SIST-TP CEN/CLC/TR 17602-70-23:2021

(Main)Space product assurance - Materials, mechanical parts and processes obsolescence management handbook

Space product assurance - Materials, mechanical parts and processes obsolescence management handbook

This Handbook provides guidelines to manage obsolescence of Materials, Mechanical Parts and Processes (in-house and sub-contracted).

It is useful for any actor of the European Space sector.

It covers Materials, Mechanical Parts and Processes (MMPP) used in flight hardware as well as ground support equipment (including test systems) and materials or tools used during process (not in the final product) and skills (knowhow).

It is not within the scope of this Handbook to address EEE components and software.

This document describes the general causes of obsolescences and introduces the concepts of proactive and reactive obsolescence management, depending of the programme phase.

Raumfahrtproduktsicherung - Handbuch für Obsoleszenzmanagement von Materialien, mechanischen Bauteilen und Prozessen

Assurance produit des projets spatiaux - Manuel de gestion de l’obsolescence des matériaux, des pièces mécaniques et des procédés

Zagotavljanje kakovosti proizvodov v vesoljski tehniki - Priročnik za upravljanje zastarelosti materialov, mehanskih delov in procesov

General Information

- Status

- Published

- Public Enquiry End Date

- 14-Jul-2021

- Publication Date

- 14-Oct-2021

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 13-Oct-2021

- Due Date

- 18-Dec-2021

- Completion Date

- 15-Oct-2021

Overview

CEN/CLC/TR 17602-70-23:2021 - Space product assurance: Materials, mechanical parts and processes obsolescence management handbook - is a European Technical Report that provides guidelines (not normative requirements) for managing obsolescence of Materials, Mechanical Parts and Processes (MMPP) in the space sector. It covers MMPP used in flight hardware, ground support equipment (GSE and test systems), process materials/tools and skills/know‑how. The handbook explicitly excludes EEE components and software. It explains root causes of obsolescence and introduces proactive and reactive obsolescence management approaches mapped to programme phases.

Key topics

- Causes of obsolescence: regulatory change (e.g., REACH), supplier changes, market dynamics, supplier bankruptcy, loss of skills, export controls (ITAR/EAR).

- Proactive vs Reactive strategies: anticipatory measures during design and procurement vs actions taken once discontinuance is confirmed.

- Obsolescence management team & network: roles (obsolescence manager, procurement, design, quality, production, environmental/EHS) and responsibilities for information collection, analysis and communication.

- Obsolescence management plan (OMP): planning, watch activities, risk assessment and mitigation integrated with programme lifecycle.

- Obsolescence risk analysis: prioritisation of MMPP by criticality, probability and impact; link to programme risk management.

- Data management: use of obsolescence databases, templates (Annex A), examples of database content (Annex B) and plan examples (Annex C).

- Regulatory guidance: practical information on REACH and legal implications for material selection and substitutes (Annex D).

- Best practices: supply chain management, declared lists (DML/DPL/DMPL), watch processes and substitute qualification.

Practical applications

This handbook helps organisations to:

- Ensure uninterrupted manufacturing and long-term maintenance of space systems.

- Avoid late-stage redesign and schedule/cost overruns caused by MMPP obsolescence.

- Implement an obsolescence watch, document mitigation actions and qualify substitutes.

- Maintain supply‑chain resilience and regulatory compliance (e.g., chemical restrictions).

- Reduce lifecycle risk for low‑volume, long‑lifetime space programmes that rely on heritage technologies.

Who should use this standard

- Space prime contractors and subsystem suppliers

- Programme and project managers

- Procurement and supply‑chain teams

- Quality, materials and processes engineers

- Production, AIT (assembly, integration and test) teams

- Obsolescence managers and R&D teams

Related standards

- EN 16602‑70 (ECSS-Q-ST-70) Space product assurance - Materials, mechanical parts and processes

- EN 16602‑70‑71 ECSS-Q-ST-70-71 (materials/process data selection)

- EN 16601‑10, EN 16601‑80 (project planning, risk management)

- EN 62402:2007 (Obsolescence management application guide)

- European REACH regulation (ECHA) - regulatory context and obligations

Keywords: obsolescence management, space product assurance, materials mechanical parts processes, MMPP, obsolescence risk analysis, REACH, obsolescence management plan, supply chain management.

Frequently Asked Questions

SIST-TP CEN/CLC/TR 17602-70-23:2021 is a technical report published by the Slovenian Institute for Standardization (SIST). Its full title is "Space product assurance - Materials, mechanical parts and processes obsolescence management handbook". This standard covers: This Handbook provides guidelines to manage obsolescence of Materials, Mechanical Parts and Processes (in-house and sub-contracted). It is useful for any actor of the European Space sector. It covers Materials, Mechanical Parts and Processes (MMPP) used in flight hardware as well as ground support equipment (including test systems) and materials or tools used during process (not in the final product) and skills (knowhow). It is not within the scope of this Handbook to address EEE components and software. This document describes the general causes of obsolescences and introduces the concepts of proactive and reactive obsolescence management, depending of the programme phase.

This Handbook provides guidelines to manage obsolescence of Materials, Mechanical Parts and Processes (in-house and sub-contracted). It is useful for any actor of the European Space sector. It covers Materials, Mechanical Parts and Processes (MMPP) used in flight hardware as well as ground support equipment (including test systems) and materials or tools used during process (not in the final product) and skills (knowhow). It is not within the scope of this Handbook to address EEE components and software. This document describes the general causes of obsolescences and introduces the concepts of proactive and reactive obsolescence management, depending of the programme phase.

SIST-TP CEN/CLC/TR 17602-70-23:2021 is classified under the following ICS (International Classification for Standards) categories: 03.120.99 - Other standards related to quality; 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST-TP CEN/CLC/TR 17602-70-23:2021 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST-TP CEN/CLC/TR 17602-70-23:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2021

Zagotavljanje kakovosti proizvodov v vesoljski tehniki - Priročnik za upravljanje

zastarelosti materialov, mehanskih delov in procesov

Space product assurance - Materials, mechanical parts and processes obsolescence

management handbook

Raumfahrtproduktsicherung - Handbuch für Obsoleszenzmanagement von Materialien,

mechanischen Bauteilen und Prozessen

Assurance produit des projets spatiaux - Manuel de gestion de l’obsolescence des

matériaux, des pièces mécaniques et des procédés

Ta slovenski standard je istoveten z: CEN/CLC/TR 17602-70-23:2021

ICS:

03.120.99 Drugi standardi v zvezi s Other standards related to

kakovostjo quality

49.140 Vesoljski sistemi in operacije Space systems and

operations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL REPORT

CEN/CLC/TR 17602-70-

RAPPORT TECHNIQUE

TECHNISCHER BERICHT

October 2021

ICS 49.140

English version

Space product assurance - Materials, mechanical parts and

processes obsolescence management handbook

Assurance produit des projets spatiaux - Manuel de Raumfahrtproduktsicherung - Handbuch für

gestion de l'obsolescence des matériaux, des pièces Obsoleszenzmanagement von Materialien,

mécaniques et des procédés mechanischen Bauteilen und Prozessen

This Technical Report was approved by CEN on 16 August 2021. It has been drawn up by the Technical Committee CEN/CLC/JTC

5.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium,

Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre:

Rue de la Science 23, B-1040 Brussels

© 2021 CEN/CENELEC All rights of exploitation in any form and by any means Ref. No. CEN/CLC/TR 17602-70-23:2021 E

reserved worldwide for CEN national Members and for

CENELEC Members.

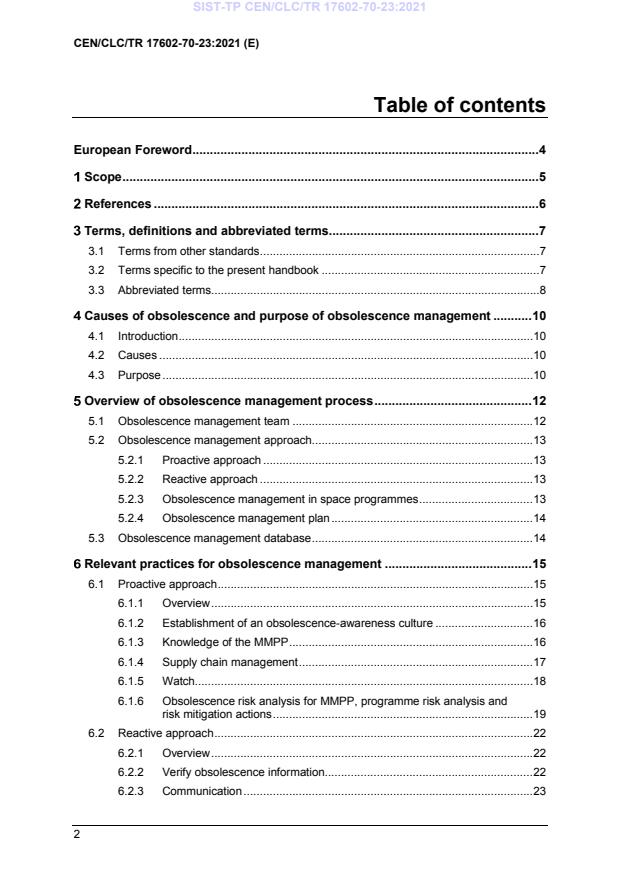

Table of contents

European Foreword . 4

Scope . 5

References . 6

Terms, definitions and abbreviated terms . 7

3.1 Terms from other standards . 7

3.2 Terms specific to the present handbook . 7

3.3 Abbreviated terms. 8

Causes of obsolescence and purpose of obsolescence management . 10

4.1 Introduction . 10

4.2 Causes . 10

4.3 Purpose . 10

Overview of obsolescence management process . 12

5.1 Obsolescence management team . 12

5.2 Obsolescence management approach . 13

5.2.1 Proactive approach . 13

5.2.2 Reactive approach . 13

5.2.3 Obsolescence management in space programmes . 13

5.2.4 Obsolescence management plan . 14

5.3 Obsolescence management database . 14

Relevant practices for obsolescence management . 15

6.1 Proactive approach . 15

6.1.1 Overview . 15

6.1.2 Establishment of an obsolescence-awareness culture . 16

6.1.3 Knowledge of the MMPP . 16

6.1.4 Supply chain management . 17

6.1.5 Watch. 18

6.1.6 Obsolescence risk analysis for MMPP, programme risk analysis and

risk mitigation actions . 19

6.2 Reactive approach . 22

6.2.1 Overview . 22

6.2.2 Verify obsolescence information. 22

6.2.3 Communication . 23

6.2.4 Application case analysis . 23

6.2.5 Obsolescence treatment . 23

Obsolescence data management . 25

7.1 In-house data management . 25

7.2 Network communication. 25

Annex A Obsolescence information template . 26

Annex B Example of content of obsolescence management database . 27

Annex C Example of obsolescence management plan . 28

Annex D Information about the REACH regulation . 29

Background . 29

D.1.1 Overview . 29

D.1.2 Definition of terms . 29

D.1.3 Relationship between substances, mixtures, and articles . 30

Technical consequences of REACH . 31

Additional information . 36

Figures

Figure 5-1: Obsolescence management versus space programme phases . 14

Figure 6-1: Proactive approach best practices scheme . 15

Figure 6-2: Reactive approach best practices scheme . 22

Tables

Table D-1 : Summary of legal obligations of industry, possible associated actions,

schedules as a function of regulatory step - Possibly long-term . 33

Table D-2 : Summary of legal obligations of industry, possible associated actions,

schedules as a function of regulatory step - Possibly mid-term . 34

Table D-3 : Summary of legal obligations of industry, possible associated actions,

schedules as a function of regulatory step - Imminent . 35

European Foreword

This document (CEN/CLC/TR 17602-70-23:2021) has been prepared by Technical Committee

CEN/CLC/JTC 5 “Space”, the secretariat of which is held by DIN.

It is highlighted that this technical report does not contain any requirement but only collection of data

or descriptions and guidelines about how to organize and perform the work in support of EN 16602-

70-23.

This Technical report (CEN/CLC/TR 17602-70-23:2021) originates from ECSS-Q-HB-70-23A.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such

patent rights.

This document has been prepared under a mandate given to CEN by the European Commission and

the European Free Trade Association.

This document has been developed to cover specifically space systems and has therefore precedence

over any TR covering the same scope but with a wider domain of applicability (e.g.: aerospace).

Scope

This Handbook provides guidelines to manage obsolescence of Materials, Mechanical Parts and

Processes (in-house and sub-contracted).

It is useful for any actor of the European Space sector.

It covers Materials, Mechanical Parts and Processes (MMPP) used in flight hardware as well as

ground support equipment (including test systems) and materials or tools used during process (not in

the final product) and skills (know-how).

It is not within the scope of this Handbook to address EEE components and software.

This document describes the general causes of obsolescences and introduces the concepts of proactive

and reactive obsolescence management, depending of the programme phase.

References

EN Reference Reference in text Title

EN 16601-00-01 ECSS-S-ST-00-01 ECSS system – Glossary of terms

EN 16602-70 ECSS-Q-ST-70 Space product assurance – Materials, mechanical parts and

processes

EN 16602-70-71 ECSS-Q-ST-70-71 Space product assurance – Material, processes and their

data selection

EN 16601-10 ECSS-M-ST-10 Space project management – Project planning and

implementation

EN 16601-80 ECSS-M-ST-80 Space project management – Risk management

EN 62402:2007 Obsolescence management - Application guide

T. Rohr et al., ISMSE-12 Impact of REACH Legislation on European Space

ESTEC Noordwijk, The Programs

Netherlands, 2012

M. Chevalier et al., ISMSE- A method to customize qualification of substitutes in case

13 Pau, France, 2015 of material or process obsolescence

Terms, definitions and abbreviated terms

3.1 Terms from other standards

a. For the purpose of this document, the terms and definitions from ECSS-S-ST-00-01 apply, in

particular the following terms:

1. design

2. development

3. life cycle

4. lifetime

5. material

b. For the purpose of this document, the terms and definitions from ECSS-Q-ST-70 apply, in

particular the following term:

1. mechanical part

2. process

3.2 Terms specific to the present handbook

3.2.1 bill of MMPP

list of materials, processes or mechanical parts that are needed to manufacture or repair an end

product

NOTE This is reported in Declared Materials List (DML), Declared Processes

List (DPL) and Declared Mechanical Parts List (DMPL).

3.2.2 criticality

measure of severity of the consequences of MMPP obsolescence with regard to its use

3.2.3 obsolescence

transition from availability to unavailability of a material, mechanical part or process from the

manufacturer or supplier

NOTE The unavailability can be permanent or temporary.

3.2.4 obsolescence management network

network of persons in charge of collecting, transmitting and recording all the information concerning

obsolescence issues and responsible to implement risk mitigation actions and obsolescence treatment

actions

NOTE Members of the obsolescence network can represent different

functions (e.g. procurement, quality, production, and design office)

3.2.5 obsolescence manager

person in charge of coordinating and supervising obsolescence management at company level and

following up obsolescence treatment projects progress

3.2.6 obsolescence risk analysis

assessment of the probability and severity of the risk of obsolescence and prioritization of the

obsolescence risk

3.2.7 proactive obsolescence management

actions to anticipate obsolescence and to mitigate the risks linked to obsolescence issues

3.2.8 reactive obsolescence management

reactive strategy consists in reacting only when the obsolescence is proven

1 Obsolescence is considered as proven when a discontinuance date is

known.

2 The discontinuance date can be transmitted through a formal

document by the supplier or related to date of ban determined by a

regulation.

3.3 Abbreviated terms

For the purpose of this document, the following abbreviated terms apply:

Abbreviation Meaning

application for authorization

AfA

assembly, integration and test

AIT

Aerospace and Defense Industries Association of Europe

ASD

bill of material

BOM

Chemical Abstract Service Number

CAS Number

classification and labelling

C&L

classification, labelling and packaging

CLP

carcinogenic, mutagenic, reprotoxic

CMR

community rolling action plan

CoRAP

commercial off-the-shelf

COTS

declared materials list

DML

declared mechanical parts list

DMPL

Abbreviation Meaning

declared processes list

DPL

Export Administration Regulations

EAR

European Chemical Agency

ECHA

European Community number

EC Number

European Economic Area

EEA

electrical, electronic and electromechanical

EEE

environment, health and safety

EHS

European Union

EU

Groupement des industries françaises aéronautiques et

GIFAS

spatiales (French Aerospace Industries Association)

handbook

HB

harmonised classification and labelling

HCL

International Traffic in Arms Regulations

ITAR

materials, mechanical parts and processes

MMPP

materials and processes

M&P

Materials, Mechanical Parts and Processes Control Board

MPCB

Materials and Processes Technology Board

MPTB

member state

MS

ozone depleting substance

ODS

obsolescence management

OM

obsolescence management plan

OMP

Public Activities Coordination Tool

PACT

persistent, bioaccumulative and toxic

PBT

persistent organic pollutants

POP

research and development

R&D

Registration, Evaluation and Authorization of Chemicals

REACH

(European regulation)

risk management option analysis

RMOA

restriction of hazardous substances

RoHS

safety data sheet

SDS

substitute it now list

SIN List

substance of very high concern

SVHC

technology readiness level

TRL

very persistent and very bioaccumulative

vPvB

Causes of obsolescence and purpose of

obsolescence management

4.1 Introduction

Obsolescence can affect all space products throughout their lifecycle. Through obsolescence

management appropriate actions are put in place to minimise detrimental impact and costs

throughout the product life.

4.2 Causes

The main causes of obsolescence are:

a. Regulations and their evolution: Environmental regulations such as REACH, health and safety.

b. Import – export constraints: export control (e.g. ITAR), export licence, embargo.

c. Changes from suppliers such as

1. product evolution (formulation, raw material supply chain, packaging, product

properties, deviation from original specification),

2. manufacturing processes and means, streamlining of product ranges, manufacturing

stop, change of manufacturing location,

3. product designation, industrial re-organization.

d. Supplier force major circumstances: bankruptcies, industrial accidents (e.g. fire, explosion), loss

of know-how, natural disasters (e.g. flooding, storm, earthquake).

e. Market competitiveness such as too low volume of production, outdated technology, indirect

impact of environmental regulations.

NOTE Indirect impact of environmental regulations means that even if the

space sector is out of the scope (e.g. RoHS), the market availability is

driven by much larger actors that need to comply and drive

alternative product development.

f. Loss of employee specific skills and company know-how.

4.3 Purpose

The increasing number of obsolescence issues affects the space sector particularly due to the specific

characteristics of space programmes:

a. Long life cycles (especially for space transportation).

b. Low purchase volumes.

c. Long MMPP qualification time (e.g. high performance requirements, high safety standards,

complex interactions between systems, and multinational programmes).

d. Low production volumes.

e. Use of proven technologies (heritage).

f. Complex contractual supply chain.

Obsolescence management of MMPP is an added-value to limit impacts of obsolescence to:

a. Ensure undisrupted manufacturing and maintenance of the space hardware during the whole

programme life time.

b. Avoid redesign during a later stage of the space programme.

c. Minimise cost and planning time.

d. Meet customer requirements related to obsolescence management.

e. Guarantee quality and sustainability of the supply chain.

f. Avoid use a non-qualified MMPP.

Overview of obsolescence management

process

5.1 Obsolescence management team

The establishment of an obsolescence management team is key of success of obsolescence

management (OM), including the identification of a person devoted to centralize information. This

person is responsible for the control of information as follows:

a. Set up actions to get the information as soon as possible

b. Information analysis

c. Communication of the information within internal network

This person can rely on the obsolescence management-dedicated network. This network can be

composed of different representatives that include the following functions:

a. Programme and project management

b. Procurement

c. M&P support

d. Quality control

e. Production

f. Design

g. Environment, health and safety

h. Product stewardship (product management and regulation specialist)

i. Legal support (REACH, export control …)

It is important that within companies a reciprocal communication line between OM management team

and other company members is established.

The OM team manages the implementation and the follow-up of actions, e.g. preventing obsolescence,

mitigating risk, treating obsolescence. It is responsible for the communication of the obsolescence

information to other members of the company.

It is essential that the OM team members are clearly identified inside the company. By that, any

member of the company becoming aware of obsolescence issues, informs the obsolescence

management team in timely manner.

5.2 Obsolescence management approach

5.2.1 Proactive approach

The proactive OM approach consists of tracking any potential cause of obsolescence in order to

anticipate future obsolescence cases. It also aims at:

a. anticipating strategies in order to have a mitigation solution once obsolescence occurs.

b. not selecting obsolete or limited-life MMPP as alternative solution or as baseline in new

developments

The proactive approach is implemented at each step of the life of space products to meet product

lifetime requirements. It is important that the proactive approach is applied to all stages of a product

life-cycle, starting from the design phase.

This approach includes continuous monitoring for MMPP availability that allows identifying or

predicting their obsolescence date. This monitoring also allows assessing the risk of obsolescence

occurrence and its criticality for space hardware.

5.2.2 Reactive approach

Following the reactive strategy, actions are taken only when the obsolescence is confirmed, e.g.

identification of alternative solutions, stock-piling, no action.

5.2.3 Obsolescence management in space programmes

Obsolescence management involves implementing scheduled and coordinated actions in order to

secure the availability of a product during its entire life-cycle, through technical and economical

means (e.g. replacement, stockpiling). It can be implemented, as early as possible for better

anticipation, during all phases of a space programme such as design definition, development,

production, use, maintenance, spares and repairs.

Whenever possible, priority can be given to the proactive over reactive approach. A general scheme

describing the interaction between OM and space programme phases is shown in Figure 5-1.

Obsolescence management starts with the implementation of an obsolescence management plan. It

can start as early as the feasibility phase of space programmes by setting up an approach for

obsolescence management.

Implementation of proactive measures can start as soon as possible, for example from preliminary

definition, before bills of MMPP are available. A preliminary item list can be assessed in order to

identify obsolete or potential obsolete items. Also the manufacturer or supplier can be required to

inform the customer about the MMPP obsolescence status.

A detailed process to verify obsolescence issues can be typically implemented after PDR during the

detailed definition phase (phase C). During this stage, appropriate actions can be carried out in

accordance to the defined OM approach. A periodical review of obsolescence risks for products and

technologies can be managed at least at each design review throughout the whole programme.

It is important to perform communication between the OM team and other members of the company

in a continuous way, and is prerequisite for successful obsolescence management. It is also important

to collect, analyze, store and distribute information (knowledge management) to improve the

company OM process.

Space programme phases:

Preparatory phase Development phase Vehicle exploitation phase

Phase 0

Phase B Phase D Phase E

Phase C

Phase A Phase F

Mission Analysis /

Preliminary Qualification & Operation &

Needs Feasibility Detailed definition Disposal

definition Production Utilisation

identification

Obsolescence management:

Design for obsolescence

Implement proactive measures as early

as possible, preferably in the design

phase

Plan for obsolescence Check for new obsolescence&Act as planned

Develop obsolescence management

Check for new obsolescence to ensure early

approach in the framework of

reaction, consult the OM approach and apply an

product life cycle management

appropriate reactive option to handle occurred

obsolescence

Knowledge management

Communicating

[Based on ECSS-M-ST-10 and EN 62402:2007]

Figure 5-1: Obsolescence management versus space programme phases

5.2.4 Obsolescence management plan

Implementing an obsolescence management plan can be an effective way to mitigate obsolescence risk

especially for long-term space programmes. An example of the content of an obsolescence

management plan is provided in the Annex C. This plan is part of the proactive approach and can

complement the project risk management process.

5.3 Obsolescence management database

To anticipate and treat obsolescence, it is important to gather all the information in an obsolescence

management database independent of the considered OM approach (proactive or reactive). An

example of the content for an OM database is given in Annex B.

Relevant practices for obsolescence

management

6.1 Proactive approach

6.1.1 Overview

Proactive best practices are summarized in Figure 6-1. The steps coloured in orange are explained in

the present section 6.1.

Bill of

MMPP

- Knowledge of

MMPP

- Watch

- Supply chain

management

Establish

obsolescence

risk level for

each MMPP

Risk analysis

vs impact on

program

yes

Risk?

Risk

no

mitigation

actions

Monitoring

of

MMPP list

Manufacturing

Figure 6-1: Proactive approach best practices scheme

6.1.2 Establishment of an obsolescence-awareness culture

Establishing an obsolescence-awareness culture inside a company can constitute a change of mindset

in programme management, through communication and participation of all company employees. It

allows to anticipate obsolescence issues as integral part of project management. Obsolescence

management training can be an appropriate way to raise obsolescence awareness. It is important to

involve all members of the company, especially newcomers in such a training.

6.1.3 Knowledge of the MMPP

Prerequisite of obsolescence management is the knowledge of MMPP, this means to have the most

complete information about the composition of selected materials, mechanical parts and formulations

used during manufacturing processes. The detailed knowledge about MMPP allows the identification

of MMPP changes, including the identification of substances that are part of MMPP and face

obsolescence risks due to regulatory impact. The relevant information can be collected from suppliers

or sub-contractors or obtained in-house and be included in the obsolescence management database.

The following information can be collected:

a. Information from suppliers

1. Safety data sheets (SDS) analysis: The information relevant to be analyzed in SDSs are

CAS or EC numbers, changes to be checked and verified with supplier (change of CAS or

EC numbers, change of substance percentages, addition or removal of substances). It is

important to ask the supplier on a regular basis for an update of SDSs, especially for

products less frequently procured

2. Interviews of suppliers: Information about precursor or auxiliary substances,

intermediates, information about the supplier’s obsolescence risk management process

3. Request for procurement specification changes

4. Certificates of performance and associated test data

5. Supplier’s declarations, incl. REACH article 33 declarations

b. Information obtained in-house

Any change in performance and possibly composition can be tracked through incoming

inspections tests or monitoring of drift of process control parameters.

c. Information obtained from subcontractors

Information can be gathered through basic contractual documentation to be delivered to

customers, such as DML, DMPL and DPL. It is the responsibility of each customer in the supply

chain to ask its subcontractors to provide their obsolescence analysis. Such request can be done

e.g. during materials process control boards (MPCB), or even earlier during a preliminary

review milestone.

1 The MMPP lists do not provide the entire design information.

2 Performing MPCBs even for recurrent equipment, can be

recommended to track obsolescence issues.

d. Any other information

Information can also be found in literature, patents, and through networking. All the gathered

information can be systematically included in a dedicated tool for MMPP knowledge

management. It is important to maintain it up-to-date in order to facilitate subsequent risk

analysis.

6.1.4 Supply chain management

6.1.4.1 Overview

It is important to involve actively downstream supply chain actors in obsolescence management. It

can be done by specifying contractual obsolescence management requirements, through suppliers and

subcontractors monitoring, or by dedicated procurement specifications with suppliers.

6.1.4.2 Contractual obsolescence management requirements to supply

chain

Contractual clauses for obsolescence management can include:

a. notification modes, process how obsolescence is communicated, and schedules

b. possible consequences in case the notification deadline was not respected

c. stock constitution modes if relevant (minimum quantity)

The supplier or subcontractor can be asked to demonstrate how he continuously monitors the

availability of MMPP used in the design or manufacturing of the equipment. This can include but is

not be limited to:

a. having an obsolescence management system in place to identify early and to react to an

occurrence of MMPP obsolescence

b. making agreements with suppliers and subcontractors to provide early warning of supply

disruption or MMPP obsolescence

6.1.4.3 Supplier and subcontractor monitoring

To gain better knowledge of supplier products in addition to product changes (section 6.1.3), the

customer can perform supplier or subcontractor monitoring for obsolescence issues to track the

following changes:

a. Plans for production shut down

b. Change of production location or capacity

c. Change of minimum order volume

d. Company re-organization

e. Risk of bankruptcy

f. Design change

g. Loss of know-how

h. Technology development road map

i. Change of manufacturing means

The monitoring process can be performed through:

a. Audits

b. Regular exchanges (meetings, visits) whatever the frequency of orders.

c. Asking for notification letters

d. Financial analysis

e. Networking (outside the direct supply chain)

6.1.4.4 Procurement specification with the supplier

A procurement specification can be agreed with the supplier which can include:

a. A requirement to inform its customer of any change of its product or process used to

manufacture it at defined number of months before the implementation of change (early

warning of supply obsolescence or disruption)

NOTE It is important that the deadline for early warning covers the time to

ensure maintenance of the production capability of the hardware

b. Capacity to procure the MMPP in quantity necessary before switching to an alternative

solution. Stockpiling needs to cover the qualification period for new products or to allow

finalization of the production.

c. Detailed description of a product including composition and processes used.

6.1.5 Watch

Continuous survey of regulatory and market developments is necessary to gather obsolescence-

related information. This monitoring can involve all company employees as everybody can get

information and contribute to obsolescence anticipation. For efficient information exchange, a

dedicated network can be established (see section 5.1). The monitoring perimeter needs to be defined,

monitoring can be more or less active depending on the criticality of the products. More attention can

be paid to products that are more critical and less frequently ordered. The following aspects of

monitoring can be considered:

a. Regulation watch

1. Environmental regulations including RoHS, REACH, radiation protection regulation

(Directive 2003/122/Euratom), environmental national regulations, ODS, POP.

2. Export control including ITAR, EAR, and embargos.

3. Anticipation of environmental regulation developments including SIN list, REACH

CoRAP, REACH PACT.

NOTE For more details regarding the REACH regulation, the reader can

refer to the Annex D.

b. Market watch for products and market trends, existing and future technologies, alternative

technologies, information about supply-demand

1. Public information from the internet

2. Trade shows

3. Technology publications

4. Manufacturers and suppliers visits

c. Strategic materials watch

1. British Geological Survey (www.bgs.ac.uk)

2. Conflict materials (www.conflictfreesourcing.org)

d. Networking

Gathering and sharing experience with obsolescence issues with other organizations (external

communication) is a recommended approach. Information can be shared amongst organizations in

order to implement joint actions (consortium, professional groups). Examples of such groups for

space sector are the MPTB, ASD-Eurospace and other national associations (e.g. GIFAS in France).

6.1.6 Obsolescence risk analysis for MMPP, programme risk

analysis and risk mitigation actions

The first step of proactive obsolescence management is to establish for each MMPP an obsolescence

risk analysis. For this, some obsolescence risk indicators are presented in the Table 6-1. It is up to each

company to determine the relative weight of each obsolescence risk. Information about risk

management in space projects can be found in ECSS-M-ST-80.

Based on the output of this obsolescence risk analysis, higher risk rated MMPP are assessed regarding

their use and criticality in the programme. The result can be included in the programme risk matrix

and in the critical items list.

An action plan is triggered when the risk is higher than a certain level to be determined by each

company. According to the results of the risk analysis, following actions can be implemented to

decrease the programmatic risk (see Table 6-1).

Table 6-1: Examples of risk mitigation actions to be implemented as a function of

obsolescence risk type

Category Obsolescence Risk Factor Risk mitigation actions

• identify and possibly evaluate and qualify a

second source

Single source

• improve contractual relationship with the

supplier

• REACH authorization

• Analysis of alternative

• Clarify with supplier its position

Legislative impact (incl. environmental

• Exemption

regulation impact, for instance from

• Check the impact of restriction on the market

REACH or RoHS, and export control) and

• Identify non-Export Control sources

geopolitics constraints.

• Stockpiles (life time of MMPP to be

considered)

• Lobbying

• Stockpiles

Scarce (shortage such as for carbon fibres,

• Lobbying

strategic materials such rare-earth-based

materials, embargo, risk of counterfeit…)

• Having information about supply-demand

• improve contractual relationship with the

supplier

• search for another supplier

Long time for delivery (in case of non-

conformity of a lot)

• Buffer stockpile (periodical restocking?)

Procurement

• Implement some intermediate tests to ensure

that the lot will be compliant

• Find synergies with other companies

Low consumption level (risk of

o Lobbying

rationalization if Space sector is the only

user)

• Stockpile

Specific requirements (properties difficult Technical survey to adapt the specification to the

to obtain on the market) for non-COTS market

• Technical audit

• Contact directly the manufacturer

Lack of knowledge of the supply chain

• Avoid as far as possible intermediates in

(brokers) procurement

• Technical audits

• Improve procurement specification if

Recurrent quality problems with the

necessary

supplier or subcontractor

• Look for another supplier

No procurement agreement with the Improve contractual(or not) relationship with

supplier or manufacturer the supplier

Bad financial situation of the supplier Identify another supplier

Very small company Identify another supplier

Category Obsolescence Risk Factor Risk mitigation actions

Design driver (change in one MMPP

would induce a change in the whole Improve design robustness to allow the

design (for instance impact on mass), such substitutions of MMPP

as for beryllium case)

Design

• Strong R&D capability

Technology driver (for example, in the

case of the hydrazine and gallium

• Strong relationship with scientific

arsenide, MMPP too application-specific)

laboratories

Common MMPP, multiple company

Exhaustive mapping of all materials usages

usages

• Maintain skills through training

Scarce skills involved • Avoid single point failure

• Anticipate retirement

• Buffer stockpile

Used in end product that has a long

• Start obsolescence management at design

operational life (maintenance) and long

phase

life cycle (recurrent manufacturing, long

Application -

space programme from design to

• Select up-to-date technologies

manufacturing)

Manufacturing

• Anticipate manufacturing of spare parts

and AIT

• Anticipate procurement of spare parts for

(assembly

maintenance of machines

integration &

• Develop close relationship with the

Use of technology or process outdated

manufacturer of the machine

test)

(for example, machine maintenance more

and more difficult to ensure)

• Use second hand market for spare parts of

machines

• Evaluate an up-to-date technology

• Inform supplier of the targeted application

• Identify an alternative solution whose

MMPP not used according to the

function determined by supplier corresponds

application for which this MMPP has been

developed by the supplier to the application

• Improve design review process

• Design change

No viable alternative identified or

evaluated

• R&D

Availability of

alternatives • Design change

High cost of alternative

and • R&D

technology

• Stockpile

High cost and duration of qualification

readiness level compared to available budget and

• Take decision of procurement at an

schedule

intermediate milestone of the qualification

Collateral effects on higher level

assemblies (for example, the replacement

Exhaustive mapping of all higher level impacted

of a primer can induce requalification of

MMPP

paints, adhesive bonding used

subsequently)

Note 1: In case of stockpile, it can be useful to assess possibility to extent lifetime of the MMPP.

Note 2: Periodical restocking can be preferred to long term storage to maintain a certain monitoring on the

product, when it is possible.

6.2 Reactive approach

6.2.1 Overview

Reactive best practices are summarized in Figure 6-2. The steps coloured in orange are explained in

more detail in the present section 6.2.

Verifying if

yes

Application Program action

Used?

obsolescence is

cases analysis

plan

proven

no

No action

Obsolescence

treatment

Implementation

into

Manufacturing

Figure 6-2: Reactive approach best practices scheme

6.2.2 Verify obsolescence information

The first step for the reactive approach is to verify that the obsolescence is proven. As an example, it

can be determined through an official statement from the supplier or through regulatory decisions.

Gathering obsolescence information is necessary to adopt mitigation measures. The required

information can include (non-exhaustive list):

a. Definition of the obsolescence type: REACH, manufacturing stop, change of manufacturing site,

change of manufacturing process, export control regulations, reformulation of material or

mechanical part.

b. Date of the effectiveness of the obsolescence.

c. Possibility of last-buy order including quantity and date.

d. Proposal of alternative solution in the obsolescence notification (if available) and date of

availability of this alternative.

NOTE This information can be gathered in a template to ensure efficiency,

completeness and consistency of information (see Annex A).

In addition to an official statement, for understanding the consequences of obsolescence as well as

performance of proposed alternatives, other technical information can be collected. This can be done

by communication with product suppliers or manufacturers, through working groups, partners, and

sub-contractors. It is important to collect obsolescence related information from a wide range of

information sources to verify the use of the MMPP (in-house, at supplier or sub-contractor level).

6.2.3 Communication

It is important to disseminate obsolescence related information inside the company and flag this

information in dedicated tools to ensure that designers, procurement and product assurance are aware

of the obsolescence issue. It is also important to share the obsolescence information outside the

company with defined actors such as sub-contractors, customers, and other organizations (e.g. MPTB).

6.2.4 Application case analysis

To enable a consolidated MMPP application case (impact) analysis, it is important to collect at least

information about the MMPP uses, their applications, and programmes that are impacted. When an

obsolescence issue occurs, the following non-exhaustive list can be verified:

a. Analyze the time required to treat the obsolescence in line with the programme schedule

b. Check the possibility of stockpiling

c. Investigate availability of MMPP alternative

d. Verify the duration of the alternative MMPP qualification

e. Validate if the alternative MMPP is compliant with regulation or import-export constraints

f. Evaluate the possibility of change of technical specifications to accommodate the new

performance of alternative MMPP or to change the design

g. Assess the possibility to ensure regulation compliance (e.g. REACH authorization or

exemption)

With this application case analysis a programme action plan for obsolescence mitigation can be

implemented.

6.2.5 Obsolescence treatment

Several mitigation actions can be implemented (non-exhaustive list):

a. Prepare a stockpile of MMPP, where the feasibility depends on:

1. product availability from suppliers

2. last buy order

3. shelf life of the product

4. status of the product with regard to regulations

5. storage costs

b. Anticipate the production life-cycle and volume to manufacture stockpiles.

c. Evaluate and qualify an alternative MMPP solution such as:

1. new material or process

2. new supplier

3. new sub-contractor

4. new solution proposed by the supplier

d. Modify the design.

e. Change or prepare deviation of requirements (in early programme phase).

f. Take no actions, e.g. in case when the programme ends before the obsolescence date or for very

minor MMPP changes not imposing any tests. It is important to justify and record this decision.

1 Several of these actions can be managed in combination.

2 Several of these actions can be considered as a transitory solution,

giving time to qualify a permanent solution.

3 An example of methodology of obsolescence treatment can be found

in “A me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...