SIST EN 13942:2009

(Main)Petroleum and natural gas industries - Pipeline transportation systems - Pipeline valves (ISO 14313:2007 modified)

Petroleum and natural gas industries - Pipeline transportation systems - Pipeline valves (ISO 14313:2007 modified)

This International Standard specifies requirements and provides recommendations for the design, manufacturing, testing and documentation of ball, check, gate and plug valves for application in pipeline systems meeting the requirements of ISO 13623 for the petroleum and natural gas industries.

This International Standard is not applicable to subsea pipeline valves, as they are covered by a separate International Standard (ISO 14723).

This International Standard is not applicable to valves for pressure ratings exceeding PN 420 (Class 2 500).

On-land supply systems used by the gas supply industry are excluded from the scope of this standard.

Erdöl- und Erdgasindustrie - Rohrleitungstransportsysteme - Rohrleitungsarmaturen (ISO 14313:2007, modifiziert)

Industries du pétrole et du gaz naturel - Systèmes de transport par conduites - Robinets de conduites (ISO 14313:2007 modifiée)

La présente Norme internationale spécifie les exigences et fournit des recommandations pour la conception, la fabrication, les essais et la documentation des appareils de robinetterie à tournant sphérique, des appareils de robinetterie à tournant, des robinets-vannes et des clapets de non-retour en vue d’une application dans les conduites satisfaisant aux exigences de l’ISO 13623 pour les industries du pétrole et du gaz naturel.

La présente Norme internationale ne s’applique pas aux robinets de conduites immergés car ils font l’objet d’une Norme internationale séparée (ISO 14723).

La présente Norme internationale ne s’applique pas aux robinets avec des valeurs de pression nominale supérieures à PN 420 (Class 2 500).

Les systèmes d’alimentation terrestres utilisés par l’industrie d’alimentation en gaz sont exclus du domaine d’application de la présente norme.

Industrija za predelavo nafte in zemeljskega plina - Transportni cevovodni sistemi - Armature cevovodov (ISO 14313:2007, spremenjen)

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Oct-2008

- Publication Date

- 17-Mar-2009

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 10-Mar-2009

- Due Date

- 15-May-2009

- Completion Date

- 18-Mar-2009

Relations

- Effective Date

- 01-May-2009

- Effective Date

- 01-Jul-2009

Overview

EN 13942:2009 (adopted from ISO 14313:2007, modified) is a European standard for pipeline valves used in the petroleum and natural gas industries. It specifies requirements and provides recommendations for the design, manufacture, testing and documentation of ball, check, gate and plug valves intended for pipeline transportation systems that meet ISO 13623. The standard excludes subsea pipeline valves (covered by ISO 14723), valves above PN 420 (Class 2500) and on‑land gas‑supply systems.

Keywords: EN 13942:2009, pipeline valves, ISO 14313, petroleum and natural gas, pipeline transportation systems.

Key topics and technical requirements

EN 13942:2009 addresses practical and technical aspects relevant to pipeline valve safety and performance, including:

- Valve types and configurations – ball, check, gate, plug; full‑opening, uni/bi‑directional, DBB (double‑block‑and‑bleed) and DIB (double‑isolation‑and‑bleed) features.

- Design requirements – dimensional, pressure‑rating and operational considerations aligned with ISO 13623.

- Materials – material selection guidance for pipeline service (includes references to ISO 15156 for H2S environments).

- Welding and fabrication – qualification of welders, welding procedures and acceptance criteria (references to EN/ISO and ASME welding standards).

- Quality control and inspection – manufacturing quality systems, inspection documents, and acceptance testing.

- Non‑destructive examination (NDE) – requirements and annexed acceptance levels for radiography, ultrasonic, magnetic particle and penetrant testing.

- Pressure testing – hydrostatic and leakage tests, with reference to ISO 5208 and other recognized methods.

- Coating, marking and documentation – protective coatings, marking examples and detailed documentation/purchase guidance.

- Units and conformance – use of SI or USC units, rounding rules, and responsibilities for demonstrating compliance.

Example technical detail included: the standard defines flow coefficient Kv (water flow at 5–40 °C producing 0.1 MPa pressure loss).

Applications

EN 13942:2009 is used to ensure reliable, safe valve components in onshore and offshore pipeline transportation of hydrocarbons (excluding subsea valves). Typical applications:

- Transmission pipelines for crude oil, natural gas and refined products

- Midstream pipeline installations and valve stations

- Valve specification for pipeline projects and procurement

Keywords: pipeline valve specification, valve testing, hydrocarbon pipeline valves.

Who should use this standard

- Valve manufacturers and fabricators

- Pipeline operators and asset owners

- Engineering, procurement and construction (EPC) firms

- Inspection and testing laboratories

- Regulatory and conformity assessment bodies

Related standards

EN 13942 references and aligns with many international standards (ISO, ASME, NACE, ASTM, MSS) such as ISO 13623, ISO 14313, ISO 5208, ISO 10497 and ASME B16.34 - useful cross‑references for detailed design, testing and material requirements.

Frequently Asked Questions

SIST EN 13942:2009 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Petroleum and natural gas industries - Pipeline transportation systems - Pipeline valves (ISO 14313:2007 modified)". This standard covers: This International Standard specifies requirements and provides recommendations for the design, manufacturing, testing and documentation of ball, check, gate and plug valves for application in pipeline systems meeting the requirements of ISO 13623 for the petroleum and natural gas industries. This International Standard is not applicable to subsea pipeline valves, as they are covered by a separate International Standard (ISO 14723). This International Standard is not applicable to valves for pressure ratings exceeding PN 420 (Class 2 500). On-land supply systems used by the gas supply industry are excluded from the scope of this standard.

This International Standard specifies requirements and provides recommendations for the design, manufacturing, testing and documentation of ball, check, gate and plug valves for application in pipeline systems meeting the requirements of ISO 13623 for the petroleum and natural gas industries. This International Standard is not applicable to subsea pipeline valves, as they are covered by a separate International Standard (ISO 14723). This International Standard is not applicable to valves for pressure ratings exceeding PN 420 (Class 2 500). On-land supply systems used by the gas supply industry are excluded from the scope of this standard.

SIST EN 13942:2009 is classified under the following ICS (International Classification for Standards) categories: 23.060.01 - Valves in general; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13942:2009 has the following relationships with other standards: It is inter standard links to SIST EN 13942:2004, SIST EN 13942:2009/AC:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13942:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Industrija za predelavo nafte in zemeljskega plina - Transportni cevovodni sistemi - Armature cevovodov (ISO 14313:2007, spremenjen)Erdöl- und Erdgasindustrie - Rohrleitungstransportsysteme - Rohrleitungsarmaturen (ISO 14313:2007, modifiziert)Industries du pétrole et du gaz naturel - Systèmes de transport par conduites - Robinets de conduites (ISO 14313:2007 modifiée)Petroleum and natural gas industries - Pipeline transportation systems - Pipeline valves (ISO 14313:2007 modified)75.200Petroleum products and natural gas handling equipment23.060.01Ventili na splošnoValves in generalICS:Ta slovenski standard je istoveten z:EN 13942:2009SIST EN 13942:2009en,fr01-maj-2009SIST EN 13942:2009SLOVENSKI

STANDARDSIST EN 13942:20041DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13942January 2009ICS 23.040.01; 75.200Supersedes EN 13942:2003

English VersionPetroleum and natural gas industries - Pipeline transportationsystems - Pipeline valves (ISO 14313:2007 modified)Industries du pétrole et du gaz naturel - Systèmes detransport par conduites - Robinets de conduites (ISO14313:2007 modifiée)Erdöl- und Erdgasindustrie - Rohrleitungstransportsysteme- Rohrleitungsarmaturen (ISO 14313:2007, modifiziert)This European Standard was approved by CEN on 27 December 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13942:2009: ESIST EN 13942:2009

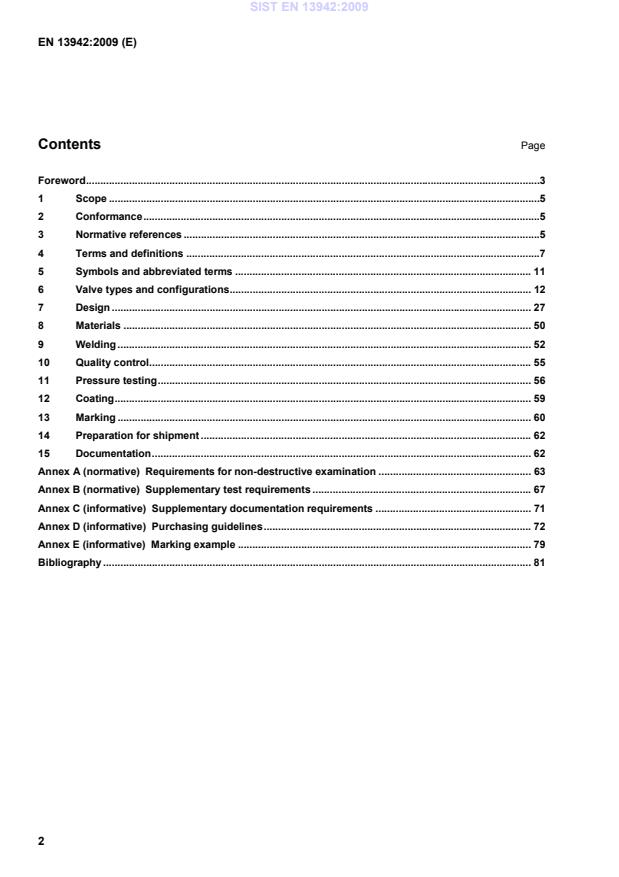

Requirements for non-destructive examination . 63Annex B (normative)

Supplementary test requirements . 67Annex C (informative)

Supplementary documentation requirements . 71Annex D (informative)

Purchasing guidelines . 72Annex E (informative)

Marking example . 79Bibliography . 81

1) American Society of Mechanical Engineers International, 345 East 47th Street, NY 10017-2392, USA SIST EN 13942:2009

2) American Society of Non-Destructive Testing, P.O. Box 28518, 1711 Arlingate Lane, Columbus, OH 43228-0518, USA. 3) ASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, USA. 4) The American Welding Society, 550 NW LeJeune Road, Miami, FL 33126, USA. SIST EN 13942:2009

6 Valve types and configurations 6.1 Valve types 6.1.1 Gate valves Typical configurations for gate valves with flanged and welding ends are shown, for illustration purposes only, in Figures 1 and 2. Gate valves shall have an obturator that moves in a plane perpendicular to the direction of flow. The gate can be constructed of one piece for slab-gate valves or of two or more pieces for expanding-gate valves. Gate valves shall be provided with a back seat or secondary stem sealing feature in addition to the primary stem seal. 6.1.2 Lubricated and non-lubricated plug valves Typical configurations for plug valves with flanged and welding ends are shown, for illustration purposes only, in Figure 3. Plug valves shall have a cylindrical or conical obturator that rotates about an axis perpendicular to the direction of flow. 6.1.3 Ball valves Typical configurations for ball valves with flanged or welding ends are shown, for illustration purposes only, in Figures 4, 5 and 6. Ball valves shall have a spherical obturator that rotates on an axis perpendicular to the direction of flow. 6.1.4 Check valves Typical configurations for check valves are shown, for illustration purposes only, in Figures 7 to 13. Check valves can also be of the wafer, axial flow and lift type. Check valves shall have an obturator which responds automatically to block fluid in one direction. 6.2 Valve configurations 6.2.1 Full-opening valves Full-opening flanged-end valves shall be unobstructed in the fully opened position and shall have an internal bore as specified in Table 1. There is no restriction on the upper limit of valve bore sizes. SIST EN 13942:2009

Key 1 stem indicator 2 stem enclosure 3 handwheel 4 yoke nut 5 yoke 6 stem 7 yoke bolting 8 stem packing 9 relief valve 10 bonnet 11 bonnet bolting 12 gate guide 13 gate assembly 14 seat ring 15 body 16 support ribs or legs 17 raised face 18 welding end 19 ring joint A raised-face face-to-facedimension B welding-end end-to-enddimension C ring-joint end-to-end dimension NOTE See Tables 2 to 6 for dimensions A, B and C.Figure 1 — Expanding-gate/rising-stem gate valve SIST EN 13942:2009

Key 1 stem indicator 2 stem enclosure 3 hand-wheel 4 yoke nut 5 yoke 6 stem 7 yoke bolting 8 stem packing 9 relief valve 10 bonnet 11 bonnet bolting 12 gate

13 seat ring 14 body 15 support ribs or legs 16 raised face 17 welding end 18 ring joint A raised-face face-to-face dimension B welding-end end-to-end dimension C ring-joint end-to-end dimension NOTE See Tables 2 to 6 for dimensions A, B and C. Figure 2 — Slab-gate/through-conduit rising-stem gate valve SIST EN 13942:2009

Key 1 lubricator screw 2 gland studs and nuts 3 gland 4 cover studs and nuts 5 cover 6 cover gasket 7 stem packing 8 lubricant check valve 9 plug 10 body 11 stop collar 12 raised face 13 welding end 14 ring joint A raised-face face-to-face dimension B welding-end end-to-end dimension C ring-joint end-to-end dimension NOTE See Tables 2 to 6 for dimensions A, B and C. Figure 3 — Plug valve SIST EN 13942:2009

Key 1 stem seal 2 bonnet cover 3 bonnet 4 body bolting 5 body 6 seat ring 7 stem 8 ball 9 raised face 10 welding end 11 ring joint A raised-face face-to-face dimension B welding-end end-to-end dimension C ring-joint end-to-end dimension NOTE See Tables 2 to 6 for dimensions A, B and C. Figure 4 — Top-entry ball valve SIST EN 13942:2009

Key 1 stem 2 body cover 3 stem seal 4 body 5 seat ring 6 ball 7 body bolting 8 closure 9 raised face 10 welding end 11 ring joint A raised-face face-to-face dimension B welding-end end-to-end dimension C ring-joint end-to-end dimension NOTE See Tables 2 to 6 for dimensions A, B and C. Figure 5 — Three-piece ball valve SIST EN 13942:2009

Key 1 stem 2 body cover 3 stem seal 4 body 5 seat ring 6 ball 7 closure 8 raised face 9 welding end 10 ring joint A raised-face face-to-face dimension B welding-end end-to-end dimension C ring-joint end-to-end dimension NOTE See Tables 2 to 6 for dimensions A, B and C. Figure 6 — Welded-body ball valve SIST EN 13942:2009

Key 1 cover bolting 2 cover 3 body 4 clapper disc arm 5 shaft 6 clapper disc 7 seat ring 8 support ribs or legs 9 raised face 10 welding end 11 ring joint 12 direction of flow A raised-face face-to-face dimension B welding-end end-to-end dimension C ring-joint end-to-end dimension NOTE See Tables 2 to 6 for dimensions A, B and C. Figure 7 — Reduced-opening swing check valve SIST EN 13942:2009

Key 1 cover bolting 2 cover 3 body 4 clapper disc arm 5 shaft 6 seat ring 7 clapper disc 8 support ribs or legs 9 raised face 10 welding end 11 ring joint 12 direction of flow A raised-face face-to-face dimension B welding-end end-to-end dimension C ring-joint end-to-end dimension NOTE See Tables 2 to 6 for dimensions A, B and C. Figure 8 — Full-opening swing check valve SIST EN 13942:2009

Key 1 body 2 hinge 3 nut 4 closure plate/stud assembly 5 seat ring 6 bearing spacers 7 hinge pin 8 hinge pin retainers 9 direction of flow Figure 9 — Single-plate wafer-type check valve, long pattern SIST EN 13942:2009

Key 1 body 2 closure plate 3 stop pin 4 spring 5 hinge pin 6 plate lug bearings 7 body lug bearings 8 stop pin retainers 9 hinge pin retainers 10 spring bearings 11 direction of flow Figure 10 — Typical dual-plate wafer-type check valve, long pattern SIST EN 13942:2009

Key 1 body 2 clapper 3 pin 4 clapper seal 5 body seal 6 lifting eye 7 direction of flow Figure 11 — Single-plate wafer-type check valve, short pattern SIST EN 13942:2009

Key 1 body 2 rod guidance 3 disc 4 bearing 5 spring 6 flow direction A raised-face face-to-face dimension B welding-end end-to-end dimension C ring-joint end-to-end dimension NOTE See Tables 2 to 6 for dimensions A, B and C. Figure 12 — Axial flow check valve SIST EN 13942:2009

Key 1 cover bolting 2 cover 3 body 4 piston 5 liner 6 seat ring 7 support ribs or legs 9 raised face 10 welding end 11 ring joint 12 direction of flow A raised-face face-to-face dimension B welding-end end-to-end dimension C ring-joint end-to-end dimension NOTE See Tables 2 to 6 for dimensions A, B and C. Figure 13 — Piston check valve 7 Design 7.1 Design standards and calculations Pressure-containing parts, including bolting, shall be designed with materials specified in Clause 8. Design and calculations for pressure-containing elements shall be in accordance with an internationally recognized design code or standard with consideration for pipe loads, operating forces, etc. The choice of standard shall be by agreement. SIST EN 13942:2009

joint C Raised face A Welding end B Ring

joint C PN 20 (class 150) PN 50 (class 300) 50 65 80 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 2 2½ 3 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 178 191 203 229 267 292 330 356 381 406 432 457 — 508 559 610 610 a 711 762 711 b 216 241 283 305 403 419 457 502 572 610 660 711 — 813 864 914 914 965 1 016 1 016 191 203 216 241 279 305 343 368 394 419 445 470 — 521 — — — — — — 216 241 283 305 403 419 457 502 762 838 914 991 1 092 1 143 1 245 1 346 1 397 1 524 1 626 1 727 216 241 283 305 403 419 457 502 762 838 914 991 1 092 1 143 1 245 1 346 1 397 1 524 1 626 1 727 232 257 298 321 419 435 473 518 778 854 930 1 010 1 114 1 165 1 270 1 372 1 422 1 553 1 654 1 756

(to be continued)

joint C Raised face A Welding end B Ring

joint C PN 64 (class 400) PN 100 (class 600) 50 65 80 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 2 2½ 3 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 292 330 356 406 495 597 673 762 826 902 978 1 054 1 143 1 232 1 308 1 397 1 524 1 651 1 778 1 880 292 330 356 406 495 597 673 762 826 902 978 1 054 1 143 1 232 1 308 1 397 1 524 1 651 1 778 1 880 295 333 359 410 498 600 676 765 829 905 981 1 060 1 153 1 241 1 321 1 410 1 537 1 667 1 794 1 895 292 330 356 432 559 660 787 838 889 991 1 092 1 194 1 295 1 397 1 448 1 549 1 651 1 778 1 930 2 083 292 330 356 432 559 660 787 838 889 991 1 092 1 194 1 295 1 397 1 448 1 549 1 651 1 778 1 930 2 083 295 333 359 435 562 664 791 841 892 994 1 095 1 200 1 305 1 407 1 461 1 562 1 664 1 794 1 946 2 099

(to be continued)

joint C Raised face A Welding end B Ring

joint C PN 150 (class 900) PN 250 (class 1500) 50 65 80 100 150 200 250 300 350 400 450 500 550 600 2 2½ 3 4 6 8 10 12 14 16 18 20 22 24 368 419 381 457 610 737 838 965 1 029 1 130 1 219 1 321 — 1 549 368 419 381 457 610 737 838 965 1 029 1 130 1 219 1 321 — 1 549 371 422 384 460 613 740 841 968 1 038 1 140 1 232 1 334 — 1 568 368 419 470 546 705 832 991 1 130 1 257 1 384 1 537 1 664 — 1 943 368 419 470 546 705 832 991 1 130 1 257 1 384 1 537 1 664 — 1 943 371 422 473 549 711 841 1 000 1 146 1 276 1 407 1 559 1 686 — 1 972

PN 420 (class 2500)

50 65 80 100 150 200 250 300 2 2½ 3 4 6 8 10 12 451 508 578 673 914 1 022 1 270 1 422 451 508 578 673 914 1 022 1 270 1 422 454 514 584 683 927 1 038 1 292 1 445 a Through-conduit valves shall be 660 mm. b Through-conduit valves shall be 813 mm.

PN 50 (class 300) 50 65 80 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 2 2½ 3 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 216 241 283 305 403 419 457 502 — — — — — — — — — — — — 267 305 330 356 457 521 559 635 — — — — — — — — — — — — 232 257 298 321 419 435 473 518 — — — — — — — — — — — — — — — — 403 502 568 — — — 914 991 1 092 1 143 1 245 1 346 1 397 1 524 1 626 1 727 — — — — — — — — — — — — — — — — — — — — — — — — 419 518 584 — — — 930 1 0101 1141 1651 2701 3721 4221 5531 6541 756— — — — 403 419 457 502 762 838 914 991 1 092 1 143 1 245 1 346 1 397 1 524 1 626 1 727 — — — — 457 521 559 635 762 838 914 991 1 092 1 143 1 245 1 346 1 397 1 524 1 626 1 727 — — — — 419 435 473 518 778 854 930 1 010 1 114 1 165 1 270 1 372 1 422 1 553 1 654 1 756 283 330 387 457 559 686 826 965 — — — — — — — — — — — — 283 330 387 457 559 686 826 965 — — — — — — — — — — — — 298 346 403 473 575 702 841 981 — — — — — — — — — — — —

(to be continued)

(to be continued)

PN 150 (class 900) 50 65 80 100 150 200 250 300 400 2 2½ 3 4 6 8 10 12 16 368 419 381 457 610 737 838 — — — — 381 457 610 737 838 — — 371 422 384 460 613 740 841 — — — — — — 610 737 838 965 1 130 — — — — 610 737 838 965 1 130 — — — — 613 740 841 968 1 140 381 432 470 559 737 813 965 1 118 — — — — — — — — — — 384 435 473 562 740 816 968 1 121 —

(to be continued)

PN 420 (class 2500) 50 65 80 100 150 200 250 300 2 2½ 3 4 6 8 10 12 451 508 578 673 914 1 022 1 270 1 422 — — — — — — — — 454 514 584 683 927 1 038 1 292 1 445 — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

(to be continued)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...