SIST EN 15610:2019+A1:2025

(Main + Amendment)Railway applications - Acoustics - Rail and wheel roughness measurement related to noise generation

Railway applications - Acoustics - Rail and wheel roughness measurement related to noise generation

1.1 This document specifies a direct measurement method for characterizing the surface roughness of the rail and wheel associated with rolling noise ("acoustic roughness"), in the form of a one-third octave band spectrum.

This document describes a method for:

a) selecting measuring positions along a track or selecting wheels of a vehicle;

b) selecting lateral positions for measurements;

c) the data acquisition procedure;

d) measurement data processing in order to estimate a set of one-third octave band roughness spectra;

e) presentation of this estimate for comparison with limits of acoustic roughness;

f) comparison with a given upper limit in terms of a one-third octave band wavelength spectrum;

g) the measuring system requirements.

1.2 It is applicable to the:

a) compliance testing of reference track sections in relation to the acceptance test for noise emitted by railway vehicles;

b) performance testing of track sections in relation to noise emitted by railway vehicles;

c) acceptance of the running surface condition only in the case where the acoustic roughness is the acceptance criterion;

d) assessment of the wheel surface condition as an input for the acoustic acceptance of brake blocks;

e) assessment of the wheel and rail roughness as input to the calculation of combined wheel rail roughness;

f) diagnosis of wheel-rail noise issues for specific tracks or wheels;

g) assessment of the wheel and rail roughness as input to rolling noise modelling;

h) assessment of the wheel and rail roughness as input to noise source separation methods.

1.3 It is not applicable to the:

a) measurement of roughness (rail roughness, wheel roughness or combined roughness) using an indirect method;

b) analysis of the effect of wheel-rail interaction, such as a “contact filter”;

c) approval of rail and wheel reprofiling, including rail grinding operations, except for those where the acoustic roughness is specifically the approval criterion (and not the grinding quality criteria as provided in e.g. EN 13231-3);

d) characterization of track and wheel geometry except where associated with noise generation.

Bahnanwendungen - Akustik - Messung der Schienen- und Radrauheit im Hinblick auf die Entstehung von Rollgeräuschen

Applications ferroviaires - Acoustique - Mesurage de la rugosité des rails et des roues relative à la génération du bruit de roulement

Železniške naprave - Akustika - Merjenje hrapavosti (neravnin) vozne površine tirnice in kolesa pri povzročanju hrupa (vključno z dopolnilom A1)

1.1 Ta dokument določa neposredno merilno metodo za ovrednotenje hrapavosti (neravnin) vozne površine tirnice in kolesa, ki povzroča hrup med vožnjo (»akustična hrapavost«), v obliki frekvenčnega pasu ene tretjine oktave. Ta dokument opisuje metodo za: a) izbiranje merilnih položajev vzdolž tirnice ali izbiranje koles vozila; b) izbiranje stranskih položajev za meritve; c) postopek zbiranja podatkov; d) obdelavo merilnih podatkov za oceno hrapavosti v obliki frekvenčnega pasu ene tretjine oktave; e) predstavitev te ocene za primerjavo z mejami akustične hrapavosti; f) primerjavo z določeno zgornjo mejo glede na valovno dolžino frekvenčnega pasu ene tretjine oktave; g) zahteve merilnega sistema. 1.2 Uporablja se za: a) preskušanje skladnosti referenčnih odsekov tirnice glede na preskus sprejemljivosti hrupa, ki ga oddajajo železniška vozila; b) preskušanje učinkovitosti odsekov tirnice glede hrupa, ki ga oddajajo železniška vozila; c) sprejemljivost stanja vozne površine samo, če je akustična hrapavost merilo za sprejemljivost; d) oceno stanja vozne površine kolesa kot vnosa za akustično sprejemljivost zavornih blokov; e) oceno hrapavosti vozne površine kolesa in tirnice kot vnosa za izračun kombinirane hrapavosti vozne površine kolesa in tirnice; f) diagnozo spornosti hrupa kolesa in tirnice za določene tirnice ali kolesa; g) oceno hrapavosti vozne površine kolesa in tirnice kot vnosa pri modeliranju hrupa med vožnjo; h) oceno hrapavosti vozne površine kolesa in tirnice kot vnosa za metode ločevanja virov hrupa. 1.3 Ne uporablja se za: a) merjenje hrapavosti (hrapavost vozne površine tirnice, hrapavost vozne površine kolesa ali kombinirana hrapavost vozne površine kolesa in tirnice) s posredno metodo; b) analizo učinka interakcije kolo-tirnica, kot je »kontaktni filter«; c) odobritev preoblikovanja tirnice in kolesa, vključno z brušenjem tirnice, razen kadar je akustična hrapavost posebno merilo za sprejemljivost (in ne merilo kakovosti brušenja, kot je določeno npr. v standardu EN 13231-3); d) opredelitev geometrije tirnice in kolesa, razen kadar je to povezano s povzročanjem hrupa.

General Information

- Status

- Published

- Publication Date

- 18-Jun-2025

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 18-Jun-2025

- Due Date

- 23-Aug-2025

- Completion Date

- 19-Jun-2025

Relations

- Effective Date

- 01-Sep-2025

- Effective Date

- 01-Sep-2025

Overview

EN 15610:2019+A1:2025 (CEN) defines a direct measurement method to characterise rail and wheel surface roughness related to rolling noise - termed acoustic roughness - and expresses results as a one‑third octave band spectrum. The standard specifies how to select measurement positions, acquire and process data, set measuring‑system requirements, and present spectra for comparison with acoustic limits. It updates EN 15610:2019 with Amendment A1 (2025).

Key topics and technical requirements

- Acoustic roughness metric: Characterisation of rail and wheel roughness specifically related to noise generation, reported as one‑third octave band spectra.

- Measurement planning:

- Selection of track test sections and wheels.

- Lateral measurement positions on the rail or wheel running surface.

- Measuring system requirements:

- Sensor performance, dimensions and tracking, sampling interval, record length, calibration and traceability to national standards.

- Data acquisition:

- Test section and vehicle preparation, data sampling procedures, and quality checks.

- Data processing:

- Spike removal, curvature processing, spectral analysis, averaging and extending wavelength ranges to estimate one‑third octave spectra.

- Presentation & reporting:

- Formats for presenting spectra and for comparing measured spectra to specified acoustic roughness limits or upper‑limit wavelength spectra.

- Scope exclusions:

- Indirect roughness measurement methods, analysis of wheel‑rail contact filters, and approval of reprofiling/grinding except where acoustic roughness is the specific approval criterion.

Practical applications

EN 15610:2019+A1:2025 supports decisions and technical workflows in areas such as:

- Compliance and performance testing of reference track sections for vehicle noise acceptance.

- Acceptance of running surface condition where acoustic roughness is the criterion.

- Assessment of wheel condition when evaluating brake block acoustic performance.

- Input data for rolling‑noise models and noise source separation methods.

- Diagnostics of track‑ or wheel‑related noise issues to guide maintenance (e.g., reprofiling, grinding) and mitigation planning.

Who should use this standard

- Railway acoustics engineers and noise consultants

- Track and rolling‑stock maintenance teams

- Test laboratories and certification bodies

- Rolling‑stock and brake‑block manufacturers

- Regulatory agencies and infrastructure managers seeking standardised acoustic roughness measurements

Related standards and references

- EN 13231‑3 (rail grinding/ reprofiling quality criteria) - referenced when reprofiling approvals are considered.

- ISO/IEC Guide 98‑3 (GUM) - referenced in the standard’s uncertainty analysis annex.

Keywords: railway acoustics, rail roughness measurement, wheel roughness, acoustic roughness, rolling noise, one‑third octave band spectrum, EN 15610:2019+A1:2025, CEN.

Frequently Asked Questions

SIST EN 15610:2019+A1:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Acoustics - Rail and wheel roughness measurement related to noise generation". This standard covers: 1.1 This document specifies a direct measurement method for characterizing the surface roughness of the rail and wheel associated with rolling noise ("acoustic roughness"), in the form of a one-third octave band spectrum. This document describes a method for: a) selecting measuring positions along a track or selecting wheels of a vehicle; b) selecting lateral positions for measurements; c) the data acquisition procedure; d) measurement data processing in order to estimate a set of one-third octave band roughness spectra; e) presentation of this estimate for comparison with limits of acoustic roughness; f) comparison with a given upper limit in terms of a one-third octave band wavelength spectrum; g) the measuring system requirements. 1.2 It is applicable to the: a) compliance testing of reference track sections in relation to the acceptance test for noise emitted by railway vehicles; b) performance testing of track sections in relation to noise emitted by railway vehicles; c) acceptance of the running surface condition only in the case where the acoustic roughness is the acceptance criterion; d) assessment of the wheel surface condition as an input for the acoustic acceptance of brake blocks; e) assessment of the wheel and rail roughness as input to the calculation of combined wheel rail roughness; f) diagnosis of wheel-rail noise issues for specific tracks or wheels; g) assessment of the wheel and rail roughness as input to rolling noise modelling; h) assessment of the wheel and rail roughness as input to noise source separation methods. 1.3 It is not applicable to the: a) measurement of roughness (rail roughness, wheel roughness or combined roughness) using an indirect method; b) analysis of the effect of wheel-rail interaction, such as a “contact filter”; c) approval of rail and wheel reprofiling, including rail grinding operations, except for those where the acoustic roughness is specifically the approval criterion (and not the grinding quality criteria as provided in e.g. EN 13231-3); d) characterization of track and wheel geometry except where associated with noise generation.

1.1 This document specifies a direct measurement method for characterizing the surface roughness of the rail and wheel associated with rolling noise ("acoustic roughness"), in the form of a one-third octave band spectrum. This document describes a method for: a) selecting measuring positions along a track or selecting wheels of a vehicle; b) selecting lateral positions for measurements; c) the data acquisition procedure; d) measurement data processing in order to estimate a set of one-third octave band roughness spectra; e) presentation of this estimate for comparison with limits of acoustic roughness; f) comparison with a given upper limit in terms of a one-third octave band wavelength spectrum; g) the measuring system requirements. 1.2 It is applicable to the: a) compliance testing of reference track sections in relation to the acceptance test for noise emitted by railway vehicles; b) performance testing of track sections in relation to noise emitted by railway vehicles; c) acceptance of the running surface condition only in the case where the acoustic roughness is the acceptance criterion; d) assessment of the wheel surface condition as an input for the acoustic acceptance of brake blocks; e) assessment of the wheel and rail roughness as input to the calculation of combined wheel rail roughness; f) diagnosis of wheel-rail noise issues for specific tracks or wheels; g) assessment of the wheel and rail roughness as input to rolling noise modelling; h) assessment of the wheel and rail roughness as input to noise source separation methods. 1.3 It is not applicable to the: a) measurement of roughness (rail roughness, wheel roughness or combined roughness) using an indirect method; b) analysis of the effect of wheel-rail interaction, such as a “contact filter”; c) approval of rail and wheel reprofiling, including rail grinding operations, except for those where the acoustic roughness is specifically the approval criterion (and not the grinding quality criteria as provided in e.g. EN 13231-3); d) characterization of track and wheel geometry except where associated with noise generation.

SIST EN 15610:2019+A1:2025 is classified under the following ICS (International Classification for Standards) categories: 17.140.30 - Noise emitted by means of transport; 45.080 - Rails and railway components; 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15610:2019+A1:2025 has the following relationships with other standards: It is inter standard links to SIST EN 15610:2019, SIST EN 15610:2019/kFprA1:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15610:2019+A1:2025 is associated with the following European legislation: EU Directives/Regulations: 2010-01-4867. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 15610:2019+A1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2025

Nadomešča:

SIST EN 15610:2019

Železniške naprave - Akustika - Merjenje hrapavosti (neravnin) vozne površine

tirnice in kolesa pri povzročanju hrupa (vključno z dopolnilom A1)

Railway applications - Acoustics - Rail and wheel roughness measurement related to

noise generation

Bahnanwendungen - Akustik - Messung der Schienen- und Radrauheit im Hinblick auf

die Entstehung von Rollgeräuschen

Applications ferroviaires - Acoustique - Mesurage de la rugosité des rails et des roues

relative à la génération du bruit de roulement

Ta slovenski standard je istoveten z: EN 15610:2019+A1:2025

ICS:

17.140.30 Emisija hrupa transportnih Noise emitted by means of

sredstev transport

45.080 Tračnice in železniški deli Rails and railway

components

93.100 Gradnja železnic Construction of railways

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15610:2019+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

June 2025

EUROPÄISCHE NORM

ICS 17.140.30; 93.100 Supersedes EN 15610:2019

English Version

Railway applications - Acoustics - Rail and wheel

roughness measurement related to noise generation

Applications ferroviaires - Acoustique - Mesurage de la Bahnanwendungen - Akustik - Messung der Schienen-

rugosité des rails et des roues relative à la génération und Radrauheit im Hinblick auf die Entstehung von

du bruit de roulement Rollgeräuschen

This European Standard was approved by CEN on 21 January 2019 and includes Amendment 1 approved by CEN on 20 January

2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15610:2019+A1:2025 E

worldwide for CEN national Members.

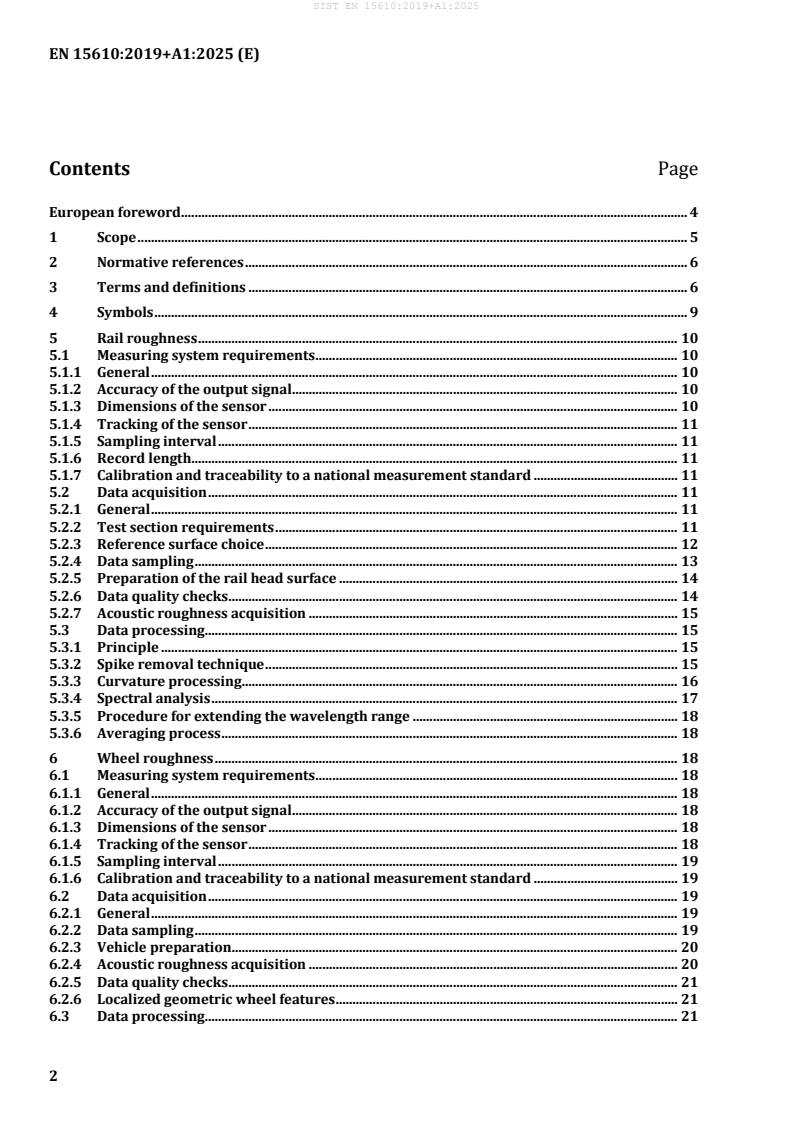

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 6

3 Terms and definitions . 6

4 Symbols . 9

5 Rail roughness . 10

5.1 Measuring system requirements . 10

5.1.1 General . 10

5.1.2 Accuracy of the output signal . 10

5.1.3 Dimensions of the sensor . 10

5.1.4 Tracking of the sensor . 11

5.1.5 Sampling interval . 11

5.1.6 Record length. 11

5.1.7 Calibration and traceability to a national measurement standard . 11

5.2 Data acquisition . 11

5.2.1 General . 11

5.2.2 Test section requirements . 11

5.2.3 Reference surface choice . 12

5.2.4 Data sampling . 13

5.2.5 Preparation of the rail head surface . 14

5.2.6 Data quality checks . 14

5.2.7 Acoustic roughness acquisition . 15

5.3 Data processing . 15

5.3.1 Principle . 15

5.3.2 Spike removal technique . 15

5.3.3 Curvature processing . 16

5.3.4 Spectral analysis . 17

5.3.5 Procedure for extending the wavelength range . 18

5.3.6 Averaging process . 18

6 Wheel roughness . 18

6.1 Measuring system requirements . 18

6.1.1 General . 18

6.1.2 Accuracy of the output signal . 18

6.1.3 Dimensions of the sensor . 18

6.1.4 Tracking of the sensor . 18

6.1.5 Sampling interval . 19

6.1.6 Calibration and traceability to a national measurement standard . 19

6.2 Data acquisition . 19

6.2.1 General . 19

6.2.2 Data sampling . 19

6.2.3 Vehicle preparation . 20

6.2.4 Acoustic roughness acquisition . 20

6.2.5 Data quality checks . 21

6.2.6 Localized geometric wheel features . 21

6.3 Data processing . 21

6.3.1 Principle . 21

6.3.2 Spike removal technique . 21

6.3.3 Curvature processing . 22

6.3.4 Spectral analysis . 23

6.3.5 Averaging the roughness spectra . 23

7 Wheel roughness measurements for the assessment of acoustic performance of

brake blocks . 23

7.1 General . 23

7.2 Measuring system requirements . 24

7.3 Data acquisition . 24

7.3.1 General . 24

7.3.2 Data sampling . 24

7.3.3 Test preparation . 24

7.3.4 Acoustic roughness acquisition . 25

7.3.5 Data quality checks . 25

7.4 Data processing . 25

8 Acceptance criteria . 25

8.1 Rail roughness . 25

8.2 Wheel roughness . 25

8.3 Assessment of acoustic performance of brake blocks. 26

9 Presentation of the rail and wheel roughness spectra . 27

10 Report . 27

10.1 Rail roughness . 27

10.2 Wheel roughness . 28

10.3 Assessment of acoustic performance of brake blocks. 28

Annex A (informative) Examples of !geometrical features" on the rail . 29

Annex B (normative) Algorithm used to synthesize a one-third octave band spectrum from

a corresponding narrow band spectrum for rail roughness . 31

Annex C (informative) Determination of the combined roughness (and contact filters) . 32

Annex D (informative) Quantification of measurement uncertainties according to

ISO/IEC Guide 98-3 . 33

D.1 General . 33

D.2 Mathematical model . 34

D.3 Determination of the standard uncertainties . 34

D.4 Determination of the combined standard uncertainty . 35

D.5 Determination of the expanded uncertainty . 36

Annex E (informative) An example of a rail roughness report sheet . 37

Annex F (informative) Specific intervals during the brake performance test program . 38

Bibliography . 39

European foreword

This document (EN 15610:2019+A1:2025) has been prepared by Technical Committee CEN/TC 256

“Railway applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by December 2025, and conflicting national standards

shall be withdrawn at the latest by December 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 20 January 2025.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document supersedes !EN 15610:2019".

!deleted paragraphs"

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

1 Scope

1.1 This document specifies a direct measurement method for characterizing the surface roughness

of the rail and wheel associated with rolling noise (“acoustic roughness”), in the form of a one-third

octave band spectrum.

This document describes a method for:

a) selecting measuring positions along a track or selecting wheels of a vehicle;

b) selecting lateral positions for measurements;

c) the data acquisition procedure;

d) measurement data processing in order to estimate a set of one-third octave band roughness

spectra;

e) presentation of this estimate for comparison with limits of acoustic roughness;

f) comparison with a given upper limit in terms of a one-third octave band wavelength spectrum;

g) the measuring system requirements.

1.2 It is applicable to the:

a) compliance testing of reference track sections in relation to the acceptance test for noise emitted by

railway vehicles;

b) performance testing of track sections in relation to noise emitted by railway vehicles;

c) acceptance of the running surface condition only in the case where the acoustic roughness is the

acceptance criterion;

d) assessment of the wheel surface condition as an input for the acoustic acceptance of brake blocks;

e) assessment of the wheel and rail roughness as input to the calculation of combined wheel rail

roughness;

f) diagnosis of wheel-rail noise issues for specific tracks or wheels;

g) assessment of the wheel and rail roughness as input to rolling noise modelling;

h) assessment of the wheel and rail roughness as input to noise source separation methods.

1.3 It is not applicable to the:

a) measurement of roughness (rail roughness, wheel roughness or combined roughness) using an

indirect method;

b) analysis of the effect of wheel-rail interaction, such as a “contact filter”;

c) approval of rail and wheel reprofiling, including rail grinding operations, except for those where the

acoustic roughness is specifically the approval criterion (and not the grinding quality criteria as

provided in e.g. EN 13231-3);

d) characterization of track and wheel geometry except where associated with noise generation.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 61260-1:2014, Electroacoustics - Octave-band and fractional-octave-band filters - Part 1:

Specifications (IEC 61260-1:2014)

!EN 16452:2015+A1:2019, Railway applications - Braking - Brake blocks"

EN ISO 266:1997, Acoustics - Preferred frequencies (ISO 266:1997)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

acoustic roughness

r(x)

variation in the height of the running surface associated with rolling noise excitation expressed as a

function of distance x along the running surface

3.2

acoustic roughness spectrum

r()λ

amplitude of the acoustic roughness expressed as a function of the wavelength λ

3.3

acoustic roughness level

L

r

level expressed in decibels, given by the following formula:

r

RMS

(1)

L 10⋅log

r 10

2

r

where

L is the acoustic roughness level in dB;

r

is the root mean square roughness in μm;

rRMS

r is the reference roughness; r = 1 μm.

0 0

Note 1 to entry This definition applies to values measured either in the form of a one-third octave band

wavelength spectrum, or for a specific wavelength band.

=

3.4

combined effective roughness

roughness function that excites rolling noise

Note 1 to entry: The combined effective roughness is the RMS of the rail and wheel roughness spectra. It

becomes the combined effective roughness when the effect of the contact patch filter is included.

3.5

direct roughness measurement method

acoustic roughness measurement method for which the sensor measures the running surface

roughness so that either the rail or the wheel roughness is measured independently of any effect of

wheel-rail interaction

3.6

indirect roughness measurement method

acoustic roughness measurement method that measures a quantity that is the result of wheel-rail

interaction, such as noise, rail or axle box vibration, whereby the original excitation by the combined

effective wheel and rail roughness is inferred

3.7

test section

specific section of track associated with a particular set of measurements

3.8

RMS

root mean square average which is required in the standard where averaging of spectra is required

Note 1 to entry: This is defined for each spectral band as:

22 2

a + a ++ a

1 2 N

(2)

RMS=

N

where:

a is a spectral amplitude; and

N is the number of spectral band value from which the average is being calculated.

Note 2 to entry: In terms of levels, this is equivalent to:

LL//10 10 L /10

1 2 N

10 + 10 ++ 10

(3)

L = 10log

average 10

N

3.9

running surface

part of the wheel tread or of the rail head, along which the wheel-rail contact passes during rolling

Note 1 to entry: In the case of the rail this is the bright band of the surface of the rail head that contains all the

running positions of the wheel-rail contact, associated with current traffic.

3.10

partially conditioned surface

part of the rail head outside the rail running surface that nevertheless can appear to have been affected

by the passage of vehicles

3.11

reference surface

surface of the rail head, within the running surface, that is chosen for the acoustic roughness

assessment

3.12

reference length

dimension of the reference surface in the longitudinal rail direction

3.13

reference width

w

ref

dimension of the reference surface across the rail

Note 1 to entry: Figure 1 shows an example of some of the defined terms

Key

1 running surface

2 reference surface

3 partially conditioned surface

Figure 1 — Example showing defined parameters

3.14

field face

outer face of the railhead, offering a reference position constant during the rail wear process

!

3.15

single value wheel roughness indicator

I

cbb

indicator describing the acoustic performance of brake blocks"

4 Symbols

!

Symbol Meaning

C(x) circular curve used for the acoustic roughness processing

d position, relative to the outer surface of the rail head, of the longitudinal axis of

ref

symmetry of the reference surface

h height of a spike

I indicator describing the acoustic performance of brake blocks

cbb

L Measured weighted transfer function [36]

h,weighted

L acoustic roughness level

r

L Weighted transfer function added to the energetic sum of the rail and wheel

r,comb,weighted

roughness

L Measured rail roughness used as reference for the calculations [36]

r,ref,rail

L Wheel roughness spectrum in one-third octave band wavelength, determined for

r,wheel

the assessment of brake blocks

r(x) acoustic roughness

r()λ discrete Fourier Transform of r(x)

r'(x) acoustic roughness processed with the spike removal and curvature algorithm

W width of a spike

W width of the reference surface

ref

X variable of the distance along the rail

X particular position along the rail

i

Z mean value of height over a given interval

λ Wavelength

"

5 Rail roughness

5.1 Measuring system requirements

5.1.1 General

This subclause summarizes the requirements of the measuring system and its calibration. The

measuring devices shall be checked and calibrated regularly.

5.1.2 Accuracy of the output signal

The measuring system shall be capable of making valid measurements in the wavelength range and at

the acoustic roughness levels for the test site being characterized.

NOTE Typical rail roughness spectra can be found in [11], [18], [22], [23] and [25].

However, where it is required simply to show that the estimated acoustic roughness does not exceed a

given upper limit, the measuring system shall effect valid measurements for one-third octave band

acoustic roughness levels equal to or greater than this limit. This case applies particularly for test

section approval.

A measurement device shall be considered making valid measurements if the uncertainty resulting

from the measuring device, expressed in terms of its standard uncertainty, does not exceed 3 dB.

!The permissible speed range for carrying out the measurements shall be stated in the user’s

guide."

5.1.3 Dimensions of the sensor

If a contact sensor is used, the sensor tip shall be spherical and its radius shall not exceed 7 mm.

In the case of a non-contacting sensor, its effective width shall be less than the sampling interval.

5.1.4 Tracking of the sensor

The measuring system sensor shall follow a line on the rail head parallel to the field (outer) face of the

rail head, with a tolerance of ± 1 mm.

5.1.5 Sampling interval

The measuring system shall measure data with a sampling interval less than or equal to 1 mm to an

accuracy of no worse than 3 %.

5.1.6 Record length

The system shall provide records of length ≥ 1 m.

5.1.7 Calibration and traceability to a national measurement standard

The calibration shall verify the accuracy and the compliance of the measuring device

The calibration shall include the traceability to a national measurement standard or a primary standard.

This shall be done in terms of a reference roughness standard (e.g. a section of a reference rail or beam).

The surface geometry of the reference roughness standard shall be measured by a national or primary

standards laboratory. For comparing the measurement values to a limit curve, the roughness of this

reference roughness standard shall be of a measureable value and shall be no greater than 10 dB above

the respective limit curve over the whole wavelength range of the limit curve.

The calibration procedure shall be documented. The documentation shall justify the calibration and the

checking of all aspects of the instrument including the electronics and processing.

An instrument shall always be recalibrated if it has been repaired or is suspected of fault or damage or

wear. The maximum time from the last calibration of the instrument shall be 24 months.

5.2 Data acquisition

5.2.1 General

The aim of the data acquisition procedure is to obtain digitized records of the acoustic roughness of the

two rails in the test section measured at a sufficiently high sampling rate (samples per unit length) and

with a record length sufficient to derive from it the acoustic roughness spectrum. Record lengths of at

least 1 m are required to estimate the acoustic roughness spectrum covering the wavelength range up

to the 0,25 m one-third octave band.

To attain wavelengths greater than 0,25 m, records longer than those specified in this sub clause shall

be obtained. The record length shall be at least 4 times of mid wavelength the one-third octave band

wavelength.

5.2.2 Test section requirements

5.2.2.1 Track structure

The track structure design shall be constant along the test section, at least in terms of the following

parameters: rail cross-section, rail inclination and rail supporting structure. In the case of a ballasted

track, the rail supporting structure parameters are: the rail pad type, the rail fasteners, the sleeper type,

the sleeper spacing and the ballast.

If the track structure changes, separate test sections shall be defined and the acoustic roughness of each

shall be assessed and presented.

!

5.2.2.2 Geometric features"

There is no specific requirement for the test section to be free from !defects". However, it may

contain some !geometrical features" (e.g.: weld, large dips, wheel burns) that it is permitted to

exclude in the assessment of the acoustic roughness related to the generation of rolling noise. See

Annex A for guidance concerning features that may be edited out of the record.

NOTE The generation of noise at !defects" is not linearly related to their amplitude compared to general

roughness so that defects are less significant in the assessment of the source of rolling noise.

5.2.3 Reference surface choice

5.2.3.1 General

The acoustic roughness of the test section shall be assessed over a reference surface. The reference

surface shall be inside the running surface and is specified as follows:

a) length along the rail;

b) transverse width w ;

ref

c) relative distance d to the field face of the rail.

ref

The running surface can be wide and experience shows that there is considerable variation of the

acoustic roughness with lateral position. It is common that particular vehicles will only use part of this

surface. Therefore, the standard allows for an assessment to apply only to a part of the running surface

that may correspond to the requirements of a particular test, i.e. the reference surface.

5.2.3.2 Cases

It is the responsibility of the measurement team to define the length, width and position of the

reference surface of the two rails and to justify its decision.

The reference length may be given by standards.

Where the acoustic rail roughness measurement is required for rolling stock type acceptance testing,

any of the three following cases for that justification shall be used:

a) Case 1: the running surface (band) on the rail head is clear visually and it is known that this running

surface is produced by the rolling stock to be measured.

Considering that the wheel-rail contact patch is approximately 10 mm wide, any partially conditioned

area at the edges of the running surface that are less than half this width shall not be considered to be

part of the running surface (see Figure 1).

b) Case 2: the wheel-rail contact zone can be determined for the specific train under test at the time of

the acceptance test.

It is recommended that a line be drawn across the rail head with a marker pen before a train passby to

identify the wheel-rail contact position satisfactorily. It is advisable to check the position at both ends of

the test section.

Figure 2 shows a sample application of this method:

Key

1 effective running surface produced by the specific train under test

2 marker ink outside the running surface

Figure 2 — Example of using a permanent marker on the rail surface

In judging the width of the reference surface, the minimum width shall be taken that is consistent along

the test section.

c) Case 3: the wheel-rail contact position during running on the test site can be predicted from the

geometry of rail and wheel transverse profiles using simulation tools.

There are specific situations (such as hollow worn wheels or worn rail head profiles) in which the

contact position on the rail head is erratic. Such situations should be avoided for acceptance tests as

they would lead to uncertainties in the test conditions.

5.2.4 Data sampling

5.2.4.1 General

Because the conditions of 5.2.2.1 shall be met, a reduced sample of measurements can be assumed to be

representative of the two rails. Considering that the existing measuring systems record the acoustic

roughness in lines along the rail, the variation in the acoustic roughness across the rail head shall be

assessed at a limited number of discrete lateral positions.

The following data sampling method of the rail reference surface shall be applied both in the

longitudinal and transverse directions.

5.2.4.2 Longitudinal sampling

The acoustic roughness of the test section shall be assessed using a number of measured samples

distributed over the whole reference length. To obtain a reliable assessment of the roughness up to a

given wavelength, a minimum total record length is required.

If the acoustic roughness is sampled in such a way that it forms less than 80 % of the overall length of

the test section, it is the responsibility of the measurement team to select samples and to justify

whether these samples are representative of the reference length.

The following minimum criteria shall apply if sampling is used:

a) the samples shall be assessed over at least 5 measuring positions for each rail, each at least 1 m

long, distributed over the test section;

b) depending on the bandwidth range of interest, the samples shall total a length of at least:

1) 15 m for each rail, if the bandwidth range involved does not exceed the 0,25 m one-third octave

band;

2) 7,2 m for each rail, if the bandwidth range involved does not exceed the 0,1 m one-third octave

band;

c) the overall length of roughness record for each longitudinal line shall be at least 20 % of the

reference length.

5.2.4.3 Lateral sampling

The acoustic roughness shall be assessed equally on each rail for a given width of rail head surface,

irrespective of the actual range of wheel-rail contact positions for a given category of rolling stock and

shall only be considered valid for the part of the rail head that is conditioned by running wear.

Therefore, an important aspect of the acquisition process is to define the lateral position of the valid

reference surface of the rail.

The acoustic roughness shall be measured on the reference surface centre line. If the reference surface

is wide enough, two supplementary, parallel, equidistant lines at either side of the centre line shall be

measured. The distance between the centre line and the supplementary lines depends on the reference

width:

a) w ≤ 20 mm: measurement of one line;

ref

b) 20 mm < w ≤ 30 mm: measurement of three lines, each 5 mm apart;

ref

c) w > 30 mm: measurement of three lines, each 10 mm apart.

ref

Regardless of the above, a greater number of lines of acoustic roughness can be measured. In this case

the lines selected from a greater data set for comparison with acceptance criteria shall conform to these

rules.

5.2.5 Preparation of the rail head surface

Contamination shall be removed from the rail head surface before measuring the acoustic roughness.

!

5.2.6 Data quality checks

Quality checks shall be made in order to ensure the accuracy of the measurements.

For the repeated measurements (minimum three measurements), the one-third octave band spectra

shall be compared. A maximum spread of 3 dB in any one-third octave band of all repeated

measurements shall be permissible."

5.2.7 Acoustic roughness acquisition

Following the above operations, all the measurements shall be taken and all the data saved before being

processed.

!The validated range of sensor moving speed shall be kept.

NOTE The speed of moving the sensor along the measurement trace can affect the results. It is good practice

to record the target speed. In case of trolley systems additional measurements can be taken to determine the

influence of the walking speed."

5.3 Data processing

5.3.1 Principle

The following algorithm shall be applied.

a) The data shall be processed in three stages before calculating the wavelength spectrum.

1) Edit out the data relating to any rail joints, rail head defects and welds. No discontinuities shall

be included in the data that would affect the final spectrum analysis (see Annex A).

2) Process the data so as to remove narrow upward spikes that are regarded as being linked with

the presence of small particles of foreign matter on the rail surface. This is called the “spike

removal” process (see 5.3.2).

3) Process the data to take account of the effect of the small radius of the sensor tip compared to

that of the wheel. This is called the “curvature processing” process (see 5.3.3).

NOTE This processing takes into account some of the effects of the wheel-rail contact that cause a change in

the spectrum content affecting the excitation mechanism of the rolling noise. It cannot be done after the

acoustic roughness spectrum has been produced. Other effects, such as that of the “contact filter”, are not

within the scope of this document (see Annex C).

b) Calculate the one-third octave band spectrum for each acoustic roughness record (see 5.3.4).

c) Estimate the mean acoustic roughness spectra for the reference section (see 5.3.6).

5.3.2 Spike removal technique

The spike removal technique is as follows (see Figure 3).

a) On the basis of the roughness r(x), calculate the first derivative dr/dx and the second derivative

2 2

d r/dx .

b) Locate sign changes of dr/dx, indicating a local data minimum or maximum.

2 2 7 2

c) Identify the spikes by the criteria d r/dx < −10 µm/m and a change of sign for dr/dx.

d) Identify the edges of each spike as being the samples (x and x ) on either side of the maxima or

1 2

minima, for which abs(dr/dx) becomes less than 5 × 10 µm/m.

e) Calculate the width w of the spike with the formula w = abs (x -x ).

2 1

a) Raw data for roughness b) Raw data for spike removal

Key

X1 distance along the rail (metres) X2 distance along the rail (metres)

Y1 roughness amplitude (micrometres) Y2 roughness amplitude (micrometres)

1 spike 3 measured signal

signal processed with the spike removal

2 pit 4

algorithm

Figure 3 — Raw data

The ratio between height h and width w of each spike shall be tested with the following criterion:

h > w /a, where h and w are expressed in metres and a = 3 m. If this condition is verified, the spike shall

be removed by linear interpolation between x and x .

1 2

The spike removal procedure shall be repeated until no further spike is detected.

5.3.3 Curvature processing

For each roughness data point x from the r(x) roughness function, a circular curve C (x) of radius

i i

R = 0,375 m is defined passing through the data point r(x ), with its centre located at x above the r(x)

i i

function (see Figure 4).

The correction of the acoustic roughness at the roughness data point x is taken as the maximum

i

difference between the roughness function r(x) and this curve C (x), so that the resulting height r'(x ) of

i i

the roughness function r(x) is given by the following equation: r’(x ) = max(r(x) - C (x)) + r(x ), where

i i i

C (x)= R− R−(x− x )+ rx( )

i ii

Not to scale

Key

1 C (x) X1 sampled values of x

i

2 r(x) Y roughness amplitude

3 x X2 distance along rail

i

4 r’(x ) – r(x ) 5 r’(x)

i i

NOTE Left: principle applied to position x – Right: effect of the curvature processing on a deep pit.

i

Figure 4 — Curvature processing

5.3.4 Spectral analysis

5.3.4.1 General

The one-third octave band acoustic roughness spectrum shall be determined on the basis of the

r()λ

roughness data after removal of the pits and spikes, r’(x), using one of the two methods described

below.

5.3.4.2 Method A: Fourier analysis

For this, long data records can be divided into segments. In all cases, the length of the data used in a

Fourier transform shall correspond to a length of at least 1 m. If a record is divided into successive

segments, a 75 % overlap shall be applied. Each segment shall have the mean value subtracted and the

linear trend removed. A Hann window shall then be applied.

The discrete Fourier transform (DFT) of each segment is used to produce results in terms of wave

number. The magnitude squared of the Fourier transforms of each segment shall be averaged to make

up a narrow band spectrum which shall be expressed as a function of the wavelength.

The one-third octave band spectrum shall be synthesized on the basis of the narrow band spectrum.

Each one-third octave band value shall be calculated as the sum of the squares of the narrow band

amplitudes from the discrete Fourier transform. At the one-third octave band boundaries, only the

narrow band spectrum values corresponding to the portion of the spectrum included in the one-third

octave in question shall be taken into account (see Annex B).

5.3.4.3 Method B: digital filtering

The one-third octave band values shall be obtained by applying digital one-third octave band filters

directly to the roughness data r'(x). The digital filters shall comply with EN 61260-1.

If the one-third octave digital filtering method is used, the data affected by the filter transient at either

end of the record shall be discarded.

In total, there shall be a processed record of at least 15 m available after the transients have been

removed.

5.3.5 Procedure for extending the wavelength range

Fixed-length records produce wavelength data that are inherently limited to about a quarter of the

length of the record.

If it is required to assess longer wavelengths, the records shall be concatenated by overlapping the

measured records. The overlap shall not be used for spectral components of 0,1 m or less. The record

concatenation method shall be described in the report.

5.3.6 Averaging process

The average of the one-third octave band spectra shall be their RMS. This shall be calculated for each

acoustic roughness line separately. No weighting of the roughness records shall be applied with regard

to their position in the test section. Therefore, either one average spectrum or three average spectra

shall be produced for each rail in accordance with 5.2.4.3, depending on the reference width.

In addition, the mean roughness spectrum on all lines and both rails shall be calculated as an RMS.

6 Wheel roughness

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...