SIST EN 17735:2023

(Main)Commercial dishwashing machines - Hygiene requirements and testing

Commercial dishwashing machines - Hygiene requirements and testing

This document specifies hygiene requirements for the operation of commercial dishwashing machines (hereinafter referred to as dishwashing machines) and the tests to be performed on these machines. It specifies requirements for reaching an appropriate hygienic status of articles treated in the dishwashing machines. This document also includes guidelines for the hygienic and proper operation, care and maintenance of dishwashing machines. Furthermore, methods for testing hygienic operation are defined.

This document applies to dishwashing machines used in a professional environment for cleaning wash ware that is used in contact with food, such as plates, crockery, glassware, cutlery, reusable boxes and similar articles.

Dishwashing machines are used in professional kitchens, e.g. in restaurants, canteens and hospitals and in businesses such as bakeries, butcher's shops, etc.

This document does not apply to domestic dishwashing machines, washer disinfectors for the treatment of medical devices and machines for industrial use.

Gewerbliche Spülmaschinen - Hygieneanforderungen und Prüfung

Dieses Dokument legt Hygieneanforderungen an das Betreiben von gewerblichen Spülmaschinen (nachfolgend als Spülmaschinen bezeichnet) und an die Prüfungen, die an diesen Maschinen durchzuführen sind, fest. Es legt Anforderungen zum Erreichen eines angemessenen hygienischen Zustands des in Spülmaschinen behandelten Spülguts fest. Dieses Dokument enthält auch einen Leitfaden für den hygienischen und ordnungsgemäßen Betrieb, die Pflege und Wartung von Spülmaschinen. Darüber hinaus werden Verfahren zum Prüfen eines hygienischen Betriebs festgelegt.

Dieses Dokument ist anwendbar für Spülmaschinen, die in gewerblicher Umgebung zum Reinigen von Spülgut eingesetzt werden, das in Kontakt mit Lebensmitteln verwendet wird, wie z. B. Teller, Geschirr, Glaswaren, Besteck, Mehrwegbehälter und ähnliche Artikel.

Spülmaschinen werden in gewerblichen Küchen, wie z. B. in Restaurants, Kantinen, Krankenhäusern, und in Unternehmen, wie z. B. in Bäckereien und Fleischereien, verwendet.

Dieses Dokument ist nicht anwendbar für Spülmaschinen für den Hausgebrauch, nicht für Reinigungs- und Desinfektionsgeräte zur Aufbereitung von Medizinprodukten und nicht für Maschinen für den industriellen Gebrauch.

Machines à laver la vaisselle commerciales - Exigences liées à l'hygiène et essais

Le présent document spécifie les exigences en matière d’hygiène relatives au fonctionnement des machines à laver la vaisselle commerciales (ci-après dénommées machines à laver la vaisselle) et aux essais à réaliser sur ces machines. Il spécifie les exigences pour atteindre un état hygiénique approprié des articles traités dans les machines à laver la vaisselle. Le présent document inclut également des lignes directrices pour le fonctionnement hygiénique et adéquat, l’entretien et la maintenance des machines à laver la vaisselle. Des méthodes d’essai de fonctionnement hygiénique sont en outre définies.

Le présent document s’applique aux machines à laver la vaisselle utilisées dans un environnement professionnel, destinées à nettoyer les articles de vaisselle qui sont utilisés en contact avec les aliments, comme les assiettes, la vaisselle, la verrerie, les couverts, les boîtes réutilisables et les articles similaires.

Les machines à laver la vaisselle sont utilisées dans les cuisines professionnelles, par exemple dans les restaurants, les cantines et les hôpitaux, ainsi que dans les commerces, tels que les boulangeries, les boucheries, etc.

Le présent document ne s’applique pas aux lave-vaisselle domestiques, aux laveurs-désinfecteurs pour le traitement des dispositifs médicaux et aux machines à usage industriel.

Komercialni pomivalni stroji - Higienske zahteve in preskušanje

Ta dokument določa higienske zahteve v zvezi z delovanjem komercialnih pomivalnih strojev (v nadaljevanju: »pomivalni stroji«). Določa zahteve za higienske rezultate izdelkov, obdelanih v pomivalnem stroju. To vključuje tudi smernice za njihovo higiensko in pravilno delovanje ter nego in vzdrževanje. Opredeljene so tudi metode za preskušanje higienskega delovanja.

Pomivalni stroji se uporabljajo v profesionalnem okolju za čiščenje pribora, ki se uporablja v stiku z živili.

Ta dokument se uporablja za pomivalne stroje za čiščenje izdelkov, ki se uporabljajo v stiku z živili, kot so posoda, steklenina, jedilni pribor, škatle za večkratno uporabo in podobni izdelki.

Pomivalni stroji (glej točko 3.3) se na primer uporabljajo v kuhinjah restavracij, menz in bolnišnic ter v trgovskih podjetjih, kot so pekarne, mesnice itd.

Ta dokument se ne uporablja za gospodinjske pomivalne stroje, čistilno-dezinfekcijske naprave za obdelavo medicinskih pripomočkov in stroje za industrijsko uporabo (npr. stroje za čiščenje pladnjev za vzhajanje in povratnih steklenic, opremo drugih strojev, kot so mesoreznice, rezalniki, delilniki testa, gnetilniki ali mešalniki, ter vse druge vrste strojev, dele katerih bi bilo mogoče očistiti zunaj območja uporabe (WOP)).

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Nov-2021

- Publication Date

- 22-Jan-2023

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 04-Jan-2023

- Due Date

- 11-Mar-2023

- Completion Date

- 23-Jan-2023

Overview

EN 17735:2022 - published by CEN - defines hygiene requirements and testing for commercial dishwashing machines used in professional environments. The standard covers functional and process requirements to achieve an appropriate hygienic status of wash ware (plates, glassware, cutlery, reusable boxes, etc.), plus guidance for hygienic operation, care, maintenance and specific methods for testing hygienic performance. It applies to machines in restaurants, canteens, hospitals, bakeries and butcheries - not to domestic dishwashers, medical washer-disinfectors or industrial machines.

Key Topics

EN 17735:2022 addresses both technical and operational aspects related to food-contact hygiene for commercial dishwashing machines. Major topics include:

- Process requirements - parameters and operational conditions needed to reach hygienic washing results (e.g., programme cycles, contact time, temperature guidance).

- Technical requirements - construction materials and functional features that affect hygiene and cleanability.

- Treating agents - requirements and guidance for detergents and rinse aids used in professional dishwashing.

- Testing methods - defined test types and procedures including type tests and post-installation tests, with microbiological methods such as bioindicator reduction and aerobic colony counts.

- Test documentation - reporting, record sheets and sample numbers for microbiological testing.

- Annexes with practical guidance - onsite technical recommendations, planning and organization of dishwashing processes, maintenance and servicing, plus example record sheets and an alternative test method.

Applications and Who Uses It

EN 17735 is intended for stakeholders involved in food safety and commercial warewashing:

- Manufacturers and designers of commercial dishwashing machines (to design to hygienic requirements).

- Catering operators and facility managers (restaurants, canteens, hospitals) to ensure machine operation meets hygiene targets.

- Kitchen planners and installers (for proper installation and commissioning tests).

- Quality, safety and maintenance teams (for routine inspections, post-installation tests and logbooks).

- Regulatory bodies and auditors assessing compliance and hygienic performance.

- Third-party testing laboratories performing microbiological validation and type approval.

Related Standards

EN 17735 references and complements other standards, including:

- EN IEC 63136 - electric dishwashers for commercial use - performance test methods

- EN ISO 18593 - surface sampling methods (microbiology of the food chain)

- EN 10088-3 - stainless steels (material delivery conditions)

EN 17735:2022 is a practical resource to specify, test and document hygienic performance of commercial dishwashing machines - supporting food safety and operational reliability in professional kitchens.

Frequently Asked Questions

SIST EN 17735:2023 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Commercial dishwashing machines - Hygiene requirements and testing". This standard covers: This document specifies hygiene requirements for the operation of commercial dishwashing machines (hereinafter referred to as dishwashing machines) and the tests to be performed on these machines. It specifies requirements for reaching an appropriate hygienic status of articles treated in the dishwashing machines. This document also includes guidelines for the hygienic and proper operation, care and maintenance of dishwashing machines. Furthermore, methods for testing hygienic operation are defined. This document applies to dishwashing machines used in a professional environment for cleaning wash ware that is used in contact with food, such as plates, crockery, glassware, cutlery, reusable boxes and similar articles. Dishwashing machines are used in professional kitchens, e.g. in restaurants, canteens and hospitals and in businesses such as bakeries, butcher's shops, etc. This document does not apply to domestic dishwashing machines, washer disinfectors for the treatment of medical devices and machines for industrial use.

This document specifies hygiene requirements for the operation of commercial dishwashing machines (hereinafter referred to as dishwashing machines) and the tests to be performed on these machines. It specifies requirements for reaching an appropriate hygienic status of articles treated in the dishwashing machines. This document also includes guidelines for the hygienic and proper operation, care and maintenance of dishwashing machines. Furthermore, methods for testing hygienic operation are defined. This document applies to dishwashing machines used in a professional environment for cleaning wash ware that is used in contact with food, such as plates, crockery, glassware, cutlery, reusable boxes and similar articles. Dishwashing machines are used in professional kitchens, e.g. in restaurants, canteens and hospitals and in businesses such as bakeries, butcher's shops, etc. This document does not apply to domestic dishwashing machines, washer disinfectors for the treatment of medical devices and machines for industrial use.

SIST EN 17735:2023 is classified under the following ICS (International Classification for Standards) categories: 97.040.40 - Dishwashers. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17735:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2023

Komercialni pomivalni stroji - Higienske zahteve in preskušanje

Commercial dishwashing machines - Hygiene requirements and testing

Gewerbliche Spülmaschinen - Hygieneanforderungen und Prüfung

Machines à laver la vaisselle commerciales - Exigences liées à l'hygiène et essais

Ta slovenski standard je istoveten z: EN 17735:2022

ICS:

97.040.40 Pomivalni stroji Dishwashers

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17735

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2022

EUROPÄISCHE NORM

ICS 97.040.40

English Version

Commercial dishwashing machines - Hygiene

requirements and testing

Machines à laver la vaisselle commerciales - Exigences Gewerbliche Spülmaschinen - Hygieneanforderungen

liées à l'hygiène et essais und Prüfung

This European Standard was approved by CEN on 14 November 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17735:2022 E

worldwide for CEN national Members.

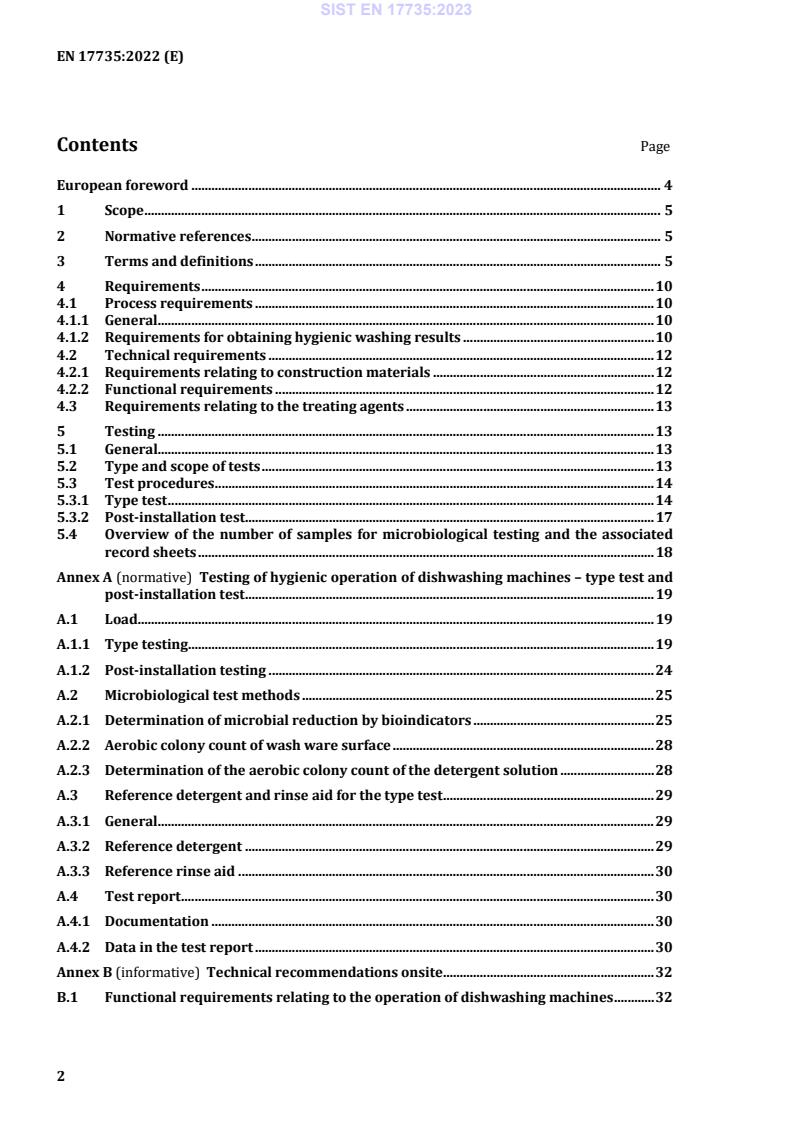

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Requirements . 10

4.1 Process requirements . 10

4.1.1 General. 10

4.1.2 Requirements for obtaining hygienic washing results . 10

4.2 Technical requirements . 12

4.2.1 Requirements relating to construction materials . 12

4.2.2 Functional requirements . 12

4.3 Requirements relating to the treating agents . 13

5 Testing . 13

5.1 General. 13

5.2 Type and scope of tests . 13

5.3 Test procedures . 14

5.3.1 Type test . 14

5.3.2 Post-installation test . 17

5.4 Overview of the number of samples for microbiological testing and the associated

record sheets . 18

Annex A (normative) Testing of hygienic operation of dishwashing machines – type test and

post-installation test . 19

A.1 Load. 19

A.1.1 Type testing . 19

A.1.2 Post-installation testing . 24

A.2 Microbiological test methods . 25

A.2.1 Determination of microbial reduction by bioindicators . 25

A.2.2 Aerobic colony count of wash ware surface . 28

A.2.3 Determination of the aerobic colony count of the detergent solution . 28

A.3 Reference detergent and rinse aid for the type test . 29

A.3.1 General. 29

A.3.2 Reference detergent . 29

A.3.3 Reference rinse aid . 30

A.4 Test report . 30

A.4.1 Documentation . 30

A.4.2 Data in the test report . 30

Annex B (informative) Technical recommendations onsite . 32

B.1 Functional requirements relating to the operation of dishwashing machines . 32

B.1.1 General . 32

B.1.2 Water quality. 32

B.1.3 Temperature . 33

B.1.4 Contact time . 33

B.1.5 Requirements relating to the treating agents . 34

B.2 Testing . 35

B.2.1 General . 35

B.2.2 Type of tests and scope of testing onsite . 35

B.2.3 Daily inspection . 36

B.2.4 Periodic inspection . 36

B.2.5 Overview of the number of samples for microbiological testing and the associated

record sheets . 36

Annex C (informative) Guideline for planning, organization of the dishwashing process,

maintenance and servicing of dishwashing machines and also relating to wash ware

................................................................................................................................................................... 37

C.1 Planning of dishwashing machine facilities . 37

C.2 Organization of the dishwashing process . 38

C.2.1 Operating personnel . 38

C.2.2 Receiving of used wash ware . 38

C.2.3 Pre-cleaning and loading of dishwashing machines . 38

C.2.4 Dishwashing machine programme cycle . 38

C.2.5 Drying and preparation and storage of the wash ware for further use . 39

C.3 Maintenance and servicing . 39

C.3.1 Operational and functional safety . 39

C.3.2 Operation logbook. 39

C.3.3 Cleaning of dishwashing machine . 39

C.4 Wash ware . 40

C.4.1 General . 40

C.4.2 Shape . 40

C.4.3 Surface characteristics . 40

C.4.4 Shape and surface of drinking glasses . 40

Annex D (informative) Examples record sheets . 41

D.1 Evaluation of the determination of the surface aerobic colony count . 41

D.2 Checking the aerobic microorganism count of the detergent solution . 41

D.3 Results of inspection with bioindicators . 42

Annex E (informative) Alternative Test Method . 45

Bibliography . 46

European foreword

This document (EN 17735:2022) has been prepared by Technical Committee CEN/TC 429 “Food hygiene

- Commercial warewashing machines - Hygiene requirements and testing”, the secretariat of which is

held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2023, and conflicting national standards shall be

withdrawn at the latest by June 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies hygiene requirements for the operation of commercial dishwashing machines

(hereinafter referred to as dishwashing machines) and the tests to be performed on these machines. It

specifies requirements for reaching an appropriate hygienic status of articles treated in the dishwashing

machines. This document also includes guidelines for the hygienic and proper operation, care and

maintenance of dishwashing machines. Furthermore, methods for testing hygienic operation are defined.

This document applies to dishwashing machines used in a professional environment for cleaning wash

ware that is used in contact with food, such as plates, crockery, glassware, cutlery, reusable boxes and

similar articles.

Dishwashing machines are used in professional kitchens, e.g. in restaurants, canteens and hospitals and

in businesses such as bakeries, butcher's shops, etc.

This document does not apply to domestic dishwashing machines, washer disinfectors for the treatment

of medical devices and machines for industrial use.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 10088-3, Stainless steels — Part 3: Technical delivery conditions for semi-finished products, bars, rods,

wire, sections and bright products of corrosion resisting steels for general purposes

EN IEC 63136, Electric dishwashers for commercial use — Test methods for measuring the performance

(IEC 63136)

EN ISO 18593, Microbiology of the food chain — Horizontal methods for surface sampling (ISO 18593)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

• ISO Online browsing platform: available at https://www.iso.org/obp

• IEC Electropedia: available at https://www.electropedia.org/

3.1

wash ware

articles and utensils that come into contact with foodstuffs and re-usable crates/containers that are

cleaned in a dishwashing machine

Note 1 to entry: Examples of wash ware are plates, crockery, cutlery, glasses, kitchen utensils, pots, containers,

crates and trays made of materials such as porcelain, plastic, glass, stainless steel and silver as well as coated

materials.

3.2

re-usable container

wash ware that is used to store and transport unpacked easily perishable foods used in a professional

environment

Note 1 to entry: The container can be a crate.

3.3

wash ware carrier

device for holding and/or supporting wash ware in the optimum orientation for cleaning

Note 1 to entry: The wash ware carrier can be e.g. racks, conveyor belts, cutlery trays.

3.4

dishwashing machine

appliance that is specially designed for use in professional environments and that cleans and rinses

plates, glasses, cutlery, and, in some cases, cooking utensils by chemical, mechanical and thermal means

3.4.1

batch dishwashing machine

dishwashing machine, in which the wash ware carrier loaded with wash ware stays in the same treatment

zone during the cleaning process

Note 1 to entry: A distinction is made between the following machine designs:

— dishwashing machine in which recirculated detergent solution is used for the detergent circulation process

and fresh water is used for the fresh water rinsing; the fresh water rinsing circuit is separate from the detergent

circulation circuit;

— dishwashing machine in which fresh water is used in each detergent circulation or rinsing process; the rinsing

circuit is not necessarily separate from the detergent circulation circuit.

Note 2 to entry: Batch-type dishwashing machines can be loaded with one or more racks at the same time.

3.4.2

conveyor dishwashing machine

dishwashing machine in which the wash ware carriers loaded with wash ware are automatically

conveyed through the machine during the cleaning process

Note 1 to entry: A distinction is made between the following machine designs:

— rack conveyor dishwashing machine; dishwashing machine in which racks loaded with wash ware are

conveyed through the machine automatically by a rack transporting system;

— flight conveyor dishwashing machine; dishwashing machine in which the wash ware is conveyed through the

machine automatically on an endless conveyor.

Note 2 to entry: Conveyor type dishwashing machines can include different treatment zones. Zones are for

example prewash zone, detergent circulation zone and fresh water rinsing zone.

3.5

treating agent

product used to clean and/or sanitize and/or rinse and/or descale wash ware in dishwashing machines

Note 1 to entry: Examples of treating agents are: detergent, rinse aid and granules.

3.5.1

detergent

chemical product used to remove soil from wash ware and which prevents re-contamination of the wash

ware by soil in the detergent solution

Note 1 to entry: A detergent can also improve the sanitisation process.

3.5.2

detergent solution

water mixed with detergent used for the detergent circulation process

3.5.3

rinse aid

chemical product added to the water in the final rinsing operation which decreases the surface tension

of the rinse aid solution

Note 1 to entry: Rinse aid can also improve drying and reduce water spots on wash ware.

3.5.4

rinse aid solution

fresh water mixed with rinse aid used for fresh water rinsing

3.5.5

soaking agent

special detergent used in pre-soaking tanks outside the dishwashing machine to remove e.g. stubborn

soil from wash ware

3.5.6

descaling agent

chemical product used to remove lime-scale, mixed lime, calcium or magnesium phosphate deposits in

the dishwashing machine and on the wash ware

3.5.7

granules

particles, e.g. of plastic, which are added to the detergent solution to assist the mechanical cleaning effect

3.6

fresh water

untreated or treated water which, from the microbiological point of view, is of drinking water quality,

contains no substances that are harmful to health, and is used to supply the dishwashing machine

3.7

treated water

water which has been subjected to a treatment process to modify its ingredients

Note 1 to entry: A distinction is made between processes for softening the water and processes for reducing the

overall salt content

3.7.1

softened water

water from which the hardness ions or minerals have been removed in a water softener by cation

exchange processes without any reduction in the overall salt content

Note 1 to entry: The precipitation of water-insoluble salts is prevented.

3.7.2

demineralized water

water from which the salt content has been removed

Note 1 to entry: For example, by ion exchange or reverse osmosis processes.

3.8

pre-cleaning

removing loose scraps and food residues from the wash ware and emptying hollow vessels

Note 1 to entry: Pre-cleaning is normally carried out by wiping off the residues into waste containers and - if

possible - by rinsing the wash ware with warm water (max. 35 °C). Pre-cleaning reduces the amount of soiling

entering the dishwashing machine.

3.9

detergent circulation

process during which the detergent solution, which is kept heated to the nominal temperature, is

circulated and sprayed onto the surface of the wash ware to remove the soil

3.10

auxiliary rinsing

circulation rinsing upstream to fresh water rinsing, in which no detergent is dosed

3.11

fresh water rinsing

process after detergent circulation, during which the wash ware is sprayed with rinse aid solution in

order to remove residues of detergent solution, dissolved and undissolved soil particles

3.12

drying

process during which the moisture drips or evaporates from the surface of the wash ware

3.13

cleaning process

process including at least one detergent circulation process and one fresh-water rinsing process

3.14

sanitisation

chemical and/or physical process that reduces microorganisms to a level which is neither harmful to

health nor impairs the quality of foodstuffs

3.15

re-contamination

soiling of the wash ware between the end of the cleaning process and the preparation for further use

which causes deterioration of the cleaning result

3.16

contact time

time during which the detergent solution impacts the wash ware

Note 1 to entry: For conveyor-type machines the contact time commences from the centre of first prewash nozzle

and extends until the centre of the first fresh water rinse nozzle. For batch type dishwashing machines, the contact

time commences upon start of the detergent circulation and lasts until the start of the fresh water rinsing.

3.17

operating time

period during which the dishwashing machine is operational

3.18

spray system

sum of all pipelines, jets and spray pipes required to circulate and spray detergent and rinse aid solutions

3.19

interior

all parts of the dishwashing machine which come into contact with detergent solution, rinse aid solution

or the wash ware during the cleaning process as intended

3.20

exterior

all parts of the dishwashing machine which do not come into contact during the cleaning process with

detergent solution and rinse aid solution (e.g. pedestals, adjustable feet, handles, casing) but which are

accessible from outside

3.21

bioindicator

standardised test object meant to be contaminated with a test soiling media and a test microorganism

and is used to check the sanitisation performance of dishwashing machines

Note 1 to entry: Examples are stainless steel bioindicators.

3.22

operating company

company who actually uses the appliance to clean wash ware within its own activity

Note 1 to entry: Examples are the operators of restaurants or canteens.

3.23

hygiene requirement

condition of the wash ware which is neither harmful to health nor impairs the quality of foodstuffs

3.24

programme

series of operations that are pre-defined within the dishwashing machine and that are declared by the

manufacturer as suitable for cleaning certain wash ware

Note 1 to entry: Programme time, conveyer speed and temperatures are examples of main parameters which

define a programme.

Note 2 to entry: If there is no end of programme indicator, the programme time is equal to the cycle time.

3.25

cycle

complete cleaning process, as defined by the programme selected, consisting of a series of operations

(detergent circulation, fresh water rinsing, drying, etc.) and including any operations that occur after the

completion of the programme

Note 1 to entry: Examples of operations that can occur after the completion of the programme are refilling of the

boiler, heating, operation of pumps and fans.

4 Requirements

4.1 Process requirements

4.1.1 General

Each cleaning process as well as the resultant cleanliness and the hygienic condition of the wash ware

are determined by the interaction of several main factors:

— temperature of all process steps;

— contact time;

— treating agents;

— mechanics;

— design and interior shape of the wash ware;

— rinsing;

— drying.

4.1.2 Requirements for obtaining hygienic washing results

General requirements are:

a) The wash ware shall be visually clean under practical conditions at the customers' side.

b) The wash ware shall be dry upon removal from the wash ware carriers, with remaining droplets on

the supporting points and residual moisture in the interior of hollow articles being tolerated.

c) The machine shall lead, under test conditions (see 5.3.1.2), to a level of hygienic performance in

accordance with the requirements as specified in Table 1.

d) Treating agents used in the cleaning process shall be removed from the wash ware to a level that is

not harmful to health.

NOTE For further information see Annex B and Annex C.

Table 1 — Hygienic Performance

Microbiological requirements

Type of test Test object Criteria Requirement Test method

Bioindicators in the Bacterial In the cutlery tray: according to

cutlery tray, on test reduction A.2.1

Minimum 7 out of

plates

8 bioindicators shall

show a minimum

reduction of 5-log

a

levels ;

None of the

bioindicators shall

show a reduction

a

below 4-log levels .

On test plates:

Minimum 90 % of

the

Type test

bioindicators shall

show a minimum

reduction of 5-log

a

levels ;

None of the

bioindicators shall

show a reduction

a

below 4-log levels .

Bioindicators in the Bacterial All 10 bioindicators according to

test rack reduction shall show a A.2.1

minimum reduction

a

of 5-log levels .

b 2

Wash ware except Aerobic colony Contact plate

≤5 cfu per 10 cm

of re-usable count method

Post-

crates/containers according to

installation

made of plastic A.2.2

test

b

Detergent solution Aerobic colony according to

<500 cfu /ml

count A.2.3

a

Log levels are expressed as logarithms (base 10).

b

cfu: colony forming units.

4.2 Technical requirements

4.2.1 Requirements relating to construction materials

In terms of hygiene, the materials used shall be serviceable, scratch-proof, ageing-resistant and

corrosion-resistant under normal conditions of use. These conditions are:

— in the interior: contact with food remnants, detergents, disinfectants and rinse aids, descaling agent

solutions and hot air;

— on the exterior: contact with water, cleaning agents, disinfectants and care products.

4.2.2 Functional requirements

4.2.2.1 General

It shall be possible to place the wash ware easily into the wash ware carriers and the wash ware carriers

in the intended optimum position.

4.2.2.2 Temperature control

To ensure that the nominal temperature range has been reached, an indication (e.g. lamp, display

information) is required. Alternatively, the machine controls shall be designed so that the machine can

start operating only when the nominal temperature range is reached. In the intended range of

temperatures, the measurement instruments shall have an uncertainty of measurements of ± 3 K. This

can be temperature in tanks, zones, boilers.

The operation of a dishwashing machine requires a constant supply of energy. It is principally not

permissible to switch off heating elements temporarily to avoid electrical peak loads (operation at partial

load) as this would involve a reduction of the temperature.

Additional recommendations are given in Annex B.

4.2.2.3 Programme

Dishwashing machines usually have several programmes with different contact times.

At least one programme shall ensure that the requirements specified in 4.1.2 are fulfilled and it shall be

in accordance to 5.3.1.2.2.

4.2.2.4 Dosing

Correct dosing of the detergent and rinse aid into the detergent and rinse aid solutions shall be ensured

at any time.

NOTE Automatic dosing equipment is a good possibility for providing a correct dosing.

4.2.2.5 Design

Effective distribution of detergent solution and rinse aid solution to the wash ware shall be ensured.

All parts which have to be removed for cleaning (e.g. strainers and parts of the spray system) shall be

removable without use of tools and easily accessible. The removal and the reposition of the parts shall be

done according to the manufacturer’s instruction.

NOTE Additional information is given in Annex C.

4.3 Requirements relating to the treating agents

If treating agents are used they shall be used according to the manufacturers' instructions.

NOTE Additional information is given in the Annex B.

5 Testing

5.1 General

The dishwashing machine manufacturer’s instructions regarding installation and use of the dishwashing

machines shall be followed, except if they stand in conflict to this document. In this case, this document

shall prevail.

The dishwashing machine shall be checked to ensure that it is operating correctly before measurements

are made. All tests shall be started with the appliance at the conditions in accordance with 5.3.1.2.

The test materials specified in A.1 shall be used.

The following tests, which differ in scope, shall be carried out to check the hygienic results of the articles

treated in the dishwashing machine:

Types of test:

— type test;

— post-installation test.

Additional test method is under consideration (see Annex E).

5.2 Type and scope of tests

The individual types of test and the scope of testing can be found in Table 2.

Table 2 — Types of test and scope of testing

Type of test Area of application Test Methods/checks

a

Type test (arranged by Machines in series production

— Temperature check

manufacturer)

— Check of dosing/concentration of

a

treating agents

— Tests with bioindicators

— Visual inspection of cleanliness and

dryness of the wash ware

a

Post-installation test Customised machines after

— Temperature check

(arranged by the installation under practical

— Check of dosing/concentration of

operating company) conditions

a

treating agents

— Incoming fresh water quality check

— Determination of the aerobic colony

count of the wash ware surface

— Microbiological testing of the

detergent solution

— Visual inspection of cleanliness and

dryness of the wash ware

a

According to information/specification given by the manufacturer of the machine and/or the treating

agents.

5.3 Test procedures

5.3.1 Type test

5.3.1.1 General

The purpose of the type test is to verify the hygienic results of the articles treated depending on the main

use of the dishwashing machine .

5.3.1.2 General conditions for measurements

5.3.1.2.1 Electricity supply

The dishwashing machine shall be supplied at the rated voltage ±2 % and this shall be maintained at the

appliance's terminal throughout the test.

The supply frequency shall be at the rated frequency ±1 %.

If the appliance has a rated voltage range and/or a frequency range, then the test voltage and/or

frequency shall be the nominal voltage and/or frequency of the country in which the dishwashing

machine is intended to be used.

5.3.1.2.2 Test programme

The programme to be tested shall be the one that cleans normally soiled wash ware (standard cleaning

programme).

The manufacturer shall declare the programme to be used for testing.

For dishwashing machines in the scope of EN IEC 63136, the programme for the test shall be the one used

for the EN IEC 63136 performance test.

5.3.1.2.3 Ambient conditions

The following ambient conditions shall be maintained throughout the measurements:

— ambient temperature of the room: (23 ± 2) °C;

— relative humidity: (55 ± 5) % RH.

5.3.1.2.4 Water supply

a) Water supply – Hardness

If the dishwashing machine is fitted with an integrated water softening unit, it shall be deactivated (set

to soft water supply). During testing, soft water shall have a total hardness of

(Ca2+ + Mg2+) < 0,54 mmol/l.

b) Water supply – Pressure

The flow pressure of the water supply shall be set to 240 kPa and shall be maintained within the range

±20 kPa. If it is not possible to maintain the pressure within this range, a flow rate of (15 ± 2) l/min shall

be maintained.

The method described below deals with a test method for commercial dishwashing machines used primarily

for washing plates and cutlery. As future projects it is planned to develop test methods for commercial

dishwashing machines used primarily for washing glasses or re-usable crates and containers.

5.3.1.2.5 Detergent

The reference detergent described in A.3 shall be used for the tests.

The concentration shall be (3 ± 0,3) g/l for the tests.

The amount of detergent shall be calculated by the given concentration and the measured water

consumption of the previous operation.

The detergent shall be added by hand directly into the wash chamber except for conveyor machines.

The detergent used during the tests shall all be from the same batch. The detergent shall be stored and

handled in accordance with the detergent manufacturer's specifications.

5.3.1.2.6 Rinse aid

The reference rinse aid described in A.3 shall be used for the tests.

The dosing of the rinse aid shall be done in accordance with the rinse aid manufacturer’s instructions.

The concentration of the rinse aid shall be set in accordance with the rinse aid manufacturer’s

instructions.

The rinse aid used during the tests shall all be from the same batch. The rinse aid shall be stored and

handled in accordance with the rinse aid manufacturer's specifications.

5.3.1.2.7 Load

The load is the relevant wash ware carrier, with the appropriate wash ware items (see A.1.1). The wash

ware carrier shall be filled in accordance with the manufacturer’s instructions.

5.3.1.3 Procedure for batch-type dishwashing machines

5.3.1.3.1 Conditioning of the machine

For the conditioning of the machine the load is the relevant load according to A.1.1.2 but without

bioindicators.

Switch on the dishwasher and wait until it has reached the ready-to-use mode and all energy-consuming

elements are inactive.

Load the machine, close the door/hood and start the first programme cycle.

After the machine is indicating the end of the programme, wait until all energy-consuming elements are

inactive.

Open door/hood and keep it open for 30 s to unload and load and add detergent.

Close door/hood and start the next conditioning cycle immediately.

After the 3rd conditioning cycle, unload the machine and close the door/hood.

Wait until the dishwasher is in the ready-to-use mode and all energy-consuming elements are inactive.

The test shall now be started within 5 min.

5.3.1.3.2 Test with the bioindicators

For the test the load is the relevant load according to A.1.1.2.

Open door/hood and keep it open for 30 s to load the machine.

Load the machine, close the door/hood and start the first programme cycle.

After the machine is indicating the end of the programme, open door/hood and keep it open for 30 s to

unload the machine.

Unload the machine. Close the door/hood and wait until all energy-consuming elements are inactive.

Open door/hood and keep it open for 30 s to add detergent and load the next rack previously prepared

for the second cycle.

Close door/hood and start the programme cycle immediately.

Open door/hood and unload the machine.

After each of the two cycles process the bioindicator as detailed in procedure A.2.1.4.

After the completion of the test, follow procedure 5.3.1.6 to decontaminate the machine.

5.3.1.4 Procedure for conveyor-type dishwashing machines

5.3.1.4.1 Conditioning of the machine

Switch on the dishwasher and wait until it has reached the ready-to-use mode and all energy-consuming

elements are inactive.

The dosing of chemical treating agents shall be carried out using a suitable dosing device according to

manufacturer’s instructions.

Start the dishwashing machine and run it for a time of 5 min.

During this time all pumps and all other equipment relevant for the cleaning process shall be activated

by continuously running empty racks or similar suitable means.

The test shall now be started within 5 min.

5.3.1.4.2 Test with the bioindicators

For the test the load is the relevant load according to A.1.1.2.

Load the machine and start the first cycle.

After the first load has left the machine start the second cycle.

Unload the machine.

After each of the two cycles process the bioindicator as detailed in procedure A.2.1.4.

After the completion of the test, follow procedure 5.3.1.6 to decontaminate the machine.

5.3.1.5 Test results

The results of the type test shall be presented in a test report complying with A.4 (see Annex D for record

sheets examples); for evaluation criteria see Table 1

5.3.1.6 Dishwashing machine decontamination procedure

Add an active chlorine-based chemical to the detergent solution, to achieve a concentration of at least

10 mg/l of active chlorine. Then decontaminate the machine by running it for a complete cycle. Then

drain off the detergent solution and refill the machine with water. When the set temperature has been

achieved, run for another full cycle and empty the tank.

5.3.2 Post-installation test

5.3.2.1 General

The purpose of the post-installation test, arranged by the operating company, is to verify that the hygienic

results of the articles treated in the dishwashing machines, if operated in accordance with the

manufacturer’s instructions.

The post-installation test consists of:

— the aerobic colony count of the wash ware surface;

— the aerobic colony count of the detergent solution.

All the wash ware tested shall be given a visual inspection for cleanliness and dryness. The wash ware

shall be externally dry when removed from the wash ware carriers, water droplets on the supporting

points and residual moisture in the interior of hollow articles are acceptable

NOTE For further information see Annex B and Annex C.

5.3.2.2 General conditions for measurements

5.3.2.2.1 Test programme

The standard cleaning programme, suitable for normally soiled wash ware, shall be used for the test.

The manufacturer shall declare the programme to be used for testing.

For dishwashing machines included in the scope of EN IEC 63136, the programme to be tested shall be

the one that is used in performance test according to EN IEC 63136.

5.3.2.2.2 Water supply

Fresh water supplying the machine should fulfil the manufacturer’s instructions.

Water hardness can cause deposits in the machine and on the wash ware. To avoid these deposits the

incoming water shall be suitably treated (e.g. softened or fully demineralized).

5.3.2.2.3 Chemical treating agents

The chemical treating agents shall be chosen taking into account the fresh water quality.

Chemical treating agents shall be used according to the treating agents’ manufacturers’ instruction.

5.3.2.2.4 Load

The load is the relevant wash ware carrier, with the appropriate wash ware items (see A.1.2).

The wash ware carrier shall be filled in accordance with the manufacturer’s instructions.

5.3.2.3 Procedure

5.3.2.3.1 Conditioning of the machine

The test shall be carried out during the main operating period, at the earliest after the dishwashing

machine has been operating fully loaded for at least 0,5 h or after at least three wash cycles.

5.3.2.3.2 Aerobic colony count of the surface of the wash ware (see A.2.2)

The aerobic colony count shall be determined using the contact plate method as specified in

EN ISO 18593. At least ten wash ware items according to A.1.2 shall be used for this purpose.

5.3.2.3.3 Determination of the aerobic microorganism count of the detergent solution

The aerobic colony count of the detergent solution shall be determined according to A.2.3.

5.3.2.4 Test results

The results of the post-installation test shall be evaluated in a test report according to A.4 (see Annex D

for record sheets examples); evaluation criteria are listed in Table 1.

5.4 Overview of the number of samples for microbiological testing and the associated

record sheets

Table 3 gives an overview of the number of microbiological test samples (bioindicators), depending on

the test object with details of the requirements, methods and record sheets.

Table 3 — Number of microbiological test samples/bioindicators

Test object Test with Number of samples Requirements, methods

bioindicators Type test and record sheet

Batch-type Bioindicator in the 2 x 8 Table 1

cutlery tray

and rack conveyor 5.3.1

dish-washing A.1.1

machine D.3.1

Bioindicator on test 1 x number of plates Table 1

plates depending on loading

5.3.1

A.1.1

D.3.2

Flight conveyor dish- Bioindicator in the 2 x 8 Table 1

washing machine cutlery tray

5.3.1

A.1.1

D.3.1

Bioindicator in the 1 x 10 Table 1

test rack

5.3.1

A.1.1

D.3.3

Table 4 gives an overview of the number of microbiological test samples/surface aerobic colony count

samples, depending on the test object for the post-installation test with details of the requirements,

methods and record sheets.

Table 4 — Number of samples for microbiological tests/surface aerobic colony count

Test object Surface aerobic colony Number of samples Requirements,

count test Post-installation test methods and

record sheets

Wash ware (except Aerobic colony count 10 A.2.2

re-usable D.1

crates/container

Table 1

made of plastic)

Annex A

(normative)

Testing of hygienic operation of dishwashing machines – type test and post-

installation test

A.1 Load

A.1.1 Type testing

A.1.1.1 General

The load is the appr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...