SIST EN 17417:2021

(Main)Determination of the ultimate biodegradation of plastics materials in an aqueous system under anoxic (denitrifying) conditions - Method by measurement of pressure increase

Determination of the ultimate biodegradation of plastics materials in an aqueous system under anoxic (denitrifying) conditions - Method by measurement of pressure increase

This document specifies a method for the determination of the ultimate anoxic biodegradation of plastics made of organic compounds, where the amount of the produced nitrogen and carbon dioxide at the end of the test is measured.

The test substance is exposed to an inoculum stemming from the denitrification tank of a wastewater treatment plant. Testing is performed under defined laboratory conditions.

Claims of performance are limited to the numerical result obtained in the test and not used for making unqualified claims such as "disposable in waste water treatment plants" and similar.

Bestimmung der vollständigen Bioabbaubarkeit von Kunststoff-Materialien in wässriger Phase unter anoxischen (denitrifizierenden) Bedingungen - Verfahren mittels Messung der Druckzunahme

Dieses Dokument legt ein Verfahren fest, mit dem durch Messung der Menge des produzierten Stickstoffs und des gebildeten Kohlenstoffdioxids am Ende der Prüfung die vollständige anoxische Bioabbaubarkeit von Kunststoffen aus organischen Verbindungen bestimmt wird.

Die Prüfsubstanz wird einem Inokulum ausgesetzt, das aus einem Denitrifikationsbecken einer Kläranlage stammt. Die Prüfung erfolgt unter definierten Bedingungen im Labor.

Qualitätsansprüche sind auf die in der Prüfung erhaltenen numerischen Ergebnisse begrenzt und werden nicht für unsachgemäße Aussagen wie „in Kläranlagen entsorgbar“ und dergleichen verwendet.

Détermination de la biodégradation ultime des matériaux plastiques dans un système aqueux dans des conditions anoxiques (dénitrifiantes) - Méthode par mesure de l'augmentation de pression

LLe présent document spécifie une méthode pour la détermination de la biodégradation anoxique ultime des plastiques constitués de composés organiques, où la quantité d’azote et de dioxyde de carbone produite à la fin de l’essai est mesurée.

La substance d’essai est exposée à un inoculum provenant du bassin de dénitrification d’une station d’épuration des eaux usées. Les essais sont effectués dans des conditions de laboratoire définies.

Les revendications de performance sont limitées au résultat numérique obtenu lors de l'essai et ne sont pas utilisées pour faire des affirmations non confirmées telles que «jetable dans les stations d'épuration» et similaires.

Ugotavljanje dokončne biorazgradnje plastičnih materialov v vodnem sistemu pri anoksičnih (denitrifikacijskih) pogojih - Metoda z meritvijo zviševanja tlaka

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Oct-2019

- Publication Date

- 12-Nov-2020

- Technical Committee

- IPMA - Polimer materials and products

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 12-Nov-2020

- Due Date

- 17-Jan-2021

- Completion Date

- 13-Nov-2020

Overview

EN 17417:2020 - a CEN European Standard - defines a laboratory method to determine the ultimate anoxic (denitrifying) biodegradation of plastic materials in an aqueous system. The method quantifies mineralization by measuring gas production (nitrogen and carbon dioxide) via a pressure increase technique. Test material is incubated with an inoculum taken from the denitrification tank of a wastewater treatment plant under controlled laboratory conditions. Performance claims from the test are strictly limited to the numerical results obtained and must not be used to make unqualified disposal claims (e.g., “disposable in wastewater treatment plants”).

Key topics and technical requirements

- Test principle: Measurement of pressure increase in closed reactors to infer nitrogen (N2) and CO2 generation during anoxic biodegradation.

- Inoculum: Activated sludge sourced specifically from a denitrification (anoxic) tank of a wastewater treatment plant.

- Controlled conditions: Incubation at defined temperature and stirring; elimination of oxygen (argon sparging) to maintain anoxic/denitrifying conditions.

- Equipment & reagents: Pressure measurement system, stirrers, argon, KOH (for CO2 sorption), HCl (titration), pH meter, membrane filters, analytical balance.

- Analyses & balances:

- Nitrogen balance and calculation of theoretical vs. produced nitrogen.

- Carbon balance including dissolved inorganic carbon (DIC), DOC and CO2 absorbed in traps.

- Determination of suspended solids, ammonia/nitrite/nitrate, protein and DOC as required for mass balances.

- Data evaluation: Calculation of biodegradation level relative to nitrogen and carbon production, degradation curves, and validity criteria.

- Limitations: Results relate to the specific test conditions and inoculum; standard prohibits extrapolating to unqualified operational claims.

Applications

- Assessing biodegradability of plastics under anoxic/denitrifying conditions relevant to wastewater denitrification units, sediments, or oxygen-depleted water layers.

- Screening polymers and formulations for use as solid or soluble carbon sources to support denitrification in wastewater treatment.

- Supporting regulatory, research, and product development decisions where anoxic mineralization behavior is a key performance parameter.

Who should use this standard

- Environmental laboratories performing biodegradation testing.

- Plastic manufacturers and material developers assessing end-of-life behavior.

- Wastewater treatment engineers and process designers evaluating alternative carbon sources.

- Regulatory authorities and conformity assessors needing standardized anoxic biodegradation data.

Related standards

- EN 14987 (aerobic biodegradability & water solubility testing - referenced in the standard introduction)

- EN 872:2005 (suspended solids determination) - normative reference in EN 17417

- EN ISO 14852 (related DOC/DIC terminology and methods) - referenced concepts

Keywords: EN 17417:2020, anoxic biodegradation, denitrifying conditions, plastics biodegradability, pressure increase method, wastewater treatment.

Frequently Asked Questions

SIST EN 17417:2021 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Determination of the ultimate biodegradation of plastics materials in an aqueous system under anoxic (denitrifying) conditions - Method by measurement of pressure increase". This standard covers: This document specifies a method for the determination of the ultimate anoxic biodegradation of plastics made of organic compounds, where the amount of the produced nitrogen and carbon dioxide at the end of the test is measured. The test substance is exposed to an inoculum stemming from the denitrification tank of a wastewater treatment plant. Testing is performed under defined laboratory conditions. Claims of performance are limited to the numerical result obtained in the test and not used for making unqualified claims such as "disposable in waste water treatment plants" and similar.

This document specifies a method for the determination of the ultimate anoxic biodegradation of plastics made of organic compounds, where the amount of the produced nitrogen and carbon dioxide at the end of the test is measured. The test substance is exposed to an inoculum stemming from the denitrification tank of a wastewater treatment plant. Testing is performed under defined laboratory conditions. Claims of performance are limited to the numerical result obtained in the test and not used for making unqualified claims such as "disposable in waste water treatment plants" and similar.

SIST EN 17417:2021 is classified under the following ICS (International Classification for Standards) categories: 13.030.99 - Other standards related to wastes; 83.080.01 - Plastics in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17417:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2021

Ugotavljanje dokončne biorazgradnje plastičnih materialov v vodnem sistemu pri

anoksičnih (denitrifikacijskih) pogojih - Metoda z meritvijo zviševanja tlaka

Determination of the ultimate biodegradation of plastics materials in an aqueous system

under anoxic (denitrifying) conditions - Method by measurement of pressure increase

Bestimmung der vollständigen Bioabbaubarkeit von Kunststoff-Materialien in wässriger

Phase unter anoxischen (denitrifizierenden) Bedingungen - Verfahren mittels Messung

der Druckzunahme

Détermination de la biodégradation ultime des matériaux plastiques dans un système

aqueux dans des conditions anoxiques (dénitrifiantes) - Méthode par mesure de

l'augmentation de pression

Ta slovenski standard je istoveten z: EN 17417:2020

ICS:

13.030.99 Drugi standardi v zvezi z Other standards related to

odpadki wastes

83.080.01 Polimerni materiali na Plastics in general

splošno

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17417

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2020

EUROPÄISCHE NORM

ICS 13.030.99; 83.080.01

English Version

Determination of the ultimate biodegradation of plastics

materials in an aqueous system under anoxic

(denitrifying) conditions - Method by measurement of

pressure increase

Détermination de la biodégradation ultime des Bestimmung der vollständigen Bioabbaubarkeit von

matériaux plastiques dans un système aqueux dans des Kunststoff-Materialien in wässriger Phase unter

conditions anoxiques (dénitrifiantes) - Méthode par anoxischen (denitrifizierenden) Bedingungen -

mesure de l'augmentation de pression Verfahren mittels Messung der Druckzunahme

This European Standard was approved by CEN on 21 September 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17417:2020 E

worldwide for CEN national Members.

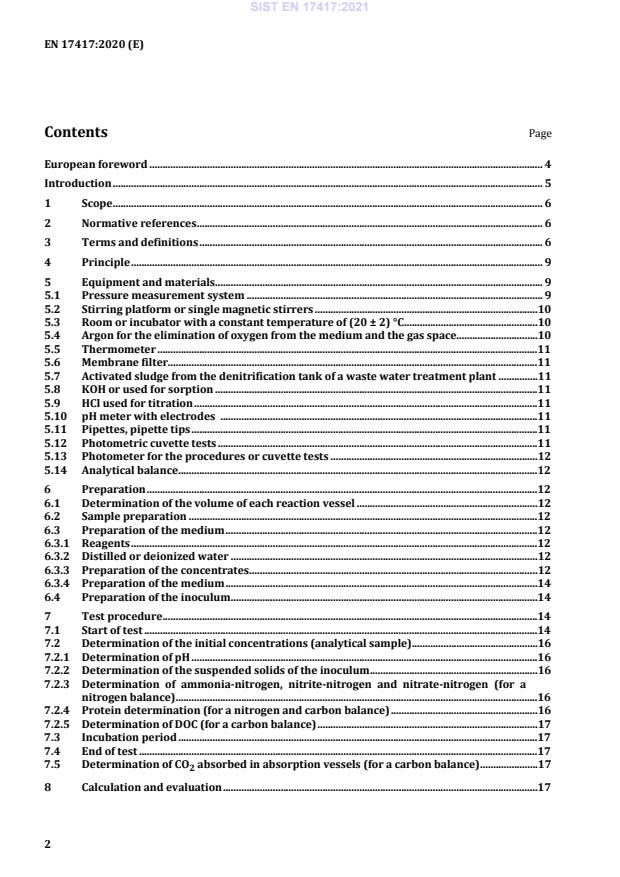

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Principle . 9

5 Equipment and materials. 9

5.1 Pressure measurement system . 9

5.2 Stirring platform or single magnetic stirrers .10

5.3 Room or incubator with a constant temperature of (20 ± 2) °C .10

5.4 Argon for the elimination of oxygen from the medium and the gas space.10

5.5 Thermometer .11

5.6 Membrane filter.11

5.7 Activated sludge from the denitrification tank of a waste water treatment plant .11

5.8 KOH or used for sorption .11

5.9 HCl used for titration .11

5.10 pH meter with electrodes .11

5.11 Pipettes, pipette tips .11

5.12 Photometric cuvette tests .11

5.13 Photometer for the procedures or cuvette tests .12

5.14 Analytical balance .12

6 Preparation .12

6.1 Determination of the volume of each reaction vessel .12

6.2 Sample preparation .12

6.3 Preparation of the medium .12

6.3.1 Reagents .12

6.3.2 Distilled or deionized water .12

6.3.3 Preparation of the concentrates .12

6.3.4 Preparation of the medium .14

6.4 Preparation of the inoculum .14

7 Test procedure .14

7.1 Start of test .14

7.2 Determination of the initial concentrations (analytical sample) .16

7.2.1 Determination of pH .16

7.2.2 Determination of the suspended solids of the inoculum .16

7.2.3 Determination of ammonia-nitrogen, nitrite-nitrogen and nitrate-nitrogen (for a

nitrogen balance) .16

7.2.4 Protein determination (for a nitrogen and carbon balance) .16

7.2.5 Determination of DOC (for a carbon balance) .17

7.3 Incubation period .17

7.4 End of test .17

7.5 Determination of CO absorbed in absorption vessels (for a carbon balance) .17

8 Calculation and evaluation .17

8.1 Calculation of the theoretical N production . 17

8.2 Calculation of the present N production . 18

8.3 Calculation of the level of degradation related to the nitrogen production . 19

8.4 Generation of a nitrogen balance . 19

8.5 Evaluation and expression of results . 20

9 Validity of results . 20

10 Test report . 21

Annex A (informative) Test scheme — Calculation of the maximum permitted initial mass

of the test substance and the minimum nitrate concentration . 22

A.1 General . 22

A.2 Upper pressure measurement limit . 22

A.3 Sorption capacity of the sorption solution (if applicable) . 23

A.4 pH buffer capacity of the medium . 23

A.5 Minimum nitrate concentration . 24

Annex B (informative) Examples of degradation curves . 25

Annex C (informative) Calculation of the produced inorganic carbon and preparation of a

carbon balance . 28

C.1 Calculation of the produced inorganic carbon . 28

C.2 Generation of a carbon balance . 29

C.3 Calculation of the level of biodegradation related to carbon . 30

Bibliography . 31

European foreword

This document (EN 17417:2020) has been prepared by Technical Committee CEN/TC 249 “Plastics”,

the secretariat of which is held by NBN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2021, and conflicting national standards shall be

withdrawn at the latest by May 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

Biodegradation of a chemical substance strongly depends on environmental conditions. The presence

or the absence of oxygen is significant for the metabolic pathway on which the degradation by bacteria

can take place. At present, several test methods for the investigation of biodegradability of polymers

under aerobic conditions, but only a few test methods for the investigation of biodegradability under

anaerobic conditions exist. However, degradation under anoxic (denitrifying) conditions has barely

been considered yet. The concept “anoxic” has been created by engineers and designates conditions

under which denitrification can take place. This means that either a little amount of oxygen or no

−

oxygen at all (< 0,1 mg/l) but nitrate (> 0,1 mg/l NO -N) is present. During heterotrophic

denitrification, e.g. inside the denitrification tank of a wastewater treatment plant, nitrate is reduced to

nitrogen and at the same time organic substrate is oxidized to CO . In nature, anoxic conditions can be

present within the hypolimnion of eutrophic lakes or within the sediment at the transition zone

between the aerobic and the anaerobic zone.

A way to use biodegradable polymers after intended service life would be their addition as additional

carbon source to the denitrification unit of a wastewater treatment plant. In order to check if this way of

disposing a polymer is possible, the biodegradability under anoxic (denitrifying) conditions shall be

determined. Even if a substance shows good aerobic degradability, this does not necessarily apply

under anoxic conditions.

Furthermore, a distinction shall be made between biodegradable polymers that are soluble in water and

those not soluble in water.

Those biodegradable polymers that are soluble in water could be added systematically and

continuously to the denitrification unit as a solid substrate, which is quickly converted and which can

therefore replace the addition of an external liquid carbon source such as ethanol or acetic acid. Testing

their aerobic degradability, their water solubility and, if necessary, their water dispersibility can be

carried out in accordance with EN 14987 [1]. In addition to this, special testing regarding their use as a

carbon source for denitrification is done according to this document. As long as these biodegradable

polymers are present as a solid substance, it shall be ensured that they remain in the denitrification

tank in order to prevent operational failure during other phases of the wastewater treatment plant.

Those biodegradable polymers that are not soluble in water are discontinuously introduced as a solid

substance into a specially designed denitrification reactor, where they substantially remain because of

an appropriate process control. Induced by bacterial activity, they continuously release carbon for the

purpose of denitrification during a process of anoxic degradation, the duration of which depends on

their dimensions (surface/volume ratio). Special testing regarding their use as a water insoluble carbon

source for denitrification is described in this document.

1 Scope

This document specifies a method for the determination of the ultimate anoxic biodegradation of

plastics made of organic compounds, where the amount of the produced nitrogen and carbon dioxide at

the end of the test is measured.

The test substance is exposed to an inoculum stemming from the denitrification tank of a wastewater

treatment plant. Testing is performed under defined laboratory conditions.

Claims of performance are limited to the numerical result obtained in the test and not used for making

unqualified claims such as “disposable in waste water treatment plants” and similar.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 872:2005, Water quality — Determination of suspended solids — Method by filtration through glass

fibre filters

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

ultimate anoxic biodegradation

degradation of an organic compound into carbon dioxide, water and mineral salts of any of the present

elements (mineralization) as well as new biomass by means of microorganisms in the presence of

oxidized nitrogen compounds (nitrate, nitrite) and in the absence of oxygen

3.2

suspended solids

solids obtained by filtration under specified conditions

[SOURCE: EN 872:2005, 3.1]

3.3

dissolved inorganic carbon

DIC

part of the inorganic carbon in water which cannot be removed by specified phase separation

−2

Note 1 to entry: Phase separation can be achieved for example by centrifugation at 40 000 m s for 15 min or by

membrane filtration using membranes with pores of 0,2 µm to 0,45 µm in diameter

[SOURCE: EN ISO 14852:2018, 3.4]

3.4

lag phase

time, measured in days, from the start of a test until adaptation and/or selection of the degrading

microorganisms is achieved and the level of biodegradation of a chemical compound or organic matter

has increased to about 10 % of the maximum level of biodegradation

[SOURCE: EN ISO 14855-1:2012, 3.7]

3.5

level of biodegradation related to the nitrogen production

measured level of biodegradation of a chemical compound or organic substance in a test, calculated

from the amount of actually produced nitrogen divided by the theoretical maximum amount of nitrogen

Note 1 to entry: It is expressed as a percentage.

3.6

level of biodegradation related to carbon

measured level of biodegradation of a chemical compound or organic substance in a test, calculated

from the final products of mineralization of the carbon fraction (amount of carbon from carbon dioxide

and biomass) divided by the carbon fraction of the amount of the test substance used

Note 1 to entry: It is expressed as a percentage.

3.7

maximum level of biodegradation

measured level of biodegradation of a chemical compound or organic substance in a test, above which

no further biodegradation takes places during the test

Note 1 to entry: It is expressed as a percentage.

[SOURCE: EN ISO 14855-1:2012, 3.8, modified — the unit “percentage” has been included in the Note]

3.8

biodegradation phase

time from the end of the lag phase of a test until about 90 % of the maximum level of biodegradation

has been reached

Note 1 to entry: It is expressed in days.

[SOURCE: EN ISO 14855-1:2012, 3.9, modified — the unit “days” has been included in the Note]

3.9

plateau phase

time from the end of the biodegradation phase until the end of a test

Note 1 to entry: It is expressed in days.

[SOURCE: EN ISO 14855-1:2012, 3.10, modified — the unit “days” has been included in the Note]

3.10

nitrogen recovery rate

sum of the mass concentrations of the nitrogen fractions of nitrate, nitrite, ammonium, protein and of

elementary nitrogen at the end of the test divided by the sum of the corresponding mass concentrations

at the beginning of the test

Note 1 to entry: It is expressed in percent.

3.11

carbon recovery rate

sum of the mass concentrations of the dissolved organic carbon (DOC), the carbon fractions of the test

substance, of carbon dioxide and of biomass at the end of the test divided by the sum of the

corresponding mass concentrations at the beginning of the test

Note 1 to entry: It is expressed in percent.

3.12

theoretical oxygen demand

ThOD

theoretical maximum amount of oxygen required to completely oxidize a chemical compound

Note 1 to entry: It is calculated from the molecular formula of this compound and expressed in milligram of

oxygen uptake per milligram of the test compound.

3.13

theoretical nitrogen production

ThNP

theoretical maximum amount of nitrogen produced during biodegradation under denitrifying

conditions

Note 1 to entry: It is calculated from the molecular formula of the test compound and the stoichiometry of the

anoxic biodegradation of this compound (simplified, without biomass) and expressed in milligram of nitrogen

produced per milligram of the test compound.

3.14

theoretical nitrate demand

ThND

theoretical maximum amount of nitrate-nitrogen that is reduced during biodegradation under

denitrifying conditions

Note 1 to entry: It is calculated from the molecular formula of the test compound and the stoichiometry of the

anoxic biodegradation of this compound (simplified, without biomass) and is expressed in milligram of nitrate-

nitrogen produced per milligram of the test compound.

3.15

preadaptation

pre-incubation of an inoculum in the presence of the chemical compound or organic substance under

test, with the aim of enhancing the ability of the inoculum to biodegrade the test substance by

adaptation and/or selection of the microorganisms

4 Principle

In order to investigate anoxic degradation, the nitrogen production (N ) is monitored by means of

pressure measurement in a closed system.

A mineral salt medium, free of oxygen and containing nitrate, with the test substance being the only

carbon source, is placed in a pressure-tight bottle and inoculated with the inoculum from the

denitrification tank of a waste water treatment plant; The gas space of the bottle shall be gassed with

argon or nitrogen in order to prevent oxygen from entering. Subsequently, the vessel is closed by means

of a pressure measuring head. The use of KOH is favourable if the absorbed CO is to be measured by

means of titration in order to prepare a carbon balance.

NOTE KOH is used as its sorption capacity is higher than NaOH, especially if the solution cannot be stirred [4].

Therefore, the pressure increase inside the bottle is proportional to the nitrogen that is produced

during denitrification. Pressure measurement values of a sample are captured and recorded by

pressure sensors and can be transmitted to a personal computer any time. The analytical determination

− − +

NO NO NH

of the , , and protein content at the beginning and the end of the test allows a nitrogen

3 2 4

balance which provides information about the plausibility of results and, in particular, about the leak-

tightness of the system. Based on experience, the resulting concentrations of the metabolites NO and

N O will be very low, which is why they can be neglected.

The level of biodegradation under anoxic conditions is expressed as a percentage and determined by

comparison of the actual and the theoretical nitrogen production. The test result is the maximum level

of biodegradation determined from the plateau phase of the biodegradation curve. Optionally, a carbon

balance can be calculated in order to obtain additional information regarding biodegradation and to

improve the evaluation of biodegradation (see C.2).

5 Equipment and materials

5.1 Pressure measurement system

The following example represents the principle of a system for measuring the produced nitrogen by

means of pressure measurement.

1)

The pressure measurement system (see Figure 1) consists of:

— pressure measuring heads, a combination of a screw cap with integrated pressure sensor;

— bottles capable of being sealed pressure-tight for being used as reaction vessels, nominal volume:

500 ml (or 1 000 ml) with side necks made of glass also capable of being sealed pressure-tight;

— sorption vessel for the purpose of CO sorption in the reaction vessels.

® ®

1)

The OxiTop Control system of WTW, Weilheim, Germany, consisting of “OxiTop -C” pressure measuring

heads, sorption vessels, adequate bottles and accessories, is an example of a suitable product available

commercially. For this system, pressure measurement values of a sample are continuously recorded by the ®

OxiTop heads. At the start of the test, the value is automatically set to ambient pressure (relative zero). The

heads are controlled (e.g. mode, start, measurement duration, GLP monitoring, etc.) by means of a controller ®

(OxiTop OC110) using an infrared interface. The relevant pressure measurement values can be retrieved,

displayed and further processed by a software programme any time. This information is given for the convenience

of users of this standard and does not constitute an endorsement by CEN of the product named.

Key

1 pressure measuring head with IR interface

2 sorption vessel for CO sorption

3 volume of the gas space (V )

gas

4 reaction vessel containing the test mixture with medium, test substance and inoculum

5 magnetic stirrer bar

6 controller with IR interface

7 pH electrode (optional version with pH measurement)

Figure 1 — Pressure measurement system for measuring biodegradation

under anoxic conditions (example)

5.2 Stirring platform or single magnetic stirrers

2)

Stirring platforms or magnetic stirrers with a heat emission as low as possible should be used. The

temperature inside the test vessels should largely remain constant because temperature variations

strongly influence the measurement results.

5.3 Room or incubator with a constant temperature of (20 ± 2) °C

3)

The incubator should maintain the temperature setpoint as closely as possible because temperature

variations strongly influence the measurement results.

5.4 Argon for the elimination of oxygen from the medium and the gas space

Argon 5.0 with a purity of > 99,999 % shall be used.

2)

The stirring platform IS 6-Var of WTW, Weilheim, Germany, for 6 test vessels is an example of a suitable

product available commercially. This information is given for the convenience of users of this standard and does

not constitute an endorsement by CEN of the product named.

3)

The Thermostat Cabinets of WTW, Weilheim, Germany, are an example of a suitable product available

commercially. This information is given for the convenience of users of this standard and does not constitute an

endorsement by CEN of the product named.

5.5 Thermometer

A thermometer serves for measuring the temperature of the inoculum and for checking the set

temperature inside the incubator.

5.6 Membrane filter

The following membrane filters are used for suspended solids determination:

— cellulose acetate membrane filter (with a pore size of 0,45 µm);

— cellulose nitrate membrane filter (with a pore size of 0,45 µm).

5.7 Activated sludge from the denitrification tank of a waste water treatment plant

5.8 KOH or used for sorption

4)

A freshly prepared aqueous standard solution with a concentration of 5 mol/l is used (designation:

“original KOH”).

5.9 HCl used for titration

5)

A freshly prepared aqueous standard solution with a concentration of 1 mol/l is used .

6)

5.10 pH meter with electrodes

5.11 Pipettes, pipette tips

5.12 Photometric cuvette tests

7)

Commercially available products shall be used.

4)

Potassium hydroxide solution Titrisol®, of Merck, Darmstadt, Germany, is an example of a suitable product

available commercially. This information is given for the convenience of users of this standard and does not

constitute an endorsement by CEN of the product named.

5)

Hydrochloric acid, Titrisol®, of Merck, Darmstadt, Germany, is an example of a suitable product available

commercially. This information is given for the convenience of users of this standard and does not constitute an

endorsement by CEN of the product named.

6)

Multi 340i, of WTW, Weilheim, Germany, is an example of a suitable product available commercially. This

information is given for the convenience of users of this standard and does not constitute an endorsement by CEN

of the product named.

7)

Photometric cuvette tests of the Hach Lange GmbH, Düsseldorf, Germany, are examples of suitable products

available commercially.

− −

Nitrate-nitrogen NO -N LCK 340 (measuring range 5 mg/l to 35 mg/l NO -N)

3 3

−

LCK 339 (measuring range 0,23 mg/l to 13,5 mg/l NO -N)

+ +

NH NH

Ammonia-nitrogen ( + NH3)-N LCK 302 (measuring range 47 mg/l to 130 mg/l -N),

4 4

+

NH

LCK 303 (measuring range 2 mg/l to 47 mg/l -N)

− −

Nitrite-nitrogen NO -N LCK 341 (measuring range 0,015 mg/l to 0,6 mg/l NO -N)

2 2

−

LCK 342 (measuring range 0,6 mg/l to 6,0 mg/l NO -N)

With LCK 304 (Ammonia-nitrogen), the pH buffering of the sample excessively influences the pH of the analytical

solution, this leads to incorrect values. In this case, this cuvette test is inappropriate.

5.13 Photometer for the procedures or cuvette tests

5.14 Analytical balance

A balance with an accuracy of 0,1 mg shall be used.

6 Preparation

6.1 Determination of the volume of each reaction vessel

First, weigh each reaction vessel in empty state, then fill them with degassed distilled water without air

bubbles and weigh again. The total volume can be calculated from the difference of the masses and the

density of water at the corresponding temperature (see appropriate tables). The volume of the gas

space is given by the difference of the total volume and the volume of the liquid phase of the

corresponding test mixture. Furthermore, this gas volume is diminished by inserted parts, e.g. magnetic

stir bar, absorber vessel, KOH standard solutions.

6.2 Sample preparation

Dry the test substances in a drying oven (at 105 °C). Let substances with a low melting point dry at

room temperature and store in a desiccator. Insoluble test substances shall be used in powder form

(preferably with a defined grain size range) or small pieces of film (preferably with defined thickness

and dimensions) (e.g. according to ISO 10210 [5]).

6.3 Preparation of the medium

6.3.1 Reagents

All reagents shall be of analytical grade.

6.3.2 Distilled or deionized water

Water (e.g. grade 3 according to ISO 3696 [6]) shall be free of toxic substances (copper in particular),

and containing less than 2 mg/l DOC.

6.3.3 Preparation of the concentrates

The medium is based on the “optimized test medium” used in aerobic degradation tests (according to

EN ISO 14851 [7]) and, as such, it contains a strong phosphate buffer in order to closely maintain a

constant pH during the degradation process. This is even more important for denitrification than for

− –

aerobic processes, since 1 mol OH is produced per mol of reduced NO according to the stoichiometry

+

of Formula (1). Differing from the “optimized test medium” used in aerobic degradation tests, no NH

but NaNO is added here for the bacteria as the only N source. Because iron is contained in an important

2+

enzyme for denitrification, about 0,8 mg/l Fe in form of FeSO (stabilized with EDTA) and other trace

elements are added (see Table 1). The maximum amount of the test substance under standard

conditions should not exceed about 100 mg, but can be varied depending on the conditions given in

Annex A.

The following concentrates, solutions A to E, are stable over an extended period at 4 °C to 10 °C, only

solution F shall be prepared daily.

This information is given for the convenience of users of this standard and does not constitute an endorsement by

CEN of the product named.

6.3.3.1 Solution A

Dissolve

a) anhydrous potassium dihydrogen phosphate (KH PO ) 37,5 g,

2 4

b) disodium hydrogen phosphate dihydrate (Na HPO · 2 H O) 87,3 g,

2 4 2

in water (see 6.3.2) and make up to 1 000 ml.

6.3.3.2 Solution B

Dissolve 22,5 g magnesium sulfate heptahydrate (MgSO · 7 H O) in water (see 6.3.2) and make up to

4 2

1 000 ml.

6.3.3.3 Solution C

Dissolve 36,4 g calcium chloride dihydrate (CaCl · 2 H O) in water (see 6.3.2) and make up to 1 000 ml.

2 2

6.3.3.4 Solution D

Dissolve 303,4 g NaNO in water (see 6.3.2) and make up to 1 000 ml (this solution contains

−

NO

50 g/l -N).

8)

6.3.3.5 Solution E (trace element solution SL6)

Dissolve

— ZnSO · 7 H O 0,10 g,

4 2

— MnCl · 4 H O 0,03 g,

2 2

— H BO 0,30 g,

3 3

— CoCl · 6 H O 0,20 g,

2 2

— CuCl · 2 H O 0,01 g,

2 2

— NiCl · 6 H O 0,02 g,

2 2

— Na MoO · 2 H O 0,03 g

2 4 2

in water (see 6.3.2) and make up to 1 000 ml.

8)

SL6 is a recommendation of the Deutsche Sammlung von Mikroorganismen und Zellkulturen GmbH

(DSMZ) [8], Inhoffenstraße 7 B, 38124 Braunschweig, Germany.

9)

6.3.3.6 Solution F (SL4)

Dissolve

— FeSO · 7 H O 0,2 g,

4 2

— ethylenediaminetetraacetic acid solution (C H N O ) 0,5 g,

10 16 2 8

in water (see 6.3.2) and add

— solution E (SL6) 100 ml

and make up to 1 000 ml.

6.3.4 Preparation of the medium

In order to prepare 1 l of the test medium, fill a volumetric flask with about 500 ml water (see 6.3.2)

and add 100 ml of solution A, 1 ml of solution B and 1 ml of solution C. Furthermore, add 6 ml of

−

NO

solution D (for approximately 300 mg/l -N). According to the nitrate reduction to be expected

other nitrate concentrations may also be set (see Annex A). Then 20 ml of solution F is added.

Thereafter, make up to 1 000 ml with water (see 6.3.2).

Proper composition of the test medium can be verified by measuring the pH, which should be 7,0 ± 0,2.

Subsequently, stir the medium for at least 1 h in a vacuum (e.g. produced by a liquid jet vacuum pump)

and then gas with Ar (or N ) until an oxygen concentration of less than 0,05 mg/l is measured (oxygen

electrode). The advantage of Ar over N is that its density is higher than that of air. Therefore, during

the filling procedure, Ar is settling on the medium as a protective layer.

6.4 Preparation of the inoculum

−

Adjust nitrate concentration to about 100 mg/l NO -N in the activated sludge stemming from the

effluent of a denitrification tank of a wastewater treatment plant (e.g. 1 ml of solution D per 500 ml

activated sludge) containing between 3 g/l and 6 g/l of suspended solids. Adapt to the incubation

temperature in a sealed vessel for at least 3 h (but not more than 24 h) while stirring occasionally.

For the determination of the suspended solids, quickly remove a certain volume (e.g. 10 ml) with a

pipette from the stirred activated sludge and pass through a membrane filter (m ), pore size 0,45 µm,

which has previously been dried and weighted. Again, dry the membrane filter at (105 ± 2) °C (for about

2 h) and cool it down to room temperature inside a desiccator, then weigh the membrane filter once

again (m ). The difference (m − m ) divided by the volume of the filtered water sample results in the

2 2 1

concentration of the suspended solids.

7 Test procedure

7.1 Start of test

At the start of the test, it shall be ensured that the medium and reaction vessels are as oxygen-free as

possible. Therefore, gas the storage bottle and reaction vessels with Ar before and during the complete

filling procedure until the vessels are sealed.

9)

SL4 is a recommendation of the Deutsche Sammlung von Mikroorganismen und Zellkulturen GmbH

(DSMZ) [8], Inhoffenstraße 7 B, 38124 Braunschweig, Germany.

For the sorption of CO that is developing during incubation, fill about 5 g of soda lime into the absorber

vessels. If a carbon balance is to be prepared, alternatively fill each absorber vessel with 5 ml KOH

(“original KOH”) with a concentration of 5 mol/l. This amount is sufficient for the sorption of

13 mmol CO at maximum.

CAUTION For not disturbing the test operation, KOH solution shall not contaminate the medium.

First weigh (exactly) the test substances or the reference substance (positive reference for testing the

inoculum, see Table 1) and transfer to the reaction vessels containing a magnetic stirring bar. Add the

prepared medium while gassing with Ar (e.g. with a bottle-top dispenser) and finally add the prepared

inoculum (volume fraction: 5 % of the total liquid volume, concentration of suspended solids in the test

mixture: 150 mg/l to 300 mg/l). No test substance is added for blank values. At least three reaction

vessels for each test substance, reference substance and blank value should be used.

Two flasks for test material, blank and reference material may be used instead of three for screening

purposes.

The reference substance should be well and quickly degradable under denitrifying conditions. As a

reference substance, PHB (poly-β-hydroxybutyric acid) in powder form is recommended. For the test

substance as well as for the reference substance, a grain size distribution is recommended whose

particle size does not exceed an upper limit value of 250 µm.

Immediately after filling, tightly seal the reaction vessels by using screw plugs on the side necks and

pressure measuring probes (tight sealing is very important). For reaction vessels with suitable lateral

fittings, pH and/or oxygen electrodes can also be included. In this case, the total volume of the aqueous

phase should be increased to 400 ml in order to immerse the sensors in the liquid. For this purpose, the

initial mass of the test sample should be calculated according to Annex A.

If further information about the degradation process is to be gained, the development of the pH can be

monitored in one or more of the reaction vessels. Therefore, the pH electrodes shall be fitted pressure-

tight inside the bottles. Connect each of them to a pH meter. It shall be equipped with a data logger and

be able to transmit these values to a personal computer. In this case, the volume of the electrode shall

be taken into account when determining the volume of the gas space of each reaction vessel.

Place the reaction vessels inside an incubator (or room) with constant temperature (20 ± 1) °C) and

gently stir on a magnetic stirrer. Because the temperature adaption inside the reaction vessels can take

several hours depending on the temperature difference with changing pressure, the measurement

10)

should only start after the temperature has stabilized (start of the measurement) .

As an alternative, pressure measurement can also be started in the laboratory and the reaction vessels

can then be placed inside the incubator. This shall be taken into account during evaluation and

appropriate correction values shall be added to the pressure values.

For the analytical sample (see Table 1), just as for the blank values, no test substance is added. It serves

for the determination of the initial concentrations (see 7.2) and can therefore be prepared in any vessel.

®

10)

For the WTW OxiTop Control System, the maximum number of data points per pressure measuring

head is limited to 360. Consequently, setting the test duration automatically changes the measurement intervals; a

test duration of 60 d results in a measurement interval of 4 h, which is sufficient according to experience. For

eventual longer test durations, the pressure measuring heads can be restarted during incubation after data ®

transfer, see the manual of the WTW OxiTop Control System.

Table 1 — Example of addition into the reaction vessels

Reaction vessel — Blank Test Reference Analytical

a a a

Designation value substance substance sample

Initial mass m in mg – ≈ 100 ≈ 100 –

Volume of the medium

237 237 237 237

in ml

Volume of the inoculum

13 13 13 13

in ml

Total volume of the liquid

250 250 250 250

phase in ml

a

Three replicates are needed.

7.2 Determination of the initial concentrations (analytical sample)

7.2.1 Determination of pH

The determination is carried out in accordance with EN ISO 10523 [9].

7.2.2 Determination of the suspended solids of the inoculum

The determination of the suspended solids of the inoculum shall be done in accordance to EN 872:2005.

To ensure a well-mixed suspension, the sample should be stirred well prior to pipetting. Pass an

accurately measured volume (e.g. 50 ml) of the analytical sample through a preweighted cellulose

acetate membrane filter (pore size 0,45 µm). Dry the membrane filter including the residue for about

2 h inside the drying oven at approximately 105 °C, cool down inside the desiccator (for at least 30 min)

and weigh. The filtrate can be used for the determination of ammonium, nitrite and nitrate. An

analytical balance is recommended for mass determination.

7.2.3 Determination of ammonia-nitrogen, nitrite-nitrogen and nitrate-nitrogen (for a nitrogen

balance)

The determination can be carried out for example with: DIN 38406-5 (ammonia-nitrogen) [10],

EN 26777 (nitrite) [11] and DIN 38405-9 (nitrate) [12] or according to the guidelines of the relevant

cuvette tests with the corresponding photometers (see 5.12).

NOTE Strong pH buffering of the medium can possibly influence the measurement result for ammonia.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...