SIST EN 16602-70-39:2019

(Main)Space product assurance - Welding of metallic materials for flight hardware

Space product assurance - Welding of metallic materials for flight hardware

This Standard specifies the processing and quality assurance requirements for the different types of metallic welding (manual, automatic, semi-automatic and machine) for space flight applications. This standard can also be used for weld activities on space related ground equipment and development models for flight hardware. The Standard covers all welding processes used for joining metallic materials for space applications. This includes, but is not limited to:

- Gas Tungsten Arc Welding (GTAW) / Tungsten Inert Gas (TIG), (process 14)

- Gas Metal Arc Welding (GMAW) / Metal Inert Gas (MIG) (process 13)

- Plasma Arc Welding (PAW) / Plasma of Transferred Arc (PTA), (process 15)

- Electron beam welding (EBW), (process 51)

- Laser beam welding (LBW), (process 52)

- Friction Stir welding (process 43)

- Magnetic Pulse welding (process 442)

- Linear friction welding (process 42)

- Rotary friction welding (process 42)

The specific process numbers mentioned above are listed according to the standard ISO 4063:2009.

This Standard does not detail the weld definition phase and welding pre-verification phase, including the derivation of design allowables.

This standard may be tailored for the specific characteristic and constraints of a space project in conformance with ECSS-S-ST-00.

Raumfahrtproduktsicherung - Teil 70-39: Anforderungen an Verarbeitung und Qualitätssicherung für das Metallschweißen in Flug-Hardware

Assurance produit spatiale - Soudure de matériaux métalliques pour matériel de vol

La présente Norme spécifie les exigences relatives au traitement et à l'assurance qualité de différents types de soudage métallique (manuel, automatique, semi automatique et mécanisé) pour des applications de vol spatial. La présente Norme peut également être appliquée aux activités de soudage des équipements au sol relatifs au domaine spatial et aux modèles de développement des matériels de vol. La présente Norme couvre tous les procédés de soudage utilisés pour la liaison de matériaux métalliques pour des applications spatiales. Cela comprend, sans toutefois s'y limiter :

- le soudage à l'arc sous gaz avec électrode de tungstène (GTAW)/sous gaz inerte avec électrode de tungstène (TIG), (procédé 14)

- le soudage à l'arc sous gaz avec électrode fusible (GMAW)/sous gaz inerte avec électrode fusible (MIG), (procédé 13)

- le soudage à l'arc au plasma (PAW)/plasma avec arc transféré (PTA), (procédé 15)

- le soudage par faisceau d'électrons (EBW), (procédé 51)

- le soudage par faisceau laser (LBW), (procédé 52)

- le soudage par friction-malaxage (procédé 43)

- le soudage par impulsion magnétique (procédé 442)

- le soudage par friction linéaire (procédé 42)

- le soudage par friction rotative (procédé 42)

Les numéros spécifiques des procédés ci-dessus sont listés selon la norme ISO 4063:2009.

La présente Norme ne donne pas de détails sur les phases de définition et de pré vérification du soudage, y compris les écarts de conception autorisés.

La présente norme peut être adaptée aux caractéristiques et contraintes spécifiques d'un projet spatial conformément à l'ECSS-S-ST-00.

Zagotavljanje varnih proizvodov v vesoljski tehniki - Varjenje kovinskih materialov za letalsko strojno opremo

Ta standard določa zahteve za obdelavo in zagotavljanje kakovosti za različne vrste kovinskega varjenja (ročno, avtomatsko, polavtomatsko in strojno) za letalsko strojno opremo. Standard zajema vse postopke varjenja, ki se uporabljajo za spajanje kovinskih materialov za letalsko strojno opremo. To vključuje, vendar ni omejeno na: • varjenje z volframovo elektrodo (GTAW)/varjenje TIG, (proces 14) • varjenje s taljivo elektrodo (GMAW)/varjenje MIG (proces 13) • plazemsko obločno varjenje (PAW)/varjenje PTA, (proces 15) • varjenje z elektronskim snopom (EBW), (proces 51) • lasersko varjenje (LBW), (proces 52) • varjenje z gnetenjem (proces 43) • magnetno pulzno varjenje (proces 442) • linearno varjenje s trenjem (proces 42) • rotacijsko varjenje s trenjem (proces 42) Zgornje številke procesov so navedene v skladu s standardom ISO 4063. Ta dokument ne zajema popravila zvarov. Ta standard se lahko prilagodi posameznim lastnostim in omejitvam vesoljskega projekta v skladu s standardom ECSS-S-ST-00.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Apr-2016

- Publication Date

- 09-Dec-2018

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Dec-2018

- Due Date

- 10-Feb-2019

- Completion Date

- 10-Dec-2018

Overview

EN 16602-70-39:2018 - Space product assurance - Welding of metallic materials for flight hardware (CEN) defines processing and quality-assurance requirements for welding metallic materials used in space flight hardware. It covers manual, semi‑automatic, automatic and machine welding processes and can also be applied to space-related ground equipment and development models. The standard addresses the full set of welding technologies commonly used in space hardware, referencing ISO 4063 process numbers, and is intended for European adoption of ECSS-derived requirements.

Key topics and requirements

- Covered welding processes: Gas Tungsten Arc Welding (GTAW / TIG, process 14), Gas Metal Arc Welding (GMAW / MIG, process 13), Plasma Arc Welding (PAW / PTA, process 15), Electron Beam Welding (EBW, process 51), Laser Beam Welding (LBW, process 52), Friction Stir Welding (process 43), Magnetic Pulse (process 442), Linear and Rotary Friction Welding (process 42), etc.

- Welding procedure control: Development and maintenance of Welding Procedure Specifications (WPS) and Welding Verification Test Plans (WVTP) including normative templates (DRD).

- Personnel and training: Qualification and certification of welders, welding operators, welding supervisors and inspectors; validity limits and process‑specific requirements.

- Equipment and materials: Qualification, maintenance and calibration of welding equipment; controls on base materials, filler materials, shielding/backing gases and tooling.

- Inspection and testing: Non‑destructive testing (visual, penetrant, radiographic, ultrasonic, CT/tomography), destructive testing (metallography, hardness, tensile), and requirements for weld samples and process verification.

- Acceptance & classification: Weld safety classes and weld sensitivity levels, tailoring of weld acceptance criteria by project, and procedures for delta verification, repairs and re‑welds.

- Quality assurance & documentation: Traceability, process records, anomaly handling, reference samples and production controls for flight hardware.

Note: EN 16602-70-39:2018 does not detail the weld definition phase or pre‑verification derivation of design allowables; it may be tailored to project constraints in conformance with ECSS‑S‑ST‑00.

Applications and users

- Primary users: Space agencies, prime contractors, subsystem suppliers, and welding/quality engineers working on spacecraft structures, propulsion assemblies, pressure vessels and mechanisms.

- Use cases: Verifying and controlling welding for flight hardware, qualification of welding processes for critical assemblies, audits and supplier oversight, and adapting welding QA for development models and ground support equipment.

Related standards

- ECSS-Q-ST-70-39 (origin reference)

- ISO 4063 (welding process numbering)

- ECSS‑S‑ST‑00 (tailoring guidance)

Keywords: EN 16602-70-39:2018, space product assurance, welding, flight hardware, TIG, MIG, EBW, LBW, friction stir welding, welding procedure specification, welding verification.

Frequently Asked Questions

SIST EN 16602-70-39:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Space product assurance - Welding of metallic materials for flight hardware". This standard covers: This Standard specifies the processing and quality assurance requirements for the different types of metallic welding (manual, automatic, semi-automatic and machine) for space flight applications. This standard can also be used for weld activities on space related ground equipment and development models for flight hardware. The Standard covers all welding processes used for joining metallic materials for space applications. This includes, but is not limited to: - Gas Tungsten Arc Welding (GTAW) / Tungsten Inert Gas (TIG), (process 14) - Gas Metal Arc Welding (GMAW) / Metal Inert Gas (MIG) (process 13) - Plasma Arc Welding (PAW) / Plasma of Transferred Arc (PTA), (process 15) - Electron beam welding (EBW), (process 51) - Laser beam welding (LBW), (process 52) - Friction Stir welding (process 43) - Magnetic Pulse welding (process 442) - Linear friction welding (process 42) - Rotary friction welding (process 42) The specific process numbers mentioned above are listed according to the standard ISO 4063:2009. This Standard does not detail the weld definition phase and welding pre-verification phase, including the derivation of design allowables. This standard may be tailored for the specific characteristic and constraints of a space project in conformance with ECSS-S-ST-00.

This Standard specifies the processing and quality assurance requirements for the different types of metallic welding (manual, automatic, semi-automatic and machine) for space flight applications. This standard can also be used for weld activities on space related ground equipment and development models for flight hardware. The Standard covers all welding processes used for joining metallic materials for space applications. This includes, but is not limited to: - Gas Tungsten Arc Welding (GTAW) / Tungsten Inert Gas (TIG), (process 14) - Gas Metal Arc Welding (GMAW) / Metal Inert Gas (MIG) (process 13) - Plasma Arc Welding (PAW) / Plasma of Transferred Arc (PTA), (process 15) - Electron beam welding (EBW), (process 51) - Laser beam welding (LBW), (process 52) - Friction Stir welding (process 43) - Magnetic Pulse welding (process 442) - Linear friction welding (process 42) - Rotary friction welding (process 42) The specific process numbers mentioned above are listed according to the standard ISO 4063:2009. This Standard does not detail the weld definition phase and welding pre-verification phase, including the derivation of design allowables. This standard may be tailored for the specific characteristic and constraints of a space project in conformance with ECSS-S-ST-00.

SIST EN 16602-70-39:2019 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes; 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16602-70-39:2019 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 16602-70-39:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Zagotavljanje varnih proizvodov v vesoljski tehniki - Varjenje kovinskih materialov za letalsko strojno opremoRaumfahrtproduktsicherung - Teil 70-39: Anforderungen an Verarbeitung und Qualitätssicherung für das Metallschweißen in Flug-HardwareAssurance produit spatiale - Soudure de matériaux métalliques pour matériel de volSpace product assurance - Welding of metallic materials for flight hardware49.140Vesoljski sistemi in operacijeSpace systems and operations25.160.10Varilni postopki in varjenjeWelding processesICS:Ta slovenski standard je istoveten z:EN 16602-70-39:2018SIST EN 16602-70-39:2019en,fr,de01-februar-2019SIST EN 16602-70-39:2019SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16602-70-39

November

t r s z ICS

t wä s x rä s râ

v {ä s v r

English version

Space product assurance æ Welding of metallic materials for flight hardware

Assurance produit des projets spatiaux æ Soudage de matßriaux mßtalliques pour matßriel de vol

Raumfahrtproduktsicherung æ Metallschweißen in FlugæHardware This European Standard was approved by CEN on

u September

t r s zä

C Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN and CENELEC memberä

translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels y any means reserved worldwide for CEN national Members and for CENELEC Membersä Refä Noä EN

s x x r tæ y ræ u {ã t r s z ESIST EN 16602-70-39:2019

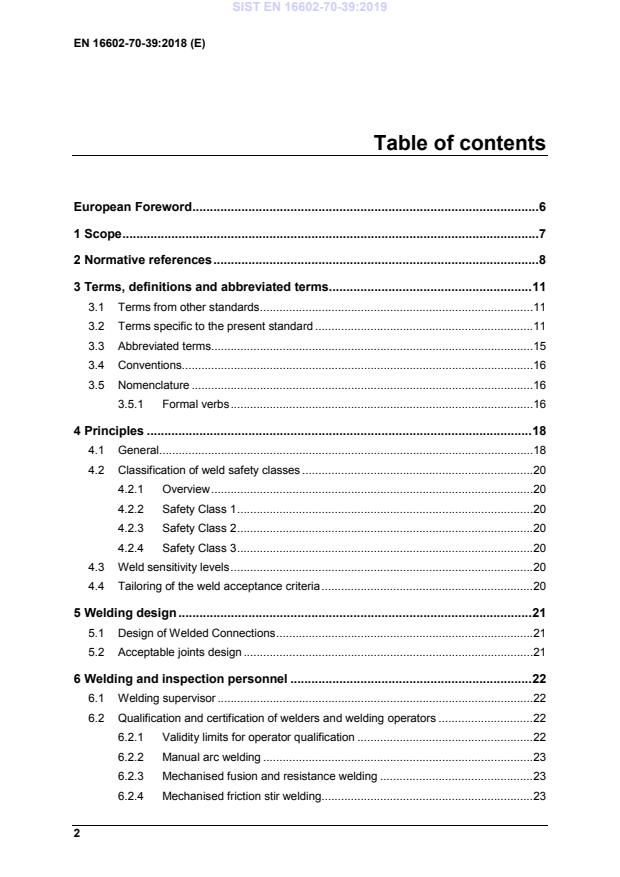

Welding Procedure Specification (WPS) - DRD . 58 A.1.1 Requirement identification and source document . 58 A.1.2 Purpose and objective . 58 A.2 Expected response . 58 A.2.1 Scope and content . 58 A.2.2 Special remarks . 67 SIST EN 16602-70-39:2019

Figures Figure 4-1 Flow chart showing the steps required to produce a verified weld process and flight hardware . 19 Figure 9-1: Discoloration of the inside of austenitic stainless steel tubes . 33

Tables Table 7-1: Acceptable gas purity levels . 27 Table 7-2: Recommended shielding gases for welding . 27 Table 9-1: Colour acceptance criteria for titanium fusion welds . 32 Table 9-2: Examples of weld discoloration for titanium fusion welds (for information only) . 33 Table 10-1: Outer features for fusion welds . 38 Table 10-2: Inner Features for Fusion Welds . 43 Table 10-3: Features for friction stir welds . 46 Table 11-1: Minimum acceptable amount of testing for manual arc welding . 49 Table 11-2: Minimum acceptable amount of testing for all mechanised welding processes class 1 and 2 welds . 49 Table 11-3: Minimum acceptable amount of testing for class 1 and 2 welds (all processes) . 50 Table 12-1: Dew point conditions for welding . 54 Table 12-2: Tests to be performed on parts performed during production of flight hardware . 55

EN reference Reference in text Title EN 16601-00-01 ECSS-S-ST-00-01 ECSS system – Glossary of terms EN 16603-32-01 ECSS-E-ST-32-01 Space engineering –Fracture control EN 16601-40 ECSS-M-ST-40 Space management – Configuration and information management EN 16602-10-09 ECSS-Q-ST-10-09 Space product assurance – Nonconformance control system EN 16602-20 ECSS-Q-ST-20 Space product assurance – Quality assurance

AMS 2644:2006 Inspection material, penetrant

ASTM E164-13:2013 Standard Practice for Contact Ultrasonic Testing of Weldments

ASTM E3:2007

Standard Guide for Preparation of Metallographic Specimens

ASTM E340:2013 Standard Test Method for Macroetching Metals and Alloys

ASTM E407:2007 Standard Practice for Microetching Metals and Alloys

AWS D18.2:2009 Guide to weld discoloration levels on inside of austenitic stainless steel tube

DIN 29595:2007-04 Fusion welded metallic components – requirements

DIN 65153:1997-06 Acceptance testing of plasma arc welding equipment.

EN 4179:2009 Aerospace series. Qualification and approval of personnel for non-destructive testing

EN 60974

Arc welding equipment

Part 1:2012 Welding power sources

Part 2:2013 Liquid cooling systems SIST EN 16602-70-39:2019

Part 3:2013 Arc striking and stabilizing devices

Part 4:2010 Periodic inspection and testing

Part-5:2013 Wire feeders

Part 6:2010 Limited duty equipment

Part 7:2013 Torches

Part 8:2009 Gas consoles for welding and plasma cutting systems

Part 9: 2010 Installation and use

Part 10:2014 Electromagnetic compatibility (EMC) requirements

Part 11:2010 Electrode holders

Part 12:2011 Coupling devices for welding cables

Part 13:2011 Welding clamp

ISO 2553:2013 Welding and allied processes -- Symbolic representation on drawings -- Welded joints

ISO 3452 Non-destructive testing - Penetrant testing

Part 1:2013 General principles

Part 2:2013 Testing of penetrant materials

Part 3:2013 Reference test blocks

Part 4:1998 Equipment

Part 5: 2008 Penetrant testing at temperatures higher than 50 degrees C

Part 6:2008 Penetrant testing at temperatures lower than 10 degrees C

ISO 4063:2009 Welding and allied processes - Nomenclature of processes and reference numbers

ISO 4136:2012 Destructive tests on welds in metallic materials - Transverse tensile test

ISO 6848:2004 Arc welding and cutting - Nonconsumables tungsten electrodes - Classification

ISO 6947:2011 Welding and allied processes - Welding positions

ISO 9015 Destructive tests on welds in metallic materials - Hardness testing (Part 1 and 2)

Part 1:2001 Hardness test on arc welded joints

Part 2:2003 Microhardness testing of welded joints

EN 10204:2004 Metallic products - Types of inspection documents

ISO 11611:2007 Protective clothing for use in welding and allied processes

ISO 14731:2006 Welding coordination - Tasks and responsibilities

ISO 14732:2013 Welding personnel – Qualification testing of welding operators and weld setters for mechanized and automatic welding of metallic materials

ISO 14744 Acceptance inspection of electron beam welding machines SIST EN 16602-70-39:2019

Part 1:2008 Principles and acceptance conditions

Part 2:2000 Measurement of accelerating voltage characteristics

Part 3:2000 Measurement of beam current characteristics

Part 4:2000 Measurement of welding speed

Part 5:2000 Measurement of run-out accuracy

Part 6:2000 Measurement of stability of spot position

ISO 15614-2:2005 Specification and qualification of welding procedures for metallic materials - Welding procedure test - Part 2: Arc welding of aluminium and its alloys

ISO 15616 Acceptance tests for CO2-laser beam machines for high quality welding and cutting

Part 1:2003 General principles, acceptance conditions

Part 2:2003 Measurement of static and dynamic accuracy

Part 3:2003 Calibration of instruments for measurement of gas flow and pressure

Part 4:2008 Acceptance tests for CO2-laser beam machines for high quality welding and cutting - Part 4: Machines with 2-D moving optics

ISO 17636:2013 Non-destructive testing of welds - Radiographic testing

Part 1:2013 X- and gamma-ray techniques with film

Part 2:2013 X- and gamma-ray techniques with digital detectors

EN-ISO 17637:2011 Non-destructive testing of welds - Visual testing of fusion-welded joints

ISO 17640:2010 Non-destructive testing of welds - Ultrasonic testing - Techniques, testing levels, and assessment

ISO 22826:2005 Destructive tests on welds in metallic materials - Hardness testing of narrow joints welded by laser and electron beam (Vickers and Knoop hardness tests)

ISO 22827:2005 Acceptance tests for Nd: YAG laser beam welding machines - Machines with optical fibre delivery

Part 1:2005 Laser assembly

Part 2:2005 Moving mechanism

ISO 24394:2008 Welding for aerospace applications - Qualification test for welders and welding operators - Fusion welding of metallic components

ISO 25239-3:2011 Friction stir welding - Aluminium - Part 3: Qualification of welding operators

ISO 25239-5:2011 Friction stir welding - Aluminium - Part 5: Quality and inspection requirements SIST EN 16602-70-39:2019

1. critical b. For the purpose of this Standard, the terms and definitions from ECSS-E-ST-32-01 apply. 1. fail-safe 3.2 Terms specific to the present standard 3.2.1 acceptable weld weld that has no defects and passes all acceptance criteria 3.2.2 all weld metal tensile test specimen test specimen with the reduced section composed of only weld metal 3.2.3 alpha sample

weld sample produced prior to the start of a production run, used to verify selected aspects of the quality of the weld to be produced during production NOTE The term "pre-weld sample" is synonymous. 3.2.4 base metal part of the welded joint which remains un-melted or un-stirred for friction stir welding, and unaffected by the heat of the process, such that the microstructure and mechanical properties are unaffected 3.2.5 beta sample weld sample produced at the end of a production run, used to verify selected aspects of the quality of the weld to be produced during production NOTE The term "post-weld sample" is synonymous. SIST EN 16602-70-39:2019

Abbreviation Meaning AC alternating current AVC arc voltage control CoC

certificate of conformance DC direct current DRD document requirements definition EBW electron beam welding FSW friction stir welding GMAW gas metal arc welding GTAW gas tungsten arc welding HAZ

heat affected zone LBW laser beam welding SIST EN 16602-70-39:2019

c. The term "qualification test report (QTR)" used in common welding documentation is synonymous with the term "welding verification test report (WVTR)" from the ECSS-Q-ST-70-39. 3.5 Nomenclature 3.5.1 Formal verbs The following nomenclature applies throughout this document: a. The word "shall" is used in this document to express requirements. All the requirements are expressed with the word "shall". SIST EN 16602-70-39:2019

/

samples (pre- and post test)•=NDT inspection•=Production of witness samples (long term storage•=Destructive testingProduction of flight hardwareProduction of flight hardwareIssue WPS and test report Figure 4-1 Flow chart showing the steps required to produce a verified weld process and flight hardware SIST EN 16602-70-39:2019

Level A represents the more stringent requirements, and level C the least stringent requirements and B is in between A and C. 4.4 Tailoring of the weld acceptance criteria Verification of welded products takes into account the requirements and acceptance criteria of this standard. If they turn out to be insufficient (or too strict) tailoring can be necessary in agreement with the customer. SIST EN 16602-70-39:2019

NOTE Examples of durability critical include fatigue, corrosion, creep. 5.2 Acceptable joints design a. The acceptable joint design shall be in accordance with the requirements of ISO 2553:2013. SIST EN 16602-70-39:2019

1. a qualification record is maintained from the date of the initial qualification, 2. regular audit of the records specified in the 6.2.1e.1 is performed, 3. the welder and welding operator use the process within every six month period.

f. The welders and welding operators shall be assigned by the responsible welding supervisor 6.2.2 Manual arc welding a. Manual arc welding shall be performed by welders who have a valid qualification certificate in accordance with ISO 24394:2008. 6.2.3 Mechanised fusion and resistance welding a. Mechanised fusion and resistance welding shall be performed by welding operators who have a valid certificate in accordance with ISO 14732:2013. 6.2.4 Mechanised friction stir welding a. Mechanised friction stir welding shall be performed by welding operators who have a valid certificate in accordance with ISO 25239-3:2011. 6.3 Qualification and certification of welding inspectors a. The personnel for welding inspection shall be assigned and briefed by the responsible qualified welding inspector. b. The personnel for visual inspection shall be qualified and certified in accordance with EN 4179:2009. c. Welding inspectors shall be qualified and certified in NDI in accordance with EN 4179:2009.

6.4 Clothing requirements a. For welding processes the clothing shall specified by the welding supervisor, except the case specified in the requirement 6.4c

b. The protective clothing used for arc welding and allied processes shall be in accordance with ISO 11611:2007. c. When welding in a clean room, only nitrile gloves shall be used by the welders, welding operators and all other personnel involved in the welding process. SIST EN 16602-70-39:2019

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...