SIST EN 16602-70-55:2015

(Main)Space product assurance - Microbiological examination of flight hardware and cleanrooms

Space product assurance - Microbiological examination of flight hardware and cleanrooms

This standard defines test procedures for quantitative and/or qualitative microbiological examination of surfaces of flight hardware and in microbiologically controlled environments (e.g. cleanroom surfaces, cleanroom air, isolator systems).

The following test methods are described:

• Surface and air sampling and detection of biological contaminants with swabs, wipes, contact plates and air samplers, followed by cultivation for bioburden determination.

• Sampling of biological contaminants by DNA analysis from swabs and wipes.

The test methods described in this standard apply to controlling the microbiological contamination on all manned and unmanned spacecraft, launchers, payloads, experiments, ground support equipment, and cleanrooms with planetary protection constraints.

This standard does not address molecular contamination control.

This standard does not address the principles and basic methodology for controlling cleanrooms and associated controlled environments

with constraints on particulate contamination.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Raumfahrtproduktsicherung - Mikorbiologische Prüfung von Flughardware und Reinräumen

Assurance produit des projets spatiaux - Examen microbiologique des matériels de vol et des salles blanches

Zagotavljanje varnih proizvodov v vesoljski tehniki - Mikrobiološka preiskava letalske strojne opreme in čistih prostorov

Ta standard določa preskusne postopke za kvantitativno in/ali kvalitativno mikrobiološko preiskavo površin letalske strojne opreme in v mikrobiološko nadzorovanih okoljih (npr. površine čistih prostorov, zrak v čistih prostorih, sistemi izolacije). Opisane so naslednje preskusne metode: • vzorčenje površin in zraka ter odkrivanje bioloških onesnaževal z brisi, stičnimi ploščami in vzorčevalniki zraka ter z naknadno kultivacijo za ugotavljanje biološke obremenitve; • vzorčenje bioloških onesnaževal na podlagi analize DNK brisov. Preskusne metode, opisane v tem standardu, se uporabljajo za nadzor mikrobiološke onesnaženosti vesoljskih plovil s posadko ali brez nje, lansirnikov, tovorov, poskusov, podporne opreme na tleh in čistih sob z omejitvami planetarne zaščite. Ta standard se ne nanaša na nadzor molekularne onesnaženosti. Ta standard se ne nanaša na načela in osnovno metodologijo za nadzor čistih sob in povezanih nadziranih okolij z omejitvami glede onesnaženosti z delci. Ta standard se lahko prilagodi posameznim lastnostim in omejitvam vesoljskega projekta v skladu s standardom ECSS-S-ST-00.

General Information

- Status

- Published

- Public Enquiry End Date

- 19-Aug-2014

- Publication Date

- 18-Oct-2015

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Oct-2015

- Due Date

- 11-Dec-2015

- Completion Date

- 19-Oct-2015

Overview

EN 16602-70-55:2015 (CEN) - Space product assurance: Microbiological examination of flight hardware and cleanrooms - defines standardized test procedures for detecting and quantifying microbiological contamination (bioburden) on spacecraft hardware and in microbiologically controlled environments. The standard covers sampling with swabs, wipes, contact plates and active air samplers, cultivation-based bioburden assays and DNA-based sampling from swabs and wipes for biodiversity analysis. It is intended to support planetary protection requirements for manned and unmanned spacecraft, launchers, payloads, experiments, ground support equipment and cleanrooms.

Key topics and requirements

- Scope and exclusions

- Applies to microbiological examination of surfaces and air in controlled environments with planetary protection constraints.

- Does not address molecular contamination control or basic particulate cleanroom control methodology.

- Sampling methods

- Surface sampling: swabs (up to 25 cm²) and wipes (up to 1 m²); multiple swabs/wipes allowed for larger areas.

- Cleanroom monitoring: contact plates and active air sampling for continuous air surveillance.

- DNA analysis procedures for non-cultivable organisms from swabs/wipes are included.

- Assays and analysis

- Bioburden quantification: culture-based assays (example: aerobic mesophilic bacteria).

- Biodiversity: culture-based identification and non-culture molecular methods (PCR/DNA).

- Environmental and laboratory controls

- Recommended ambient conditions: ~22 ±3 °C and 55 ±10 % RH unless otherwise specified.

- Good laboratory practice and traceability for sample identification, handling, storage and reporting.

- Validation of test procedures and determination of sampling/analysis efficiencies (correction factors) required.

- Documentation

- Formal Request, Work Proposal and Test Report DRDs (Annex A–C).

- Detailed procedural annexes (Annex D–G) with flow charts, primers and method steps.

- Quality and safety requirements reference ECSS quality system clauses.

Practical applications & users

- Who uses it:

- Contamination control engineers, spacecraft systems engineers, planetary protection officers, aerospace microbiologists, cleanroom managers, and qualified test laboratories.

- Typical uses:

- Pre-launch verification of flight hardware and payloads.

- Routine and campaign cleanroom monitoring and qualification.

- Project-specific tailoring of microbiological test plans to meet mission planetary protection constraints.

- Benefits:

- Consistent, auditable methods for bioburden control, helping missions meet legal and scientific obligations under planetary protection regimes.

Related standards

- ECSS-Q-ST-70-01 (cleanliness & contamination control)

- ECSS-S-ST-00-01 (ECSS glossary and system)

- ECSS-Q-ST-20 / ECSS-Q-ST-10-09 (quality and nonconformance)

- Laboratory quality best practice: ISO/IEC 17025 (recommended)

Keywords: EN 16602-70-55, microbiological examination, space product assurance, bioburden, cleanroom testing, planetary protection, flight hardware, swab assay, wipe assay, contact plates, air sampling, DNA analysis.

Frequently Asked Questions

SIST EN 16602-70-55:2015 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Space product assurance - Microbiological examination of flight hardware and cleanrooms". This standard covers: This standard defines test procedures for quantitative and/or qualitative microbiological examination of surfaces of flight hardware and in microbiologically controlled environments (e.g. cleanroom surfaces, cleanroom air, isolator systems). The following test methods are described: • Surface and air sampling and detection of biological contaminants with swabs, wipes, contact plates and air samplers, followed by cultivation for bioburden determination. • Sampling of biological contaminants by DNA analysis from swabs and wipes. The test methods described in this standard apply to controlling the microbiological contamination on all manned and unmanned spacecraft, launchers, payloads, experiments, ground support equipment, and cleanrooms with planetary protection constraints. This standard does not address molecular contamination control. This standard does not address the principles and basic methodology for controlling cleanrooms and associated controlled environments with constraints on particulate contamination. This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

This standard defines test procedures for quantitative and/or qualitative microbiological examination of surfaces of flight hardware and in microbiologically controlled environments (e.g. cleanroom surfaces, cleanroom air, isolator systems). The following test methods are described: • Surface and air sampling and detection of biological contaminants with swabs, wipes, contact plates and air samplers, followed by cultivation for bioburden determination. • Sampling of biological contaminants by DNA analysis from swabs and wipes. The test methods described in this standard apply to controlling the microbiological contamination on all manned and unmanned spacecraft, launchers, payloads, experiments, ground support equipment, and cleanrooms with planetary protection constraints. This standard does not address molecular contamination control. This standard does not address the principles and basic methodology for controlling cleanrooms and associated controlled environments with constraints on particulate contamination. This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

SIST EN 16602-70-55:2015 is classified under the following ICS (International Classification for Standards) categories: 07.100.99 - Other standards related to microbiology; 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16602-70-55:2015 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 16602-70-55:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Raumfahrtproduktsicherung - Mikorbiologische Prüfung von Flughardware und ReinräumenAssurance produit des projets spatiaux - Examen microbiologique des matériels de vol et des salles blanchesSpace product assurance - Microbiological examination of flight hardware and cleanrooms49.140Vesoljski sistemi in operacijeSpace systems and operations07.100.99Drugi standardi v zvezi z mikrobiologijoOther standards related to microbiologyICS:Ta slovenski standard je istoveten z:EN 16602-70-55:2015SIST EN 16602-70-55:2015en,fr,de01-november-2015SIST EN 16602-70-55:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16602-70-55

September 2015 ICS 49.140

English version

Space product assurance - Microbiological examination of flight hardware and cleanrooms

Assurance produit des projets spatiaux - Examen microbiologique des matériels de vol et des salles blanches Raumfahrtproduktsicherung - Mikorbiologische Prüfung von Flughardware und Reinräumen This European Standard was approved by CEN on 25 October 2014.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels © 2015 CEN/CENELEC All rights of exploitation in any form and by any means reserved worldwide for CEN national Members and for CENELEC Members. Ref. No. EN 16602-70-55:2015 E SIST EN 16602-70-55:2015

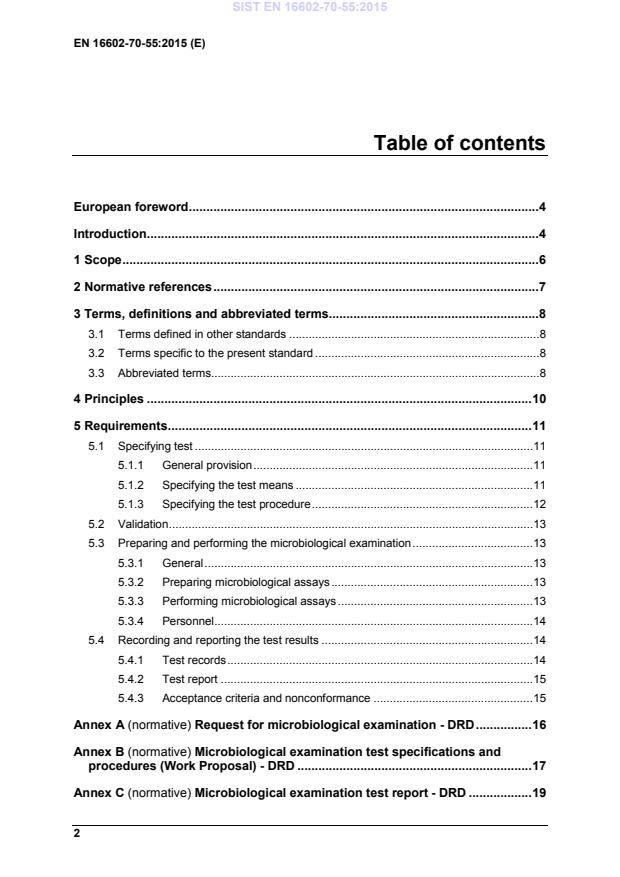

Figures Figure 4-1: Microbiological examination process overview . 10 Figure D-1 : Flow chart for the standard swab assay (swab assay 1) . 21 Figure D-2 : Flow chart for swab assay 2. 24 Figure D-3 : Flow chart for swab assay 3. 26 Figure D-4 : Flow chart for swab assay 4. 29 Figure D-5 : Flow chart for swab assay 5 (anaerobic conditions from resuspension onwards) . 31 Figure E-1 : Flow chart for the standard wipe assay (wipe assay 1) . 39 Figure E-2 : Flow chart for wipe assay 2 . 42 Figure E-3 : Flow chart for wipe assay 3 . 44 Figure E-4 : Flow chart for wipe assay 4 . 47 Figure E-5 : Flow chart for wipe assay 5 (anaerobic conditions from resuspension onwards) . 50

Tables Table D-1 : Primers for amplification of 16S rDNA from Archaea, Bacteria and Fungi . 35 Table E-1 : Primers for amplification of 16S rDNA from Archaea, Bacteria and Fungi . 53

“States parties shall pursue studies of outer space, including the Moon and other celestial bodies, and conduct exploration of them so as to avoid their harmful contamination and also adverse changes in the environment of the Earth resulting from the introduction of extraterrestrial matter and, when necessary, adopt appropriate measures for this purpose”.

Harmful contamination in that sense is defined as biological contamination, including organic-constituents, to protect the environment in order to allow future exobiology research. The Committee On Space Research (COSPAR) has established some planetary protection guidelines, based on the Outer Space Treaty. These guidelines impose requirements on spaceflight missions according to target body/mission type combinations.

The objective of this Standard is to ensure that the proper procedures for establishing the microbiological contamination on flight hardware and controlled environments are in place to meet the planetary protection constraints. SIST EN 16602-70-55:2015

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00. SIST EN 16602-70-55:2015

EN reference Reference in text Title EN 16601-00-01 ECSS-S-ST-00-01 ECSS system – Glossary of terms EN 16602-10-09 ECSS-Q-ST-10-09 Space product assurance – Nonconformance control system EN 16602-20 ECSS-Q-ST-20 Space product assurance - Quality assurance EN 16602-70-01 ECSS-Q-ST-70-01 Space product assurance - Cleanliness and contamination control

Abbreviation Meaning ASTM American Society for Testing and Materials DNA Desoxyribonucleic acid DNase Deoxyribonuclease IEST Institute of Environmental Sciences and Technology IPA Isopropylalcohol ISO International Organization for Standardization PBS Phosphate buffered saline solution PCR Polymerase chain reaction PDA Potato Dextrose Agar SIST EN 16602-70-55:2015

test Work Proposal for microbiological examination (including test specification and procedure (Annex B) Microbiological examination results (including identified deviations, if any)Report for microbiological examination (Annex C) Request for microbiological examination

(Annex A) Customer approvalNCR (if any identified deviation) Figure 4-1: Microbiological examination process overview Clause 5.1 provides the test specification.

Clause 5.2 and 5.4 provide the requirements for preparing, performing, recording and reporting microbiological examination. The methods for bioburden determination are used to obtain an indication of the overall bioburden, but not for a general assessment of all microorganisms present in a sample. SIST EN 16602-70-55:2015

Examples of safety issues are hazard and health. Example of security issues is access control. e. Cleanliness and contamination control requirements according to ECSS-Q-ST-70-01 shall be applied for space hardware. f. The supplier shall provide a microbiological examination proposal in conformance with Annex B DRD. NOTE 1 Quality standards for microbiological laboratories should follow ISO 17025. NOTE 2 Additional specific requirements (e.g. avoidance of certain chemical functionalities) can be imposed by the mission objectives. 5.1.2 Specifying the test means 5.1.2.1 Facilities

a. The work area shall comply to the rules and guidelines of good laboratory practice. b. The ambient conditions for the process and work areas shall be (22 ± 3) °C with a relative humidity of (55 ± 10) % unless otherwise stated. SIST EN 16602-70-55:2015

If the test procedures proposed in Annex D - Annex G are executed by the supplier, the corresponding equipment, reagents and consumables specification is described therein. 5.1.3 Specifying the test procedure 5.1.3.1 Test procedures a.

Surfaces with an area of maximal 25 cm2 shall be sampled with swabs and surfaces with an area of maximal 1 m2 shall be sampled with wipes. NOTE

Multiple swabs and wipes can be used to sample a larger surface area.

b. Bioburden shall be determined with assays for quantification of aerobic mesophilic bacteria. NOTE 1 Example procedures are given in Annex D.1, D.2., E.1 and E.2. NOTE 2 This sampling is only appropriate for materials and material combinations (e.g. electrochemical compatibility, see ECSS-Q-ST-70-71) that can tolerate sample collection using damp materials. c. Biodiversity shall be determined with assays for determination of the type of micro-organism. NOTE 1 Example procedures are given in Annexe D.2 to D.5 (swabs) and Annexes E.2 to E.5 (wipes). NOTE 2 In addition, non-culture-based methods are used for the molecular analysis of non-cultivable microorganisms with example procedures in Annex D.6 (swab) and Annex E.6.1 (wipe).

NOTE 3 This sampling is only appropriate for materials and material combinations (e.g. electrochemical compatibility, see ECSS-Q-ST-70-71) that can tolerate sample collection using damp materials.

NOTE 4 For cleanroom control also contact plates and active air samplers can be applied with example procedures in Annex F (contact plates) and Annex G (active air sampling).

d. Air sampling shall be applied for continuous clean room monitoring. SIST EN 16602-70-55:2015

This validation can include the determination of relative or absolute efficiencies of the sampling and analysis method to establish a correction factor for the absolute bioburden numbers. 5.3 Preparing and performing the microbiological examination 5.3.1 General a. The microbiological examination proposal shall be provided for customer approval. b. The test proposal shall include the procedures. c. ECSS-Q-ST-20 shall apply for the establishment of the test procedures. 5.3.2 Preparing microbiological assays 5.3.2.1 Identification a. Locations where microbiological assays are taken shall be clearly identified with appropriate details to maintain traceability. NOTE

For example, microbiological assay plan. b. Assays shall be identified as a minimum by: 1. Date and time 2. Operator(s) 3. Reference to trace location of assay 4. Type of assay 5. Area of the assay or air volume taken 6. Storage conditions of assay sample. 5.3.2.2 Preparation, handling and storage of reagents and consumables a. Rules and guidelines of good laboratory practice shall be followed. 5.3.3 Performing microbiological assays a. The supplier shall perform the approved microbiological examination procedures in conformance with Annex B DRD. SIST EN 16602-70-55:2015

5.3.4 Personnel a. Personnel conducting microbiological examination of flight hardware and cleanrooms shall be trained in microbiology. NOTE

Guidance on training can be found in ISO 14698 part 1, Annex G. 5.4 Recording and reporting the test results 5.4.1 Test records a. The test records of the microbiological examination shall be retained for, at least, ten years or in accordance with customer requirements. b. The quality records shall contain as a minimum the following: 1. Date and time of the assay campaign 2. Operator(s)

3. Type of assay and assay procedure 4. Traceable details about assay NOTE

For example, location, area, air volume. 5. Storage conditions of assay sample NOTE

For example, temperature after sampling at packaging, transport time, temperature at start of assay. 6. Details of the equipment used for the assay 7. Comments concerning any unusual occurrence during sampling, transport or assay 8. Reports of the microbiological examination results NOTE

Depending on customer requirements the calculation of the bioburden can include a correction factor (see 5.2). c. The test records of the microbiological examination shall be composed of: 1. the request for microbiological examination in conformance with Annex A DRD, 2. the microbiological examination proposal in conformance with Annex B DRD, SIST EN 16602-70-55:2015

In the frame of research and development activities, this is not necessary. d. The supplier shall notify the customer of the non conformance details. e. Traceability shall be maintained throughout the process from incoming inspection to final measurements and calculations, including details of the test equipment and personnel employed in performing the task. f. Evaluation of other properties may be invoked by the customer. SIST EN 16602-70-55:2015

A.2

Expected response A.2.1 Scope and content a. The Request for microbiological examination shall include or refer to the following information: 1. Objective of the test activity. 2. Background and justification to the test activity. 3. Identification of flight hardware or cleanroom facilities to be investigated (including state of controlled environment at rest and operation). 4. Description of test activity. 5. Deliverables. 6. Applied quality standards for microbiological laboratory. A.2.2 Special remarks None. SIST EN 16602-70-55:2015

B.2 Expected response

B.2.1 Scope and content a. The WP shall include or refer to the following information: 1. A proposed work description giving: (a) the objectives of the test activity, (b) applied quality standards for microbiological laboratory, (c) test procedure and reference to standards (this includes sources), (d) identification of flight hardware or cleanroom facilities (including state of controlled environment at rest and operation), (e) test conditions, including environment, properties evaluated and measurement techniques, (f) expected test output, (g) validation protocol. SIST EN 16602-70-55:2015

C.2.1 Scope and content a. The microbiological examination test report shall include or refer to the following information: 1. Description of the purpose, objective, content and the reason prompting its preparation. 2. Description of the sampled flight hardware or microbiologically controlled environment or a reference to the document containing its identification characteristics. NOTE

For example, request for microbiological examination DRD., 3. Applied quality standards for microbiological laboratory. 4. Validation protocol. 5. Calibration tools. 6. The microbiological assay procedures or a reference to the document containing the description of the test procedure. SIST EN 16602-70-55:2015

For example, microbiological assay specifications and procedures DRD. It often consist in describing the as- run test procedure as well as any deviation from the initial test procedure (including a discussion of possible effect on test 7. The test results. 8. Statistical analysis. 9. Discussion about the test results. 10. Conclusion and recommendations. C.2.2 Special remarks None. SIST EN 16602-70-55:2015

Figure D-1: Flow chart for the standard swab assay (swab assay 1) SIST EN 16602-70-55:2015

Return the swab head to a tube containing 2,5 ml sterile buffer (PBS + 0,02 v/v % Tween 80, pH 7,2) by breaking the swab shaft at the breakpoint. D.1.3 Transport and storage Transport samples to the laboratory and store at (4 – 8) °C and process within 24 hours. D.1.4 Extraction Place each tube containing the buffer and the swab on a vortex mixer and vortex at maximum power for 5 - 6 seconds. NOTE

Sonification can be required depending on the swap type used. D.1.5 Heat shock Place the tube containing the vortexed suspension and the swab in a water bath at (80 ± 2) °C for 15 minutes, as determined by a pilot tube containing a thermometer. Make certain the water bath level is above the level of the liquid content of each tube being heated.

After heat shock, cool the tubes rapidly to bring the contents to (30 – 35) °C. If the entire plating procedure last more than 10 minutes, the heat shocked tubes should be placed in an ice bath for no longer than 45 minutes prior to plating.

D.1.6 Plating Vortex swab extraction suspension for 5 – 6 seconds and aseptically pipette 0,5 ml aliquots of the swab extraction suspension onto the surface of R2A Petri plates, using 2 ml total.

Use a sterile spreader to spread the dilution over the surface as evenly as possible. Allow the moisture to be absorbed into the agar before incubation. SIST EN 16602-70-55:2015

In the lab, create at least two ‘lab negative controls’ by moistening the head of a sterile swab in sterile water, as above, and return the swab to the tube containing sterile buffer without exposing it to air. Analyse the controls in the same way as the samples described above. D.1.10 Equipment, reagents and consumable materials • Dry sterile swabs • Tubes with sterile water, ASTM type IIB, for moistening of swabs • Tubes with 2,5 ml sterile buffer (PBS + 0,02 v/v % Tween 80, pH 7,2) • Refrigerator (4 – 8) °C • Cool box • Vortex mixer • Water bath (80 ± 2) °C • Ice bath • Thermometer • Microliter pipette and sterile tips • Laminar flow hood • Sterile spreaders • R2A Petri plates

(90 mm) • Incubator (32 ± 1) °C SIST EN 16602-70-55:2015

Figure D-2: Flow chart for swab assay 2 D.2.2 Sample collection Prepare a sufficient number of sterile swabs and test tubes with sterile water, ASTM type IIB, for all swab samples to be collected, plus controls. Aseptically remove a sterile swab from its container and moisten the head of the swab in a test tube with sterile water, ASTM type IIB. Express excess moisture from the swab against the interior wall of the tube. Hold the swab so that the handle makes about a 30° angle with the surface to be sampled. While moving the swab in one direction, rotate the head of the swab slowly and thoroughly over a measured 25 cm2 surface area. Change the linear direction of the swabbing motion 90° and again swab the surface thoroughly. Complete a third coverage of the surface by again changing the direction of the swabbing motion by 135°.

Return the swab head to a tube containing 2,5 ml sterile buffer (PBS + 0,02 v/v % Tween 80, pH 7,2) by breaking the swab shaft at the breakpoint. D.2.3 Transport and storage Transport samples to the laboratory and store at (4 – 8) °C and process within 24 hours. SIST EN 16602-70-55:2015

NOTE

It is important not to perform a heat-shock! D.2.5 Plating Vortex swab extraction suspension for 5 – 6 seconds and aseptically pipette 0,5 ml aliquots of the swab extraction suspension onto the surface of R2A Petri plates, using 2 ml total.

Use a sterile spreader to spread the dilution over the surface as evenly as possible. Allow the moisture to be absorbed into the agar before incubation. D.2.6 Incubation Plates should be incubated inverted at (32 ± 1) °C. D.2.7 Counting Examine the sample plates at 24 and 48 hours. If colonies visible by eyes are observed, count and record data. Examine and record final colony counts at 72 hours. Do not remove the Petri plate covers until the final 72 hour count is made. Keeping photographic evidence for biodiversity determination can be helpful. If necessary, purify the colonies by streak outs before identification and archiving.

D.2.8 Controls For each ten or fewer samples collected, also collect a 'field negative’ control, at least 3 per day. Remove the sterile swab from its container, moisten with sterile water, ASTM type IIB, as above, wave the swab through the air for 2 to 4 seconds, and return the swab to a tube containing sterile buffer.

In the lab, create at least two ‘lab negative controls’ by moistening the head of a sterile swab in sterile water, as above, and return the swab to the tube containing sterile buffer without exposing it to air. Analyse the controls in the same way as the samples described above. D.2.9 Equipment, reagents and consumable materials • Dry sterile swabs • Tubes with sterile water, ASTM type IIB, for moistening of swabs • Tubes with 2,5 ml sterile buffer (PBS + 0,02 v/v % Tween 80, pH 7,2) • Refrigerator (4 – 8) °C • Cool box • Vortex mixer SIST EN 16602-70-55:2015

(90 mm) • Incubator (32 ± 1) °C D.3 Swab assay 3 D.3.1 General With this assay aerobic psychrophiles / psychrotolerants are determined. The flow-chart for the swab assay 3 is schematically shown in Figure D-3.

Figure D-3: Flow chart for swab assay 3 D.3.2 Sample collection Prepare a sufficient number of sterile swabs and test tubes with sterile water, ASTM type IIB, for all swab samples to be collected, plus controls. Aseptically remove a sterile swab from its container and moisten the head of the swab in a test tube with sterile water, ASTM type IIB. Express excess moisture from the swab against the interior wall of the tube. Hold the swab so that the handle makes about a 30° angle with the surface to be sampled. While moving the swab in one direction, rotate the head of the swab slowly and thoroughly over a measured 25 cm2 surface area. Change the linear direction of the swabbing motion 90° and again swab the surface thoroughly. SIST EN 16602-70-55:2015

Return the swab head to a tube containing 2,5 ml sterile buffer (PBS + 0,02 v/v % Tween 80, pH 7,2) by breaking the swab shaft at the breakpoint. D.3.3 Transport and storage Transport samples to the laboratory and store at (4 – 8) °C and process within 24 hours. D.3.4 Extraction Place each tube containing the buffer and the swab on a vortex mixer and vortex at maximum power for 5 - 6 seconds. NOTE

It is important not to perform a heat-shock! D.3.5 Plating Vortex swab extraction suspension for 5 – 6 seconds and aseptically pipette 0,5 ml aliquots of the swab extraction suspension onto the surface of R2A Petri plates, using 2 ml total.

Use a sterile spreader to spread the dilution over the surface as evenly as possible. Allow the moisture to be absorbed into the agar before incubation. D.3.6 Incubation Two plates should be incubated inverted at (10 ± 1) °C, the other two at (4 ± 1) °C. D.3.7 Counting Examine the sample plates at 14 and 21 days. If colonies visible by eyes are observed, count and record data. Examine and record final colony counts at 28 days. Do not remove the Petri plate covers until the final 28 days count is made. Keeping photographic evidence for biodiversity determination can be helpful. If necessary, purify the colonies by streak outs before identification and archiving.

D.3.8 Controls For each ten or fewer samples collected, also collect a 'field negative’ control, at least 3 per day. Remove the sterile swab from its container, moisten with sterile water, ASTM type IIB, as above, wave the swab through the air for 2 to 4 seconds, and return the swab to a tube containing sterile buffer.

In the lab, create at least two ‘lab negative controls’ by moistening the head of a sterile swab in sterile water, as above, and return the swab to the tube containing sterile buffer without exposing it to air. SIST EN 16602-70-55:2015

(10 ± 1) °C • Incubator

(4 ± 1) °C D.4 Swab assay 4 D.4.1 General With this assay aerobic mesophilic fungi, that is yeasts and molds, are determined. The flow chart for the swab assay 4 is schematically shown in Figure D-4. SIST EN 16602-70-55:2015

Figure D-4: Flow chart for swab assay 4 D.4.2 Sample collection Prepare a sufficient number of sterile swabs and test tubes with sterile water, ASTM type IIB, for all swab samples to be collected, plus controls. Aseptically remove a sterile swab from its container and moisten the head of the swab in a test tube with sterile water, ASTM type IIB. Express excess moisture from the swab against the interior wall of the tube. Hold the swab so that the handle makes about a 30° angle with the surface to be sampled. While moving the swab in one direction, rotate the head of the swab slowly and thoroughly over a measured 25 cm2 surface area. Change the linear direction of the swabbing motion 90° and again swab the surface thoroughly. Complete a third coverage of the surface by again changing the direction of the swabbing motion by 135°.

Return the swab head to a tube containing 2,5 ml sterile buffer (PBS + 0,02 v/v % Tween 80, pH 7,2) by breaking the swab shaft at the breakpoint. D.4.3 Transport and storage Transport samples to the laboratory and store at (4 – 8) °C and process within 24 hours. D.4.4 Extraction Place each tube containing the buffer and the swab on a vortex mixer and vortex at maximum power for 5 - 6 seconds.

NOTE

It is important not to perform a heat-shock. SIST EN 16602-70-55:2015

In the lab, create at least two ‘lab negative controls’ by moistening the head of a sterile swab in sterile water, as above, and return the swab to the tube containing sterile buffer without exposing it to air. Analyse the controls in the same way as the samples described above. D.4.9 Equipment, reagents and consumable materials • Dry sterile swabs • Tubes with sterile water, ASTM type IIB, for moistening of swabs • Tubes with 2,5 ml sterile buffer (PBS + 0,02 v/v % Tween 80, pH 7,2) • Refrigerator (4 – 8) °C • Cool box • Vortex mixer • Microliter pipette and sterile tips • Laminar flow hood • Sterile spreaders • PDA Petri plates (90 mm) • Incubator (25 ± 1) °C SIST EN 16602-70-55:2015

Figure D-5: Flow chart for swab assay 5 (anaerobic conditions from resuspension onwards) D.5.2 Sample collection Before sampling, prepare a sufficient number of tubes with anaerobic buffer (PBS + 0,02 v/v % Tween 80). Add sodium resazurin (0,001 g/l) as redox indicator. Bubble buffer with nitrogen. Reduce PBS by adding 0,5 g/l sodium sulfide x 9 H2O. Adjust pH to 7,2 using disposable syringes and hypodermic needles. Redox indicator should turn colourless. Under anaerobic conditions (anaerobic chamber), prepare 10 ml aliquots in glass tubes with serum bottle necks, seal with butyl rubber stoppers and clamp. Add nitrogen gas phase three times by flushing and applying vacuum alternately. After the last nitrogen filling autoclave the solution. Before sampling, prepare also a mixture of cystein-HCl and sodium sulfide as follows: Dissolve 0,5 g cystein-HCl and 0,5 g Na2S x 9 H2O in 10 ml of distilled water. Adjust pH to 7. Exchange the air against nitrogen and autoclave. SIST EN 16602-70-55:2015

D.5.3 Transport and storage Transport samples to the laboratory and store at (4 – 8) °C and process within 24 hours. D.5.4 Extraction Place each tube containing the buffer and the swab on a vortex mixer and vortex at maximum power for 5 - 6 seconds.

NOTE

It is important not to perform a heat-shock. D.5.5 Plating Perform plating under anaerobic conditions. Vortex swab extraction suspension for 5 – 6 seconds and aseptically pipette 0,5 ml aliquots of the swab extraction suspension onto the surface of TG agar plates, using 2 ml total.

Use a sterile spreader to spread the dilution over the surface as evenly as possible. Allow the moisture to b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...