SIST EN 19694-6:2017

(Main)Stationary source emissions - Determination of greenhouse gas (GHG) emissions in energy-intensive industries - Part 6: Ferroalloy industry

Stationary source emissions - Determination of greenhouse gas (GHG) emissions in energy-intensive industries - Part 6: Ferroalloy industry

This European Standard provides a harmonized methodology for calculating GHG emissions from the ferro-alloys industry based on the mass balance approach . It also provides key performance indicators over time of ferro-alloys plants. It addresses the following direct and indirect sources of GHG:

- Scope 1 - Direct GHG emissions from sources that are owned or controlled by the company, such as emissions result from the following sources:

- smelting (reduction) process;

- decomposition of carbonates inside the furnace;

- auxiliaries operation related to the smelting operation (i.e. aggregates, drying processes, heating of ladles, etc.).

- Scope 2 - Indirect GHG emissions from:

- the generation of purchased electricity consumed in the company’s owned or controlled equipment.

This European Standard is to be used in conjunction with FprEN 19694-1, which contains generic, overall requirements, definitions and rules applicable to the determination of GHG emissions for all energy-intensive sectors, provides common methodological issues and defines the details for applying the rules. The application of this standard to the sector-specific standards ensures accuracy, precision and reproducibility of the results and is for this reason a normative reference standard. The requirements of these standards do not supersede legislative requirements.

Emissionen aus stationären Quellen - Bestimmung von Treibhausgasen (THG) aus energieintensiven Industrien - Teil 6: Ferrolegierungsindustrie

Diese Europäische Norm stellt eine harmonisierte Methodik zur Berechnung der Treibhausgasemissionen aus der Ferrolegierungsindustrie auf der Grundlage des Massenbilanzansatzes ) bereit. Darüber hinaus stellt sie zeitverlaufsbezogene Schlüsselleistungskennzahlen für Anlagen bereit, in denen Ferrolegierungen hergestellt werden. Sie behandelt die folgenden direkten und indirekten Treibhausgasquellen:

— Scope 1: direkte Treibhausgasemissionen aus Quellen, die im Besitz des Unternehmens sind oder von diesem kontrolliert werden, wie Emissionen aus folgenden Quellen:

— Schmelz(reduktions)prozess:

— Carbonatzerfall im Ofen;

— unterstützende Vorgänge im Zusammenhang mit dem Schmelzen, (d. h. Zuschlagstoffe, Trocknungsprozesse, Erwärmen der Pfannen usw.);

— Scope 2: indirekte Treibhausgasemissionen aus:

— der Erzeugung zugekaufter elektrischer Energie, die in den Ausrüstungen verbraucht wird, welche sich im Besitz des Unternehmens befinden oder von diesem kontrolliert werden.

Diese Europäische Norm ist in Verbindung mit der Norm FprEN 19694 1, anzuwenden, in der generische, allgemeine Anforderungen, Definitionen und Regeln behandelt sind, die für die Bestimmung von Treibhausgasemissionen aus allen energieintensiven Sektoren gelten, und in der gemeinsame methodische Aspekte beschrieben und die Einzelheiten zur Anwendung dieser Regeln festgelegt sind. Durch die Anwendung dieser Norm auf sektorspezifische Normen sind die Genauigkeit, Präzision und Wiederholbarkeit der Ergebnisse sichergestellt, daher handelt es sich hierbei um eine normative Bezugsnorm. Die Anforderungen dieser Normen ersetzen keine Rechtsvorschriften.

Émissions de sources fixes - Détermination des émissions des gaz à effet de serre dans les industries à forte intensité énergétique - Partie 6: Industrie des ferro-alliages

La présente Norme européenne fournit une méthodologie harmonisée pour calculer les émissions de GES dans l'industrie des ferro-alliages, basée sur le bilan massique . Elle fournit également des indicateurs clés qui permettront de déterminer les performances des installations de production de ferro-alliages au fil du temps. Elle examine les sources suivantes d'émissions directes et indirectes de GES :

— Type 1 – Émissions directes de GES provenant de sources détenues ou contrôlées par l'entreprise, les émissions émanant des sources suivantes :

— procédé de fusion/réduction carbothermique (réduction) ;

— décomposition des carbonates à l'intérieur du four ;

— fonctionnement des auxiliaires liés à l'opération de fusion/réduction carbothermique (granulats, procédés de séchage, chauffage des poches de coulée, etc.).

— Type 2 – Émissions indirectes de GES provenant :

— de la génération de l'électricité achetée et consommée par les équipements détenus ou contrôlés par l'entreprise.

La présente Norme européenne doit être utilisée conjointement avec le FprEN 19694-1 qui contient des exigences générales génériques, des définitions et des règles applicables pour la détermination des émissions de GES pour tous les secteurs consommateurs d'énergie, expose des questions méthodologiques communes et détaille l'application des règles exposées. L'application de la présente norme aux normes sectorielles garantit l'exactitude, la fidélité et la reproductibilité des résultats et est, de ce fait, une norme de référence normative. Les exigences de ces normes ne se substituent pas aux exigences législatives.

Emisije nepremičnih virov - Določevanje emisij toplogrednih plinov (TGP) v energetsko intenzivnih industrijah - 6. del: Proizvodnja ferozlitin

Merjenje emisij toplogrednih plinov pri proizvodnji ferozlitin s potrjeno metodo določanja. Ta standard je rezultat sprejetja M/478, pri čemer bo sestavljenih šest standardov: en splošni standard in pet standardov, povezanih z ustreznim sektorjem.

General Information

- Status

- Published

- Public Enquiry End Date

- 04-Dec-2014

- Publication Date

- 11-Jun-2017

- Technical Committee

- KAZ - Air quality

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 02-Feb-2017

- Due Date

- 09-Apr-2017

- Completion Date

- 12-Jun-2017

Overview

EN 19694-6:2016 (CEN) - Stationary source emissions: Determination of greenhouse gas (GHG) emissions in energy‑intensive industries - Part 6: Ferroalloy industry - specifies a harmonized methodology for calculating CO2 and other GHGs from ferro‑alloy plants. The standard uses a mass balance approach to quantify direct (Scope 1) and indirect (Scope 2) emissions, and provides guidance on key performance indicators (KPIs), inventory boundaries, uncertainty assessment and reporting. It is intended to be used together with EN 19694‑1 (general aspects) and is consistent with IPCC principles and EU regulatory frameworks where applicable.

Key topics and requirements

- Mass balance methodology for determining process‑related GHGs (preferred over stack measurements for accuracy in this sector).

- Scope 1 (direct) emissions coverage:

- Smelting / carbothermic reduction (primary source of CO2 in submerged electric arc furnaces - SEAF).

- Decomposition (calcination) of carbonates in furnaces.

- Auxiliaries and non‑smelting fuel use (drying, ladle heating, refractory heating, etc.).

- Scope 2 (indirect) emissions coverage:

- Purchased electricity consumed by the plant (country‑specific grid factors are provided in annexes).

- Inventory boundaries: operational and organizational boundaries are defined to ensure consistent reporting.

- Data quality & uncertainty: methods for assessing activity data uncertainty, fuel/material parameter uncertainty and overall inventory uncertainty.

- Reporting & KPIs: recommended reporting periods, baseline treatment (acquisitions/disinvestments), and plant performance indicators to track emissions over time.

- Normative annexes included:

- Tier 1 emission factors

- Minimum frequency of analysis

- Country‑wise emission factors for electricity

Practical applications - who uses this standard

- Environmental & sustainability managers in ferro‑alloy, ferro‑silicon, ferromanganese and related operations for accurate GHG inventories.

- Process and metallurgical engineers assessing carbon flows from SEAF and carbothermic reactions.

- Compliance teams and auditors preparing reports for corporate sustainability programs, EU ETS interactions or national inventory submissions.

- Consultants and LCA practitioners benchmarking plant performance, calculating KPIs and evaluating mitigation opportunities (fuel substitution, electrode use, waste heat recovery).

- Regulators and industry associations using a harmonized, reproducible methodology for sectoral comparisons.

Related standards

- EN 19694‑1:2016 - General aspects and common methodological rules for energy‑intensive industries (normative reference).

- IPCC 2006 Guidelines and relevant EU regulations are referenced for compatibility with national and international GHG reporting frameworks.

Keywords: EN 19694-6, ferroalloy industry, GHG emissions, mass balance, Scope 1, Scope 2, SEAF, CO2 inventory, emission factors, KPI, EN 19694-1.

Frequently Asked Questions

SIST EN 19694-6:2017 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Stationary source emissions - Determination of greenhouse gas (GHG) emissions in energy-intensive industries - Part 6: Ferroalloy industry". This standard covers: This European Standard provides a harmonized methodology for calculating GHG emissions from the ferro-alloys industry based on the mass balance approach . It also provides key performance indicators over time of ferro-alloys plants. It addresses the following direct and indirect sources of GHG: - Scope 1 - Direct GHG emissions from sources that are owned or controlled by the company, such as emissions result from the following sources: - smelting (reduction) process; - decomposition of carbonates inside the furnace; - auxiliaries operation related to the smelting operation (i.e. aggregates, drying processes, heating of ladles, etc.). - Scope 2 - Indirect GHG emissions from: - the generation of purchased electricity consumed in the company’s owned or controlled equipment. This European Standard is to be used in conjunction with FprEN 19694-1, which contains generic, overall requirements, definitions and rules applicable to the determination of GHG emissions for all energy-intensive sectors, provides common methodological issues and defines the details for applying the rules. The application of this standard to the sector-specific standards ensures accuracy, precision and reproducibility of the results and is for this reason a normative reference standard. The requirements of these standards do not supersede legislative requirements.

This European Standard provides a harmonized methodology for calculating GHG emissions from the ferro-alloys industry based on the mass balance approach . It also provides key performance indicators over time of ferro-alloys plants. It addresses the following direct and indirect sources of GHG: - Scope 1 - Direct GHG emissions from sources that are owned or controlled by the company, such as emissions result from the following sources: - smelting (reduction) process; - decomposition of carbonates inside the furnace; - auxiliaries operation related to the smelting operation (i.e. aggregates, drying processes, heating of ladles, etc.). - Scope 2 - Indirect GHG emissions from: - the generation of purchased electricity consumed in the company’s owned or controlled equipment. This European Standard is to be used in conjunction with FprEN 19694-1, which contains generic, overall requirements, definitions and rules applicable to the determination of GHG emissions for all energy-intensive sectors, provides common methodological issues and defines the details for applying the rules. The application of this standard to the sector-specific standards ensures accuracy, precision and reproducibility of the results and is for this reason a normative reference standard. The requirements of these standards do not supersede legislative requirements.

SIST EN 19694-6:2017 is classified under the following ICS (International Classification for Standards) categories: 13.020.40 - Pollution, pollution control and conservation; 13.040.40 - Stationary source emissions; 77.100 - Ferroalloys. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 19694-6:2017 is associated with the following European legislation: Standardization Mandates: M/478. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 19694-6:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.LQEmissionen aus stationären Quellen - Bestimmung von Treibhausgasen (THG) aus energieintensiven Industrien - Teil 6: FerrolegierungsindustrieÉmissions de sources fixes - Détermination des émissions des gaz à effet de serre dans les industries à forte intensité énergétique - Partie 6: Industrie des ferro-alliagesStationary source emissions - Determination of greenhouse gas (GHG) emissions in energy-intensive industries - Part 6: Ferroalloy industry77.100Železove zlitineFerroalloys13.040.40Stationary source emissions13.020.40Onesnaževanje, nadzor nad onesnaževanjem in ohranjanjePollution, pollution control and conservationICS:Ta slovenski standard je istoveten z:EN 19694-6:2016SIST EN 19694-6:2017en,fr,de01-julij-2017SIST EN 19694-6:2017SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 19694-6

July

t r s x ICS

s uä r v rä v r English Version

Stationary source emissions æ Determination of industries æ Part

xã Ferroalloy industry Émissions de sources fixes æ Détermination des industries énergoæintensives æ Partie

xã Industrie des ferroæalliages

Emissionen aus stationären Quellen æ Bestimmung von Industrien æ Teil

xã Ferrolegierungsindustrie This European Standard was approved by CEN on

w May

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s { x { væ xã t r s x ESIST EN 19694-6:2017

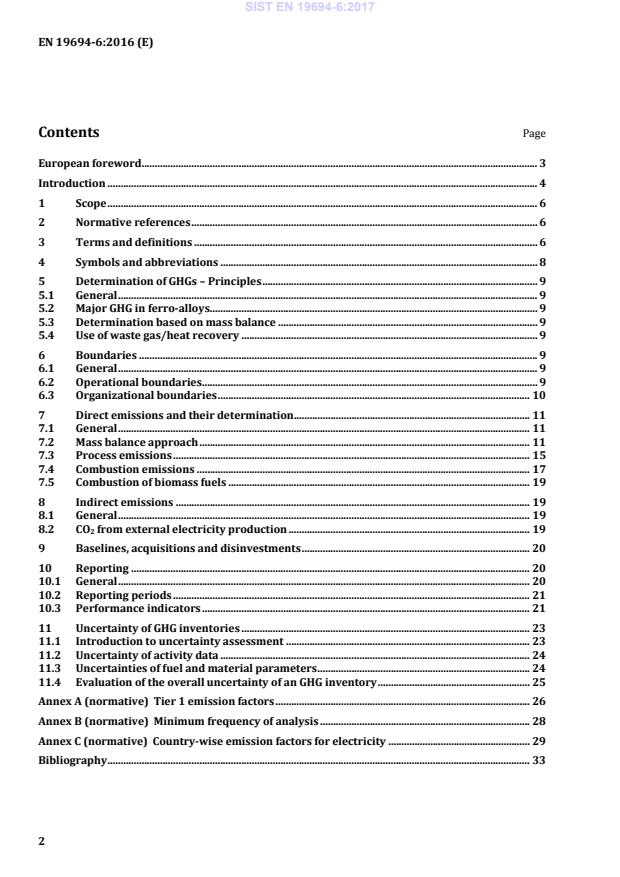

Tier 1 emission factors . 26 Annex B (normative)

Minimum frequency of analysis . 28 Annex C (normative)

Country-wise emission factors for electricity . 29 Bibliography . 33

Figure 1 — Submerged Electric Arc Furnace (SEAF) CO2 from the smelting of raw materials CO2 emissions from reducing agents and electrode use In the smelting process, CO2 is released due to the carbothermic reduction of the metallic oxides occurring with the consumption of both carbonaceous reductants and carbon based electrodes. The carbon in the reductants reacts with oxygen from the metal oxides to form CO and then CO2 (in different SIST EN 19694-6:2017

Calcinated wood

Charcoal

Graphite powder

Anthracite

CO2 emissions are estimated with/calculated from the consumption of the reducing agents and electrodes, their carbon content and the carbon content of the final products1. ores

ª reducing agent \ ferro-alloys/metal* + CO2 + dust/by-product (i.e. slags)* *

amount of carbon can be found in the products Default emission factors suggested in these documents are used, except where more recent, industry-specific data has become available.

1 The basic calculation methods used in this standard are compatible with the 2006 IPCC Guidelines for National Greenhouse Gas Inventories issued by the Intergovernmental Panel on Climate Change (IPCC), and with the Regulation 601/2012 but the objectives of this standards are of different nature implying that the data gathered can cover a broader (or reduced) boundaries as compared to the objectives of the Regulation. SIST EN 19694-6:2017

It addresses the following direct and indirect sources of GHG: — Scope 1 – Direct GHG emissions from sources that are owned or controlled by the company, such as emissions result from the following sources: — smelting (reduction) process; — decomposition of carbonates inside the furnace; — auxiliaries operation related to the smelting operation (i.e. aggregates, drying processes, heating of ladles, etc.). — Scope 2 – Indirect GHG emissions from: — the generation of purchased electricity consumed in the company’s owned or controlled equipment. This European Standard is to be used in conjunction with EN 19694-1, which contains generic, overall requirements, definitions and rules applicable to the determination of GHG emissions for all energy-intensive sectors, provides common methodological issues and defines the details for applying the rules. The application of this standard to the sector-specific standards ensures accuracy, precision and reproducibility of the results and is for this reason a normative reference standard. The requirements of these standards do not supersede legislative requirements. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 19694-1:2016, Stationary source emissions — Determination of greenhouse gas (GHG) emissions in energy intensive industries — Part 1: General aspects 3 Terms and definitions For the purposes of this document, the terms and definitions in EN 19694-1 and the following apply. 3.1 auxiliaries equipment consuming electricity/power related to the smelting process: fans, pumps, gas abatement systems (filter bags, venture scrubbers, etc.) 3.2 silica fume amorphous silicon dioxide particles from the volatilization and vaporization of furnace feed materials in the manufacture of ferrosilicon and silicon, the process off-gas that contains silica fumes beings cleaned in a baghouse using fabric filters of the open or semi-closed SEAF

2 Based on European Commission Regulation 601/2012. SIST EN 19694-6:2017

Electricity consumption for whole production process Onsite power production Waste heat recovery Room heating / cooling (negligible) Mobile transport in plant Stock inventories carbon materials

Table 3 — Process steps Process Step Scope Inclusion? Smelting Scope 1 Yes Electricity consumption for whole production process Scope 2 Yes Onsite power production

Scope 1 Yes Waste heat recovery Scope 1 Yes Room heating / cooling Scope 1. Scope 2 when the used equipment is electrically powered Yes, but negligible Stock changes Scope 1 Yes 6.3 Organizational boundaries The major source of GHG emissions in the ferroalloys sector is the process-related emissions from the Submerged Electric Arc Furnaces operations, the reduction of the metallic oxides and the consumption SIST EN 19694-6:2017

concentrates); c) combustion of conventional fuels (e.g. natural gas, coal and coke, or fuel oil); d) combustion of biomass fuels. Generally, companies are encouraged to measure the required parameters at plant level for specific raw materials. Where plant- or company-specific data are not available, standard or default factors should be used. 7.2 Mass balance approach 7.2.1 Generic approach In the mass balance approach, the CO2 quantity corresponding to each source stream included in the mass balance has to be calculated by multiplying the activity data related to the amount of material entering or leaving the boundaries of the mass balance, with the emission factor for each material. The methodologies for determining, i.e. activity data and emission factors are referred to as tiers. The increasing numbering of tiers from one upwards reflects increasing levels of accuracy, with the highest numbered tier as the preferred tier. For emission sources which emit more than 10 % of the total annual emissions of the installation, the operator shall preferably apply the highest tier given the less uncertainty. For all other emission sources, the operator shall apply at least one tier lower than the highest tier. In case the application of the highest tier is technically not feasible or incurs unreasonable costs, a next lower tier shall be used for the relevant emission source, with a minimum of tier 1. For marginal flows which jointly emit 1.000 t CO2,eq or less, or less than 2 % of the “total of all monitored items” (whichever is highest and not exceeding 20.000 t CO2,eq), it is allowed to calculate activity data and emission factors using a conservative estimation, instead of using tiers (unless it is possible to use tiers without additional effort or costs). With: (a) Activity data The operator shall analyse and report the mass flows into and from the installation and respective stock changes for all relevant fuels and materials separately (generally in GJ (for energy) or in t or mn3 for mass or volume). Tier 1 SIST EN 19694-6:2017

= RECC · 3.664 (2) where REEF is the emission factor of reducing agent or electrodes (tCO2/t); RECC is the carbon content of the reducing agent. The total C-contents of reducing agents is calculated by the following formula. RECCi = FFixC,i + Fvolatiles,i ·Cv (3) where RECC, i is the carbon content in reducing agent i, tonne C/tonne reducing agent; FFixC,I is the mass fraction of Fix C in reducing agent i, tonne C/ tonne reducing agent; Fvolatiles,I is the mass fraction of volatiles in reducing agent i, tonne volatiles/ tonne reducing agent; SIST EN 19694-6:2017

(db) Fix C % = 100 %

- % Ash – % Volatiles (6) SIST EN 19694-6:2017

Remarks

CaCO3 (limestone)

0,440

MgCO3 (= Mg carbonate – not existing as natural carbonate MgCO3-CaCO3 (dolomite) intermediate between CaCO3 and MgCO3, typical content is Mg 30 % and CaO 20 %) 0,522

general: X Y (CO3 ) Z

Emission factor = [M CO2 ]/{Y * [Mx ] + Z * [M CO3 2- ]} X = metal Mx = molecular weight of X in [g/mol] MCO2 = molecular weight of CO 2 in [g/mol] MCO3- = molecular weight of CO32- in [g/mol] Y = stoichiometric number of X Z = stoichiometric number of CO32- These values shall be adjusted for the respective moisture and gangue content of the applied carbonate material. (c) Conversion factor Tier 1 Conversion factor: 1. Based on the principle that process emissions are coming from reducing agents, therefore the total carbon of the raw materials is converted to CO2. SIST EN 19694-6:2017

Tier 1 Tier 2 Tier 3 Tier 4 Process emissions

Each input material or process residue used as input material in the process [t] ± 5 %

± 2,5 %

Mass balance methodology Each input and output material [t] ± 7,5 % ± 5 % ± 2,5 % ± 1,5 %

Tier 2 for the carbon content is used by the operator by deriving it from country specific emission factors (standard factors used by a country for its national inventory submission to the UNFCCC) for the respective fuel or material. SIST EN 19694-6:2017

where CC is the quantity of fuel consumed during the reporting period (t or mN³); LCV is the lower calorific value (TJ / t or TJ / mN³); HCV is the high calorific value (MW.h / mN³); EF is the fuel emission factor (tCO2/TJ tCO2/MW.h HCV for natural gas/ LCV); OF is the xxidation factor of fuel. 7.4.3 Calculation of the quantity of fuel The quantification method of the fuel consumed, made on the basis of the charged amount of fuel as well as the variation of storage according to the formula: Fuel C = Fuel A + (Fuel D – Fuel F) (9) where Fuel C is the fuel consumed during the reporting period under review; Fuel A is the fuel purchased during the reporting period under review; Fuel D is the fuel stock at the beginning of the reporting period under review; Fuel F is the fuel stock at the end of the reporting period in question. 7.4.4 Determination of the lower calorific value and the emission factor Tier 2 for the lower calorific value and the emission factor is used by the operator by deriving them from country specific emission factors for the respective fuel or material. The LCV and EF apply to fuels regardless of moisture, ash content and sulfur content.

3 For natural gas, HCV can be used. SIST EN 19694-6:2017

4 It covers various support systems like fans, heat exchangers, raw material handling, keeping ladles warm, etc. SIST EN 19694-6:2017

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...