SIST EN 13411-5:2004+A1:2008

(Main)Terminations for steel wire ropes - Safety - Part 5: U-bolt wire rope grips

Terminations for steel wire ropes - Safety - Part 5: U-bolt wire rope grips

This European Standard has been prepared to provide a means of conforming with the essential safety requirements of the Machinery Directive and associated EFTA Regulations.

Purchasers ordering to this standard are advised to specify in their purchasing contract that the supplier operates a quality assurance system applicable to the relevant part of this standard (e.g. EN ISO 9001) to ensure themselves that products claimed to comply consistently achieve the required level of quality.

Endverbindungen für Drahtseile aus Stahldraht - Sicherheit - Teil 5: Drahtseilklemmen mit U-förmigem Klemmbügel

Diese Europäische Norm legt die Mindestanforderungen an Drahtseilklemmen mit U-förmigem Klemmbügel aus

Eisenwerkstoffen und an die sichere Funktion von Seilendverbindungen mit Drahtseilklemmen mit U-förmigem Klemmbügel entsprechend der vom Hersteller der Drahtseilklemmen vorgesehenen Verwendung fest.

Geeignete Anwendungsfälle sind das Aufhängen statischer Lasten und einmalige Hebevorgänge, die von einer sachkundigen Person unter Berücksichtigung der entsprechenden Sicherheitsfaktoren geprüft wurden.

Drahtseilklemmen mit U-förmigem Klemmbügel sind nicht für die Verwendung bei Spiralseilen geeignet.

Die Verwendung von Drahtseilklemmen mit U-förmigem Klemmbügel als primäre Sicherungsvorrichtungen bei

Förderanlagen im Bergbau, in Seiltrieben von Kränen oder für Endverbindungen bei Anschlagseilen für allgemeine Hebezwecke ist nicht Gegenstand dieser Norm.

Beispiele für Seilklemmen und entsprechende Montageanweisungen sind in den informativen Anhängen A und B angegeben.

Gefährdungen, die in dieser Norm behandelt werden, sind in Abschnitt 4 angegeben.

Terminaisons pour câbles en acier - Sécurité - Partie 5: Serre-câbles à étrier en U

La présente Norme européenne spécifie les prescriptions minimales pour les terminaisons des serre-câbles à étrier

en U fabriqués à partir de matériaux ferreux et pour le comportement sûr des terminaisons à oeil fixées aux

serre-câbles à étrier en U, destinés à l’utilisation prévue par le fabricant du serre-câble.

Parmi les utilisations adaptées figurent la suspension de charges statiques et les opérations de levage ponctuelles

qui ont été évaluées par une personne compétente en tenant compte des facteurs de sécurité appropriés.

Les serre-câbles à étrier en U ne sont pas adaptés à l’utilisation avec les câbles monotorons.

La présente norme ne couvre pas les serre-câbles utilisés comme dispositif principal de retenue sur les monte-charge

de mines, les appareils de levage pour grues ou les terminaisons à oeil pour élingues d’usage courant.

Des exemples de serre-câbles avec les instructions de montage sont donnés dans les annexes informatives A et B.

Les phénomènes dangereux couverts par la présente norme sont identifiés à l’article 4.

Zaključki jeklenih žičnih vrvi - Varnost - 5. del: Vrvne prižemke oblike U (žabice)

General Information

- Status

- Published

- Publication Date

- 04-Nov-2008

- Technical Committee

- DTN - Lift and transport appliances

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 03-Nov-2008

- Due Date

- 08-Jan-2009

- Completion Date

- 05-Nov-2008

- Directive

- 98/37/EC - Machinery

Relations

- Replaces

SIST EN 13411-5:2004 - Terminations for steel wire ropes - Safety - Part 5: U-bolt wire rope grips - Effective Date

- 01-Dec-2008

- Consolidates

SIST EN 13411-5:2004 - Terminations for steel wire ropes - Safety - Part 5: U-bolt wire rope grips - Effective Date

- 18-Jan-2023

Overview

EN 13411-5:2003+A1:2008 - Terminations for steel wire ropes - Safety - Part 5: U-bolt wire rope grips is a CEN European Standard that specifies minimum safety, material and testing requirements for U-bolt grips used to form grip-secured eye terminations on steel wire ropes. The standard supports conformity with the essential safety requirements of the Machinery Directive and associated EFTA regulations. It covers manufacture, marking, fitting instructions, and type testing to ensure consistent performance and safe use.

Key topics and technical requirements

- Scope and limitations

- Applies to U-bolt wire rope grips manufactured from ferrous materials.

- Not suitable for spiral ropes and not intended as primary securing devices on mine or crane hoists or for general lifting slings.

- Materials and mechanical properties

- U-bolt: carbon steel, property class ≥ 5.8 and ≤ 8.8 (EN ISO 898-1).

- Bridge: malleable cast iron (W40-05 or B35-10 per EN 1562) or forged non‑ageing carbon steel.

- Nuts: carbon steel, property class ≥ 5 (EN 20898-2) and product grade A (EN ISO 4759-1).

- Performance requirements

- Grip-secured eye termination must withstand at least 80% of the rope’s minimum breaking force for 5 minutes with ≤ 1 mm slip.

- Fatigue requirement: at least 20,000 cycles under pulsatory loading.

- Cyclic test parameters: cyclic tension between 15% and 30% of the rope’s MBF; initial preload often 20% with possible re‑tightening per manufacturer; frequency ≤ 5 Hz.

- Type testing and verification

- Tests on each rope class and the highest rope grade intended; minimum of three assemblies for type testing.

- Test procedures reference EN 12385 series and EN ISO 7500‑1 for test machine verification.

- Information for use

- Mandatory manufacturer marking (grip size and identification) and comprehensive fitting instructions including torque values, spacing, orientation, rope grades and temperature range.

- Purchasers are advised to require supplier quality assurance (e.g., EN ISO 9001) in procurement contracts.

Applications and who uses this standard

- Practical uses: forming safe eye terminations for static suspension and single-use lifting operations where grips are suitable and manufacturer instructions and safety factors have been applied.

- Typical users: manufacturers of U-bolt wire rope grips, lifting equipment specifiers, safety engineers, rigging contractors, purchasers and conformity/QA teams ensuring compliance with the Machinery Directive.

Related standards

- EN 13411 series (other parts: thimbles, splicing, ferrules, sockets)

- EN 12385-1 / EN 12385-2 (steel wire ropes)

- EN ISO 898-1, EN 1562, EN ISO 4759-1, EN ISO 7500-1, EN 292-2, EN 1050

Specify EN 13411-5 compliance and the supplier’s QA system in contracts to ensure consistent product quality and safe operation.

Frequently Asked Questions

SIST EN 13411-5:2004+A1:2008 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Terminations for steel wire ropes - Safety - Part 5: U-bolt wire rope grips". This standard covers: This European Standard has been prepared to provide a means of conforming with the essential safety requirements of the Machinery Directive and associated EFTA Regulations. Purchasers ordering to this standard are advised to specify in their purchasing contract that the supplier operates a quality assurance system applicable to the relevant part of this standard (e.g. EN ISO 9001) to ensure themselves that products claimed to comply consistently achieve the required level of quality.

This European Standard has been prepared to provide a means of conforming with the essential safety requirements of the Machinery Directive and associated EFTA Regulations. Purchasers ordering to this standard are advised to specify in their purchasing contract that the supplier operates a quality assurance system applicable to the relevant part of this standard (e.g. EN ISO 9001) to ensure themselves that products claimed to comply consistently achieve the required level of quality.

SIST EN 13411-5:2004+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 53.020.30 - Accessories for lifting equipment; 77.140.99 - Other iron and steel products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13411-5:2004+A1:2008 has the following relationships with other standards: It is inter standard links to SIST EN 13411-5:2004, SIST EN 13411-5:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13411-5:2004+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13411-5:2004+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Endverbindungen für Drahtseile aus Stahldraht - Sicherheit - Teil 5: Drahtseilklemmen mit U-förmigem KlemmbügelTerminaisons pour câbles en acier - Sécurité - Partie 5: Serre-câbles à étrier en UTerminations for steel wire ropes - Safety - Part 5: U-bolt wire rope grips77.140.99Drugi železni in jekleni izdelkiOther iron and steel products53.020.30Pribor za dvigalno opremoAccessories for lifting equipmentICS:Ta slovenski standard je istoveten z:EN 13411-5:2003+A1:2008SIST EN 13411-5:2004+A1:2008en,fr01-december-2008SIST EN 13411-5:2004+A1:2008SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13411-5:2003+A1

October 2008 ICS 21.060.70; 53.020.30 Supersedes EN 13411-5:2003 English Version

Terminations for steel wire ropes - Safety - Part 5: U-bolt wire rope grips

Terminaisons pour câbles en acier - Sécurité - Partie 5: Serre-câbles à étrier en U

Endverbindungen für Drahtseile aus Stahldraht -Sicherheit - Teil 5: Drahtseilklemmen mit U-förmigem Klemmbügel This European Standard was approved by CEN on 25 March 2003 and includes Amendment 1 approved by CEN on 18 September 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13411-5:2003+A1:2008: ESIST EN 13411-5:2004+A1:2008

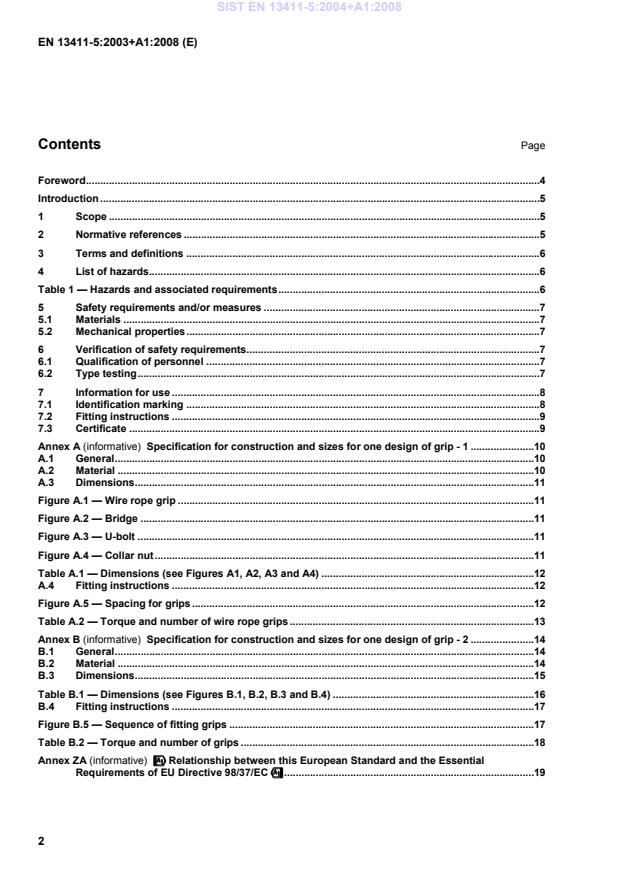

Specification for construction and sizes for one design of grip - 1.10 A.1 General.10 A.2 Material.10 A.3 Dimensions.11 Figure A.1 — Wire rope grip.11 Figure A.2 — Bridge.11 Figure A.3 — U-bolt.11 Figure A.4 — Collar nut.11 Table A.1 — Dimensions (see Figures A1, A2, A3 and A4).12 A.4 Fitting instructions.12 Figure A.5 — Spacing for grips.12 Table A.2 — Torque and number of wire rope grips.13 Annex B (informative)

Specification for construction and sizes for one design of grip - 2.14 B.1 General.14 B.2 Material.14 B.3 Dimensions.15 Table B.1 — Dimensions (see Figures B.1, B.2, B.3 and B.4).16 B.4 Fitting instructions.17 Figure B.5 — Sequence of fitting grips.17 Table B.2 — Torque and number of grips.18 Annex ZA (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC"""".19 SIST EN 13411-5:2004+A1:2008

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""".20 Bibliography.21

Part 7: Symmetric wedge socket

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom. SIST EN 13411-5:2004+A1:2008

3.2 grip-secured eye termination grip-secured eye termination: eye termination secured by wire rope grips fitted in accordance with the manufacturer’s instructions 4 List of hazards Accidental release of a load, or release of a load due to failure of a wire rope grip puts at risk either directly or indirectly the safety or health of those persons within the danger zone. Temperature hazard is not covered as in use temperature is limited by the wire rope. Table 1 contains those hazards that require action to reduce risk identified by risk assessment as being specific and significant for wire rope grips. Table 1 — Hazards and associated requirements Hazards identified in annex A of EN 1050:1996 Relevant clause of annex A of EN 292-2:1991 Relevant clause/subclause of this standard 1 Mechanical hazard due to inadequacy of strength 1.3.2 4.1.2.3 4.1.2.5 4.2.4 1.7.3 4.3.1 4.2.4

5 5 6

6 1.7 Puncture hazard 1.3 5 10.4 Errors of fitting hazard 1.5.4 7

EN ISO 898-1. 5.1.2 Bridge Malleable cast iron grade W40-05 or B35-10 in accordance with EN 1562; or forged non-ageing carbon steel. 5.1.3 Nut Carbon steel with at least property class 5 in accordance with EN 20898-2 and product grade A in accordance with EN ISO 4759-1. 5.2 Mechanical properties 5.2.1 Grip security/tensile efficiency of grip-secured eye termination When tested in accordance with 6.2.2 the grip-secured eye termination shall withstand a force of at least 80% of the minimum breaking force of the rope held for 5 minutes without the rope slipping more than 1 mm at the grip-secured eye termination. 5.2.2 Pulsatory fatigue behaviour of grip-secured eye termination When tested in accordance with 6.2.3 the grip-secured eye termination shall withstand a minimum of

20 000 cycles.

The same grip-secured eye termination subjected to the pulsatory test above shall then be tested in accordance with 6.2.2, after which the grips shall not exhibit any visible cracks, deformation or other damage. 6 Verification of safety requirements 6.1 Qualification of personnel All testing and examination shall be carried out by a competent person. 6.2 Type testing 6.2.1 General In order to prove the design, material and method of manufacture, testing shall be carried out on each class of rope for which the grips are designed. The grade of the rope shall be the highest for which the grips are designed.

Where grips are intended for use with single layer ropes with a fibre core and a steel core, testing shall be carried out on both.

At least three assemblies having a grip-secured eye termination at one end shall be tested.

NOTE The number of tests is regarded as two for assemblies having grip-secured eye terminations at both ends. SIST EN 13411-5:2004+A1:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...