electrical supply cables greater than 1 000 V AC specialist advice should be sought.

6.7 Pipework loading

6.7.1 All pipework shall have sufficient flexibility to prevent:

— excessive stress in the piping material and attached equipment caused by thermal expansion and

contraction;

— excessive bending or loading at joints; and

— movements at points of connection to equipment, at anchorage points or guide points.

NOTE This can be achieved by the use of bends, loops, etc. formed in the piping system.

6.7.2 Where flexible connections are used to allow for unavoidable pipework movement, vibration or

misalignment, their lengths should be as short as reasonably practicable and, where applicable, maintain

electrical continuity. Their orientation and length should ensure the movement does not put them into

tension or impose torsional stresses

6.8 Equipotential bonding

6.8.1 External pipework carrying liquid or vapour should have electrical continuity with the storage

vessel(s), except where cathodic protection (CP) is fitted as a precaution against static electricity. The use

of bonding straps is not normally required for flanged pipework.

6.8.2 Where underground or mounded pressure vessels are equipped with a cathodic protection

system, the cathodic protection system shall be electrically isolated from the pipework.

6.8.3 The design of equipotential bonding of pipework and other equipment shall be carried out by

competent persons.

7 Corrosion protection and identification of above-ground pipework

7.1 Corrosion protection

7.1.1 Pipework shall be protected so as to prevent external corrosion, arising from atmospheric

exposure, by the application of a protective coating system.

7.1.2 The protection system applied shall take into account:

— the local operating environment;

— the periods between periodic inspections/maintenance; and

— any external fire protection coatings or other coating.

7.1.3 Protection shall be applied in accordance with the coating manufacturer's instructions.

7.1.4 Details of the actual system used, the expected life and coating maintenance recommendations

shall be included in the operating instructions.

7.2 Colour coding

7.2.1 LPG pipework shall be clearly identified or colour coded.

7.2.2 Flow direction shall be marked where necessary.

7.3 Reflectivity

Where thermal gain from direct sunlight may cause an issue with liquid, pipework shall have a highly

reflective colour.

Table 3 — Criteria for steel pipe (operating limit ≤ 25 bar)

Acceptable pipe Acceptable fittings Acceptable welded

joints

Pipe Limiting Fitting Limiting conditions Method Limiting

conditions conditions

EN 10216-1, External Screwed Shall not to be used Fillet weld Where

EN 10216-2, corrosion flange, carbon for joining pipe in welding is

EN 10216-3 and protection steel in lengths unless other accordanc being

EN 10216-4 and required. accordance joining methods are e with carried out,

EN 10217-1, Not with impracticable. EN 15001- the welder

EN 10217-2, permitted EN 1092-1. Flanges forming a 1. shall be

EN 10217-3, for Taper joint shall be of the approved in

EN 10217-4 and undergroun external and same size and face accordance

EN 10217-6 as d service taper internal type. with

appropriate. unless threads in External corrosion EN ISO 960

EN ISO 3183 wrapped accordance protection required. 6-1.

ASME B31.3 with a with Only above ground. External

ASME B31.4 protective EN 10226-1 Not suitable for use corrosion

covering, or EN 10226- with schedule 40 protection

painted or 2. pipe. required.

sheathed or, Steel butt- External corrosion Butt weld

where welded pipe protection required. in

buried, can

fittings shall accordanc

be fitted

be in e with

with

accordance EN 15001-

cathodic

with 1.

protection

EN 10253-2.

in

Socket- External corrosion Fillet weld

accordance

welded protection required. in

with

fittings such accordanc

EN 12007-1

as tee, bend, e with

and reducer and EN 15001-

EN 12007-3.

cap shall be 1.

Not

welded in

permitted

accordance

for

with

undergroun

EN 10253-2.

d service

Welded flange Shall not to be used Slip-on

beneath a

carbon steel for joining pipe type

building.

or steel alloy lengths unless other flanges and

shall be in joining methods are other type

accordance impracticable. flanges

with Flanges forming a shall be

EN 1092-1 joint shall be of the fillet

and EN 1515- same size and face welded in

1. type. accordanc

External corrosion e with

protection required. EN 15001-

1.

Table 4 — Criteria for stainless steel pipe (operating limit ≤ 25 bar)

Acceptable pipe Acceptable fittings Acceptable welded joints

Pipe Limiting Fitting Limiting Method Limiting

conditions conditions conditions

Stainless Shall not be Suitable Butt weld in Where

Steel permitted welded accordance welding is

Welded pipe for fittings with being carried

in undergrou should be EN 15001-1. out, the

accordance nd service used in welder shall

with beneath a accordance be approved

EN 10216-5. building. with in accordance

Seamless Not EN 10253-2. with

pipe in permitted EN ISO 9606-

Welded Shall not be

accordance for 1.

flange in used for

with undergrou

accordance joining pipe

EN 10217-7. nd service

with lengths

unless

EN 1092-1. unless other

provided

joining

with methods are

protective impracticable.

covering in Flanges

accordance forming a

with

joint shall be

EN 12068.

of the same

size and face

type

Composite Shall not be Components Mechanical Joints shall be

stainless permitted that jointing using accessible for

steel flexible for use as a terminate components inspection

(Grade final with a NPT specified or and

EN 1.4404) connection thread, provided by maintenance.

pipe with or to an welding end the pipe Jointing shall

without appliance. and flanges in manufacturer be carried out

permeation accordance . by persons

barrier filler with certified by

coating and EN 1092-1 or the

with ASME B16.5. manufacturer

external PE- Component .

LD jacket. specified or

provided by

the pipe

manufacturer

.

Table 5 — Criteria for copper tube (operating limit ≤ 25 bar)

Acceptable pipe Acceptable fittings Acceptable welded joints

Pipe Limiting Fitting Limiting Method Limiting

conditions conditions conditions

Copper tube DN 6 Shall not be Copper alloy Not Compression Not permitted

−32 (outside permitted compression permitted in underground

diameter) in for fittings in ground

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...