SIST EN 13617-3:2021

(Main)Petrol filling stations - Part 3: Safety requirements for construction and performance of shear valves

Petrol filling stations - Part 3: Safety requirements for construction and performance of shear valves

This document specifies safety and environmental requirements for the construction and performance of shear valves to be fitted to metering pumps, dispensers, and/or satellite delivery systems installed at petrol filling stations and used to dispense liquid fuels and aqueous urea solution into the tanks of motor vehicles, boats and light aircraft and into portable containers at flow rates up to 200 l · min−1.

This document applies to fuels and their vapours of subdivision Group IIA according to EN ISO/IEC 80079-20-1 and also aqueous urea solution according to ISO 22241-1.

The requirements apply to shear valves at ambient temperatures from −20 °C to +40 °C with the possibility for an extended temperature range.

This document pays particular attention to mechanical and hydraulic characteristics.

This document does not apply to equipment dispensing compressed or liquefied gases.

Tankstellen - Teil 3: Sicherheitstechnische Anforderungen an Bau- und Arbeitsweise von Abscherventilen

Dieses Dokument legt die sicherheitstechnischen und Umweltanforderungen an den Bau und die Arbeitsweise von Abscherventilen an Zapfsäulen, druckversorgten Zapfsäulen und/oder Nebenzapfstellen fest, die an Tankstellen installiert werden für die Abgabe von flüssigen Kraftstoffen und wässriger Harnstofflösung in Tanks von Kraftfahrzeugen, Booten und Leichtflugzeugen sowie in tragbare Behälter bei Durchflussraten von bis zu 200 l · min−1.

Dieses Dokument gilt für Kraftstoffe der Unterbereichsgruppe IIA und deren Dämpfe nach EN ISO/IEC 80079-20-1 und auch für wässrige Harnstofflösung nach ISO 22241-1.

Die Anforderungen gelten für Abscherventile bei Umgebungstemperaturen zwischen −20 °C und +40 °C, wobei ein erweiterter Temperaturbereich möglich ist.

In diesem Dokument werden besonders die mechanischen und hydraulischen Eigenschaften berücksichtigt.

Dieses Dokument gilt nicht für Ausrüstung, die für die Abgabe von verflüssigten oder verdichteten Gasen vorgesehen ist.

Stations-service - Partie 3 : Exigences de sécurité relatives à la construction et aux performances des raccords de sécurité

Le présent document spécifie les exigences relatives à la construction et aux performances en matière de sécurité et de protection de l’environnement des vannes de sécurité à monter sur des distributeurs avec/sans pompe immergée et/ou systèmes de livraison satellites installés sur stations-service et utilisés pour distribuer des carburants liquides et une solution aqueuse d'urée dans les réservoirs de véhicules à moteur, de bateaux, d’avions légers et dans des réservoirs portables, à des débits pouvant atteindre 200 l · min-1.

Le présent document s’applique aux carburants et leurs vapeurs du Groupe de subdivision IIA conformément à l’EN ISO/IEC 80079-20-1, mais également à la solution aqueuse d'urée conformément à l’ISO 22241-1.

Les exigences s’appliquent aux raccords cassants à des températures de –20 °C à +40 °C avec la possibilité d’étendre la plage de température.

Le présent document accorde une importance particulière aux caractéristiques mécaniques et hydrauliques.

Le présent document ne s’applique pas à l’équipement distribuant des gaz comprimés ou liquéfiés.

Bencinski servisi - 3. del: Varnostne zahteve za izdelavo in lastnosti varovalnih ventilov

General Information

- Status

- Published

- Public Enquiry End Date

- 03-Dec-2018

- Publication Date

- 15-Nov-2021

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Oct-2021

- Due Date

- 06-Dec-2021

- Completion Date

- 16-Nov-2021

Relations

- Effective Date

- 01-Dec-2021

Overview

EN 13617-3:2021 - Petrol filling stations - Part 3 - specifies safety and environmental requirements for the construction and performance of shear valves fitted to metering pumps, dispensers and satellite delivery systems at petrol filling stations. It covers shear valves used to dispense liquid fuels and aqueous urea solution (AUS 32) into vehicle, boat and light aircraft tanks and portable containers at flow rates up to 200 l·min−1. The standard focuses on mechanical and hydraulic characteristics, explosion protection and testing for ambient temperatures from −20 °C to +40 °C (with provision for extended ranges), and excludes equipment for compressed or liquefied gases.

Key Topics and Requirements

- Scope & fluids: Applies to fuels and vapours of subdivision Group IIA (per EN ISO/IEC 80079-20-1) and to aqueous urea solution (ISO 22241-1).

- Explosion protection: Shear valves must meet explosion protection categories - Category 2G, EPL Gb for the shear valve and Category 1G, EPL Ga for any vapour path - and comply with EN ISO 80079-36 and EN IEC 60079-0 requirements.

- Construction requirements:

- Materials must be chemically and dimensionally stable and fuel-resistant.

- Corrosion-resistant materials or protective coatings required.

- Design must ensure separation (weak section) and complete decoupling of inlet/outlet after fracture.

- Thermal detectors and mechanical links must reliably close the main valve when triggered.

- Mechanical & hydraulic performance: Emphasis on valve closure reliability, mounting strength, pressure relief, and compatibility with liquid/vapour systems.

- Testing:

- Type tests, production acceptance tests and routine tests are defined.

- New or clarified tests include fire resistance tests and differentiated testing for vapour shear valves (tests B.16, B.17).

- Annex B lists detailed test methods (pressure, main valve closure, thermal link, liquid compatibility).

- Information & marking: Requirements for installation, user manuals and marking are specified to ensure safe operation and maintenance.

- Environmental aspects: Considered in design and documentation.

Applications and Users

EN 13617-3:2021 is intended for:

- Manufacturers of shear valves, dispensers, metering pumps and satellite delivery systems

- Filling-station equipment designers and system integrators

- ** Testing and certification laboratories** conducting type and routine tests

- Operators and maintenance personnel at petrol filling stations

- Regulators and procurement teams specifying compliant safety components

Practical benefits include improved safety during breakage or fire events, predictable hydraulic behaviour up to 200 l·min−1, and harmonised acceptance testing for market access in CEN member countries.

Related Standards

- EN 13617-1:2021 (metering pumps & dispensers)

- EN 1127-1:2019 (explosion prevention)

- EN IEC 60079-0:2018 / EN ISO 80079-36:2016 (explosive atmospheres)

- EN ISO/IEC 80079-20-1, ISO 22241-1 (AUS 32 quality)

Keywords: EN 13617-3:2021, shear valves, petrol filling stations, safety requirements, construction, performance, metering pumps, dispensers, aqueous urea solution, Group IIA.

Frequently Asked Questions

SIST EN 13617-3:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Petrol filling stations - Part 3: Safety requirements for construction and performance of shear valves". This standard covers: This document specifies safety and environmental requirements for the construction and performance of shear valves to be fitted to metering pumps, dispensers, and/or satellite delivery systems installed at petrol filling stations and used to dispense liquid fuels and aqueous urea solution into the tanks of motor vehicles, boats and light aircraft and into portable containers at flow rates up to 200 l · min−1. This document applies to fuels and their vapours of subdivision Group IIA according to EN ISO/IEC 80079-20-1 and also aqueous urea solution according to ISO 22241-1. The requirements apply to shear valves at ambient temperatures from −20 °C to +40 °C with the possibility for an extended temperature range. This document pays particular attention to mechanical and hydraulic characteristics. This document does not apply to equipment dispensing compressed or liquefied gases.

This document specifies safety and environmental requirements for the construction and performance of shear valves to be fitted to metering pumps, dispensers, and/or satellite delivery systems installed at petrol filling stations and used to dispense liquid fuels and aqueous urea solution into the tanks of motor vehicles, boats and light aircraft and into portable containers at flow rates up to 200 l · min−1. This document applies to fuels and their vapours of subdivision Group IIA according to EN ISO/IEC 80079-20-1 and also aqueous urea solution according to ISO 22241-1. The requirements apply to shear valves at ambient temperatures from −20 °C to +40 °C with the possibility for an extended temperature range. This document pays particular attention to mechanical and hydraulic characteristics. This document does not apply to equipment dispensing compressed or liquefied gases.

SIST EN 13617-3:2021 is classified under the following ICS (International Classification for Standards) categories: 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13617-3:2021 has the following relationships with other standards: It is inter standard links to SIST EN 13617-3:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13617-3:2021 is associated with the following European legislation: EU Directives/Regulations: 2014/34/EU; Standardization Mandates: M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13617-3:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2021

Nadomešča:

SIST EN 13617-3:2012

Bencinski servisi - 3. del: Varnostne zahteve za izdelavo in lastnosti varovalnih

ventilov

Petrol filling stations - Part 3: Safety requirements for construction and performance of

shear valves

Tankstellen - Teil 3: Sicherheitstechnische Anforderungen an Bau- und Arbeitsweise von

Abscherventilen

Stations-service - Partie 3 : Exigences de sécurité relatives à la construction et aux

performances des raccords de sécurité

Ta slovenski standard je istoveten z: EN 13617-3:2021

ICS:

75.200 Oprema za skladiščenje Petroleum products and

nafte, naftnih proizvodov in natural gas handling

zemeljskega plina equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13617-3

EUROPEAN STANDARD

NORME EUROPÉENNE

September 2021

EUROPÄISCHE NORM

ICS 75.200 Supersedes EN 13617-3:2012

English Version

Petrol filling stations - Part 3: Safety requirements for

construction and performance of shear valves

Stations-service - Partie 3 : Exigences de sécurité Tankstellen - Teil 3: Sicherheitstechnische

relatives à la construction et aux performances des Anforderungen an Bau- und Arbeitsweise von

raccords de sécurité Abscherventilen

This European Standard was approved by CEN on 14 June 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13617-3:2021 E

worldwide for CEN national Members.

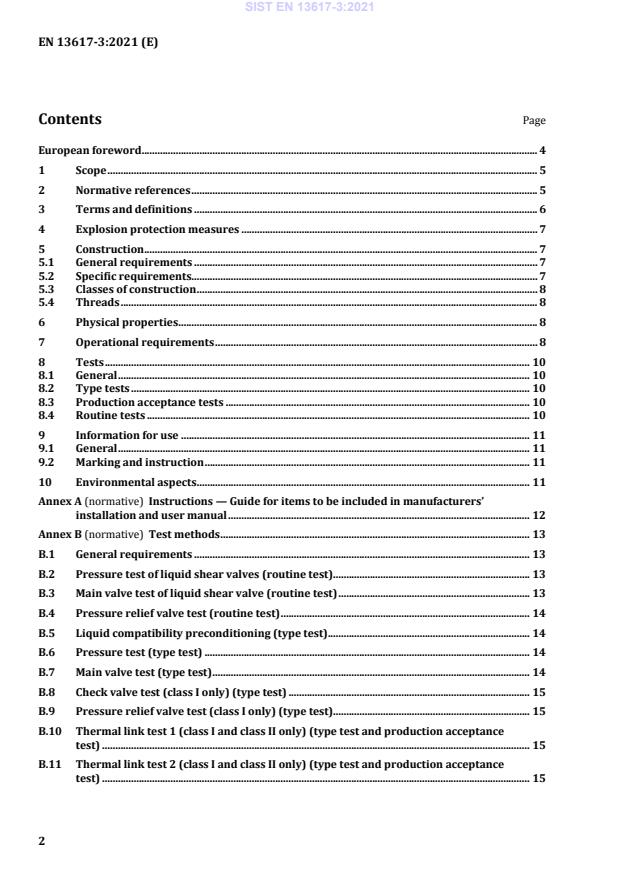

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Explosion protection measures . 7

5 Construction . 7

5.1 General requirements . 7

5.2 Specific requirements . 7

5.3 Classes of construction . 8

5.4 Threads . 8

6 Physical properties . 8

7 Operational requirements . 8

8 Tests . 10

8.1 General . 10

8.2 Type tests . 10

8.3 Production acceptance tests . 10

8.4 Routine tests . 10

9 Information for use . 11

9.1 General . 11

9.2 Marking and instruction . 11

10 Environmental aspects . 11

Annex A (normative) Instructions — Guide for items to be included in manufacturers’

installation and user manual . 12

Annex B (normative) Test methods . 13

B.1 General requirements . 13

B.2 Pressure test of liquid shear valves (routine test) . 13

B.3 Main valve test of liquid shear valve (routine test) . 13

B.4 Pressure relief valve test (routine test) . 14

B.5 Liquid compatibility preconditioning (type test) . 14

B.6 Pressure test (type test) . 14

B.7 Main valve test (type test) . 14

B.8 Check valve test (class I only) (type test) . 15

B.9 Pressure relief valve test (class I only) (type test). 15

B.10 Thermal link test 1 (class I and class II only) (type test and production acceptance

test) . 15

B.11 Thermal link test 2 (class I and class II only) (type test and production acceptance

test) . 15

B.12 Main valve closure test of liquid shear valves (type test and production acceptance

test) . 16

B.13 Main valve closure test of vapour shear valves (type test and production acceptance

test) . 16

B.14 Fire resistance test 1 (type test) . 16

B.15 Fire resistance test 2 (type test) . 17

B.16 Pressure test of vapour shear valves (routine test) . 17

B.17 Main valve test of vapour shear valve (routine test) . 17

Annex C (informative) Environmental aspects . 18

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2014/34/EU aimed to be covered . 20

Bibliography . 22

European foreword

This document (EN 13617-3:2021) has been prepared by Technical Committee CEN/TC 393 “Equipment

for storage tanks and for filling stations”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by March 2022, and conflicting national standards shall be

withdrawn at the latest by March 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13617-3:2012.

In comparison with the 2012 edition, the following significant changes were made:

— shear valves for aqueous urea solution added;

— testing for vapour shear valves further differentiated from testing for fuel shear valves. Tests B.16,

and B.17 are introduced;

— fire resistance test B.14 and B15 introduced and pass/fail criteria defined in Table 3;

— the liquid compatibility preconditioning fluid for shear valves is defined in EN 13617-1.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive 2014/34/EU.

For relationship with EU Directive, see informative Annex ZA, which is an integral part of this document.

EN 13617 consists of four parts:

— Part 1: Safety requirements for construction and performance of metering pumps, dispensers and

remote pumping units;

— Part 2: Safety requirements for construction and performance of safe breaks for use on metering pumps

and dispensers;

— Part 3: Safety requirements for construction and performance of shear valves;

— Part 4: Safety requirements for construction and performance of swivels for use on metering pumps and

dispensers.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document specifies safety and environmental requirements for the construction and performance

of shear valves to be fitted to metering pumps, dispensers, and/or satellite delivery systems installed at

petrol filling stations and used to dispense liquid fuels and aqueous urea solution into the tanks of motor

−1

.

vehicles, boats and light aircraft and into portable containers at flow rates up to 200 l · min

This document applies to fuels and their vapours of subdivision Group IIA according to

EN ISO/IEC 80079-20-1 and also aqueous urea solution according to ISO 22241-1.

The requirements apply to shear valves at ambient temperatures from −20 °C to +40 °C with the

possibility for an extended temperature range.

This document pays particular attention to mechanical and hydraulic characteristics.

This document does not apply to equipment dispensing compressed or liquefied gases.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1127-1:2019, Explosive atmospheres - Explosion prevention and protection - Part 1: Basic concepts and

methodology

EN 13617-1:2021, Petrol filling stations - Part 1: Safety requirements for construction and performance of

metering pumps, dispensers and remote pumping units

EN IEC 60079-0:2018, Explosive atmospheres - Part 0: Equipment - General requirements

(IEC 60079-0:2017)

EN ISO 80079-36:2016, Explosive atmospheres - Part 36: Non-electrical equipment for explosive

atmospheres - Basic method and requirements (ISO 80079-36:2016)

ISO 7-1:1994, Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions,

tolerances and designation

ISO 11925-3:1997, Reaction to fire tests — Ignitability of building products subjected to direct impingement

of flame — Part 3: Multi-source test

ISO 22241-1:2019, Diesel engines — NOx reduction agent AUS 32 — Part 1: Quality requirements

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 13617-1:2021 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

shear valve

component whose function is to prevent continuous liquid flow or vapour release in the event of impact

or fire

3.2

main valve

normally open valve on the inlet side, closing when the shear valve operates

3.3

main valve

normally open valve on the outlet side, closing when the shear valve operates

3.4

pressure relief valve

valve to allow liquid to return to the pipework below the dispenser if pressure in the dispenser increases

beyond a defined level

3.5

separation zone

part of the shear valve designed to be the first section to fracture when stressed

3.6

mechanical link

device to activate the closing mechanism automatically to stop the flow of liquid when the shear valve

breaks

3.7

thermal detector

device to activate the closing mechanism automatically to stop the flow of liquid when the temperature

in the vicinity of the shear valve exceeds the operating temperature

3.8

test plug

device to allow pressure testing of associated pipework

3.9

mounting point

rigid attachment facility on the inlet and outlet sections of the shear valve

4 Explosion protection measures

4.1 Explosion protection measures shall be taken in accordance with EN 1127-1:2019 and

EN 13617-1:2021, Annex B.

4.2 The shear valve shall be explosion protected and shall be Category 2G, Group II, EPL Gb in

accordance with EN ISO 80079-36:2016. When a shear valve has a vapour path, the vapour path shall be

Category 1G, Group II, EPL Ga in accordance with EN ISO 80079-36:2016. The shear valve shall fulfil the

requirements for temperature Class T3 and Group IIA in accordance with EN IEC 60079-0:2018 or

EN ISO 80079-36:2016.

5 Construction

5.1 General requirements

5.1.1 All electrical and non-electrical equipment and components, intended for use in potentially

explosive atmospheres, shall be designed and constructed according to good engineering practice and in

conformity with the required categories/EPLs for Group II equipment to ensure avoidance of any ignition

source. To classify the category/EPL of the equipment it shall be subjected to an ignition hazard

assessment in accordance with EN ISO 80079-36:2016, 5.2.

5.1.2 All materials used in the construction shall be chemically and dimensionally stable under known

service conditions. Materials likely to come into contact with fuels in both liquid and vapour phases shall

be resistant to attack by these fuels. Conformity shall be demonstrated by testing in accordance with

Clause 8.

5.1.3 Light alloys when used shall conform to EN IEC 60079-0:2018, 8.3. If other specifications for

explosion protected equipment impose more stringent requirements then the more stringent

requirement shall apply.

5.1.4 All components shall be of corrosion resistant material or shall be provided with a corrosion

resistant protective coating.

5.1.5 Outside surfaces likely to be handled shall be free of sharp edges.

5.2 Specific requirements

5.2.1 Means shall be provided to connect the shear valve to input and output pipework. The means

selected shall not fail at forces less than the design shear force of the shear valve.

5.2.2 The shear valve shall be so designed that after fracture of the weak section, the input and output

sections shall be completely decoupled.

5.2.3 The shear valve shall not have a means to prevent the main valve from closing completely when

it is operated by the weak section or by the thermal detector.

5.2.4 The thermal detector shall be so constructed that when it operates the main valve closes.

5.2.5 Shear valves for liquids may include a manual means of closing the main valve (liquid) for

maintenance purposes.

5.2.6 Test plugs, where fitted to shear valves in liquid containment systems, shall be on the inlet side

of the main valve.

5.3 Classes of construction

Shear valves are classified in accordance with Table 1.

Table 1 — Classes of construction

Valve type Class

I II III

Main valve Yes Yes Yes

Thermal detector Yes Yes No

Check valve Yes No No

Pressure relief valve Yes No No

Class I and II for liquid pressure systems, and Class III for vapour systems only.

5.4 Threads

Input and output threads shall be in accordance with ISO 7-1:1994.

6 Physical properties

The physical properties of the shear valve shall conform to Table 2 when tested by the methods indicated.

Table 2 — Physical properties of shear valve

Physical property Requirement Test method

Liquid compatibility (preconditioning) Clause 5 B.5

Electrostatic properties EN ISO 80079-36:2016, 6.7 EN ISO 80079-36:2016

Fire resistance No catastrophic failure B.14

Characteristics body and/or internal components to Metallic enclosure —

prevent dangerous, mechanically generated, sparks requirements of

(resistance to sparking), including during separation EN IEC 60079-0:2018, 8.3

of inlet and outlet sections

7 Operational requirements

The shear valve shall conform to the operational requirements according to Table 3 and Table 4 when

tested by the methods indicated.

Table 3 — Operational requirements

Item Requirement Test

method

Housing of liquid No quantifiable leakage, as evidenced by bubbles, or permanent B.2

shear valves deformation visible to an eye with normal visual acuity.

Housing of vapour No quantifiable leakage, as evidenced by bubbles, or permanent B.16

shear valves deformation visible to an eye with normal visual acuity.

Main valve of No quantifiable leakage, as evidenced by bubbles, or permanent B.3

liquid shear valves deformation visible to an eye with normal visual acuity.

Main valve of No quantifiable leakage, as evidenced by bubbles, or permanent B.17

vapour shear deformation visible to an eye with normal visual acuity.

valves

Pressure relief There shall be a continuous leak through the relief valve. B.4

valve test

Housing B.6.5 No catastrophic damage B.6

B.6.7 No leakage

Main valve B.7.5 No catastrophic damage B.7

B.7.7 No leakage

Check valve No quantifiable leakage or permanent deformation visible to an eye B.8

(class I only) with normal visual acuity.

Pressure relief There shall be a continuous leak through the relief valve. B.9

valve (class I only)

Thermal link 1 Main valve shall remain open. B.10

(class I and class II

only)

Thermal link 2 Main valve shall be closed. B.11

(class I and class II

only)

Main valve closure Main valve shall be closed. There shall be no continuous leakage past B.12

main valve. Weak section shall have permitted separation of the inlet

(Shear valve for

and outlet sections at a bending moment of ≤ 880 Nm.

liquids)

Main valve closure Main valve shall be closed. There shall be no continuous leakage past B.13

main valve. Weak section shall have permitted separation of the inlet

(Shear valve for

and outlet sections at

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...