SIST EN 14141:2013

(Main)Valves for natural gas transportation in pipelines - Performance requirements and tests

Valves for natural gas transportation in pipelines - Performance requirements and tests

This European Standard applies to all valves (plug, ball, gate and check valves) used in onshore transmission pipelines for transport of natural gas in accordance with EN 1594, but with a differing temperature range according to the following three classes in accordance with EN 682:

1) - 10 °C to 60 °C;

2) - 20 °C to 60 °C;

3) the range stated by the purchaser for special design.

This European Standard comprises all valves which are components of the pipeline.

This European Standard specifies valves for pipelines with a maximum operating pressure (MOP) over 16 bar.

Control valves and safety valves are excluded from the scope of this European Standard.

This European Standard specifies requirements and appropriate verification tests carried out during production and for certification purposes to verify that the valves conform to the requirements. A summary of the product and type tests is given in Annex G.

This European Standard makes reference to EN 13942. All the requirements of EN 13942 should be met unless otherwise stated. Paragraphs marked with a dot [•] indicate requirements which are identical to EN 13942.

Additional national requirements and tests in accordance with individual national legal regulations not yet harmonised may be necessary and are to be advised in the purchase order.

Armaturen für den Transport von Erdgas in Fernleitungen - Anforderungen an die Gebrauchstauglichkeit und deren Prüfung

Diese Europäische Norm gilt für alle Armaturen (Kegelhähne, Kugelhähne, Schieber und Rückschlagklappen) in Onshore-Fernleitungen für den Transport von Erdgas nach EN 1594, jedoch mit einem anderen Temperaturbereich entsprechend den drei folgenden Klassen nach EN 682:

1) -10 °C bis 60 °C;

2) -20 °C bis 60 °C;

3) nach dem vom Besteller angegebenen Bereich für besondere Konstruktionen.

Diese Europäische Norm umfasst alle Armaturen, die Bestandteil der Fernleitung sind.

Diese Europäische Norm legt Armaturen für Fernleitungen mit einem maximal zulässigen Betriebsdruck (en: maximum operating pressure (MOP)) über 16 bar fest.

Regelarmaturen und Sicherheitsventile sind vom Anwendungsbereich dieser Europäischen Norm ausgeschlossen.

Diese Europäische Norm legt die Anforderungen und die entsprechenden Prüfungen fest, die bei der Fertigung und für die Zertifizierung durchgeführt werden, um nachzuweisen, dass die Armaturen die Anforderungen erfüllen. Die Produkt- und Typprüfungen sind in Anhang G zusammengefasst.

Diese Europäische Norm verweist auf EN 13942. Falls nicht anders angegeben, sollten alle Anforderungen nach EN 13942 erfüllt werden. Mit einem Punkt [•] gekennzeichnete Absätze enthalten Anforderungen, die mit den Anforderungen von EN 13942 identisch sind.

Zusätzliche nationale Anforderungen und Prüfungen auf Grund noch nicht harmonisierter gesetzlicher Regelungen auf einzelstaatlicher Ebene können erforderlich werden und sind bei der Bestellung anzugeben.

Robinetterie pour le transport de gaz naturel par des pipelines - Exigences de performance et essais

La présente Norme européenne s'applique à tous les appareils de robinetterie (robinets à tournant conique, robinets à tournant sphérique, robinets-vannes et clapets de non-retour) utilisés dans des pipelines terrestres de transport du gaz naturel conformément à l'EN 1594, mais avec une plage de température différente selon les trois classes suivantes conformément à l'EN 682 :

1) - 10 °C à 60 °C ;

2) - 20 °C à 60 °C ;

3) la plage indiquée par l'acheteur pour une conception particulière.

La présente Norme européenne comprend tous les appareils de robinetterie faisant partie intégrante du pipeline.

La présente Norme européenne s'applique aux appareils de robinetterie pour pipelines dont la pression maximale de service (PMS) est supérieure à 16 bar.

Les vannes de commande et les soupapes de sûreté sont exclues du domaine d'application de la présente Norme européenne.

La présente Norme européenne spécifie les exigences et les essais de vérification appropriés réalisés en cours de production et à des fins de certification afin de démontrer que les appareils de robinetterie sont conformes aux exigences. Un récapitulatif des essais sur produit et des essais de type est donné en Annexe G.

La présente Norme européenne fait référence à l'EN 13942. Sauf spécification contraire, il convient de satisfaire à toutes les exigences de cette norme. Les paragraphes marqués du symbole [•] contiennent des exigences identiques à celles de l'EN 13942.

Des exigences et essais nationaux supplémentaires conformes à différentes réglementations nationales non encore harmonisées peuvent se révéler nécessaires et doivent être indiqués dans le bon de commande.

Armature za transport zemeljskega plina po cevovodih - Zahteve glede uporabnosti in preskušanje

Ta evropski standard velja za vse ventile (s svečko, krogelne pipe, zasune in protipovratne ventile), ki se uporabljajo pri kopenskih cevovodih za prenos naravnega plina v skladu s standardom EN 1594, vendar z različnim temperaturnim obsegom glede na naslednje tri razrede v skladu s standardom EN 682: 1) –10 °C do 60 °C; 2) –20 °C do 60 °C; 3) obseg, ki ga navede dobavitelj za posebno izvedbo. Ta evropski standard vključuje vse ventile, ki so sestavni deli cevovoda. Ta evropski standard določa ventile za cevovode z najvišjim obratovalnim tlakom (MOP) nad 16 barov. Krmilni in varnostni ventili so izključeni s področja uporabe tega evropskega standarda. Ta evropski standard določa zahteve in ustrezne preskuse, ki se izvajajo med proizvodnjo in za namene certifikacije, da se preveri skladnost ventilov z zahtevami. Povzetek izdelka in tipski preskusi so navedeni v prilogi G. Ta evropski standard se sklicuje na standard EN 13942. Izpolnjene morajo biti vse zahteve standarda EN 13942, razen če je navedeno drugače. Odstavki, označeni s piko [•], označujejo zahteve, ki so enake v standardu EN 13942. Potrebne so lahko dodatne nacionalne zahteve in preskusi v skladu s posameznimi nacionalnimi zakonskimi predpisi, ki še niso usklajeni, in se priporočijo na naročilnici.

General Information

- Status

- Published

- Public Enquiry End Date

- 14-Jan-2012

- Publication Date

- 04-Jul-2013

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 03-Jul-2013

- Due Date

- 07-Sep-2013

- Completion Date

- 05-Jul-2013

Relations

- Effective Date

- 01-Sep-2013

Overview

EN 14141:2013 - Valves for natural gas transportation in pipelines - sets performance requirements and test criteria for pipeline valves used in onshore transmission systems. Published by CEN, it applies to plug, ball, gate and check valves that are components of pipelines with a maximum operating pressure (MOP) over 16 bar. Control and safety valves are explicitly excluded. The standard defines temperature classes (per EN 682), piggability, design validation and both production and type test requirements (summary in Annex G).

Key topics and technical requirements

- Scope and valve types: Covers plug, ball, gate and check valves used in onshore transmission pipelines in accordance with EN 1594; excludes control and safety valves.

- Temperature classes: Three classes per EN 682: -10 °C to 60 °C, -20 °C to 60 °C, or purchaser-defined special range.

- Pressure rating: Applies to pipelines with MOP > 16 bar.

- Design and shell strength: Shell design must meet EN 12516 series (tabulation, calculation or experimental methods) or other recognized design codes as referenced in EN 13942. Manufacturers must document design validation.

- Dimensional requirements: End-to-end and butt-welding dimensions to conform to EN 13942, EN 558, EN 12982, EN 12627 as applicable.

- Operational features: Requirements for travel stops, anti-blow-out stem devices, protection of exposed stems, piggability (full opening valves), and lifting points for valves DN ≥ 200 (NPS 8).

- Testing and verification: Specifies product tests during manufacture and type tests for certification. Numerous NDT and inspection methods are referenced (radiography, ultrasonic, magnetic particle, penetrant). Annexes (A–G) give normative and informative test details; Annex G summarizes product and type tests.

- Marking, inspection and quality: Includes inspection, documentation (test reports) and marking requirements consistent with referenced standards.

Applications and who uses this standard

EN 14141:2013 is essential for:

- Valve manufacturers designing and producing valves for high‑pressure natural gas pipelines.

- Pipeline operators and owners specifying procurement and acceptance criteria for transmission pipeline components.

- Engineering consultants and designers validating shell strength, piggability and compliance with pipeline functional requirements.

- Inspection and certification bodies performing type testing, NDT and issuing conformity certificates.

- Procurement teams drafting purchase orders with national additional requirements if applicable.

Practical uses include procurement specifications, design validation, production inspection plans, and certification testing to ensure safe, piggable and fit-for-service pipeline valves.

Related standards

Relevant references frequently cited with EN 14141:2013:

- EN 13942 (pipeline valves / ISO 14313)

- EN 1594 (pipelines for MOP > 16 bar)

- EN 682 (elastomeric seal temperature classes)

- EN 12516 series (shell design strength)

- EN 558, EN 12982, EN 12627 (dimensions & butt-weld ends)

- EN 12266, EN ISO 10497 and various NDT standards (radiography, ultrasonic, penetrant, magnetic particle)

Keywords: EN 14141:2013, pipeline valves, natural gas transportation, performance requirements, pipeline valve tests, piggable valves, valve certification.

Frequently Asked Questions

SIST EN 14141:2013 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Valves for natural gas transportation in pipelines - Performance requirements and tests". This standard covers: This European Standard applies to all valves (plug, ball, gate and check valves) used in onshore transmission pipelines for transport of natural gas in accordance with EN 1594, but with a differing temperature range according to the following three classes in accordance with EN 682: 1) - 10 °C to 60 °C; 2) - 20 °C to 60 °C; 3) the range stated by the purchaser for special design. This European Standard comprises all valves which are components of the pipeline. This European Standard specifies valves for pipelines with a maximum operating pressure (MOP) over 16 bar. Control valves and safety valves are excluded from the scope of this European Standard. This European Standard specifies requirements and appropriate verification tests carried out during production and for certification purposes to verify that the valves conform to the requirements. A summary of the product and type tests is given in Annex G. This European Standard makes reference to EN 13942. All the requirements of EN 13942 should be met unless otherwise stated. Paragraphs marked with a dot [•] indicate requirements which are identical to EN 13942. Additional national requirements and tests in accordance with individual national legal regulations not yet harmonised may be necessary and are to be advised in the purchase order.

This European Standard applies to all valves (plug, ball, gate and check valves) used in onshore transmission pipelines for transport of natural gas in accordance with EN 1594, but with a differing temperature range according to the following three classes in accordance with EN 682: 1) - 10 °C to 60 °C; 2) - 20 °C to 60 °C; 3) the range stated by the purchaser for special design. This European Standard comprises all valves which are components of the pipeline. This European Standard specifies valves for pipelines with a maximum operating pressure (MOP) over 16 bar. Control valves and safety valves are excluded from the scope of this European Standard. This European Standard specifies requirements and appropriate verification tests carried out during production and for certification purposes to verify that the valves conform to the requirements. A summary of the product and type tests is given in Annex G. This European Standard makes reference to EN 13942. All the requirements of EN 13942 should be met unless otherwise stated. Paragraphs marked with a dot [•] indicate requirements which are identical to EN 13942. Additional national requirements and tests in accordance with individual national legal regulations not yet harmonised may be necessary and are to be advised in the purchase order.

SIST EN 14141:2013 is classified under the following ICS (International Classification for Standards) categories: 23.060.01 - Valves in general; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14141:2013 has the following relationships with other standards: It is inter standard links to SIST EN 14141:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14141:2013 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14141:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Armature za transport zemeljskega plina po cevovodih - Zahteve glede uporabnosti in preskušanjeArmaturen für den Transport von Erdgas in Fernleitungen - Anforderungen an die Gebrauchstauglichkeit und deren PrüfungRobinetterie pour le transport de gaz naturel par des pipelines - Exigences de performance et essaisValves for natural gas transportation in pipelines - Performance requirements and tests75.200Petroleum products and natural gas handling equipment23.060.01Ventili na splošnoValves in generalICS:Ta slovenski standard je istoveten z:EN 14141:2013SIST EN 14141:2013en,fr,de01-september-2013SIST EN 14141:2013SLOVENSKI

STANDARDSIST EN 14141:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14141

June 2013 ICS 23.060.01; 75.200 Supersedes EN 14141:2003English Version

Valves for natural gas transportation in pipelines - Performance requirements and tests

Robinetterie pour le transport de gaz naturel par des pipelines - Exigences de performance et essais

Armaturen für den Transport von Erdgas in Fernleitungen -Anforderungen an die Gebrauchstauglichkeit und deren Prüfung This European Standard was approved by CEN on 18 April 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14141:2013: ESIST EN 14141:2013

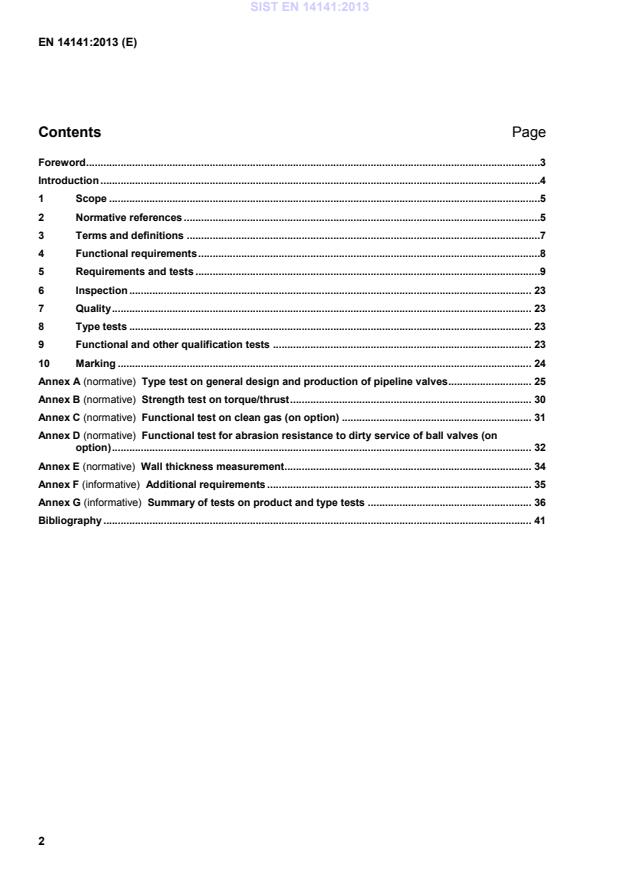

Type test on general design and production of pipeline valves . 25 Annex B (normative)

Strength test on torque/thrust . 30 Annex C (normative)

Functional test on clean gas (on option) . 31 Annex D (normative)

Functional test for abrasion resistance to dirty service of ball valves (on option) . 32 Annex E (normative)

Wall thickness measurement . 34 Annex F (informative)

Additional requirements . 35 Annex G (informative)

Summary of tests on product and type tests . 36 Bibliography . 41

1) Developed and approved by the Manufacturers Standardization Society of the Valve and Fittings Industry, Inc. 127 Park Street, NE, Vienna, Virginia 22180. SIST EN 14141:2013

If a sealant injection system is provided, it shall be equipped with:

— a check valve located on the body at each injection point;

— a universal giant button head fitting Î 22 mm to connect sealant injection gun. Drawing examination. Drawing examination. The seat sealant injection system shall be capable of distributing sealant uniformly around the seats.

Type test is applicable only to ball valves. A trial sealant injection is performed and the valve inspected to confirm adequate delivery and even distribution of sealant.

The test is conducted on a closed valve with 50 % maximum differential pressure applied using a sealant recommended by the manufacturer. The valve should be inspected to determine distribution. The sealant should form a continuous ring on the surface of the obturator. 5.1.6 Extended drain, vent and sealant lines Requirement Type test Test on product [≤z arainf vent and sealant lines shall be provided if specified and shall be extended by means of rigid pipework, if necessary. The lines shall be fastened to the valve and/ or extensions and terminate close to the stem extension top works, by agreement. Drawing examination. Drawing examination. Hydraulic pressure test at 1,5 times the rated pressure of the valve. The test may be conducted as a part of valve shell test or as a test of the preassembled pipework The welded connection to the valve body shall be inspected according to 5.5.2. [≤z arain and vent lines shall: 1) have a design pressure not

ot agreed in different way, the length of the stem extension is defined to be the distance between the horizontal axis of the passage and the axis of the wheel of the gear or of the lever. Dimensional check. Drawing examination. SIST EN 14141:2013

5.2 Operation 5.2.1 Handwheels and wrenches - Levers Requirement Test on product Type test [•z Wrenches for valves shall either be of an integral design or consist of a head which fits on the stem and is designed to take an extended handle. The head design shall allow permanent attachment of the extended section if specified by the purchaser. The maximum force required at the handwheel or wrench to apply the breakaway torque or thrust shall not exceed 360 N (80 lbf). Wrenches of integral design (not loose) shall not be longer than twice the face-to-face or end-to-end dimension, unless otherwise agreed. NOTE Loose wrenches are not considered part of the valve and are not required to meet the maximum length requirements. Handwheel diameter(s) shall not exceed the face-to-face or end-to-end length of the valve or 1 000 mm, whichever is smaller, unless otherwise agreed. Except for valve sizes DN 40 (NPS 1½) and smaller, spokes shall not extend beyond the perimeter of the handwheel unless otherwise agreed. If specified by the purchaser, the handwheel of the gearbox input shaft shall be provided with a torque-limiting device, such as a shear pin, to prevent damage to the drive train. Direction of closing shall be clockwise, unless otherwise specified. For each unique size pressure rating, material, operator combination, the following test shall be performed on 10 % (minimum of 1) of the production: — dimensional check of handwheel/lever; — determination of the handwheel/lever force to apply break away torque or thrust. No test required. 5.2.2 Protection against rapidly moving external components Requirement Test on product Type test Rapidly moving external components, e.g. rising stems, piston rods or levers on check valves, shall be fitted with protective devices (e.g. protective tubes or protective screens), for personal protection. Visual inspection. No test required. SIST EN 14141:2013

5.2.3 Manual override devices Requirement Test on product Type test Manual override devices, e.g. handwheels of electric actuators, shall be normally disengaged and shall automatically disengage when the actuator is operated. Visual inspection. No test required. 5.2.4 Torque/thrust testing Requirement Test on product Type test The torque values shall be measured and documented. Measured operating torques/thrust shall not exceed the agreed values. Torque/thrust shall be measured and recorded. — EN 13942:2009, B.6 shall be applied. — The test shall be conducted with liquid or gas in accordance with seat test in 5.8.1. A soft seated valve shall be left in the closed position with the rated differential pressure applied for 12 h after which the operating torque/thrust shall be measured and shall not exceed the agreed values. 5.3 Materials 5.3.1 Material compatibility Requirement Test on product Type test All metallic and non-metallic parts in contact with natural gas and accessory materials, as well as lubricants and sealants, shall be suitable for the service conditions specified by the purchaser and compatible with the fluids used in service and maintenance. Non-metallic parts of valves to be used at pressure of PN 100 (Class 600) and above shall be resistant to explosive decompression. Materials shall be compatible with each other and with the fluids, to avoid galvanic action and galling. No test required. Examination of documentation produced to demonstrate the compatibility of the seal. SIST EN 14141:2013

5.3.2 Shell materials 5.3.2.1 General Requirement Test on product Type test Shell materials shall be selected from steels in accordance with EN 1503-1, EN 1503-2 and EN 13942. Other steels not listed in these standards may be used when their suitability and allowable operating pressure and temperatures have been approved. Certificate in accordance with EN 10204:2004, 3.1a. Certificates in accordance with EN 10204:2004, 3.2 a Purchaser may request superior certificates. 5.3.2.2 Impact values Requirement Test on product Type test All ferritic and duplex materials for pressure containing parts and welds shall have impact values as specified in EN 1594. The test temperature shall correspond to the minimum design temperature or –10 °C whichever is lower. All ferritic and duplex materials for pressure containing parts shall be tested in accordance with the impact test provisions of EN ISO 148-1. Each heat of the material shall be in the final heat treated condition. Test coupons shall be cut from separate or attached block, taken from the same heat and where applicable given the same heat treatment as the product materials they represent. Certificate in accordance with EN 10204:2004, 3.1. Same as for test on product. SIST EN 14141:2013

5.3.2.3 Welding ends for on-site welding Requirement Test on product Type test For welding ends of valves, the maximum carbon equivalent CEVmax shall not exceed: CEVmax = 0,45 for grades with specified minimum yield strength not exceeding 360 N/mm2; CEVmax = 0,48 for grades with specified minimum yield strength above 360 N/mm2; unless otherwise agreed between purchaser and manufacturer. 5%%%6%%maxVMoCrMnCCEV++++=15%%NiCu++ where % is the percentage by weight of the ladle content of: C Carbon; Mn Manganese; Cr Chromium; Mo Molybdenum; V Vanadium; Cu Copper; Ni Nickel. Unless otherwise agreed between manufacturer and purchaser, the carbon content shall not exceed 0,21 %. The sulphur content shall not exceed 0,030 %, and the phosphorus content shall not exceed 0,035 %. The sum of sulphur and phosphorus as a total of the ladle analysis shall be smaller than or equal to 0,050 %. Certificate in accordance with EN 10204:2004, 3.1a. Same as for test on product. a Certificate according to EN 10204:2004, 3.2 where required by national regulation or by the purchaser. 5.3.3 Obturator Requirement Test on product Type test Obturator materials shall be selected from EN 1503-1 or EN 1503-2 and EN 13942 unless otherwise agreed. Certificate in accordance with EN 10204:2004, 3.1. Same as for test on product. SIST EN 14141:2013

5.3.4 Body/bonnet connection, bolting materials Requirement Test on product Type test Materials for body/bonnet connecting parts — bolts and nuts — shall meet the requirements of EN 13942 and may be selected from EN 1515-1 and EN 1515-2 and shall be compatible with the minimum service temperature. The bolting and nut materials shall be compatible with the shell material for the avoidance of galvanic corrosion. Other steels not listed in these standards may also be used when their suitability and allowable operating pressure and temperatures have been approved. Certificate in accordance with EN 10204:2004, 3.1a. Same as for test on product. a

Certificate according to EN 10204:2004, 3.2 where required by national regulation or by the purchaser. 5.3.5 Seals Requirement Test on product Type test Seals made of elastomers shall meet the requirements of EN 682 or EN 549. When seals made of thermoplastic materials, e.g. PTFE, PA, are used, the part in contact with the flow shall be of non-regenerated material. When seals made of thermoplastic materials are used, the sealing system shall be design in such a way to compensate a possible creep of the seal. Reinforcement with carbon or fibreglass is allowed. Seals made by one or more junctions with adhesives are not admitted. The technical data concerning the materials used shall be available from the valve manufacturer. – 5.4 Repair Requirement Test on product Type test — Weld repair of forgings is not permitted. Repair of castings and weldments shall conform to the following requirements. — Repair shall be performed in accordance with a written procedure specifying requirements for defect

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...