SIST EN 13774:2014

(Main)Valves for gas distribution systems with maximum operating pressure less than or equal to 16 bar - Performance requirements

Valves for gas distribution systems with maximum operating pressure less than or equal to 16 bar - Performance requirements

This European Standard deals with metal isolating valves used for gas distribution systems with maximum operating pressure up to 16 bar, and which operate with fuel gases of the first, the second and the third family, in accordance with EN 437.

The types of isolating valves to be considered are: plug and ball valves, gate valves, globe valves and butterfly valves.

This standard does not apply to:

- valves for domestic installations;

- safety type pressure relief valves;

- wellhead valves.

In the case of power operated valves, the requirements for the power source are not covered by this European Standard.

The valves covered in this European Standard operate in the following classes of temperature:

- - 10 °C to 60 °C;

- - 20 °C to 60 °C;

- the range is stated by the purchaser for special design.

This European Standard gives additional requirements to the relevant products standards. (See Annex B.)

In case of contradictions between the standards mentioned in Annex B and this European Standard, EN 13774 prevails.

Armaturen für Gasverteilungssysteme mit zulässigen Betriebsdrücken kleiner oder gleich als 16 bar - Anforderungen an die Gebrauchstauglichkeit

Diese Europäische Norm gilt für Absperrarmaturen aus Metall, die in Gasverteilungssystemen mit einem höchsten Betriebsdruck von bis zu 16 bar verwendet werden und die mit Brenngasen der ersten, zweiten und dritten Familie nach EN 437 betrieben werden.

Die zu berücksichtigenden Bauarten von Absperrarmaturen sind: Kegel- und Kugelhähne, Schieber, Absperrventile und Klappen.

Diese Norm gilt nicht für:

- Armaturen für die Hausinstallation;

- Sicherheitseinrichtungen gegen Drucküberschreitung;

- Bohrkopfarmaturen.

Für kraftbetätigte Armaturen sind die Anforderungen an die Energieversorgung nicht in dieser Europäischen Norm festgelegt.

Armaturen nach diesem Dokument arbeiten in den folgenden Temperaturklassen:

- -10 °C bis 60 °C;

- -20 °C bis 60 °C;

- für Sonderausführungen wird der Temperaturbereich vom Käufer angegeben.

Diese Europäische Norm enthält gegenüber den einschlägigen Produktnormen zusätzliche Anforderungen (siehe Anhang B).

Bei Widersprüchen zwischen den in Anhang B aufgeführten Normen gilt diese Europäische Norm EN 13774 vorrangig.

Appareils de robinetterie pour les systèmes de distribution du gaz avec une pression maximale de service inférieure ou égale à 16 bar - Exigences de performance

La présente Norme européenne s'applique aux robinets d'isolement métalliques utilisés pour les systèmes de distribution du gaz avec une pression maximale de service jusqu’à 16 bar inclus, et fonctionnant avec des gaz combustibles de la première, de la seconde et de la troisième famille conformément à l'EN 437.

Les types de robinets d'isolement à prendre en compte sont les robinets à tournant sphérique, cylindrique et conique, les robinets-vannes, les robinets à soupapes et les robinets à papillon.

La présente norme ne s'applique pas aux :

- appareils de robinetterie destinés aux installations domestiques ;

- soupapes de sécurité ;

- robinets de tête de puits.

Dans le cas d’appareils de robinetterie motorisés, les exigences du moteur ne sont pas couvertes par la présente Norme européenne.

Les appareils de robinetterie auxquels s'applique la présente Norme européenne, fonctionnent dans les plages de températures suivantes :

- - 10 °C à 60 °C ;

- - 20 °C à 60 °C ;

- la plage est établie par le client pour une conception spéciale.

La présente Norme européenne définit des exigences supplémentaires par rapport aux normes de produits appropriées (voir Annexe B).

En cas de contradiction avec les normes mentionnées dans l’Annexe B et la présente Norme européenne, l’EN 13774 prévaut.

Ventili za plinske razdelilne sisteme z največjim delovnim tlakom, manjšim ali enakim 16 bar - Zahteve glede uporabnosti

Ta evropski standard obravnava kovinske izolirne ventile, ki se uporabljajo za plinske razdelilne sisteme z največjim delovnim tlakom do 16 barov in ki delujejo z gorivnimi plini prve, druge in tretje družine, v skladu s standardom EN 437. Vrste obravnavanih izolirnih ventilov so: ventili s svečko in krogelni ventili, zasuni, zaporni ventili in zaporne lopute. Ta standard se ne uporablja za: – ventile za gospodinjske napeljave; – varnostne razbremenilne ventile; – ventile za ustja vrtin. V primeru ventilov s pogonskim mehanizmom zahteve za vir napajanja niso zajete v tem evropskem standardu. Ventili iz tega evropskega standarda delujejo v naslednjih temperaturnih razredih: – –10 °C do 60 °C; – –20 °C do 60 °C; – obseg, ki ga navede dobavitelj za posebno izvedbo. Ta evropski standard vsebuje dodatne zahteve za ustrezne standarde za proizvode (glej dodatek B). V primeru neskladij med standardi iz dodatka B in tem evropskim standardom ima prednost standard EN 13774.

General Information

- Status

- Published

- Public Enquiry End Date

- 24-Sep-2011

- Publication Date

- 01-Dec-2013

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 25-Nov-2013

- Due Date

- 30-Jan-2014

- Completion Date

- 02-Dec-2013

Relations

- Effective Date

- 01-Jan-2014

Overview

EN 13774:2013 (CEN) - "Valves for gas distribution systems with maximum operating pressure less than or equal to 16 bar - Performance requirements" - specifies additional performance, testing and marking requirements for metal isolating valves used in gas distribution networks. It applies to plug, ball, gate, globe and butterfly isolating valves operating with fuel gases of the first, second and third families (as defined in EN 437) and for maximum operating pressures up to 16 bar. Temperature classes covered include -10 °C to 60 °C, -20 °C to 60 °C or purchaser-specified ranges. The standard excludes valves for domestic installations, pressure relief (safety) valves and wellhead valves. For power-operated valves the standard does not cover the power source.

Key topics and requirements

- Scope & exclusions: Defines valve types, gas families, pressure and temperature limits and what is not covered.

- Materials: Requirements for shell, obturator, stems/shafts, springs, seals and lubricants.

- Design: Strength design, stems/shafts, bolt holes, manufacturing apertures, sealing systems, extended drain/vent/sealant lines.

- Dimensions: Threaded ends, end connections, end-to-end dimensions (coordination with flange standards).

- Performance testing: Type tests and production tests covering operability, endurance, strength of stops, mechanical resistance to excessive actuating forces, resistance of obturator to static differential pressure, shell strength, external and internal leak tightness.

- Optional tests: Resistance to wear and reference flow rate.

- Ancillary requirements: Cleanliness, storage and marking.

- Test methods & annexes: Annex A provides test methods; Annex B lists relevant product standards; EN 13774 prevails if contradictions occur.

Practical applications & users

Who uses EN 13774:

- Valve manufacturers designing and certifying metal isolating valves for gas distribution up to 16 bar.

- Gas network operators and utilities specifying procurement and acceptance criteria.

- Testing and certification bodies performing type and production testing.

- Project engineers, procurement officers and compliance teams preparing specifications, tenders and conformity documentation.

Practical uses:

- Specifying valve performance, leak-tightness and endurance for distribution pipelines and stations.

- Integrating valve selection with upstream product standards and flange/piping interfaces.

- Establishing tests and acceptance criteria for factory production and type approval.

Related standards

Annex B lists applicable product and complementary standards, examples referenced in the document include: EN 437, EN 19, EN 12266-1, EN 682, EN 1092 series, EN 12516 series, EN 1555 series and others covering materials, flanges, testing and terminology. Use EN 13774 together with those product standards for complete compliance.

Frequently Asked Questions

SIST EN 13774:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Valves for gas distribution systems with maximum operating pressure less than or equal to 16 bar - Performance requirements". This standard covers: This European Standard deals with metal isolating valves used for gas distribution systems with maximum operating pressure up to 16 bar, and which operate with fuel gases of the first, the second and the third family, in accordance with EN 437. The types of isolating valves to be considered are: plug and ball valves, gate valves, globe valves and butterfly valves. This standard does not apply to: - valves for domestic installations; - safety type pressure relief valves; - wellhead valves. In the case of power operated valves, the requirements for the power source are not covered by this European Standard. The valves covered in this European Standard operate in the following classes of temperature: - - 10 °C to 60 °C; - - 20 °C to 60 °C; - the range is stated by the purchaser for special design. This European Standard gives additional requirements to the relevant products standards. (See Annex B.) In case of contradictions between the standards mentioned in Annex B and this European Standard, EN 13774 prevails.

This European Standard deals with metal isolating valves used for gas distribution systems with maximum operating pressure up to 16 bar, and which operate with fuel gases of the first, the second and the third family, in accordance with EN 437. The types of isolating valves to be considered are: plug and ball valves, gate valves, globe valves and butterfly valves. This standard does not apply to: - valves for domestic installations; - safety type pressure relief valves; - wellhead valves. In the case of power operated valves, the requirements for the power source are not covered by this European Standard. The valves covered in this European Standard operate in the following classes of temperature: - - 10 °C to 60 °C; - - 20 °C to 60 °C; - the range is stated by the purchaser for special design. This European Standard gives additional requirements to the relevant products standards. (See Annex B.) In case of contradictions between the standards mentioned in Annex B and this European Standard, EN 13774 prevails.

SIST EN 13774:2014 is classified under the following ICS (International Classification for Standards) categories: 23.060.01 - Valves in general; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13774:2014 has the following relationships with other standards: It is inter standard links to SIST EN 13774:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13774:2014 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13774:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Armaturen für Gasverteilungssysteme mit zulässigen Betriebsdrücken kleiner oder gleich als 16 bar - Anforderungen an die GebrauchstauglichkeitAppareils de robinetterie pour les systèmes de distribution du gaz avec une pression maximale de service inférieure ou égale à 16 bar - Exigences de performanceValves for gas distribution systems with maximum operating pressure less than or equal to 16 bar - Performance requirements75.200Petroleum products and natural gas handling equipment23.060.01Ventili na splošnoValves in generalICS:Ta slovenski standard je istoveten z:EN 13774:2013SIST EN 13774:2014en,fr,de01-januar-2014SIST EN 13774:2014SLOVENSKI

STANDARDSIST EN 13774:20031DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13774

February 2013 ICS 23.060.01 Supersedes EN 13774:2003English Version

Valves for gas distribution systems with maximum operating pressure less than or equal to 16 bar - Performance requirements

Appareils de robinetterie pour les systèmes de distribution du gaz avec une pression maximale de service inférieure ou égale à 16 bar - Exigences de performance

Armaturen für Gasverteilungssysteme mit zulässigen Betriebsdrücken kleiner oder gleich 16 bar - Anforderungen an die Gebrauchstauglichkeit This European Standard was approved by CEN on 28 December 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13774:2013: ESIST EN 13774:2014

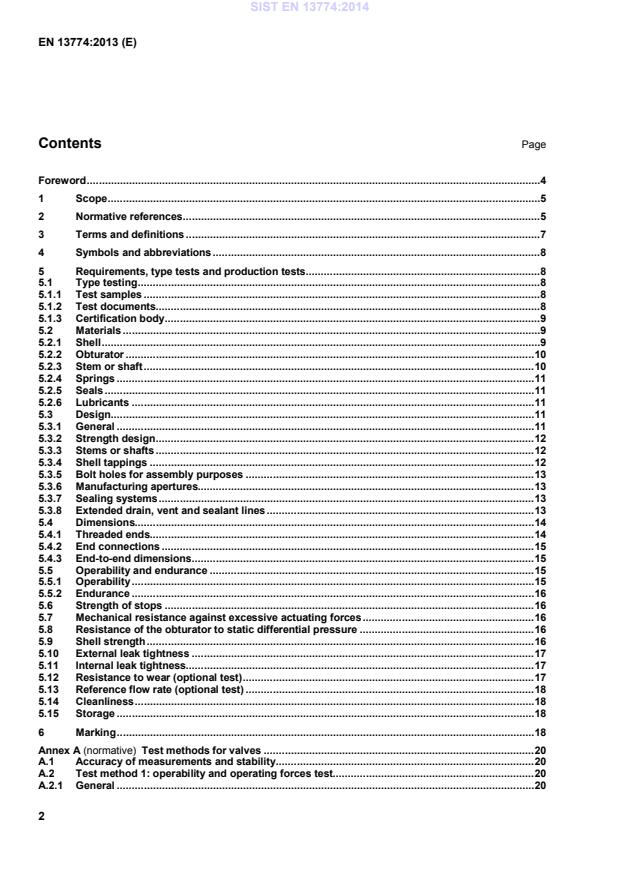

Test methods for valves . 20 A.1 Accuracy of measurements and stability . 20 A.2 Test method 1: operability and operating forces test . 20 A.2.1 General . 20 SIST EN 13774:2014

European Standards for valves. 25 Annex C (informative)

Summary of tests on product and type tests . 26 Bibliography . 29

EN 736-3:2008 and EN 764-1:2004 and the following apply. 3.1 gas distribution system pipeline system including piping above and below ground and all other equipment necessary to supply the gas to the consumers 3.2 external tightness

shell tightness tightness of the gas-containing envelope with respect to the atmosphere 3.3 internal tightness seat tightness tightness ensured between the valve inlet and outlet by the closure device in the closed position 3.4 volume rate of flow volume of fluid discharged by the valve per time unit 3.5 reference flow rate rate of the air flow in cubic metres per hour, as measured at 0 °C at the absolute pressure of 1 013 mbar, discharged by the valve and creating therein a specified pressure drop, at a specified air pressure upstream of the valve 3.6 maximum allowable pressure pmax maximum pressure at which any part of a valve continuously operates at a specified operating temperature 3.7 maximum operating pressure MOP maximum pressure in a system operated continuously under normal operating conditions Note 1 to entry: "Normal operating conditions" means no malfunctioning of the equipment or disruption to the gas flow. 3.8 maximum strength torque maximum torque applied to the stem or the shaft, with the obturator either totally open or totally closed, which causes no alteration to the functional capability of the valve SIST EN 13774:2014

DIB single valve with two seating surfaces, each of which, in the closed position, provides a seal against pressure from a single source, with a means of venting/bleeding the cavity between the seating surfaces Note 1 to entry: This feature can be provided in one direction or in both directions. 4 Symbols and abbreviations ta : mean ambient temperature (+ 20 °C ± 5 °C); tmax : maximum value of use temperature (+ 60 °C); tmin : minimum value of use temperature; pmax : maximum allowable pressure. 5 Requirements, type tests and production tests 5.1 Type testing 5.1.1 Test samples Qualification of the range shall be achieved by testing the smallest valve, the largest valve limited by DN 500 and one chosen in the middle of the range. For valves greater than DN 500, the DN 500 qualifies the range up to DN 1 000. This applies only where the materials, design and construction does not change within the range. For resistance to wear, qualification shall be achieved by testing only the smallest of the range. For each valve to be tested, one sample should be provided, and tested in accordance with the qualification test program. 5.1.2 Test documents The manufacturer shall produce a technical file containing the following documents: a) detailed drawings, including dimensions, tolerances, surface conditions and relevant calculations for pressure containing parts and principle parts; b) detailed drawings of the isolating valve with sectional drawings of all important parts; SIST EN 13774:2014

The technical data concerning the materials used shall be available from the valve manufacturer.

_ 5.2.1.2 Steel weldings ends For welding ends of valves, the maximum carbon equivalent CEVmax shall not exceed: CEVmax = 0,45 for grades with specified minimum yield strength not exceeding 360 N/mm2; CEVmax = 0,48 for grades with specified minimum yield strength above 360 N/mm2; unless otherwise agreed between purchaser and manufacturer. 5%%%6%%maxVMoCrMnCCEV++++=

% is the percentage by weight of the ladle content of: C Carbon; Mn Manganese; Cr Chromium; Mo Molybdenum; V Vanadium; Cu Copper; Ni Nickel. Unless otherwise agreed between manufacturer and purchaser, the carbon content shall not exceed 0,21 %. The sulphur content shall not exceed 0,030 %, and the phosphorus content shall not exceed 0,035 %. The sum of sulphur and phosphorus as a total of the ladle analysis shall be smaller than or equal to 0,050 %. 5.2.1.3 PE ends Materials in accordance with EN 1555-1 shall be used.

5.2.2 Obturator Requirements Type tests Production tests Materials in accordance with EN 12516-1, EN 12516-2 or EN 12516-4 shall be used. The technical data concerning the materials used shall be available from the valve manufacturer. _ 5.2.3 Stem or shaft Requirements Type tests Production tests Stem or shaft shall be made from metallic materials and shall be corrosion resistant or permanently protected against corrosion. The technical data concerning the materials used sh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...