SIST EN 13256:2016

(Main)Geotextiles and geotextile-related products - Characteristics required for use in the construction of tunnels and underground structures

Geotextiles and geotextile-related products - Characteristics required for use in the construction of tunnels and underground structures

This European Standard specifies the relevant characteristics of geotextiles and geotextile-related products used in the construction of tunnels and underground structures, and the appropriate test methods to determine these characteristics.

The intended use of these geotextiles or geotextile-related products is to protect geosynthetic barriers used in tunnels and underground structures.

This European Standard is not applicable to geosynthetic barriers, as defined in EN ISO 10318 1.

This European Standard provides for the assessment and verification of constancy of performance of the product to this European Standard and for factory production control procedures.

Particular application cases may contain requirements regarding additional properties and – preferably standardized – test methods, if they are technically relevant.

This European Standard may be used to derive design values by taking into account factors within the context of the definitions given in EN 1997 1 (Eurocode 7), e.g. factors of safety. The design life of the product should be determined, since its function may be temporary, as a construction expediency, or permanent, for the lifetime of the structure.

Geotextilien und geotextilverwandte Produkte - Geforderte Eigenschaften für die Anwendung im Tunnelbau und in Tiefbauwerken

Diese Europäische Norm legt die wichtigsten Eigenschaften von Geotextilien und geotextilverwandten Produkten, die im Tunnelbau und in Tiefbauwerken verwendet werden, sowie die geeigneten Prüfverfahren zur Bestimmung dieser Eigenschaften fest.

Die vorgesehene Anwendung dieser im Tunnelbau und in Tiefbauwerken verwendeten Geotextilien und geotextilverwandten Produkte ist das Schützen von geosynthetischen Dichtungsbahnen.

Diese Europäische Norm ist nicht auf geosynthetische Dichtungsbahnen anwendbar, wie in EN ISO 10318-1 festgelegt.

Diese Europäische Norm behandelt die Bewertung und Überprüfung der Leistungsbeständigkeit des Produkts nach dieser Europäischen Norm und die Verfahren für die werkseigene Produktionskontrolle.

Besondere Anwendungen können Anforderungen hinsichtlich zusätzlicher Eigenschaften und - vorzugsweise genormte - Prüfverfahren enthalten, wenn diese technisch relevant sind.

Diese Europäische Norm darf zur Festlegung von Bemessungswerten herangezogen werden, in dem die im Zusammenhang mit den in EN 1997-1 (Eurocode 7) angegebenen Definitionen berücksichtigt werden, z. B. Sicherheitsbeiwerte. Für das Produkt sollte die Bemessungsdauer festgelegt werden, weil seine Funktion zeitlich befristet sein darf, als Einbauhilfe, oder dauerhaft, der Lebensdauer des Bauwerks entsprechend.

Géotextiles et produits apparentés - Caractéristiques requises pour l'utilisation dans la construction de tunnels et de structures souterraines

La présente Norme européenne spécifie les caractéristiques pertinentes des géotextiles et produits apparentés utilisés dans la construction de tunnels et de structures souterraines, ainsi que les méthodes d'essai appropriées pour déterminer ces caractéristiques.

L'application de ces géotextiles ou produits apparentés est de protéger les géomembranes et/ou géosynthétiques bentonitiques utilisés dans les tunnels et les structures souterraines.

La présente Norme européenne ne s'applique pas aux géomembranes et géosynthétiques bentonitiques tels que définis dans l'EN ISO 10318 1.

La présente Norme européenne permet d'évaluer et de vérifier la constance des performances du produit à la présente Norme européenne et les procédures de contrôle de la production en usine.

Des cas d'application particuliers peuvent contenir des exigences sur des propriétés supplémentaires et méthodes d'essai – si possible normalisées – si elles sont techniquement pertinentes.

La présente Norme européenne peut être utilisée pour déduire les valeurs de calcul en prenant en compte les facteurs définis dans l'EN 1997 1 (Eurocode 7), par exemple les facteurs de sécurité. Il convient de déterminer la durée de vie prévue du produit, puisque sa fonction peut être provisoire, pour des besoins de construction, ou permanente, pour la durée de vie de la structure.

Geotekstilije in geotekstilijam sorodni izdelki - Značilnosti, ki se zahtevajo pri gradnji tunelov in podzemeljskih delov

Ta evropski standard določa pomembne značilnosti geotekstilij in geotekstilijam sorodnih izdelkov, ki se uporabljajo pri gradnji tunelov in podzemeljskih delov, ter ustrezne preskusne metode za določitev teh značilnosti.

Te geotekstilije in geotekstilijam sorodni izdelki naj bi se uporabljali za zaščito geosintetičnih zapor, ki se uporabljajo pri tunelih in podzemeljskih delih.

Ta evropski standard se ne uporablja za geosintetične zapore, kakor so opredeljene v standardu EN ISO 10318.

Ta evropski standard omogoča ocenjevanje in preverjanje stalnosti funkcionalnosti izdelka v skladu s tem evropskim standardom ter postopke kontrole proizvodnje v obratu.

OPOMBA: Posamezni primeri uporabe lahko vključujejo zahteve glede dodatnih lastnosti in – po možnosti standardiziranih – preskusnih metod, če so tehnično pomembni.

Ta evropski standard se lahko uporablja za izpeljavo projektnih vrednosti ob upoštevanju dejavnikov v okviru definicij iz standarda EN 1997 1 (Evrokod 7), npr. dejavnikov varnosti. Določila naj bi se projektna življenjska doba izdelka, saj je njegova funkcija začasna, kot zagotavljanje primernosti za gradnjo, ali stalna, tj. za življenjsko dobo konstrukcije.

General Information

- Status

- Published

- Public Enquiry End Date

- 02-Mar-2016

- Publication Date

- 09-Nov-2016

- Technical Committee

- ITEK - Textile and textile products

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 21-Oct-2016

- Due Date

- 26-Dec-2016

- Completion Date

- 10-Nov-2016

Relations

- Effective Date

- 01-Dec-2016

Overview

EN 13256:2016 is the CEN European Standard that defines the characteristics and test methods for geotextiles and geotextile-related products used to protect geosynthetic barriers in the construction of tunnels and underground structures. It prescribes how manufacturers should declare product performance, and it specifies procedures for assessment and verification of constancy of performance (AVCP) and factory production control (FPC). This standard is focused on protection products and is explicitly not applicable to geosynthetic barriers themselves (see EN ISO 10318-1).

Key topics and requirements

- Intended function: Protection of geosynthetic barriers in tunnel and underground works; additional functions (drainage, erosion control) are addressed by other standards where integrated.

- Declared characteristics: Manufacturers must provide relevant performance data for characteristics identified in the standard (e.g., tensile and seam strength, puncture resistance, friction, resistance to mechanical damage, resistance to weathering, oxidation and hydrolysis).

- Test methods: Reference to standardized tests (for example, wide‑width tensile test EN ISO 10319, static puncture CBR EN ISO 12236, dynamic perforation EN ISO 13433, weathering EN 12224, hydrolysis EN 12447, friction EN ISO 12957 series) to determine declared values.

- Durability and service life: Guidance on assessing product service life (temporary or permanent use) and repeat testing after durability exposures; Annexes provide detailed durability approaches for different service-life scenarios.

- AVCP and FPC: Procedures for product type determination (PTD), factory production control, initial inspection, continuous surveillance and verification of declared values. Annex A gives an FPC scheme and test frequencies.

- Regulatory linkage: Supports requirements under the EU Construction Products Regulation and provides guidance on Declaration of Performance (DoP) and CE marking (see informative Annex ZA).

- Design integration: Can be used to derive design values in the context of Eurocode 7 (EN 1997-1), taking into account factors of safety.

Applications and users

Who uses EN 13256:2016:

- Geosynthetic and geotextile manufacturers preparing product specifications and Declarations of Performance.

- Tunnel and underground structure designers and specifiers who need to select protective geotextiles with verified performance.

- Contractors and installers assessing suitability and handling requirements to avoid installation damage.

- Testing laboratories performing standardized tests and durability assessments.

- Regulatory bodies and project owners verifying CE marking and AVCP compliance.

Practical applications:

- Protection layers between ground and geosynthetic membranes in tunnel linings, underground containment, or waterproofing systems.

- Specifying materials for temporary construction expedients or permanent barrier protection with defined service life.

Related standards

- EN ISO 10318-1 (terms/definitions for geosynthetics)

- EN ISO 10319 (wide-width tensile)

- EN ISO 12236 (CBR puncture)

- EN ISO 13433 (dynamic perforation)

- EN 12224 (weathering)

- EN 12447 (hydrolysis)

- Eurocode 7 (EN 1997-1) - for deriving design values and safety factors

Keywords: EN 13256:2016, geotextiles, geotextile-related products, tunnels, underground structures, geosynthetic barriers, test methods, durability, factory production control, AVCP, CE marking.

Frequently Asked Questions

SIST EN 13256:2016 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Geotextiles and geotextile-related products - Characteristics required for use in the construction of tunnels and underground structures". This standard covers: This European Standard specifies the relevant characteristics of geotextiles and geotextile-related products used in the construction of tunnels and underground structures, and the appropriate test methods to determine these characteristics. The intended use of these geotextiles or geotextile-related products is to protect geosynthetic barriers used in tunnels and underground structures. This European Standard is not applicable to geosynthetic barriers, as defined in EN ISO 10318 1. This European Standard provides for the assessment and verification of constancy of performance of the product to this European Standard and for factory production control procedures. Particular application cases may contain requirements regarding additional properties and – preferably standardized – test methods, if they are technically relevant. This European Standard may be used to derive design values by taking into account factors within the context of the definitions given in EN 1997 1 (Eurocode 7), e.g. factors of safety. The design life of the product should be determined, since its function may be temporary, as a construction expediency, or permanent, for the lifetime of the structure.

This European Standard specifies the relevant characteristics of geotextiles and geotextile-related products used in the construction of tunnels and underground structures, and the appropriate test methods to determine these characteristics. The intended use of these geotextiles or geotextile-related products is to protect geosynthetic barriers used in tunnels and underground structures. This European Standard is not applicable to geosynthetic barriers, as defined in EN ISO 10318 1. This European Standard provides for the assessment and verification of constancy of performance of the product to this European Standard and for factory production control procedures. Particular application cases may contain requirements regarding additional properties and – preferably standardized – test methods, if they are technically relevant. This European Standard may be used to derive design values by taking into account factors within the context of the definitions given in EN 1997 1 (Eurocode 7), e.g. factors of safety. The design life of the product should be determined, since its function may be temporary, as a construction expediency, or permanent, for the lifetime of the structure.

SIST EN 13256:2016 is classified under the following ICS (International Classification for Standards) categories: 59.080.70 - Geotextiles; 93.020 - Earthworks. Excavations. Foundation construction. Underground works; 93.060 - Tunnel construction. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13256:2016 has the following relationships with other standards: It is inter standard links to SIST EN 13256:2014+A1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13256:2016 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/107, M/386. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13256:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Geotextilien und geotextilverwandte Produkte - Geforderte Eigenschaften für die Anwendung im Tunnelbau und in TiefbauwerkenGéotextiles et produits apparentés - Caractéristiques requises pour l'utilisation dans la construction de tunnels et de structures souterrainesGeotextiles and geotextile-related products - Characteristics required for use in the construction of tunnels and underground structures93.060Gradnja predorovTunnel construction93.020Zemeljska dela. Izkopavanja. Gradnja temeljev. Dela pod zemljoEarthworks. Excavations. Foundation construction. Underground works59.080.70GeotekstilijeGeotextilesICS:Ta slovenski standard je istoveten z:EN 13256:2016SIST EN 13256:2016en,fr,de01-december-2016SIST EN 13256:2016SLOVENSKI

STANDARDSIST EN 13256:2014+A1:20151DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13256

October

t r s x ICS

w {ä r z rä y r Supersedes EN

s u t w xã t r s v ªA sã t r s wEnglish Version

Geotextiles and geotextileærelated products æ Characteristics required for use in the construction of tunnels and underground structures Géotextiles et produits apparentés æ Caractéristiques requises pour l 5utilisation dans la construction de tunnels et de structures souterraines

Geotextilien und geotextilverwandte Produkte æ Geforderte Eigenschaften für die Anwendung im Tunnelbau und in Tiefbauwerken This European Standard was approved by CEN on

v June

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u t w xã t r s x ESIST EN 13256:2016

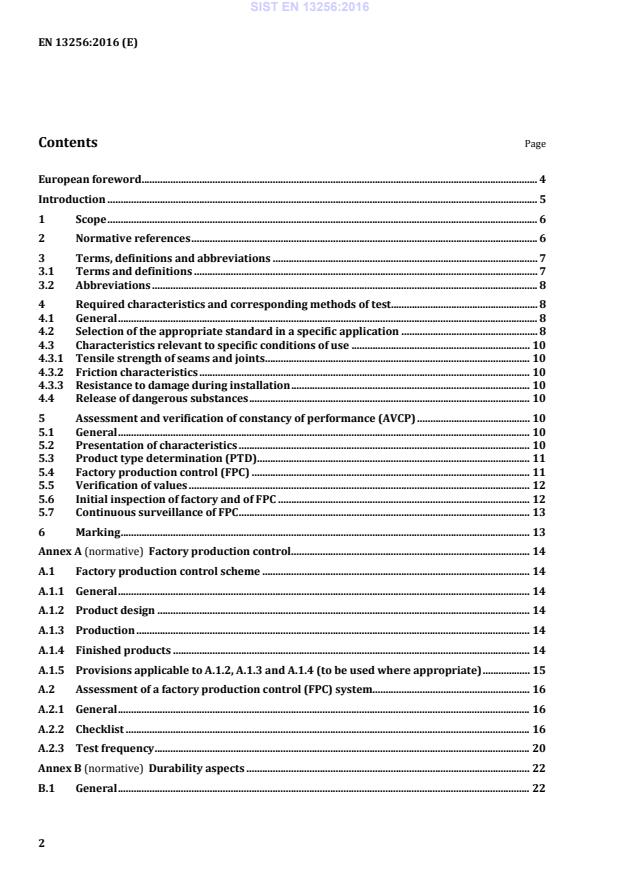

Factory production control . 14 A.1 Factory production control scheme . 14 A.1.1 General . 14 A.1.2 Product design . 14 A.1.3 Production . 14 A.1.4 Finished products . 14 A.1.5 Provisions applicable to A.1.2, A.1.3 and A.1.4 (to be used where appropriate) . 15 A.2 Assessment of a factory production control (FPC) system. 16 A.2.1 General . 16 A.2.2 Checklist . 16 A.2.3 Test frequency . 20 Annex B (normative)

Durability aspects . 22 B.1 General . 22 SIST EN 13256:2016

Guidelines for the selection of the appropriate standard in a specific application . 28 Annex D (informative)

Significant technical changes to superseded editions of this standard. 30 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Regulation . 31 ZA.1 Scope and relevant characteristics . 31 ZA.2 Procedure for AVCP of Geotextiles and geotextiles-related products for the use in the construction of tunnels and underground structures . 32 ZA.2.1 Systems of AVCP . 32 ZA.2.2 Declaration of performance (DoP) . 34 ZA.3 CE marking and labelling . 40 Bibliography . 41

A: relevant to all conditions of use

S: relevant to specific conditions of use

“–”: indicates that the characteristic is not relevant for that function. a

Static puncture resistance may not be relevant for some types of products, e.g. GGR, GCO-D or GST. b

If the mechanical properties (tensile strength and static puncture) are coded “A” in this Table, the use of only one, either tensile strength or static puncture, is usually sufficient in a project specification. c

The strength of internal structural junctions of geocells shall be tested in accordance with EN ISO 13426-1. d

The strength of internal structural junctions of geocomposites shall be tested in accordance with EN ISO 13426-2. SIST EN 13256:2016

For the durability aspects, see Table 1 and Annex B. The results of PTD tests shall be recorded and be available for inspection. The sample for the PTD tests shall be drawn according to EN ISO 9862 from a normal production run using the same materials and forming processes as used for the full production process. The size of the sample shall be big enough to allow the determination of the characteristics specified in Table 2. Handmade samples, short trial batches and other development prototypes may be tested by the same methods, but shall not be used for establishing characteristic values in PTD tests. 5.4 Factory production control (FPC) A FPC scheme shall be established and documented in a manual prior to a product type being placed on the market. Subsequently, any fundamental changes in raw materials and additives, manufacturing procedures or the control scheme that affect the properties or use of a product shall be recorded in the manual. The manual shall include the FPC procedures relevant to the declared properties, as confirmed by the product type determination. The FPC procedures shall consist of a permanent internal production control system to ensure that such products comply with this European Standard and that the measured values conform to the declared values. SIST EN 13256:2016

Factory production control A.1 Factory production control scheme A.1.1 General The items to be addressed in the factory production control manual relating to the system of control, determined from 5.4, are given in A.1. The single steps of factory production control are addressed in the check-list (A.2). NOTE Manufacturers operating an FPC system, which complies with EN ISO 9001 and which addresses the provisions of this European Standard, are considered to be able to satisfy the FPC requirements of this European Standard. A.1.2 Product design The manufacturer shall describe how product design requirements and criteria are identified, checked, controlled and updated to be unambiguous and relevant to the use of the product and its specification. The manufacturer shall describe the communication of the product design to the internal production departments or to external subcontractors. A.1.3 Production A.1.3.1 Raw or incoming materials The manufacturer shall define the acceptance criteria of raw or incoming materials and the procedures that he operates to ensure that these are met. The manufacturer shall document by analyses and/or certificates from his suppliers that all raw or incoming materials meet the declared performance, including durability performance. A.1.3.2 Production process The relevant features of the plant and production process shall be defined giving the frequency of the inspections, checks and tests, together with the values or criteria required on equipment and on work in process. The actions to be taken when control values or criteria are not obtained shall be recorded. These records shall be available for inspection. A.1.4 Finished products A.1.4.1 Tests on the finished product The size of the samples and the frequency of sampling, together with the results obtained, shall be recorded. These records shall be available for inspection. A.1.4.2 Alternative tests Where alternative tests to the reference tests are used, details of the alternative tests and procedures together with their correlation with the reference tests shall be recorded and shall be made available for inspection. SIST EN 13256:2016

Design 1.1 – Has the manufacturer a description how design requirements and criteria are identified, checked, controlled and updated to be unambiguous and relevant to the use of the product and its specification? To be assessed only if claimed by the manufacturer Refer to the manufacturer's documentation. 1.2 – Has the manufacturer a description of the communication of the design to the internal production departments or to external subcontractors? To be assessed only if claimed by the manufacturer. Refer to the manufacturer's documentation. 2 Product identification and traceability 2.1 – What are the means used for the unique identification of any individual finished product? E Refer to the manufacturer's documentation. 2.2 – Is it possible to identify and check date, place and general manufacturing conditions E Refer to the manufacturer's SIST EN 13256:2016

3 Production process control 3.1 – Are there documents which define the production process parameters which could affect quality? E Refer to the manufacturer's documentation. 3.2 – Are the standards and procedures implemented? E

3.3 – Are the specified requirements concerning process validation, including the associated personnel and equipment, documented? E Refer to the manufacturer's documentation. 4 Inspection and testing on receipt of raw materials 4.1 – Are there specification sheets concerning incoming raw materials? E Refer to the manufacturer's documentation. 4.2 – Are there documents which define what shall be done in case of non-conformance of raw materials? E Refer to the manufacturer's documentation. 4.3 – Are the nature and frequency of the evaluation of incoming raw materials described and followed? E Refer to the manufacturer's documentation. 5 Inspection and testing during manufacturing 5.1 – Are there inspections or tests during the manufacturing process with specific requirement for the results? E Refer to the manufacturer's documentation. 5.2 – Are there documents concerning inspection or testing during the manufacturing process with requirement for the results? E Refer to the manufacturer's documentation. 5.3 – Do they define what shall be done in case of non-conformance of the product with the requirements? E Refer to the manufacturer's documentation. 5.4 – Are non-conforming products isolated from conform products when they are detected during manufacturing? E Refer to the manufacturer's documentation. 5.5 – Is there a procedure for handling non-conforming products? E Refer to the manufacturer's documentation. SIST EN 13256:2016

Refer to the manufacturer's documentation. 10.2 – Are handling, storage and packaging methods and means appropriate to prevent final products from being damaged or deteriorated?

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...