SIST EN 13509:2003

(Main)Cathodic protection measurement techniques

Cathodic protection measurement techniques

This European Standard deals with the cathodic protection against corrosion of buried or immersed metallic structures, detailing the measuring methods to be used for assessing the effectiveness of cathodic protection as well as the measurements and measures taken to monitor cathodic protection during operation.

Throughout the text, the measurement techniques are described primarily for pipelines.

However, they are sufficiently general to apply to other kinds of buried or immersed (except offshore) structures.

General principles with regard to cathodic protection are described in EN 12954. Other measurement methods specific to particular cases are described in other European Standards e.g. prEN 50162.

Messverfahren für den kathodischen Korrosionsschutz

Gegenstand dieser europäischen Norm ist der kathodische Korrosionsschutz von metallenen Anlagen in Böden oder Wässern. Sie beschreibt die Meßmethoden zum Nachweis der Wirksamkeit des kathodischen Korrosionsschutzes sowie Messungen und Maßnahmen für dessen Überwachung während des Betriebs. In dieser Norm werden die Meßmethoden weitgehend am Beispiel von Rohrleitungen vorgestellt. Sie lassen sich jedoch auf alle anderen metallenen Anlagen in Böden oder Wässern anwenden.

Techniques de mesures applicables en protection cathodique

La présente Norme européenne traite de la protection cathodique contre la corrosion de structures métalliques enterrées ou immergées. Elle présente en détail les méthodes de mesure à utiliser pour évaluer l'efficacité de la protection cathodique, ainsi que les mesures et les moyens nécessaires au contrôle de fonctionnement de la protection cathodique.

Dans le texte, les techniques de mesure décrites concernent principalement les canalisations.

Elles sont cependant suffisamment générales pour être appliquées à d'autres types de structures enterrées ou immergées (sauf les structures offshore).

Les principes généraux concernant la protection cathodique sont présentés dans la norme EN 12954. D'autres méthodes de mesure spécifiques à des structures particulières sont présentées dans d'autres Normes européennes comme par exemple le prEN 50162.

.

Merilne tehnike za katodno zaščito

General Information

- Status

- Published

- Publication Date

- 30-Nov-2003

- Technical Committee

- IPKZ - Protection of metals against corrosion

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Dec-2003

- Due Date

- 01-Dec-2003

- Completion Date

- 01-Dec-2003

Overview

EN 13509:2003 - Cathodic protection measurement techniques is a European Standard published by CEN that defines measurement methods for assessing and monitoring cathodic protection (CP) of buried or immersed metallic structures (excluding offshore). The standard is written primarily with pipelines in mind but is sufficiently general to apply to other buried or immersed structures. It explains how to measure structure-to-electrolyte potential and other parameters needed to verify CP effectiveness and to support CP system design and operation.

Key Topics

- Structure-to-electrolyte potential: principles for measuring potentials (on-potential, off-potential) and the factors affecting readings, including IR drop errors.

- IR-free potential (EIR free): techniques to determine potentials without voltage errors caused by electrolyte IR drop.

- Measurement equipment & accuracy: guidance on electrodes, reference electrodes (see Annex A), and normative accuracy requirements for potential measuring equipment (Annex H).

- Potential measurement techniques: direct and indirect methods, external potential test probes and intensive measurement techniques (Annexes F and G).

- Current and resistance measurements: DC current measurement methods, current reduction technique (Annex B), and evaluation of isolating joints (Annexes I, J, K).

- Special measurement topics: above-ground potential surveys along buried pipelines (Annex C), coating condition and holiday location methods (Annex D), stray current/stray voltage effects (Annex E), and use of coupons for monitoring.

- Terms & definitions: common CP vocabulary such as polarisation, protection potential, isolating joints, foreign structures and anode/backfill definitions.

Applications

EN 13509:2003 is practical for:

- Pipeline operators and integrity teams performing CP monitoring and maintenance.

- Corrosion engineers and cathodic protection specialists designing or verifying CP systems.

- Inspection contractors and asset owners implementing routine surveys, locating coating defects, or carrying out above-ground potential mapping.

- Maintenance personnel checking isolating joints, foreign structure interactions and measuring DC currents.

Typical uses include verifying that protection potentials are met, diagnosing interference or stray current problems, locating holidays in coatings, and providing measured inputs during CP system design or retrofit.

Related Standards

- EN 12954 - General principles and application for pipelines (background CP principles).

- prEN 50162 - Measurement methods specific to particular cases (supplementary methods).

- EN ISO 8044 - Corrosion terminology.

EN 13509:2003 is intended to be used by trained personnel with calibrated instrumentation to ensure reliable, repeatable CP measurements for buried and immersed structures.

Frequently Asked Questions

SIST EN 13509:2003 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Cathodic protection measurement techniques". This standard covers: This European Standard deals with the cathodic protection against corrosion of buried or immersed metallic structures, detailing the measuring methods to be used for assessing the effectiveness of cathodic protection as well as the measurements and measures taken to monitor cathodic protection during operation. Throughout the text, the measurement techniques are described primarily for pipelines. However, they are sufficiently general to apply to other kinds of buried or immersed (except offshore) structures. General principles with regard to cathodic protection are described in EN 12954. Other measurement methods specific to particular cases are described in other European Standards e.g. prEN 50162.

This European Standard deals with the cathodic protection against corrosion of buried or immersed metallic structures, detailing the measuring methods to be used for assessing the effectiveness of cathodic protection as well as the measurements and measures taken to monitor cathodic protection during operation. Throughout the text, the measurement techniques are described primarily for pipelines. However, they are sufficiently general to apply to other kinds of buried or immersed (except offshore) structures. General principles with regard to cathodic protection are described in EN 12954. Other measurement methods specific to particular cases are described in other European Standards e.g. prEN 50162.

SIST EN 13509:2003 is classified under the following ICS (International Classification for Standards) categories: 25.220.40 - Metallic coatings. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13509:2003 is associated with the following European legislation: EU Directives/Regulations: TP075. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13509:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Messverfahren für den kathodischen KorrosionsschutzTechniques de mesures applicables en protection cathodiqueCathodic protection measurement techniques25.220.40Kovinske prevlekeMetallic coatingsICS:Ta slovenski standard je istoveten z:EN 13509:2003SIST EN 13509:2003en01-december-2003SIST EN 13509:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13509May 2003ICS 25.220.40; 77.060English versionCathodic protection measurement techniquesTechniques de mesures applicables en protectioncathodiqueMessverfahren für den kathodischen KorrosionsschutzThis European Standard was approved by CEN on 27 December 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13509:2003 ESIST EN 13509:2003

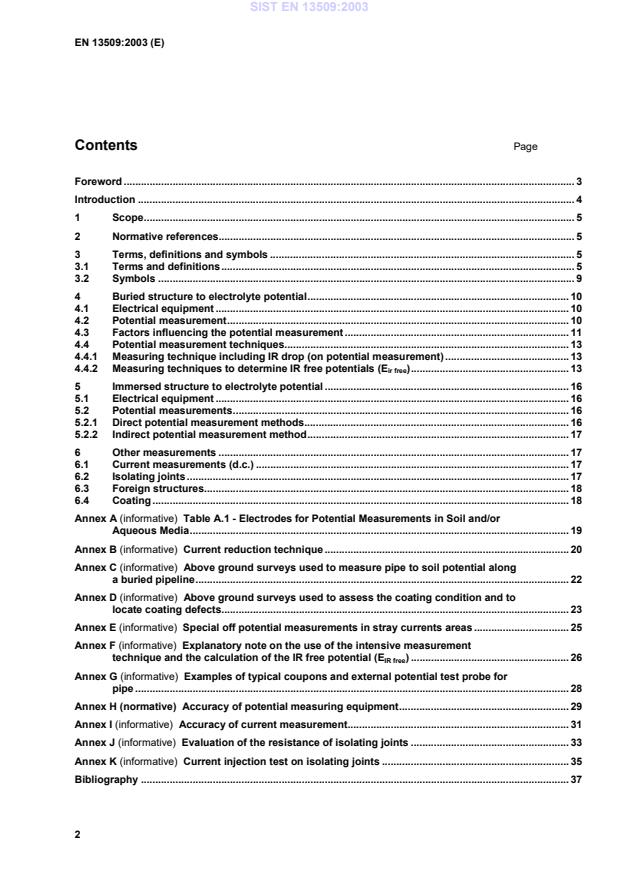

Table A.1 - Electrodes for Potential Measurements in Soil and/orAqueous Media.19Annex B (informative)

Current reduction technique.20Annex C (informative)

Above ground surveys used to measure pipe to soil potential alonga buried pipeline.22Annex D (informative)

Above ground surveys used to assess the coating condition and tolocate coating defects.23Annex E (informative)

Special off potential measurements in stray currents areas.25Annex F (informative)

Explanatory note on the use of the intensive measurementtechnique and the calculation of the IR free potential (EIR free).26Annex G (informative)

Examples of typical coupons and external potential test probe forpipe.28Annex H (normative)

Accuracy of potential measuring equipment.29Annex I (informative)

Accuracy of current measurement.31Annex J (informative)

Evaluation of the resistance of isolating joints.33Annex K (informative)

Current injection test on isolating joints.35Bibliography.37SIST EN 13509:2003

Reference electrode locations3

Soil4

PipeFigure 1 — Possible locations of reference electrodes for measurement of structure toelectrolyte potentials

1 Where water flows between a loose coating and the structure surface, the potential measured is notrepresentative of the electrochemical phenomena that occur under the disbonded coating.SIST EN 13509:2003

DEDE3/23'/2 E

(-) (+) (+) (-)(+) (-) l

l3'32154Key1, 2, 3, 3' Reference electrode locations4

Soil5

PipeFigure 2 — Locations (1), (2), (3) and (3') of reference electrodes for measurement of structureto electrolyte potentials and potential gradients on, for example, a buried pipeline, viaintensive measurement techniqueThe distance l between electrodes at location (2) and (3) should be selected to cover the total extentof the gradient.4.4.2.4 Potential measurements for pipelines with external potential test probes or couponsThe potential measurement with external potential test probe or coupons may be used to cover IRdrops caused by all currents noticed in Table 1 (protective current, equalising currents, cell currents,and fluctuating or not fluctuating currents from remote or nearby foreign sources).External potential test probes will yield information on the IR free potential even in cases where the onor off potential measurement technique or the intensive measurement technique cannot be applieddue to local conditions: (e.g. non conducting soil cover or greatly varying burial depth, new pipelineswithout holidays, fluctuating currents to Table 1, Item 2.2, or unavoidable contacts with foreignstructures etc., where synchronous measurements of the variables relevant to the intensivemeasurement technique are not possible).This technique consists of achieving IR free potential measurement by measuring off potential withthe use of external potential test probe or coupon.Example of typical exter

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...