SIST EN 16602-70-61:2022

(Main)Space product assurance - High-reliability soldering for surface mount, mixed technology and hand-mounted electrical connections

Space product assurance - High-reliability soldering for surface mount, mixed technology and hand-mounted electrical connections

This standard defines:

- the basic requirements for the verification and approval of automatic machine w ave soldering for use in spacecraft hardware. The process requirements for w ave soldering of doublesided and multilayer boards are also defined.

- the technical requirements and quality assurance provisions for the manufacture and verification of manuallysoldered, high-reliability electrical connections.

- the technical requirements and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits based on surface mounted device (SMD) and mixed technology.

- the acceptance and rejection criteria for high reliability manufacture of manually-soldered electrical connections intended to w ithstand normal terrestrial conditions and the vibrational g-loads and environment imposed by space flight.

- the proper tools, correct materials, design and w orkmanshipt. Workmanship standards are included to permit discrimination betw een proper and improper work.

SCOPE

This Standard defines the technical requirements and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits of surface mount, through hole and solderless assemblies.

The Standard defines w orkmanship requirements, the acceptance and rejection criteria for high-reliability assemblies intended to withstand normal terrestrial conditions and the environment imposed by space flight.

The mounting and supporting of components, terminals and conductors specified in this standard applies only to assemblies designed to continuously operate over the mission w ithin the temperature limits of -55 °C to +85 °C at solder joint level.

Requirements related to printed circuit boards are contained in ECSS-Q-ST-70-60 (equivalent to EN 16602-70-60) and ECSS-Q-ST-70-12 (equivalent to EN 16602-70-12).

This Standard does not cover the qualification and acceptance of the EQM and FM equipment w ith high-reliability electronic circuits of surface mount, through hole and solderless assemblies.

This Standard does not cover verification of thermal properties for component assembly.

This Standard does not cover pressfit connectors.

The qualification and acceptance tests of equipment manufactured in accordance w ith this Standard are covered by ECSS-EST-10-03 (equivalent to EN 16603-10-03).

Raumfahrtproduktsicherung - Hochzuverlässige Montage von Oberflächen-Befestigungen und Durchgangslochverbindungen

Assurance produit des projets spatiaux - Soudure haute fiabilité pour les connexions électriques à montage en surface, à technologie combinée et montées à la main

La présente norme définit les exigences techniques et les dispositions relatives à l'assurance qualité pour la fabrication et la vérification de circuits électroniques de haute fiabilité, montés en surface avec trou traversant, assemblés sans soudure, et pour le brasage d'interconnexions de fils et de faisceaux de fils.

Cette norme définit les exigences d'exécution et les critères d'acceptation et de rejet pour les assemblages de haute fiabilité destinés à résister aux conditions d'essai au sol, y compris le LTS (stockage à long terme) et l'environnement imposé par les vols spatiaux et les lanceurs.

Le montage et le support des composants, bornes et conducteurs spécifiés dans la présente norme ne s'appliquent qu'aux assemblages conçus pour fonctionner en continu pendant toute la mission dans des limites de température de -55 °C à +85 °C au niveau des joints de soudure.

Les exigences relatives aux circuits imprimés figurent dans l'ECSS-Q-ST-70-60 et l'ECSS-Q-ST-70-12.

La présente norme ne couvre pas le brasage sans queue et les exigences associées.

La présente norme ne couvre pas la qualification et l'acceptation des équipements EQM et FM avec des assemblages de circuits électroniques à haute fiabilité avec montage en surface, trou traversant et sans brasure.

La présente norme ne couvre pas la vérification des propriétés thermiques pour l'assemblage des composants.

La présente norme ne couvre pas les connecteurs à ajustement forcé, à cause des risques d'endommager le PCB qui ne sont pas évalués dans le cadre de cette exigence d'essai.

Les essais de qualification et d'acceptation des équipements fabriqués conformément à la présente norme sont couverts par l'ECSS-E-ST-10-03.

La présente norme peut être adaptée aux caractéristiques et contraintes spécifiques d'un projet spatial, conformément à l'ECSS-S-ST-00.

Zagotavljanje varnih proizvodov v vesoljski tehniki - Visoko zanesljivo spajkanje za površinsko namestitev, mešano tehnologijo in ročno pritrjene električne priključke

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Nov-2021

- Publication Date

- 14-Nov-2022

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 10-Nov-2022

- Due Date

- 15-Jan-2023

- Completion Date

- 15-Nov-2022

Relations

- Effective Date

- 09-Nov-2022

- Effective Date

- 09-Nov-2022

- Effective Date

- 09-Nov-2022

Overview

EN 16602-70-61:2022 - Space product assurance - High-reliability soldering for surface mount, mixed technology and hand-mounted electrical connections - is a CEN standard that defines technical requirements and quality assurance for manufacture and verification of high-reliability electronic assemblies used in spacecraft hardware. It covers soldering processes (including wave soldering, selective wave and reflow), surface mounted devices (SMD), mixed technology and manually‑soldered connections, plus workmanship, materials and inspection criteria needed to meet spaceflight environmental demands.

Key topics and requirements

- Scope of coverage

- Process requirements for automatic machine wave soldering of double-sided and multilayer PCBs.

- Technical and QA requirements for manual high‑reliability soldered electrical connections.

- Requirements for manufacture and verification of SMD and mixed-technology electronic circuits.

- Acceptance and rejection criteria for manually-soldered connections to withstand normal terrestrial conditions and the vibrational g-loads and environment imposed by space flight.

- Workmanship standards, proper tools, materials and design guidance to discriminate acceptable vs. unacceptable work.

- Environmental and operational limits

- Applies to assemblies designed to operate continuously within solder joint level temperature limits of -55 °C to +85 °C.

- Manufacturing controls and equipment

- Preparatory conditions: facility cleanliness, lighting, ESD protection, tooling and equipment lists (soldering irons, baking ovens, reflow and wave equipment, AOI/X‑ray inspection).

- Materials and handling

- Solder and flux selection, paste storage/handling, component moisture sensitivity, PCB substrate considerations.

- Process steps and workmanship

- Component mounting, lead forming, strain relief, solder fillet criteria, wire termination, connector solder cups, and inspection practices.

- Exclusions

- Does not cover qualification/acceptance of EQM/FM equipment, verification of thermal properties for component assembly, or pressfit connectors.

Practical applications

- Use this standard to develop manufacturing process controls, work instructions and acceptance criteria for aerospace PCBs and harness assemblies.

- Apply it when qualifying soldering processes (wave, selective, reflow) and manual soldering for flight hardware.

- Integrate its workmanship and inspection criteria into supplier quality agreements, in‑process inspections and final acceptance testing to ensure reliability under spaceflight vibration and environment.

Who should use it

- Aerospace and satellite manufacturers, electronic assemblers, QA/quality engineers, process engineers, soldering technicians, procurement and supplier quality teams working on spaceflight electronics and high‑reliability PCB assemblies.

Related standards

- ECSS‑Q‑ST‑70‑60 / EN 16602‑70‑60 (printed circuit board requirements)

- ECSS‑Q‑ST‑70‑12 / EN 16602‑70‑12

- ECSS‑EST‑10‑03 / EN 16603‑10‑03 (qualification and acceptance tests for equipment)

Keywords: EN 16602-70-61:2022, space product assurance, high-reliability soldering, surface mount, mixed technology, hand-mounted, wave soldering, SMD, workmanship standards, acceptance criteria.

Frequently Asked Questions

SIST EN 16602-70-61:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Space product assurance - High-reliability soldering for surface mount, mixed technology and hand-mounted electrical connections". This standard covers: This standard defines: - the basic requirements for the verification and approval of automatic machine w ave soldering for use in spacecraft hardware. The process requirements for w ave soldering of doublesided and multilayer boards are also defined. - the technical requirements and quality assurance provisions for the manufacture and verification of manuallysoldered, high-reliability electrical connections. - the technical requirements and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits based on surface mounted device (SMD) and mixed technology. - the acceptance and rejection criteria for high reliability manufacture of manually-soldered electrical connections intended to w ithstand normal terrestrial conditions and the vibrational g-loads and environment imposed by space flight. - the proper tools, correct materials, design and w orkmanshipt. Workmanship standards are included to permit discrimination betw een proper and improper work. SCOPE This Standard defines the technical requirements and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits of surface mount, through hole and solderless assemblies. The Standard defines w orkmanship requirements, the acceptance and rejection criteria for high-reliability assemblies intended to withstand normal terrestrial conditions and the environment imposed by space flight. The mounting and supporting of components, terminals and conductors specified in this standard applies only to assemblies designed to continuously operate over the mission w ithin the temperature limits of -55 °C to +85 °C at solder joint level. Requirements related to printed circuit boards are contained in ECSS-Q-ST-70-60 (equivalent to EN 16602-70-60) and ECSS-Q-ST-70-12 (equivalent to EN 16602-70-12). This Standard does not cover the qualification and acceptance of the EQM and FM equipment w ith high-reliability electronic circuits of surface mount, through hole and solderless assemblies. This Standard does not cover verification of thermal properties for component assembly. This Standard does not cover pressfit connectors. The qualification and acceptance tests of equipment manufactured in accordance w ith this Standard are covered by ECSS-EST-10-03 (equivalent to EN 16603-10-03).

This standard defines: - the basic requirements for the verification and approval of automatic machine w ave soldering for use in spacecraft hardware. The process requirements for w ave soldering of doublesided and multilayer boards are also defined. - the technical requirements and quality assurance provisions for the manufacture and verification of manuallysoldered, high-reliability electrical connections. - the technical requirements and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits based on surface mounted device (SMD) and mixed technology. - the acceptance and rejection criteria for high reliability manufacture of manually-soldered electrical connections intended to w ithstand normal terrestrial conditions and the vibrational g-loads and environment imposed by space flight. - the proper tools, correct materials, design and w orkmanshipt. Workmanship standards are included to permit discrimination betw een proper and improper work. SCOPE This Standard defines the technical requirements and quality assurance provisions for the manufacture and verification of high-reliability electronic circuits of surface mount, through hole and solderless assemblies. The Standard defines w orkmanship requirements, the acceptance and rejection criteria for high-reliability assemblies intended to withstand normal terrestrial conditions and the environment imposed by space flight. The mounting and supporting of components, terminals and conductors specified in this standard applies only to assemblies designed to continuously operate over the mission w ithin the temperature limits of -55 °C to +85 °C at solder joint level. Requirements related to printed circuit boards are contained in ECSS-Q-ST-70-60 (equivalent to EN 16602-70-60) and ECSS-Q-ST-70-12 (equivalent to EN 16602-70-12). This Standard does not cover the qualification and acceptance of the EQM and FM equipment w ith high-reliability electronic circuits of surface mount, through hole and solderless assemblies. This Standard does not cover verification of thermal properties for component assembly. This Standard does not cover pressfit connectors. The qualification and acceptance tests of equipment manufactured in accordance w ith this Standard are covered by ECSS-EST-10-03 (equivalent to EN 16603-10-03).

SIST EN 16602-70-61:2022 is classified under the following ICS (International Classification for Standards) categories: 25.160.50 - Brazing and soldering; 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16602-70-61:2022 has the following relationships with other standards: It is inter standard links to SIST EN 16602-70-38:2019, SIST EN 16602-70-08:2015, SIST EN 16602-70-07:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 16602-70-61:2022 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 16602-70-61:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2022

Nadomešča:

SIST EN 16602-70-07:2015

SIST EN 16602-70-08:2015

SIST EN 16602-70-38:2019

Zagotavljanje varnih proizvodov v vesoljski tehniki - Visoko zanesljivo spajkanje

za površinsko namestitev, mešano tehnologijo in ročno pritrjene električne

priključke

Space product assurance - High-reliability soldering for surface mount, mixed technology

and hand-mounted electrical connections

Raumfahrtproduktsicherung - Hochzuverlässige Montage von Oberflächen-

Befestigungen und Durchgangslochverbindungen

Assurance produit des projets spatiaux - Soudure haute fiabilité pour les connexions

électriques à montage en surface, à technologie combinée et montées à la main

Ta slovenski standard je istoveten z: EN 16602-70-61:2022

ICS:

25.160.50 Trdo in mehko lotanje Brazing and soldering

49.140 Vesoljski sistemi in operacije Space systems and

operations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD EN 16602-70-61

NORME EUROPÉENNE

EUROPÄISCHE NORM

November 2022

ICS 25.160.50; 49.140

Supersedes EN 16602-70-07:2014, EN 16602-70-

08:2015, EN 16602-70-38:2019

English version

Space product assurance - High-reliability soldering for

surface mount, mixed technology and hand-mounted

electrical connections

Assurance produit des projets spatiaux - Soudure haute Raumfahrtproduktsicherung - Hochzuverlässige

fiabilité pour les connexions électriques à montage en Montage von Oberflächen-Befestigungen und

surface, à technologie combinée et montées à la main Durchgangslochverbindungen

This European Standard was approved by CEN on 29 August 2022.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for

giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical

references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to

any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium,

Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and United Kingdom.

CEN-CENELEC Management Centre:

Rue de la Science 23, B-1040 Brussels

© 2022 CEN/CENELEC All rights of exploitation in any form and by any means Ref. No. EN 16602-70-61:2022 E

reserved worldwide for CEN national Members and for

CENELEC Members.

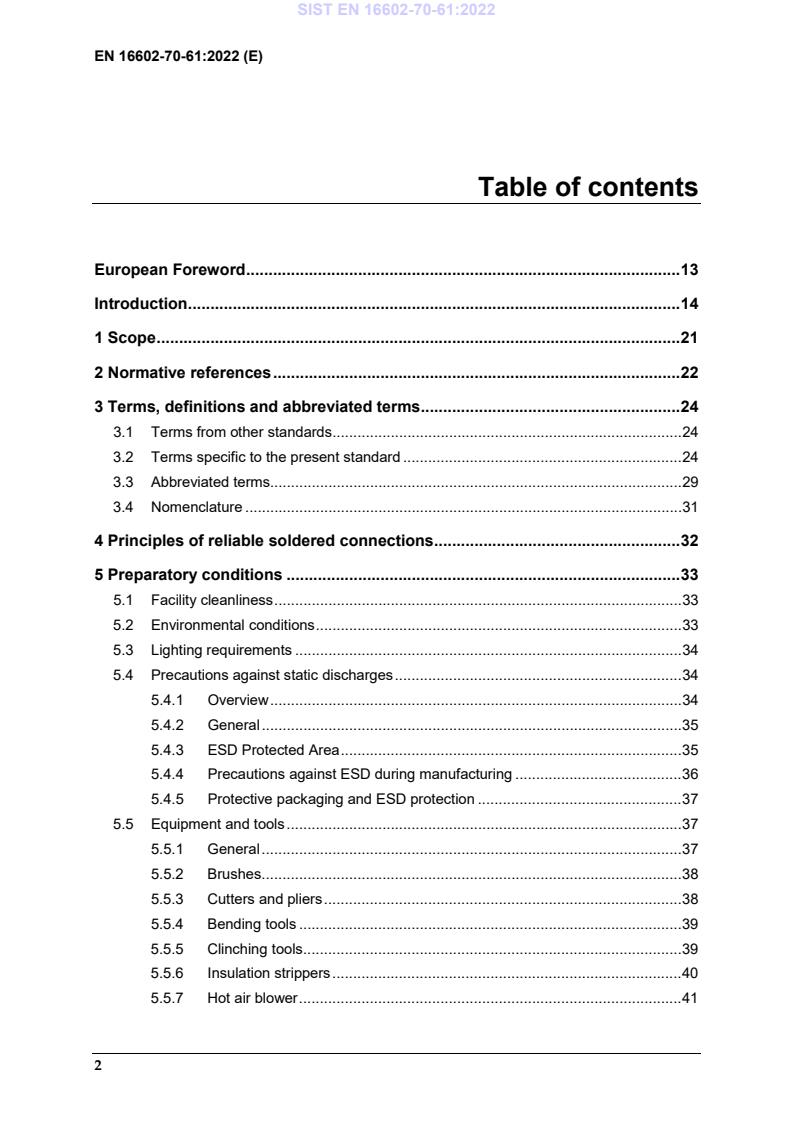

Table of contents

European Foreword . 13

Introduction . 14

1 Scope . 21

2 Normative references . 22

3 Terms, definitions and abbreviated terms . 24

3.1 Terms from other standards . 24

3.2 Terms specific to the present standard . 24

3.3 Abbreviated terms. 29

3.4 Nomenclature . 31

4 Principles of reliable soldered connections . 32

5 Preparatory conditions . 33

5.1 Facility cleanliness . 33

5.2 Environmental conditions . 33

5.3 Lighting requirements . 34

5.4 Precautions against static discharges . 34

5.4.1 Overview . 34

5.4.2 General . 35

5.4.3 ESD Protected Area . 35

5.4.4 Precautions against ESD during manufacturing . 36

5.4.5 Protective packaging and ESD protection . 37

5.5 Equipment and tools . 37

5.5.1 General . 37

5.5.2 Brushes . 38

5.5.3 Cutters and pliers . 38

5.5.4 Bending tools . 39

5.5.5 Clinching tools . 39

5.5.6 Insulation strippers . 40

5.5.7 Hot air blower . 41

5.5.8 Soldering tools . 41

5.5.9 Baking and curing ovens . 42

5.5.10 Solder deposition equipment . 43

5.5.11 Automatic component placement equipment . 43

5.5.12 Dynamic wave-solder machines . 43

5.5.13 Selective wave solder equipment . 44

5.5.14 Reflow process equipment . 45

5.5.15 Depanelization tool. 47

5.5.16 Cleanliness testing equipment . 47

5.5.17 Optical microscope . 47

5.5.18 Automatic Optical Inspection (AOI) equipment . 47

5.5.19 X-ray inspection equipment . 47

6 Material selection . 49

6.1 General . 49

6.2 Solder . 49

6.2.1 Form . 49

6.2.2 Composition . 50

6.2.3 Storage and handling of paste purity . 52

6.3 Fluxes . 52

6.3.1 Rosin based fluxes . 52

6.4 Solvents . 53

6.5 Flexible insulation materials . 54

6.6 Terminals . 54

6.6.1 Materials . 54

6.6.2 Tin, silver, and gold-plated terminals . 54

6.7 Wires . 55

6.8 Sculptured flex . 55

6.9 Printed circuits substrates . 55

6.9.1 Substrates selection . 55

6.9.2 Gold finish on PCBs footprint . 55

6.9.3 PCB design requirements for wave and selective wave soldering . 56

6.10 Components . 56

6.10.1 General . 56

6.10.2 Moisture sensitive components . 57

6.11 Adhesives, potting, underfill and conformal coatings . 57

7 Preparations prior to mounting and soldering . 58

7.1 General handling . 58

7.2 Storage . 58

7.2.1 Components. 58

7.2.2 PCBs. 58

7.2.3 Materials requiring segregation . 58

7.3 Baking conditions of PCBs . 59

7.4 Baking and storage of moisture sensitive components . 59

7.5 Preparation of components, wires, terminals, and solder cups. 60

7.5.1 Damage to insulation . 60

7.5.2 Damage to conductors and braid . 60

7.5.3 Cleaning before soldering . 61

7.5.4 Insulation clearance . 61

7.5.5 Wire lay . 61

7.6 Degolding and pretinning . 61

7.6.1 General . 61

7.6.2 Solder baths method for degolding and pretinning of components

terminations and terminals . 62

7.6.3 Solder iron method for degolding and pretinning . 64

7.6.4 Pretinning processes . 64

7.7 Preparation of the soldering tip . 65

8 Components mounting requirements prior to soldering . 67

8.1 General requirements . 67

8.2 Mounting of through hole components . 67

8.2.1 General . 67

8.2.2 Heavy components . 68

8.2.3 Metal-case components . 68

8.2.4 Glass-encased components . 68

8.2.5 Stress relief of components with bendable leads . 68

8.2.6 Stress relief of components with non-bendable leads . 71

8.2.7 Bending of component leads . 72

8.2.8 Lead attachment to PCBs . 73

8.2.9 Mounting of through hole connectors to PCBs . 76

8.2.10 Mounting of swage terminals to PCBs . 77

8.2.11 Mounting of components to terminals . 78

8.3 Mounting of surface mount components . 79

8.3.1 General . 79

8.3.2 Lead forming . 80

8.3.3 Inspection of solder paste deposition . 80

9 Attachment of conductors to terminals, solder cups and cables . 81

9.1 General . 81

9.2 Wire termination . 81

9.2.1 Breakouts from cables . 81

9.2.2 Insulation clearance . 82

9.3 Turret and straight-pin terminals . 82

9.4 Bifurcated terminals . 83

9.4.1 General . 83

9.4.2 Bottom route . 83

9.4.3 Side route . 84

9.4.4 Top route . 85

9.4.5 Combination of top and bottom routes. 86

9.4.6 Combination of side and bottom routes . 86

9.5 Hook terminals . 86

9.6 Pierced terminals . 87

9.7 Solder cups for connector . 87

9.8 Insulation sleeving . 88

9.9 Wire and cable interconnections . 89

9.9.1 General . 89

9.9.2 Preparation of wires . 89

9.9.3 Preparation of shielded wires and cables . 90

9.9.4 Pre-assembly of wires . 90

9.10 Connection of wires to PCBs . 91

9.11 Connection of coaxial cables to PCBs . 93

10 Assembly to terminals and to PCBs . 94

10.1 Overview . 94

10.2 General soldering conditions . 94

10.2.1 General . 94

10.2.2 Positioning . 95

10.2.3 Application of flux . 96

10.2.4 Flux controls for wave-soldering equipment . 97

10.2.5 Soldering temperatures . 97

10.2.6 Soldering of conductors in terminals . 99

10.3 Soldering of components, terminals, and wires into PCB through holes . 100

10.3.1 General . 100

10.3.2 Solder fillets for wires and terminations . 100

10.3.3 Solder fillets for component leads in plated or non-plated through

holes . 101

10.4 Soldering of surface mount components . 102

10.4.1 General . 102

10.4.2 Rectangular and square end-capped or end-metallized leadless chip . 104

10.4.3 Cylindrical and square end-capped components with cylindrical or

oval body . 106

10.4.4 Bottom terminated chip components . 107

10.4.5 L-Shape inwards components . 109

10.4.6 Leadless component with plane termination . 110

10.4.7 Leaded component with plane termination . 110

10.4.8 Leadless castellated ceramic chip carrier components . 112

10.4.9 No lead Quad Flat Pack . 113

10.4.10 Flat pack and gull-wing leaded components with round, rectangular,

ribbon leads . 115

10.4.11 Components with “J” leads . 116

10.4.12 Components with ribbon terminals without stress relief . 117

10.4.13 Stacked modules components with leads protruding vertically from

bottom . 119

10.4.14 Area array devices . 120

10.5 Rework and repair . 122

10.5.1 Removal of solder on unpopulated PCB . 122

10.5.2 Rework, repair and modifications . 122

10.6 High-voltage connections. 123

10.7 Solderless components . 125

11 Post soldering process requirements . 126

11.1 Cleaning of PCB assemblies . 126

11.1.1 General . 126

11.1.2 Verification of cleanliness . 127

11.1.3 Surface Insulation Resistance (SIR) testing . 127

11.1.4 Sodium chloride (NaCl) equivalent ionic contaminants testing . 128

11.1.5 Monitoring of cleanliness . 129

11.2 Staking and bonding . 129

11.3 Conformal coating, potting and underfill . 130

12 Final inspection . 132

12.1 General . 132

12.2 Visual acceptance criteria . 132

12.3 Visual rejection criteria . 133

12.4 X-ray rejection criteria . 135

12.5 Warp and twist of populated boards . 136

12.6 Inspection records . 136

13 Verification procedure. 137

13.1 Verification approval procedure . 137

13.1.1 Request for verification . 137

13.1.2 Technology sample . 137

13.1.3 Audit of assembly processing . 138

13.1.4 Verification programme documentation . 138

13.1.5 Verification samples and testing . 139

13.1.6 Final verification review . 140

13.1.7 Approval status of assembly line . 140

13.1.8 Withdrawal of approval status . 141

13.2 Verification programme . 141

13.2.1 General . 141

13.2.2 Verification for PTH manual soldering . 147

13.2.3 Additional verification for wave soldering . 147

13.2.4 Soldering log . 147

13.3 Special verification testing for ceramic area array components . 149

13.3.1 General . 149

13.3.2 Evaluation of AAD capability samples . 151

13.3.3 Electrical verification of AAD assembly . 151

13.4 Assembly verification with electrical testing procedure . 152

13.5 Verification programme with reduced temperature range . 155

13.6 Verification for solderless process . 156

13.7 Conditions for delta verification . 158

13.8 Verification by similarity . 160

13.8.1 General conditions for similarity . 160

13.8.2 Conditions for similarity for PTH components . 160

13.8.3 Conditions for similarity for SMD . 161

13.8.4 Conditions for similarity for solderless components . 164

14 Environmental tests conditions . 165

14.1 Overview . 165

14.2 Visual inspection . 165

14.3 X-ray inspection . 165

14.4 Cleanliness test . 165

14.5 Warp and twist of PCB . 165

14.6 Electrical continuity measurement . 166

14.7 Electrical continuity for wave soldered multilayers PCB . 166

14.8 Vibration . 167

14.9 Mechanical shock . 169

14.10 Damp heat test . 171

14.11 Temperature cycling test. 171

14.12 Temperature cycling test with reduced temperature range . 172

14.13 Life test . 174

14.14 Final visual inspection . 174

14.15 Microsection . 175

14.15.1 Microsection facilities . 175

14.15.2 Microsections location . 175

14.15.3 Microsection acceptance criteria . 176

14.15.4 Microsection acceptance criteria for ceramic chip capacitors . 189

14.16 Anomalies in PCB and sculptured flex during verification. 196

15 Outsourcing . 197

15.1 General . 197

16 Process identification document (PID) . 199

16.1 Overview . 199

16.2 Document preparation . 199

16.3 Approval . 199

16.4 Contact person . 199

16.5 Process identification document update . 199

17 Quality assurance . 200

17.1 General . 200

17.2 Data . 200

17.3 Nonconformance . 200

17.4 Calibration . 200

17.5 Traceability . 201

17.6 Workmanship standards . 201

17.7 Inspection points . 201

17.8 Operators, inspectors and instructors training and certification . 201

Annex A (normative) Verification programme - DRD . 203

A.1 DRD identification . 203

A.2 Expected response . 203

Annex B (normative) Verification report - DRD . 205

B.1 DRD identification . 205

B.2 Expected response . 205

Annex C (normative) Process Identification Documentation (PID) - DRD . 207

C.1 DRD identification . 207

C.2 Expected response . 207

Annex D (normative) Assembly Summary Table - DRD . 210

D.1 DRD identification . 210

D.2 Expected response . 210

Annex E (normative) Visual workmanship standards for through hole

component . 212

E.1 Soldered stud terminals . 212

E.2 Soldered turret terminals. 213

E.3 Soldered bifurcated terminals . 215

E.4 Soldered hook terminals . 216

E.5 Soldered cup terminals . 217

E.6 Miscellaneous examples of soldered wires . 218

E.7 Soldered wire to shielded cable interconnections . 219

E.8 Assembly of Dual in Line Package . 221

Annex F (informative) Visual and X-ray workmanship standards for SMDs . 222

F.1 Workmanship illustrations for standard SMDs . 222

F.2 X Ray Workmanship illustrations for solder flow and voids . 238

F.3 X Ray Workmanship illustrations for ball grid array devices . 239

F.4 Workmanship illustrations for column grid array devices . 240

Annex G (informative) Example of an SMT audit report. 242

Annex H (informative) Solder Alloys melting temperatures and choice. 251

H.1 Melting temperatures and choice . 251

Bibliography . 252

Figures

Figure 5-1: Profile of correct cutters for trimming leads. 39

Figure 5-2: Example of suitable mechanical strippers . 40

Figure 8-1: Assembly of TO-39 and CKR06 . 70

Figure 8-2: TO package with underfill . 70

Figure 8-3: Methods for incorporating stress relief with components having bendable

leads . 71

Figure 8-4: Methods for attaching wire extensions to non-bendable leads . 72

Figure 8-5: Minimum lead bend . 73

Figure 8-6: Stud leads . 74

Figure 8-7: Wires used to connect opposite sides of a PCB . 75

Figure 8-8: Clinching with stress relief for component in non-plated hole . 76

Figure 8-9: Types of terminal swaging . 78

Figure 8-10: Method of stress relieving components attached to terminals . 78

Figure 8-11: Exposed element . 79

Figure 9-1: Side route connections to turret terminals . 83

Figure 9-2: Bottom route connections to bifurcated terminal . 84

Figure 9-3: Side-route connection to bifurcated terminal . 85

Figure 9-4: Top route connection to bifurcated terminal . 85

Figure 9-5: Connections to hook terminals . 86

Figure 9-6: Connections to pierced terminals . 87

Figure 9-7: Connections to solder cups (connector type) . 88

Figure 9-8: Methods for securing wires . 91

Figure 9-9: Connection of solid or stranded wires to PCBs . 92

Figure 9-10: Connection of coaxial cables to PCBs . 93

Figure 10-1: Maximum tilt for assembled PTH component . 96

Figure 10-2: Maximum tilt for assembled SMD component . 96

Figure 10-3: Minimum acceptable wetting on component side. 102

Figure 10-4: Mounting of rectangular and square end-capped and end-metallized

components . 104

Figure 10-5: Mounting of cylindrical end-capped components . 106

Figure 10-6: Mounting of square end-capped components . 107

Figure 10-7: Mounting of bottom terminated chip component . 108

Figure 10-8: Mounting of components with “L-shape inwards” leads . 109

Figure 10-9: Mounting of leadless component with plane termination . 110

Figure 10-10: Mounting of leaded components with plane termination . 111

Figure 10-11: Mounting of leadless castellated ceramic chip carrier components . 112

Figure 10-12 Mounting of QFN . 114

Figure 10-13: Mounting of gull-wing leaded components with round, rectangular, ribbon

leads . 115

Figure 10-14: Mounting of component with “J” leads . 116

Figure 10-15: Mounting of components without stress relief . 117

Figure 10-16: Mounting of stacked module components with leads protruding vertically

from bottom . 119

Figure 10-17: Typical configuration of ceramic grid array component . 120

Figure 10-18: High voltage connection . 124

Figure 10-19: Solderless assembly configuration . 125

Figure 13-1 : Generic soldering verification flow . 146

Figure 13-2: Example of soldering log for joints discrepancy log . 148

Figure 13-3: Area Array component verification programme flow chart . 150

Figure 13-4: Assembly verification with electrical testing procedure . 154

Figure 13-5: Verification procedure for solderless technology. 157

Figure 14-1:Vibration test flow chart . 167

Figure D-1 : Example of component type preparation and mounting configuration . 211

Figure E-1 : Soldered stud terminals . 212

Figure E-2 : Soldered turret terminals with single conductors . 213

Figure E-3 : Soldered turret terminals with twin conductors . 214

Figure E-4 : Soldered bifurcated terminals. 215

Figure E-5 : Soldered hook terminals . 216

Figure E-6 : Soldered cup terminals . 217

Figure E-7 : Examples of unacceptable soldered wires . 218

Figure E-8 : Hand soldered wire to shielded cable interconnections . 219

Figure E-9 : Hand soldered wire to shielded wire interconnections . 220

Figure E-10 : Hand soldered wire interconnections - details of defects . 221

Figure F-1 : Examples of acceptable and not acceptable solder flow through and

maximum voids during X-ray . 238

Figure F-2 : Angled-transmission X-radiograph showing solder paste shadow due to

partial reflow: Reject . 239

Figure F-3 : Perpendicular transmission X-radiograph showing unacceptable defects . 239

Figure F-4 : Perpendicular transmission X-radiograph showing non-wetted footprint . 240

Figure F-5 : X-radiograph of CGA mounted on PCB showing solder bridge: Reject . 240

Figure F-6 : X-radiograph of CGA showing solder fillets at base of columns: acceptable . 241

Tables

Table 5-1: Particle concentrations classes 8 till 9 according to ISO 14644-1 (2015) . 34

Table 5-2: EPA requirements summary . 36

Table 6-1: Chemical composition of spacecraft solders . 51

Table 6-2: Fluxes . 53

Table 7-1: Clearances for insulation . 61

Table 7-2: Solder baths parameters for degolding and pretinning . 63

Table 8-1: Dimensions and tolerances for clinching component in non-plated hole . 76

Table 9-1: Dimensions for connections of solid or stranded wires to PCBs. 92

Table 9-2: Dimensions for connections of coaxial cables to PCBs . 93

Table 10-1: Dimensional and solder fillet for rectangul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...